Conductive and flame-retardant polyphenyl ether resin composition and preparation method thereof

A technology of polyphenylene ether resin and composition, which is applied in the field of conductive and flame-resistant thermoplastic resins, can solve the problems of reduced flame retardancy, and achieve the effect of solving synergy and broadening the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A conductive and flame-resistant polyphenylene ether resin composition consists of the following materials in parts by weight:

[0020] Polyphenylene ether: 80 parts

[0021] Conductive agent: 20 parts

[0022] Flame retardant: 15 parts

[0023] Extender: 8 parts

Embodiment 2

[0025] A conductive and flame-resistant polyphenylene ether resin composition consists of the following materials in parts by weight:

[0026] Polyphenylene ether: 80 parts

[0027] Conductive agent: 25 parts

[0028] Flame retardant: 15 parts

[0029] Extender: 8 parts

Embodiment 3

[0031] A conductive and flame-resistant polyphenylene ether resin composition consists of the following materials in parts by weight:

[0032] Polyphenylene ether: 80 parts

[0033] Conductive agent: 22 parts

[0034] Flame retardant: 23 parts

[0035] Extender: 8 parts

[0036] The preparation technology of above-mentioned 3 embodiments is:

[0037] A 9-stage temperature-controlled twin-screw extrusion process is adopted, the screw speed of the extruder is controlled to be 300r / min, the feeding speed is controlled to be 20r / min, and the speed of the pelletizer is 600r / min. Among them, the temperature of the 9 temperature control zones is 250°C in zone 1, 260°C in zone 2, 280°C in zone 3 to 5, 290°C in zone 6 to 9, and the temperature of the machine head is 300°C.

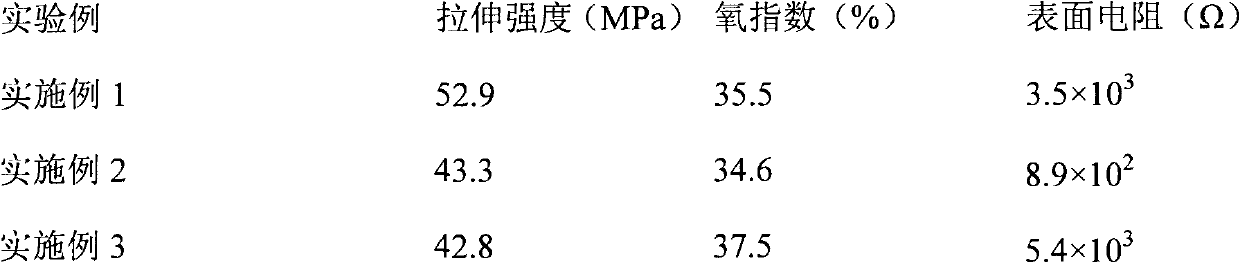

[0038] The performance detection of the conductive and flame-resistant polyphenylene ether resin composition prepared by the above examples is as follows:

[0039]

[0040] It can be seen from the above tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com