Plastic floorboard and manufacturing method thereof

A technology of plastic flooring and manufacturing methods, which is applied in the direction of chemical instruments and methods, building structures, layered products, etc., can solve problems such as time-consuming, excessive formaldehyde content, degumming and warping of the floor, and solve the problem of complicated laying procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

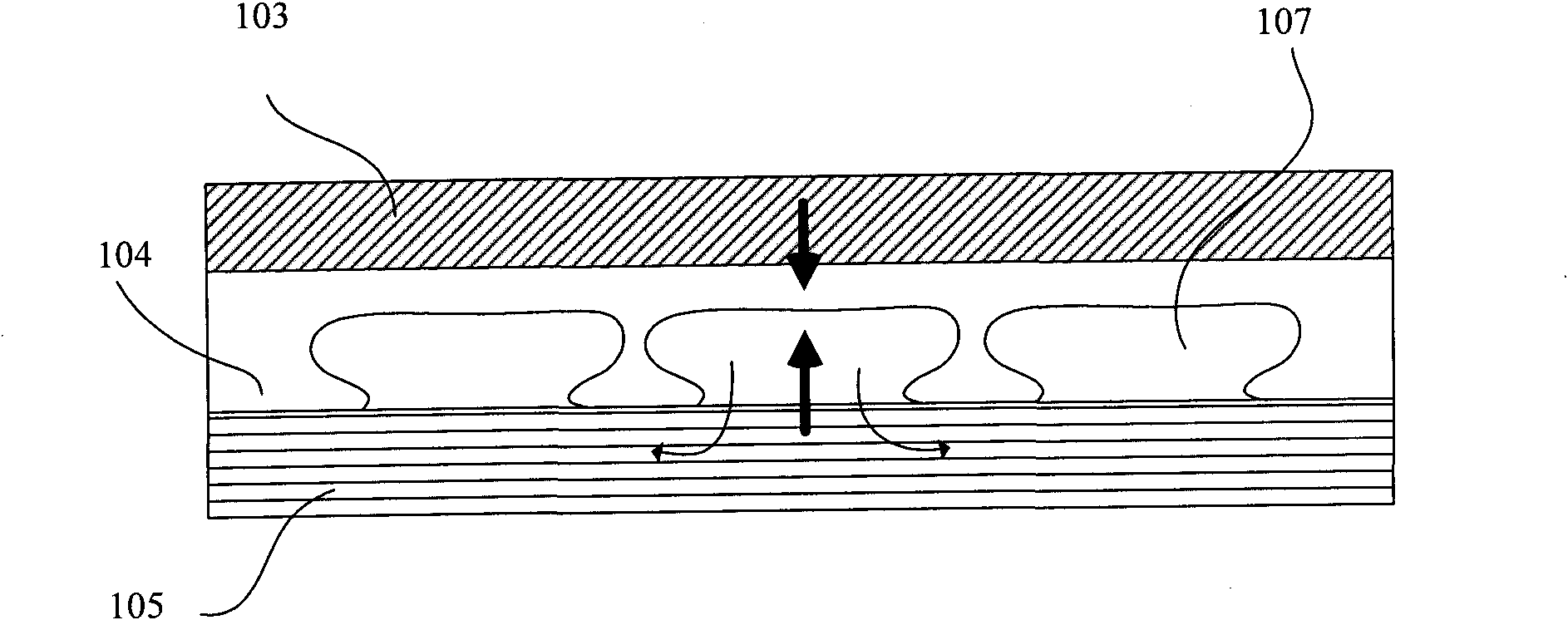

[0016] The invention provides a novel plastic floor board, which does not need glue as a bonding tool when laying the floor board. When the floor board is placed on the ground, it directly contacts the ground and can rely on its own gravity to generate adsorption force, and the floor board can also overcome technical problems such as easy arching, upturning and moisture resistance of traditional plastic floor boards.

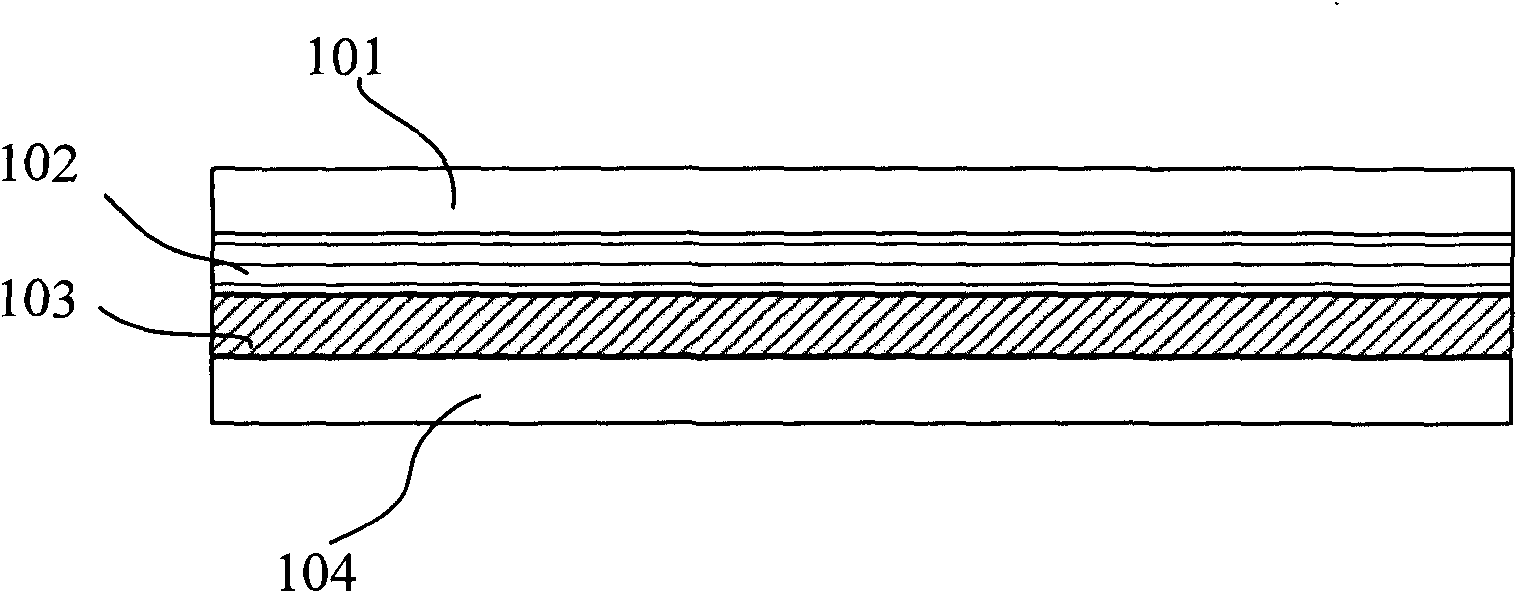

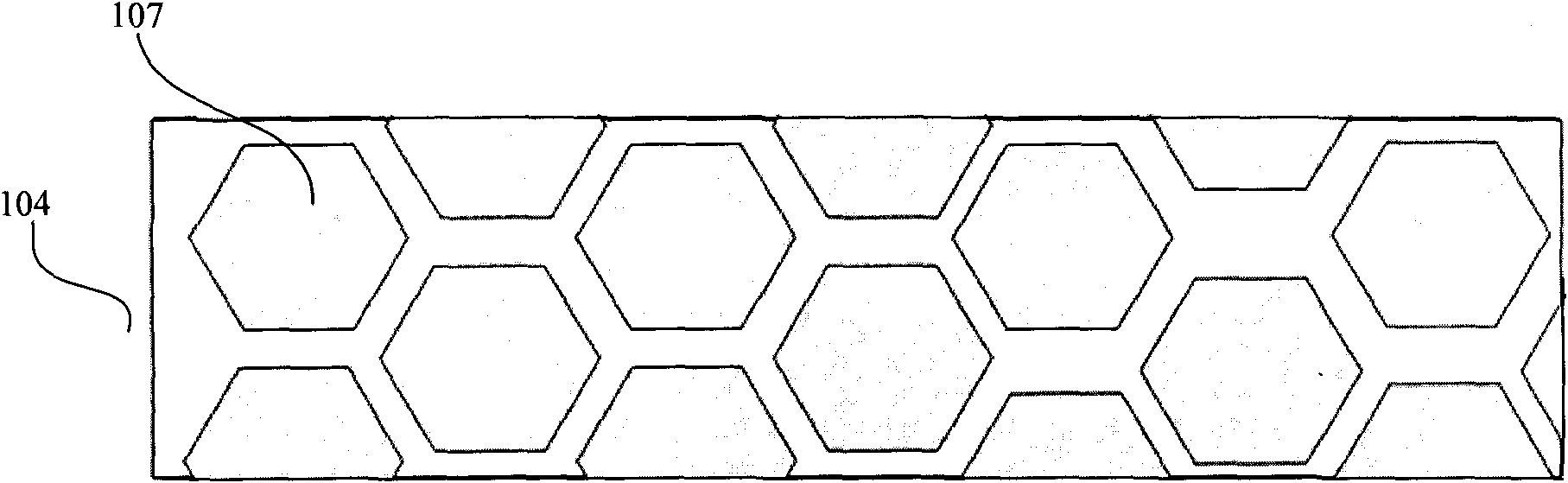

[0017] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of the plastic flooring involved in the present invention. From figure 1 As can be seen in the figure, the floorboard consists of multiple layers. Wherein, the PVC layer 101 is the wear-resistant layer of the plastic floor, and the wear-resistant layer can be used as an optional layer according to the selection of the material of the pattern laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com