Wing rail clamp

A wing rail and fixture technology, applied in the field of wing rail fixtures, can solve the problems affecting safe production, product quality and production efficiency, poor end heat treatment quality, and overburning of quenched ends, and achieves light weight and simple structure. , Eliminate the effect of overburning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail through the accompanying drawings and specific embodiments below, but the protection scope of the present invention will not be limited thereby.

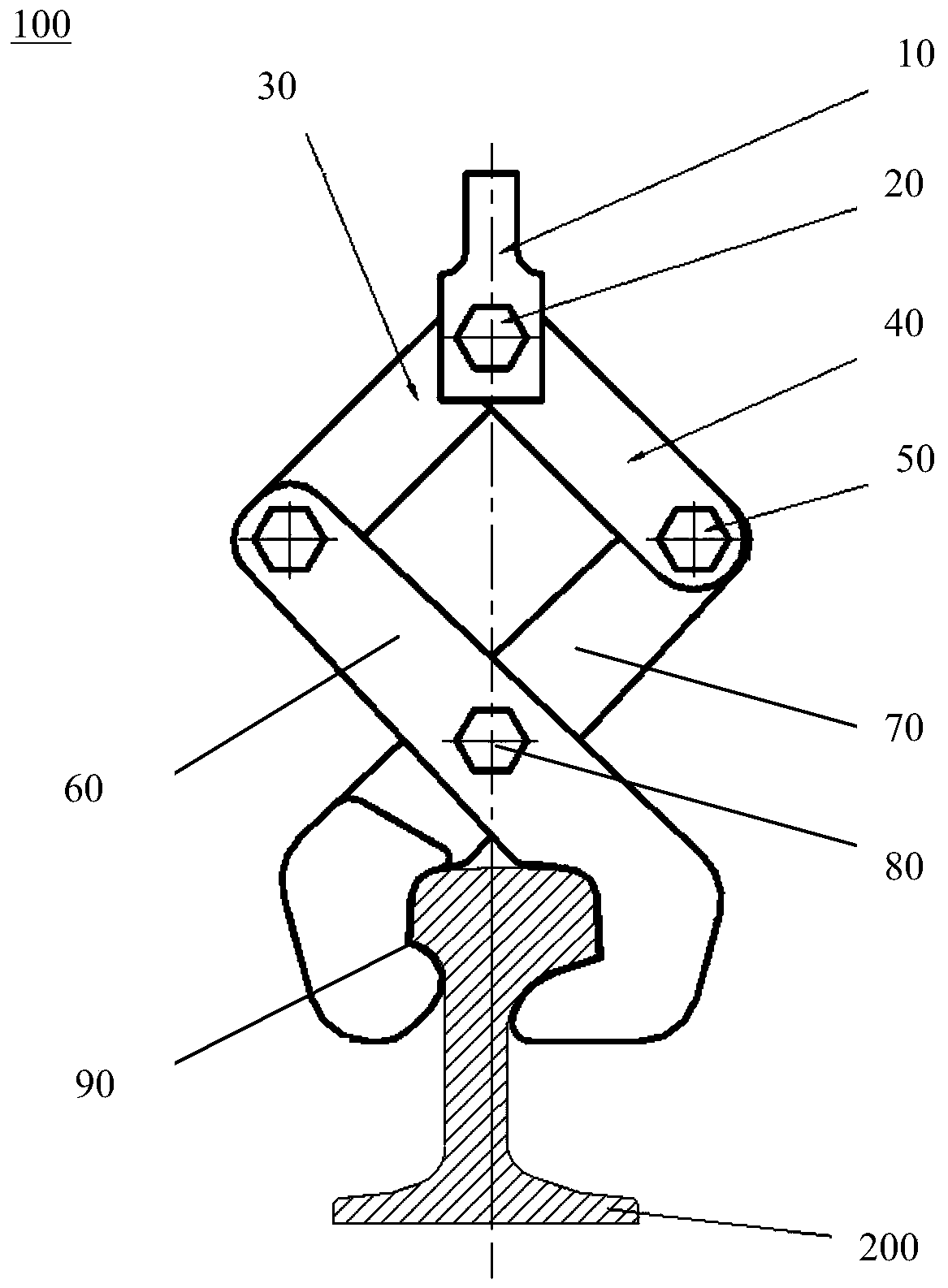

[0022] figure 1 The structure of the wing rail clamp 100 according to the present invention is shown. Such as figure 1 As shown, the wing rail clamp 100 includes lifting lugs 10 , and the lifting lugs 100 are used to connect with a lifting device, so as to lift and control the wing rail clamp 100 . The connection between the wing rail clamp 100 and the lifting device is facilitated by the lifting lug 10, and the operation is simple and easy to control.

[0023] According to the present invention, the wing rail clamp 100 further includes a first movable arm 30 and a second movable arm 40 . Such as figure 1 As shown, the first movable arm 30 and the second movable arm 40 are hinged at the ends through the first hinge shaft 20 . At the same time, the lifting lug 10 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com