Sapphire single crystal furnace

A sapphire single crystal furnace and furnace body technology, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of high requirements for the furnace body, high production cost, and large loss, so as to reduce production cost and cost , the effect of loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

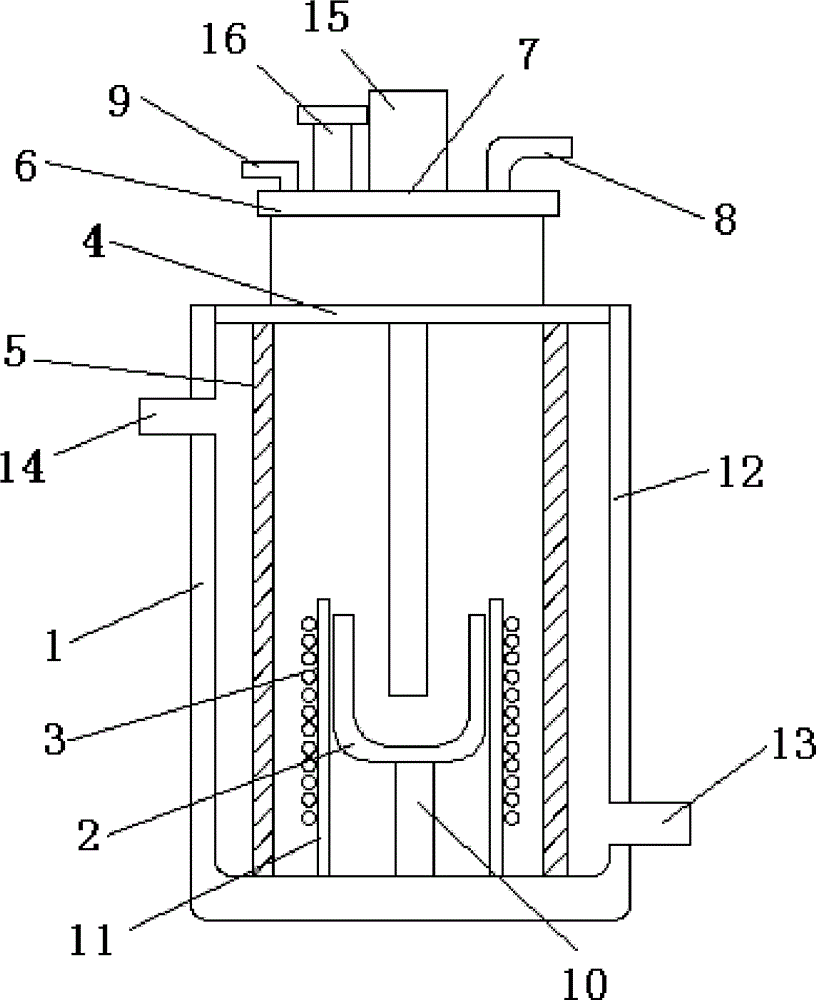

[0014] Referring to the accompanying drawings, a sapphire single crystal furnace includes a furnace body 1, a crucible 2 and a heating coil 3, the upper end of the furnace body 1 is provided with an opening 4, from the opening 4 of the furnace body 1 to the furnace body The bottom is fixedly installed with a thermal insulation tube 5, the upper end of the thermal insulation tube 5 is provided with a cover plate 6, and the cover plate 6 is provided with a lifting rod mounting hole 7, and the left and right sides of the lifting rod mounting hole 7 are respectively A nitrogen gas input port 8 and a nitrogen gas discharge port 9 are provided, a support base 10 is fixedly installed on the bottom of the heat preservation cylinder 5, a crucible 2 is fixedly installed on the support base 10, and a layer of quartz ring is wrapped on the outer wall of the crucible 2 11. A heating coil 3 is wound around the quartz ring 11 .

[0015] The thermal insulation cylinder 5 is made of metal tung...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap