Method for preparing short-chain fatty acid vinyl ester series cement dispersant

A technology of fatty acid vinyl ester and cement dispersant, which is applied in the field of dispersant for cement concrete, can solve the problems that affect the rapid promotion and application of chemical admixtures, different chemical structures, and narrow selection of raw materials, and achieve good promotion and application value , broaden the connotation and application, and improve the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

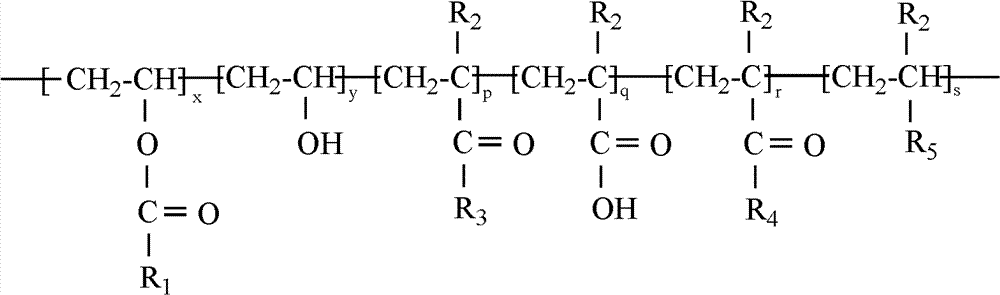

Image

Examples

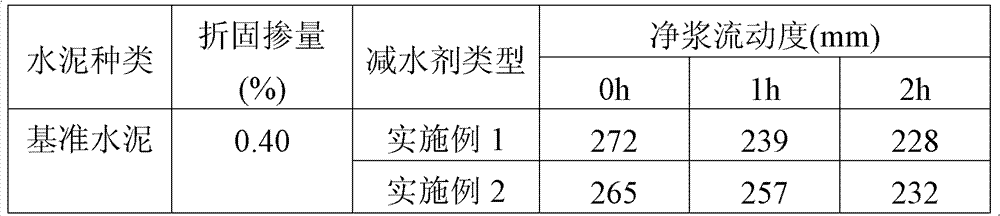

Embodiment 1

[0042] Make 0.86g of vinyl acetate into an aqueous solution with a mass fraction of 1%, stir and heat up to 60°C, and simultaneously add dropwise 8.75g of 1% potassium persulfate aqueous solution and 55.44g of 30% acrylamide and propylene The mixed aqueous solution of sodium sulfonate (containing 11.83g of acrylamide and 4.8g of sodium propylene sulfonate) was dropped within 5 hours, and the temperature was raised to 75°C with continuous stirring. After 2 hours of reaction, the temperature was lowered to 15°C with 17.49g Washed with methanol, and dried at 90°C to obtain a polymer product.

[0043] The polymerization product is made into a methanol solution with a mass fraction of 60%, and then the temperature is raised to 30°C, and 4.3g of a methanol solution with a mass fraction of 1% potassium hydroxide is added dropwise to the system. The alcoholysis product was obtained under vacuum.

[0044] The alcoholysis product was made into an aqueous solution with a mass fraction o...

Embodiment 2

[0047] After the cement dispersant obtained in Example 1 with a mass fraction of 40% was stored at 6° C. for 30 days, its implementation effect was measured.

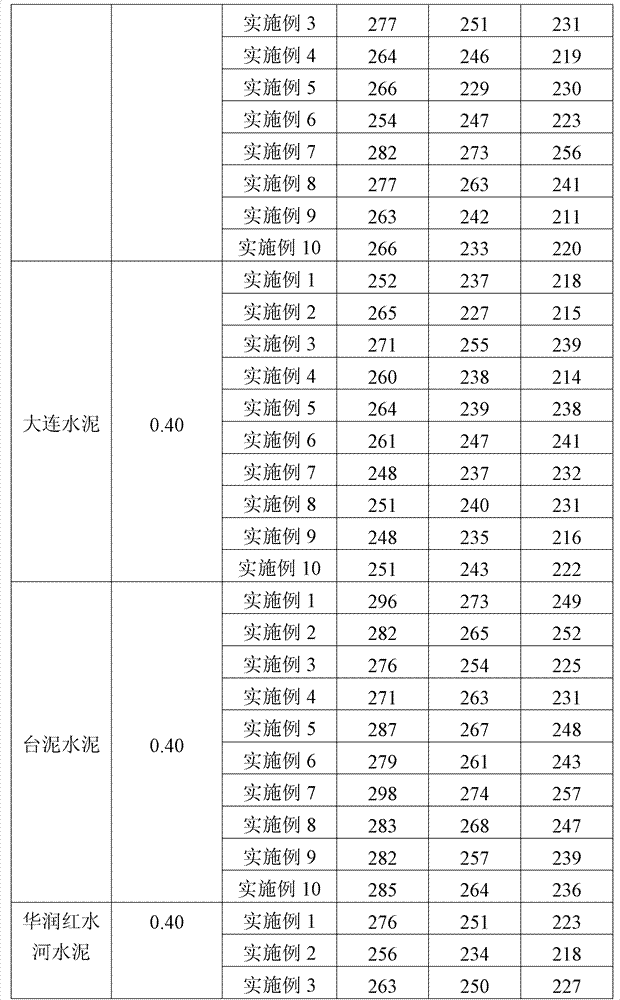

Embodiment 3

[0049] Make 5g of vinyl propionate into an aqueous solution with a mass fraction of 50%, stir and heat up to 70°C, and simultaneously add dropwise 7.64g of a 30% mass fraction of ammonium persulfate aqueous solution and 89.65g of a 20% mass fraction of methacrylamide The aqueous solution mixed with sodium styrene sulfonate (containing 16.35g methacrylamide and 1.58g sodium styrene sulfonate) was dropped within 2 hours, and the temperature was raised to 85°C with continuous stirring, and after 1 hour of reaction, the temperature was lowered to 50°C °C was washed with 11.47 g of isopropanol, and dried at 120 °C to obtain a polymer product.

[0050] The polymerization product is made into a methanol solution with a mass fraction of 20%, and then the temperature is raised to 60°C, and 0.33g of a methanol solution with a mass fraction of 15% potassium hydroxide is added dropwise to the system. The alcoholysis product was obtained under vacuum.

[0051] The alcoholysis product was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com