High-strength roller of ring spinning frame

A high-strength spinning frame technology, applied in spinning machines, textiles, papermaking, drafting equipment, etc., can solve problems such as coarse and fine end breakage, and achieve the effect of improving yarn quality, high torsion resistance and flex resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

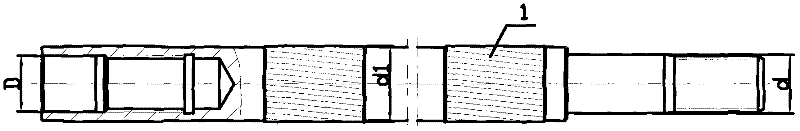

[0009] A ring spinning machine high strength roller, such as figure 1 As shown, it includes a roller 1. One end of the roller 1 is a guide rod, and the other end is a guide hole. The end of the guide rod is provided with an external thread, and the end of the guide hole is provided with an internal thread. The diameter of the guide rod is the same as that of the guide hole. Roller 1 is the front roller or the rear roller.

[0010] which is figure 1 shown in d 1 =Φ25mm, d=D=Φ19mm

[0011] d 1 =Φ27mm, d=D=Φ21mm

[0012] The working faces of the front and rear rollers are helical teeth.

Embodiment 2

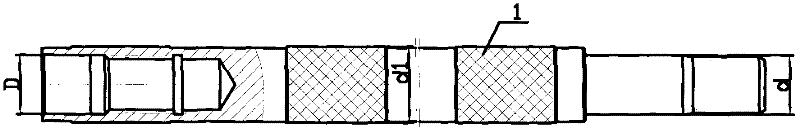

[0014] A ring spinning machine high strength roller, such as figure 2 As shown, it includes a roller 1. One end of the roller 1 is a guide rod, and the other end is a guide hole. The end of the guide rod is provided with an external thread, and the end of the guide hole is provided with an internal thread. The diameter of the guide rod is the same as that of the guide hole. Roller 1 is the middle roller.

[0015] which is figure 2 shown in d 1 =Φ25mm, d=D=Φ19mm

[0016] d 1 =Φ27mm, d=D=Φ21mm

[0017] The working surface of the middle roller is knurled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com