Vibrating armature pump

A technology of reciprocating motion and pump pistons, which is applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of unfavorable cost and trouble, and achieve the effect of saving processing time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

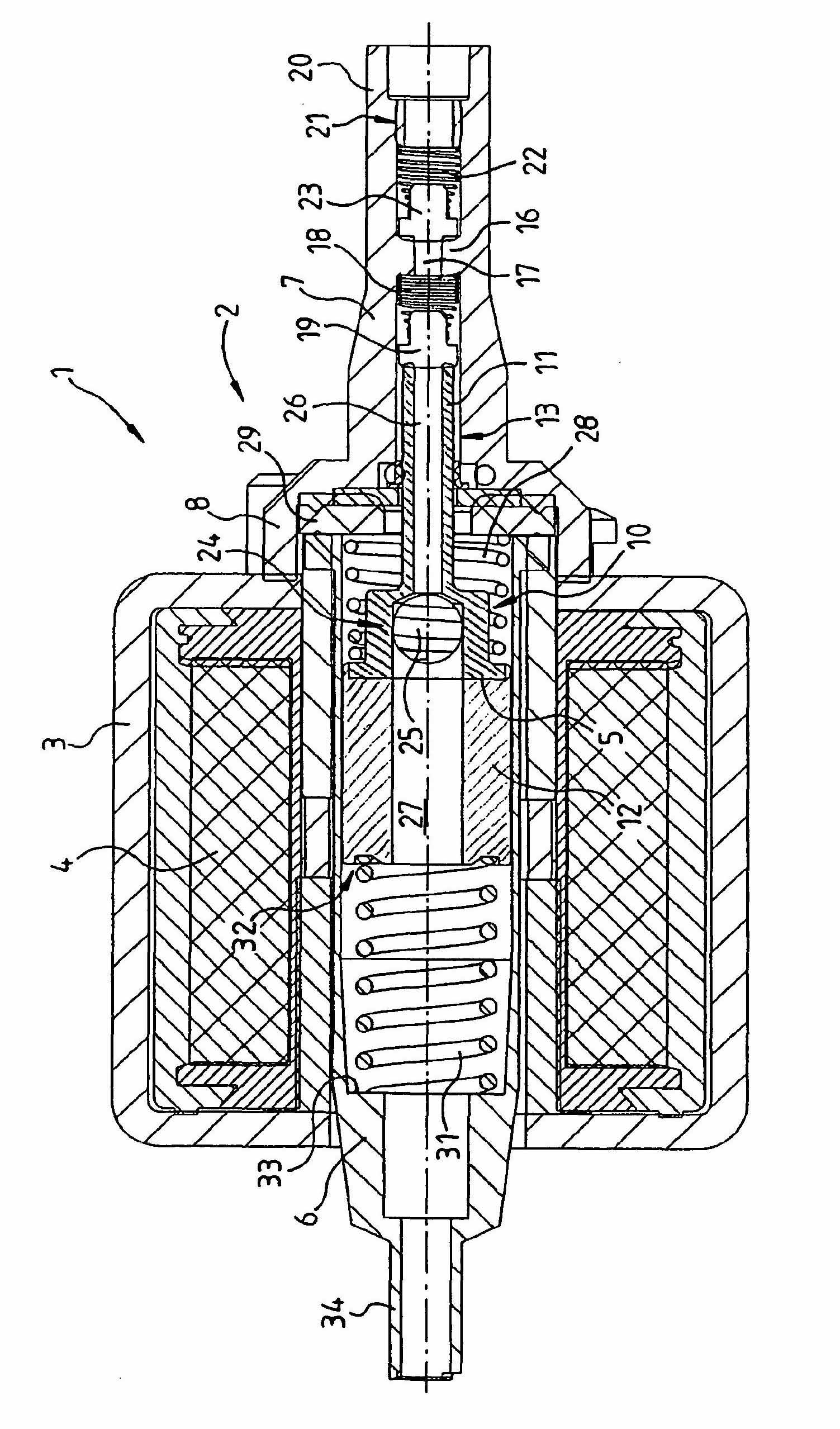

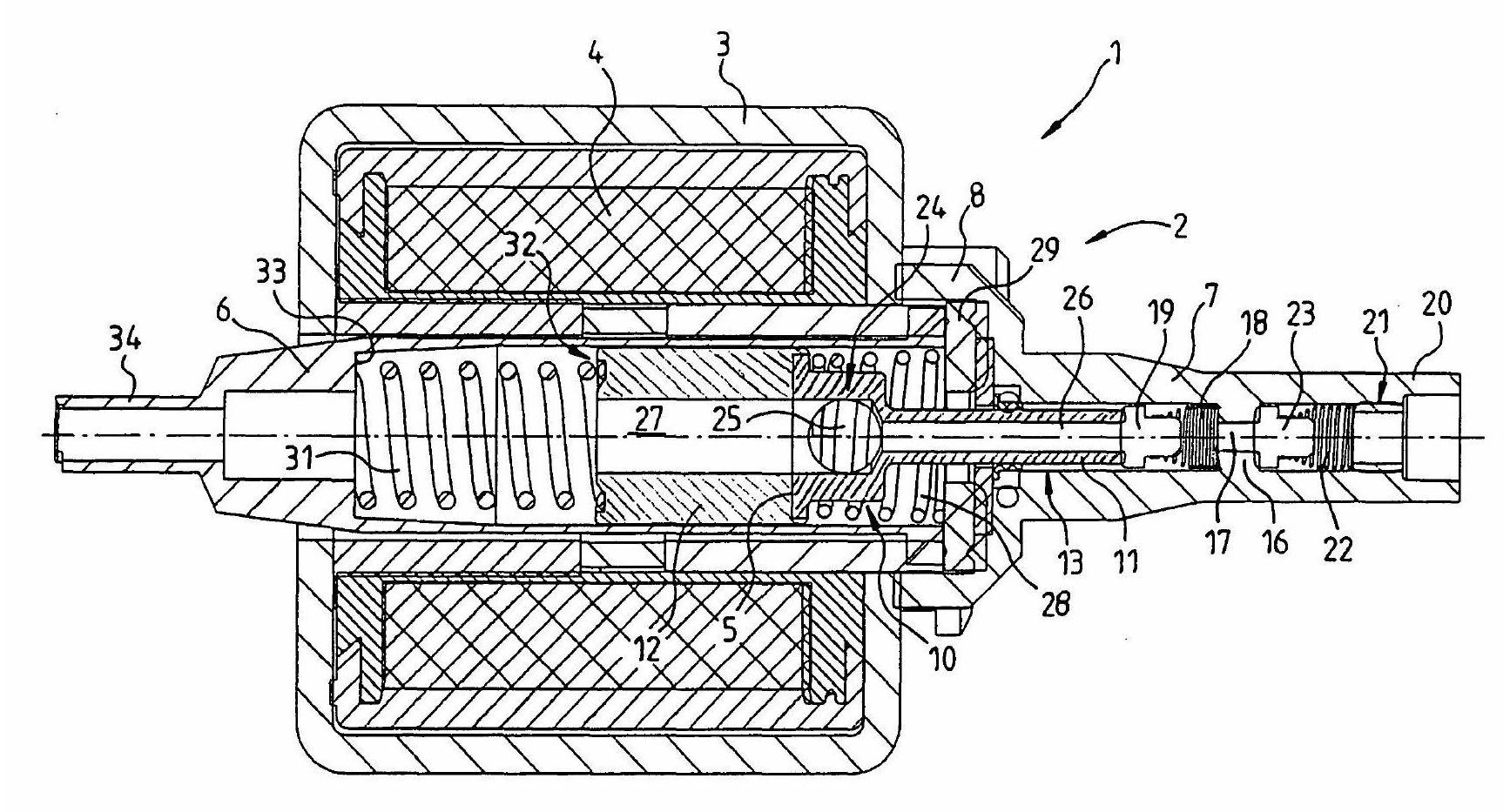

[0026] according to figure 1 The reciprocating pump 1 comprises a two-part pump housing 2 which is fixed on a yoke 3 of an electromagnetic coil 4 .

[0027] The pump housing 2 comprises a tubular armature receptacle 6 , which extends inside the coil 4 , and a cylinder part 7 which bears against the yoke 3 via a flange 8 .

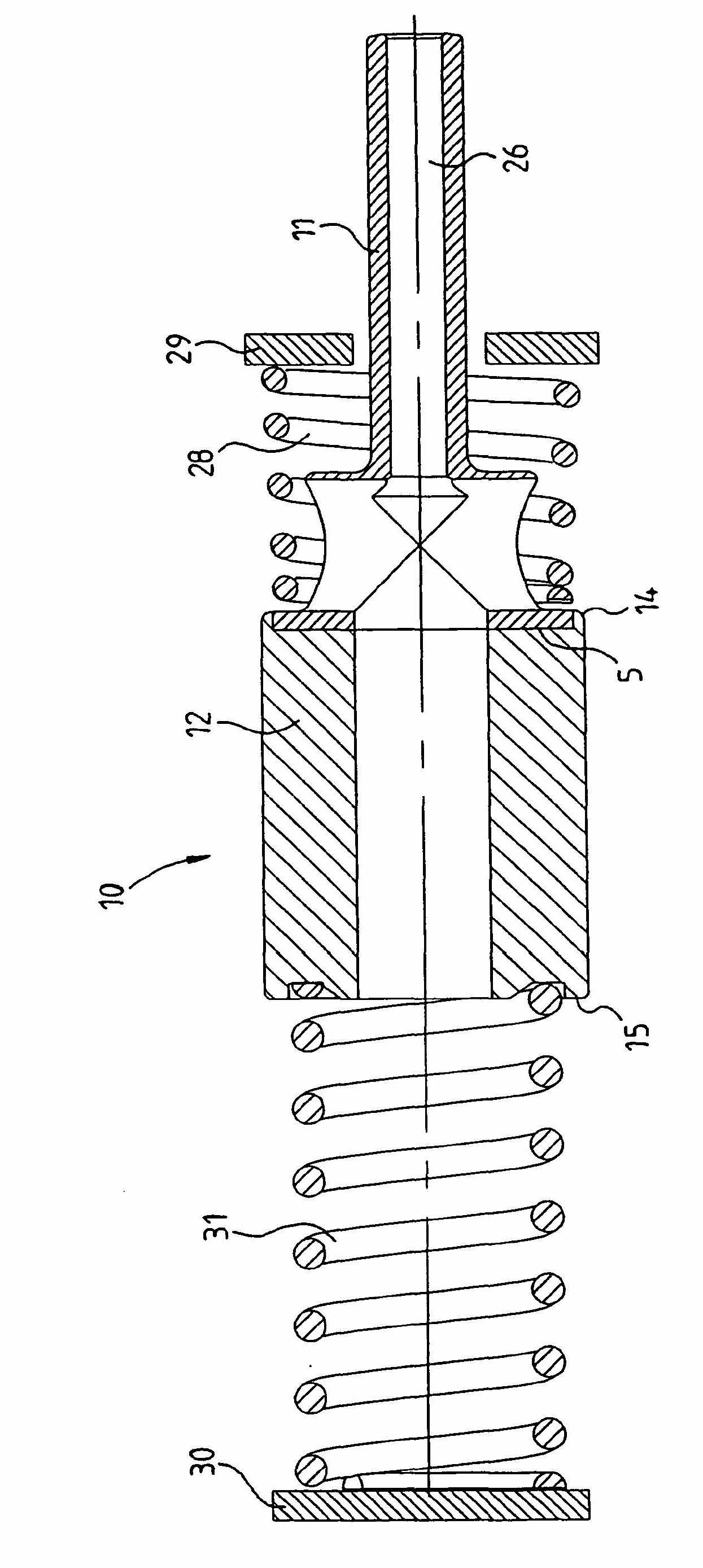

[0028] The pump piston unit or pump piston 10 penetrates into the pump housing 2 and comprises a pump part or piston part 11 and a drive part or magnetic part 12 . The piston part 11 is of tubular design and has an axial through-bore, and is immersed in a cylinder 13 which is formed in the cylinder part 7 .

[0029] During operation, the pump piston 10 and thus the piston part 11 executes a cyclic axial movement in the direction of the double arrow A, ie the pump piston oscillates periodically back and forth in the axial direction.

[0030] On the side opposite the magnetic part 12 , the cylinder 13 is closed by means of a cross arm 16 which has a central...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com