Adjustable eddy current probe fixing mechanism used for detecting central hole of turbine rotor

A technology of steam turbine rotor and eddy current probe, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of high inspection cost, and achieve the effects of improving detection efficiency, saving inspection cost, and saving customization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

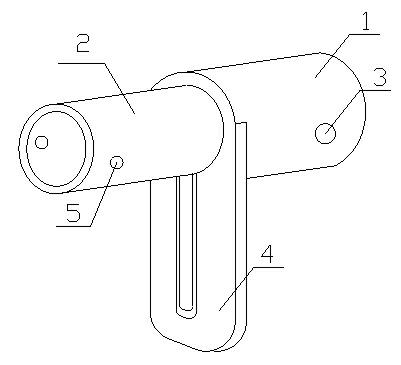

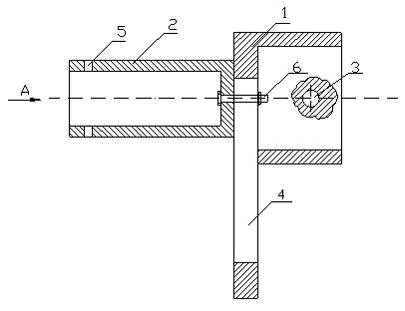

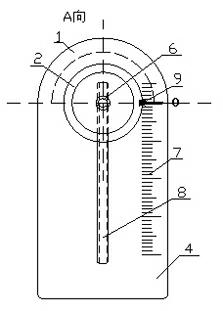

[0020] see figure 1 , figure 2 and image 3 The adjustable eddy current probe fixing mechanism for steam turbine rotor center hole detection includes a probe sleeve 1 with one axial end closed and a guide rod sleeve 2 with one axial end closed; the closed end of the probe sleeve 1 is radially connected to an outwardly extending The scale plate 4, the closed end face of the scale plate 4 and the probe sleeve are in a plane, the middle part of the scale plate 4 is provided with a guide groove 8, and the upper end of the guide groove 8 on the scale plate is located at the upper part of the center of the probe sleeve 1. The two sides of the probe sleeve 1 are respectively provided with probe bolt holes 3 in the radial direction; the center of the closed end of the guide rod sleeve 2 is provided with a threaded connector 6, and the two sides of the guide rod sleeve 2 are respectively provided with guide rod bolt holes 5 in the radial direction ; The guide rod sleeve 2 is fixedly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com