Two-position two-way piston type flanged buffer multi-medium angle seat valve

A two-position, two-way, piston-type technology, applied to valve details, valve devices, valve housing structures, etc., can solve problems such as limited performance, achieve the effects of improved performance, guaranteed use conditions, and firm connections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

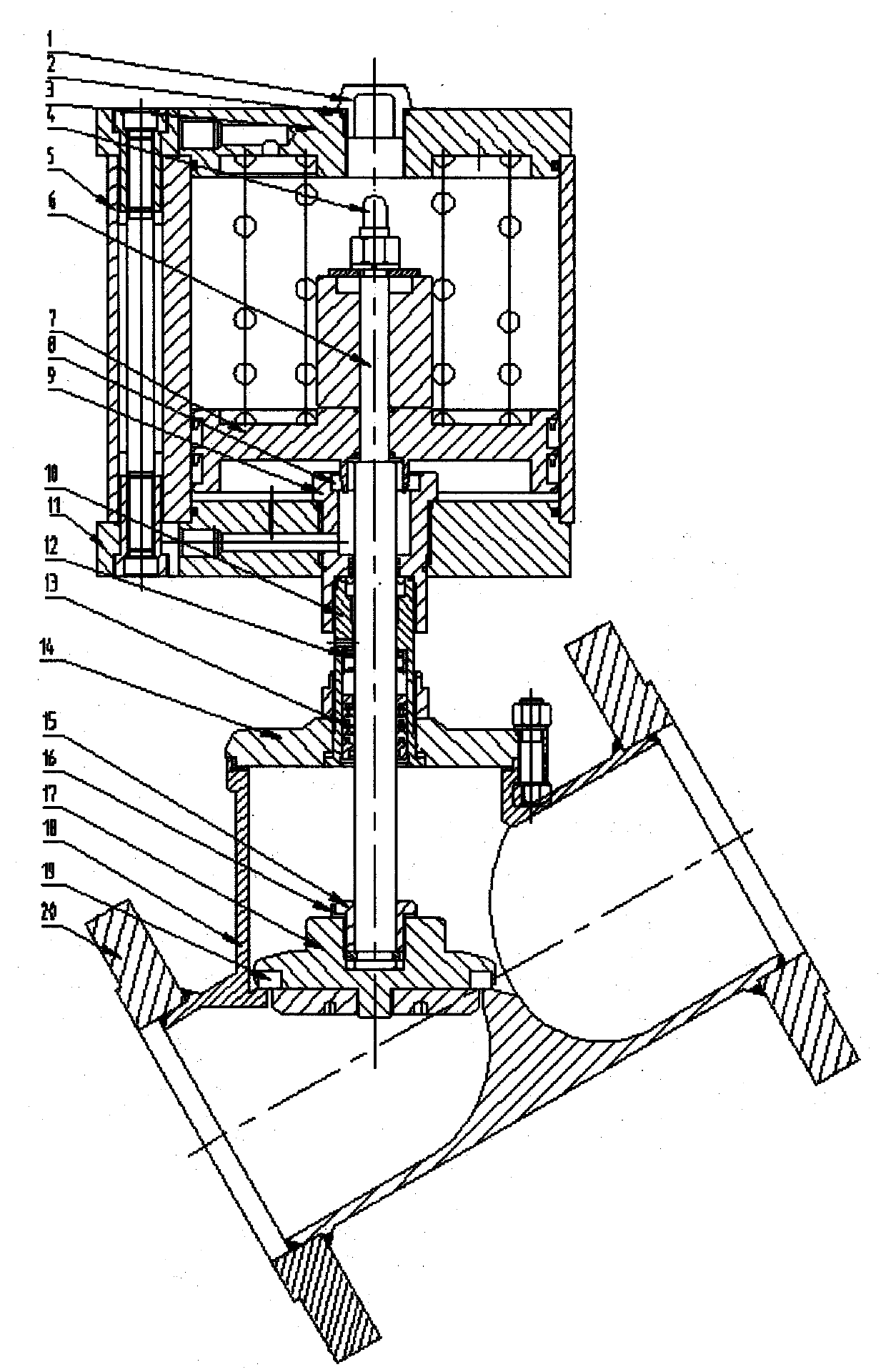

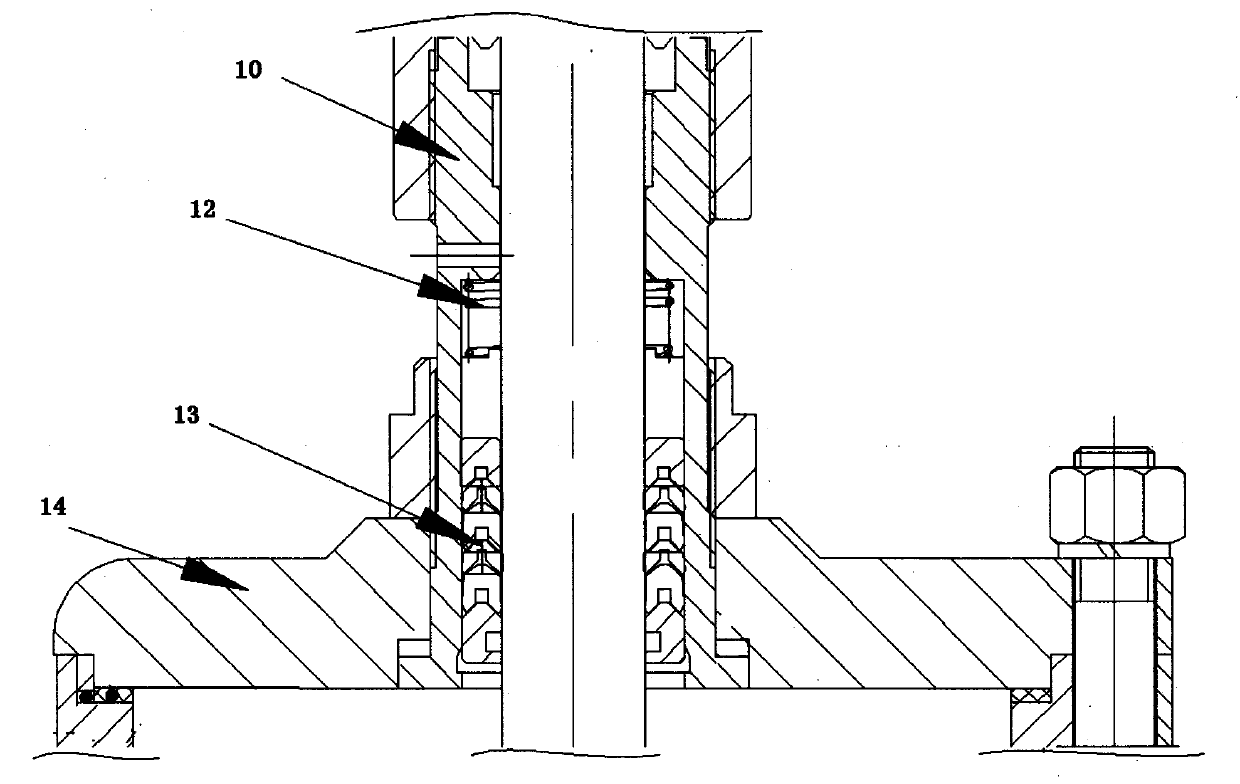

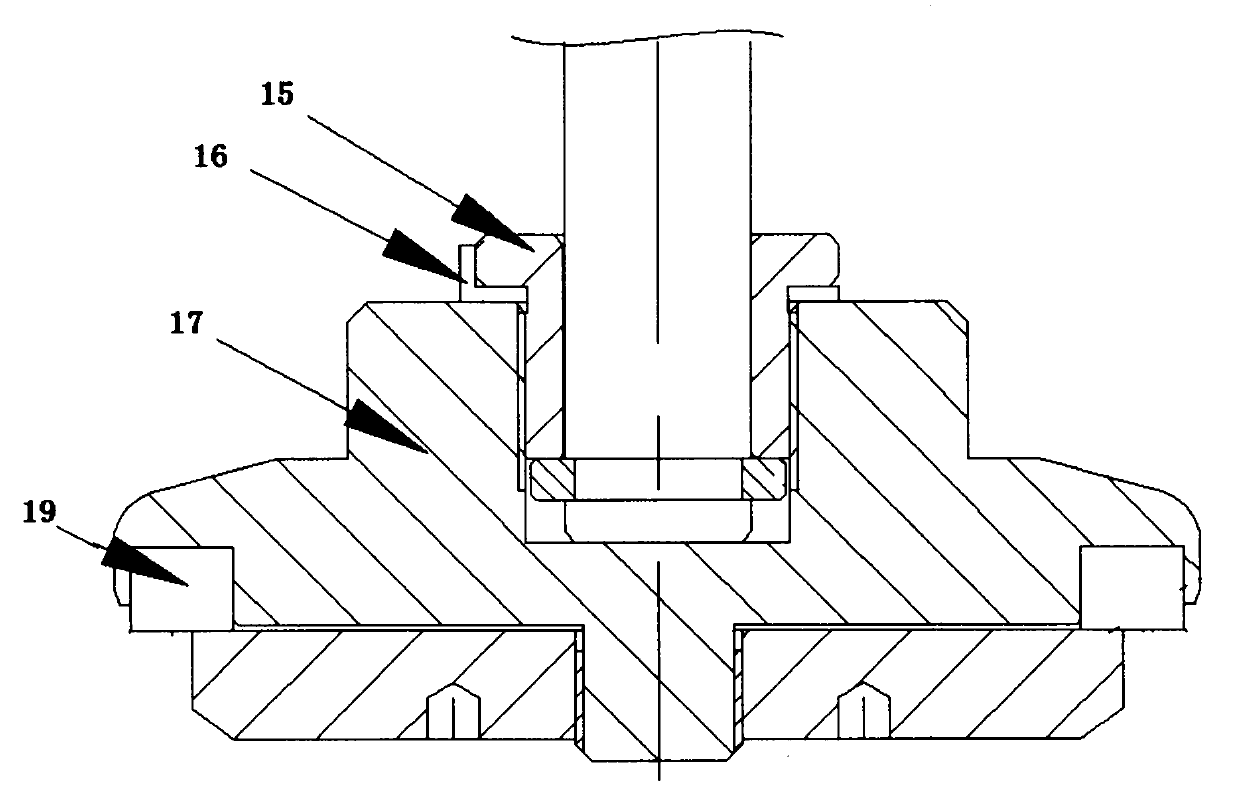

[0013] Such as figure 1 As shown, a two-position two-way piston type multi-media angle seat valve with flange buffer provided by the present invention includes a valve body 18, a valve 17 is arranged in the valve body 18, and a valve gasket 19 is arranged on the valve 17. , the joint end cover 14 is set on the top of the valve body 18, one end of the connecting sleeve 10 is set in the joint end cover 14, and the other end is connected with the bottom cover 11 through the compression screw sleeve 9, and the compression screw sleeve 9 is penetrated in the In the bottom cover 11, the cylinder body 5 is arranged on the bottom cover 11, the top of the cylinder body 5 is provided with a rear cover 3, the piston 7 is arranged in the cylinder body 5, the top of the piston rod 6 is connected with the piston 7, and the top of the piston rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com