Rotary-cutting, straw-crushing and stubble-cleaning machine and stubble cleaning tool assembly used with same

A technology of straw crushing and stubble cutting machine, which is applied in the fields of farming equipment, agricultural machinery and equipment, and application, can solve the problem that the stubble cutting machine cannot simultaneously reduce power loss and loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

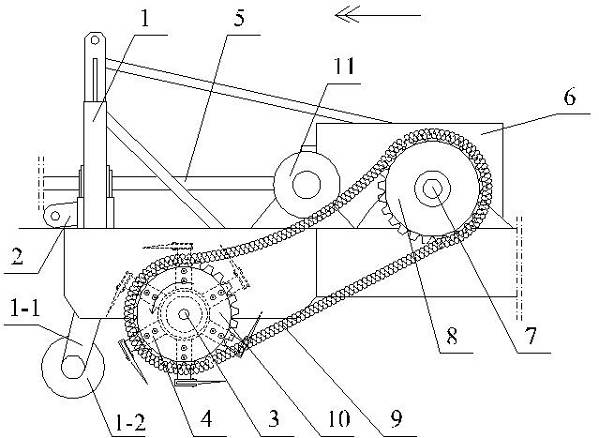

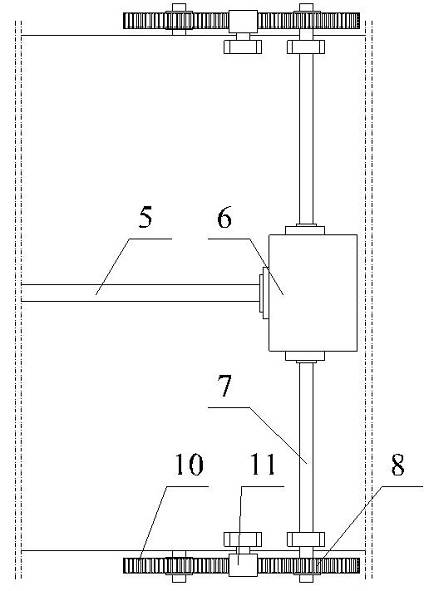

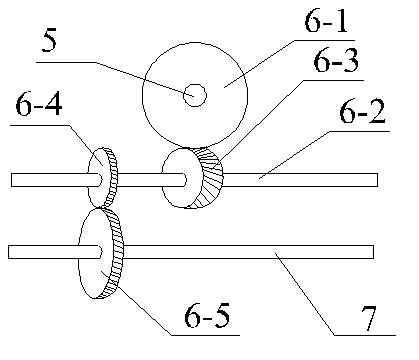

[0014] A rotary adze type straw crushing and stubble removal machine, the structure includes a frame 1 with a traction part 2 attached to the front end, a transmission gearbox 6 connected with a power output shaft 5 of a tractor, and a gear box limited on the frame 1 by means of a pair of bearings. The stubble removal mechanism formed by the stubble cutter shaft 3 and a group of stubble removal tool assemblies 4 distributed on the stubble removal cutter shaft 3, the stubble removal cutter shaft 3 is connected with the power output shaft 7 of the speed change gearbox 6 by means of a supporting transmission mechanism, the above stubble removal cutter shaft 3. It has the same direction of rotation as the driving wheel of the tractor. The front extension part 1-1 of the frame 1 is provided with a grain pressing mechanism, and the stubble cutting tool assembly 4 distributed on the stubble cutting knife shaft 3 cooperates with the grain pressing mechanism to form a continuous roll pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com