Reflection lens for LED lamp

A technology of LED lamps and reflective lenses, applied in refractors, components of lighting devices, semiconductor devices of light-emitting elements, etc., can solve the problems of high cost, eye irritation, and high energy consumption, and achieve uniform and soft light and simple operation. Convenient and expand the effect of the emission surface

Inactive Publication Date: 2012-07-18

NINGBO IKE LIGHTING

View PDF6 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Due to the strong brightness of the LED lamp, it will cause irritation to the eyes and damage the eyes. When using it, it is necessary to process the emitted light of the LED lamp to reduce the irritation. There are two main methods currently used: the first is The reflective surface of the LED lamp made of quartz glass and electroplated silver film, the light emitted by the LED lamp passes through the above reflective surface and then emerges; the second is to use a single-point optical lens, and the light emitted by the LED lamp passes through the single-point optical lens before being emitted , in the above two methods, the first method will produce multiple reflective surfaces, which can expand the emission area of the light, and the light is relatively soft and uniform, but it consumes more energy and has a higher cost. In the second method, only a single point The lens expands the unidirectional and focused light source of the LED lamp to the entire light surface of the lens. Although its cost is low, because the light emitted by the LED lamp is only reflected on one side, the softness and uniformity of the light will definitely be improved, but it is still dazzling.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

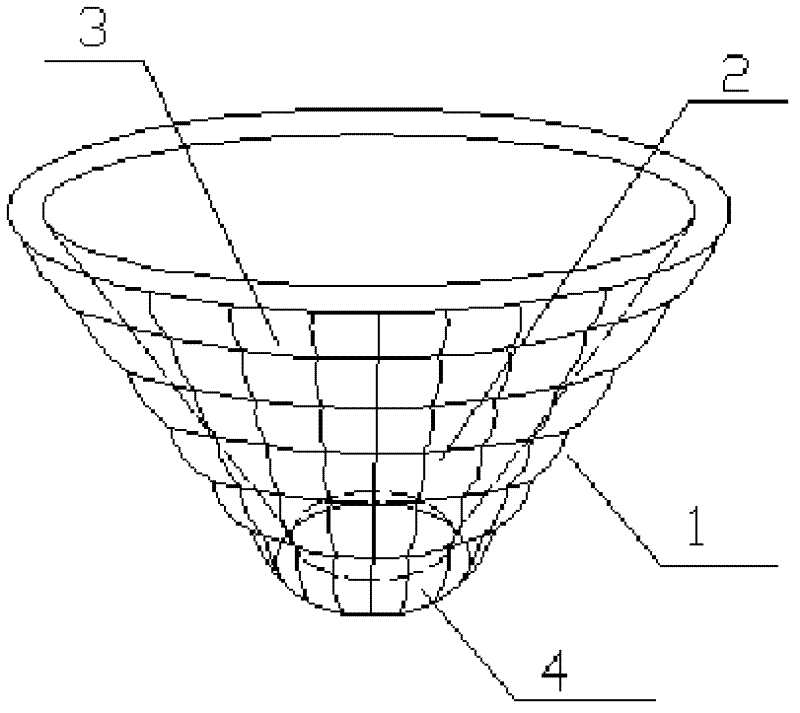

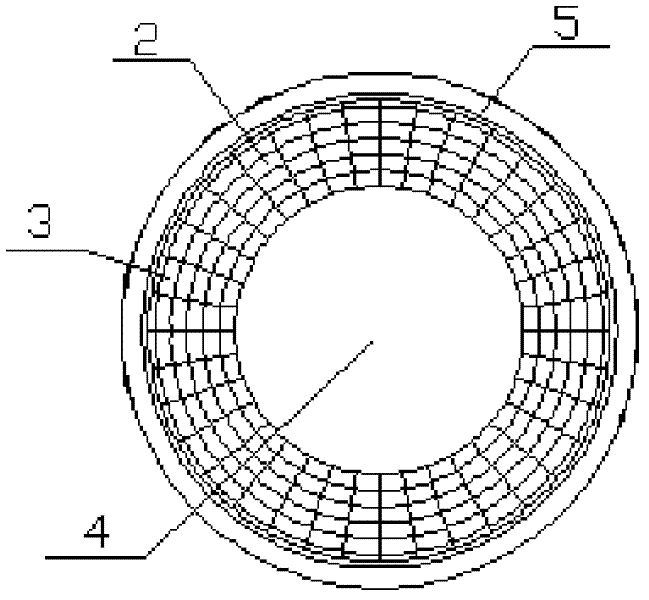

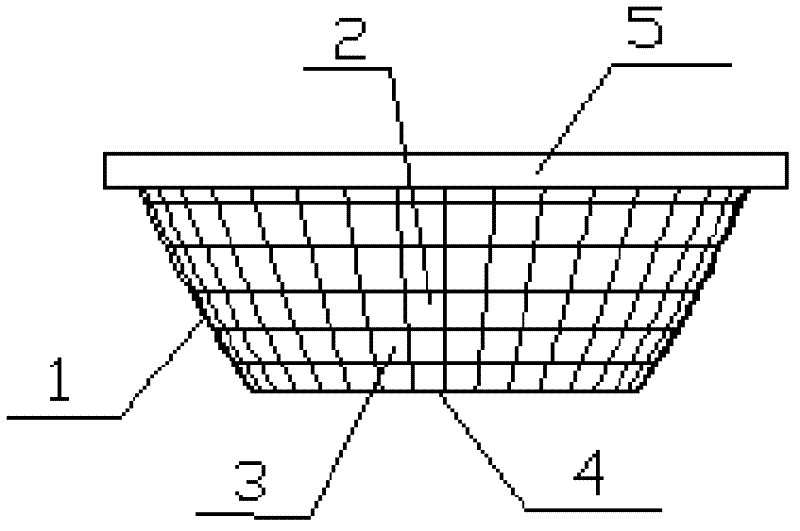

The invention discloses a reflection lens for an LED lamp, which comprises a lens body. The lens body is a conical cup, the inner side surface and / or the outer side surface of the lens body are circumferentially, uniformly and equally divided into a plurality of planar reflection unit groups, each planar reflection unit group consists of a plurality of planar reflection units arrayed along the height direction, and an included angle between each two adjacent planar reflection units along the height direction ranges from 175 degrees to 179 degrees. The reflection lens for the LED lamp has the advantages that light of the LED lamp can be reflected by a micro-lens array in a multiple manner on the premise that low cost is guaranteed, a light emission surface is expanded, and the light emitted by the LED lamp is uniform and gentle and does not irritate eyes of people.

Description

technical field [0001] The invention relates to a reflective lens, in particular to a reflective lens for LED lamps. Background technique [0002] With the continuous development of science and technology, LED lamps with low power consumption and strong brightness have been widely used as light sources in daily life. Due to the strong brightness of the LED lamp, it will cause irritation to the eyes and damage the eyes. When using it, it is necessary to process the emitted light of the LED lamp to reduce the irritation. There are two main methods currently used: the first is The reflective surface of the LED light made of quartz glass and electroplated silver film, the light emitted by the LED light passes through the above reflective surface and then emerges; the second is to use a single-point optical lens, the light emitted by the LED light passes through the single-point optical lens and then emits , in the above two methods, the first method will produce multiple refl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F21V5/04F21Y101/02F21Y115/10

Inventor 施杰军

Owner NINGBO IKE LIGHTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com