Photoelectric packaging mechanism

A technology of photoelectric induction and closing mechanism, which is applied to electrical components, casings/cabinets/drawer components, electrical equipment casings/cabinets/drawers, etc., can solve the problems of single function and poor adaptability, and reach the market The effect of wide space, simple manufacture, high application value and economic added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

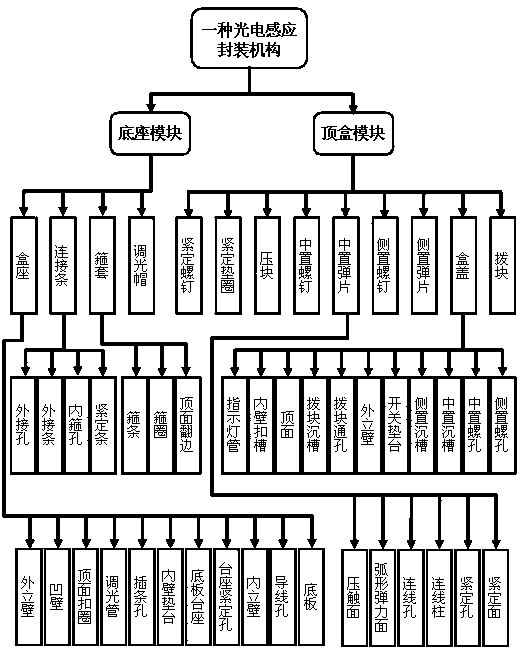

[0035] As a technical solution, the present invention can be implemented through the organic combination of corresponding parts. The organizational structure of the product of the present invention is as figure 1 shown.

[0036] figure 1 Among them, the product of the present invention is composed of two modules, a base and a top box, wherein the base module is composed of four parts: a box seat, a connecting bar, a hoop, and a dimming cap, and the top box module is composed of a set screw, a set washer, It is composed of nine parts: pressing block, middle screw, middle shrapnel, side screw, side shrapnel, box cover, and shifting block.

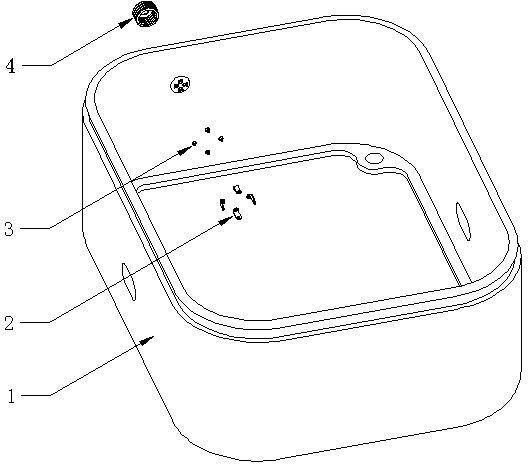

[0037] In the implementation process, each part has its own unique appearance. The appearance of each part of the base module is as follows: figure 2 shown.

[0038] figure 2 Among them, the parts arranged in the order of labels are: box base part (1), connecting bar part (2), hoop cover part (3), dimming cap part (4), among them, conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com