Gate device of atmosphere protecting furnace

A technology for protecting furnaces and gates. It is applied in the field of kilns. It can solve the problems of sparks, great damage to sealing strips, and easy collisions, etc., and achieve the effects of preventing convection, low frictional heat generation, and good sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

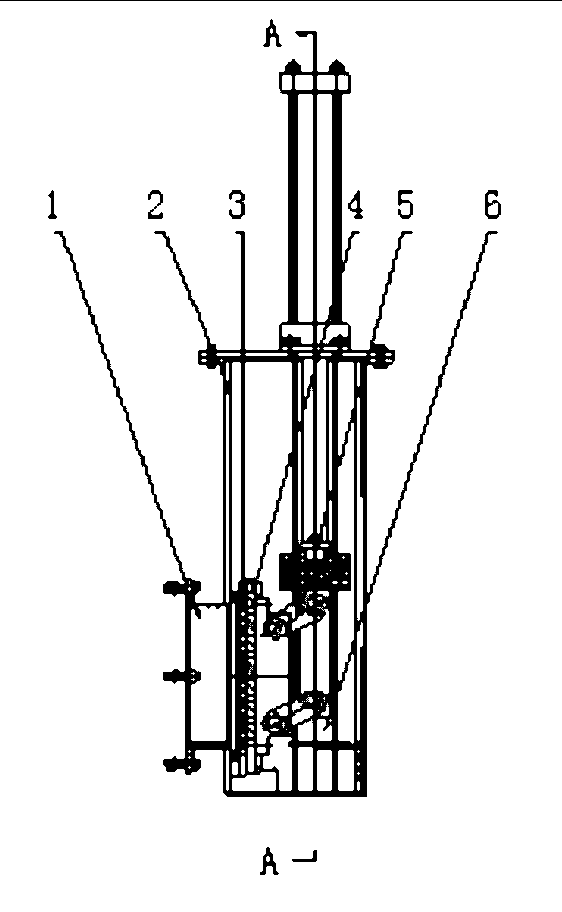

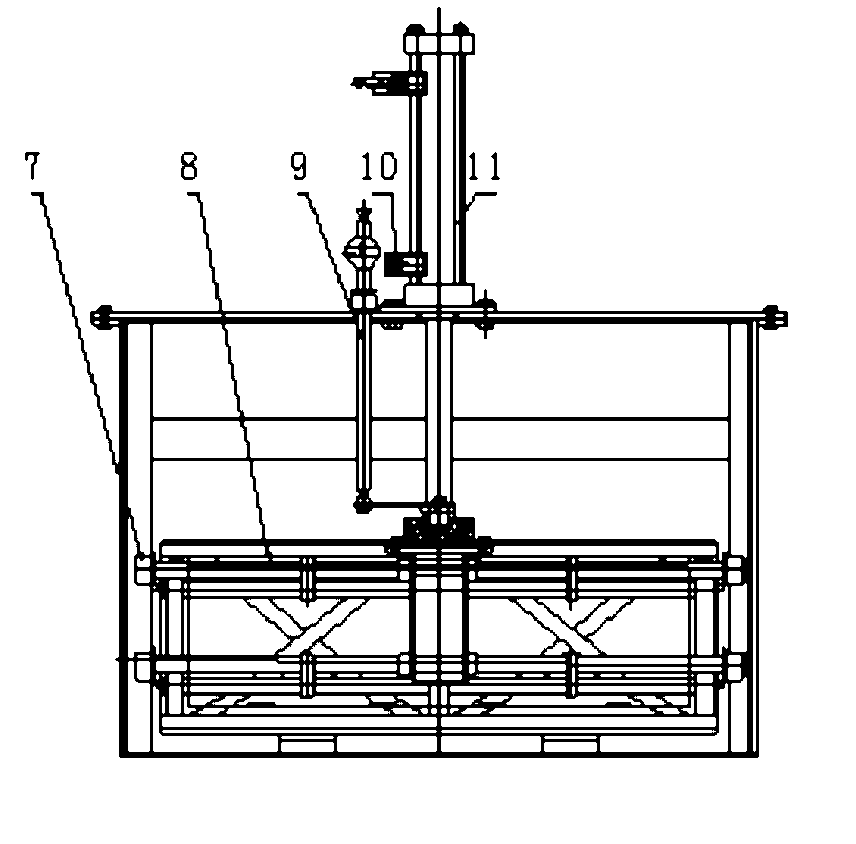

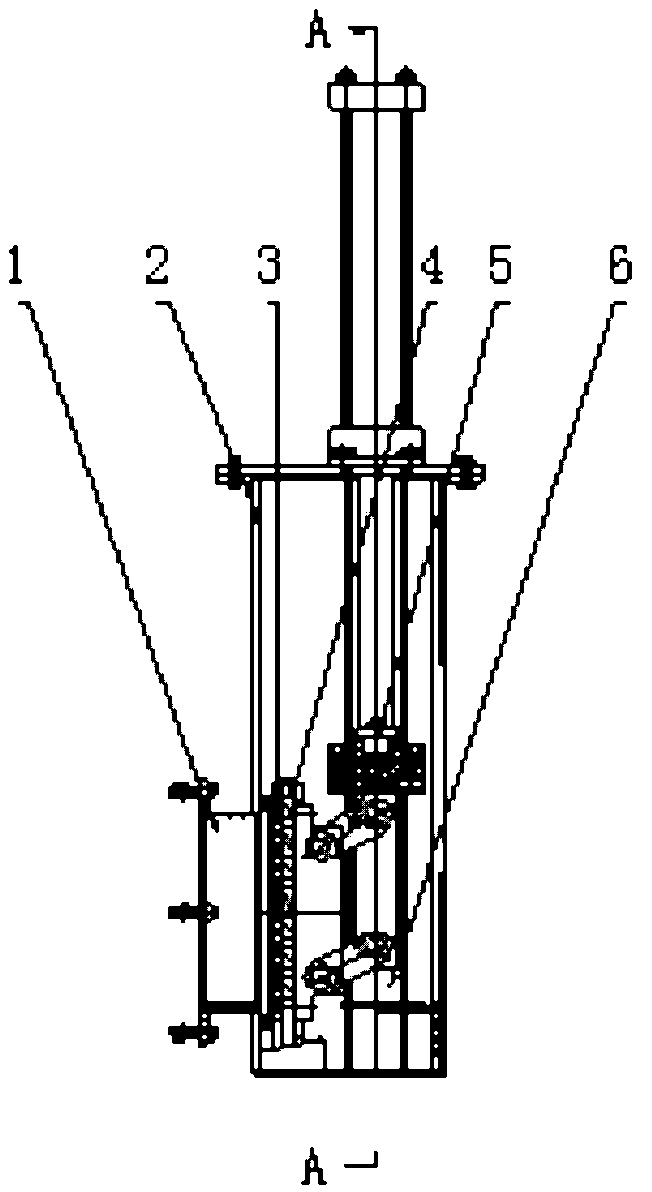

[0019] combine figure 1 and figure 2 Specifically describe the gate device of the atmosphere protection furnace of the present invention, including a door panel 4 arranged at the door of the silo body 1, a guide rail mechanism is provided between the door panel and the silo body to guide the door panel to move up and down, and the door panel is driven by a drive mechanism 11 arranged on the upper part of the silo body, The door panel and the drive mechanism are connected by a parallel four-bar linkage mechanism 5 . The guide rail mechanism includes guide rails 6 arranged on the left and right sides of the door of the warehouse body, and a roller 7 is respectively provided on the upper and lower ends of the left and right sides of the door panel, and the rollers cooperate with the guide rails. The roller is arranged on the roller shaft 8 . The roller is of resin or rubber structure. The driving mechanism is an air cylinder or a hydraulic cylinder. A striker 9 is arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com