Plastic double-sleeve capillary heat-resistant curtain

A double casing and capillary technology, applied in the direction of curtains, tents, window decorations, etc., can solve the problems of the limitation of the application of bionic skin of the outer envelope structure, the inability to handle the load of the envelope structure, and the small range of renewable energy. , to achieve flexible and convenient construction and installation, eliminate heat load, and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content of the present invention will be described in detail below in conjunction with the drawings and specific embodiments. It should be understood that the present invention is not limited to the following preferred embodiments, which are only used as illustrations of the present invention.

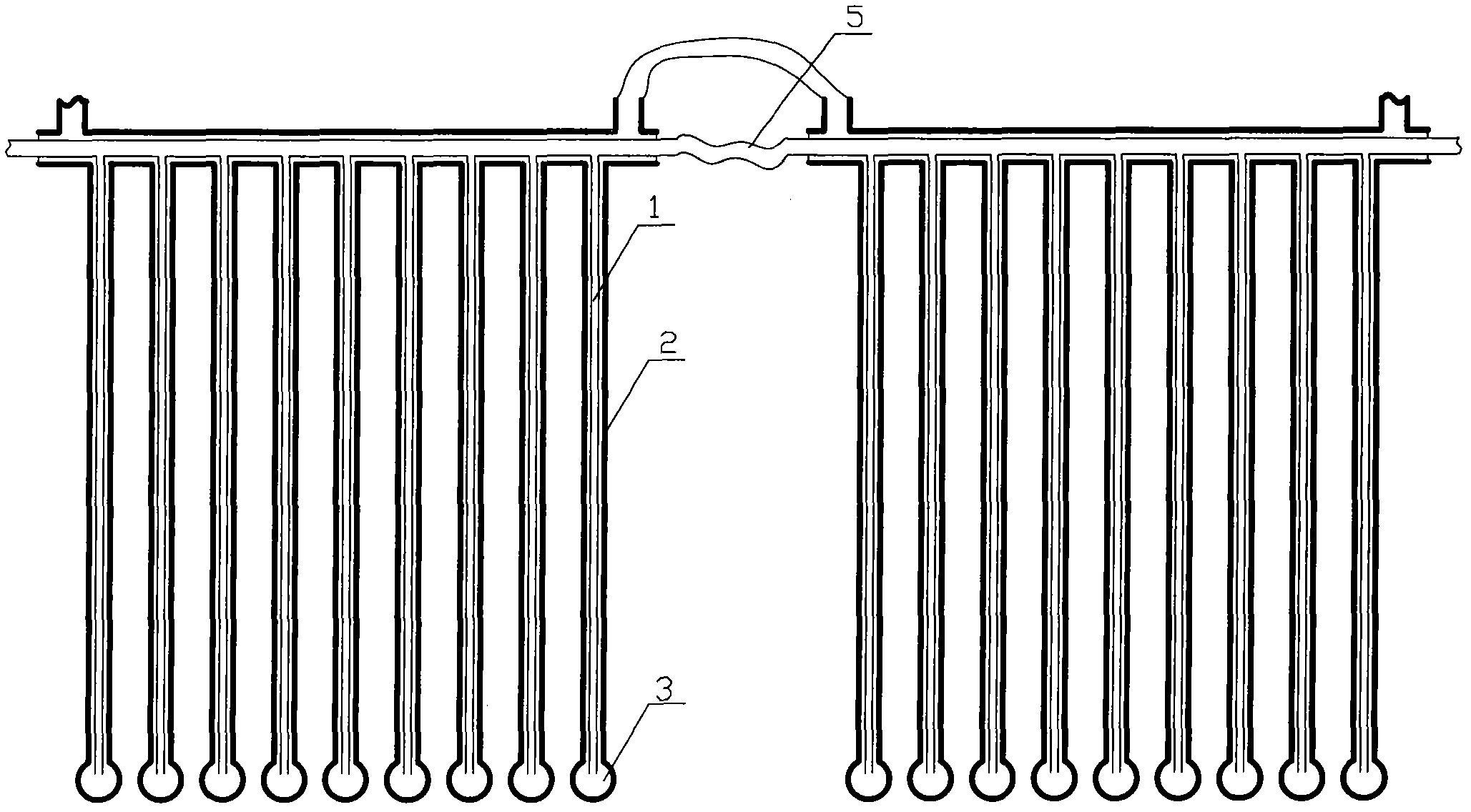

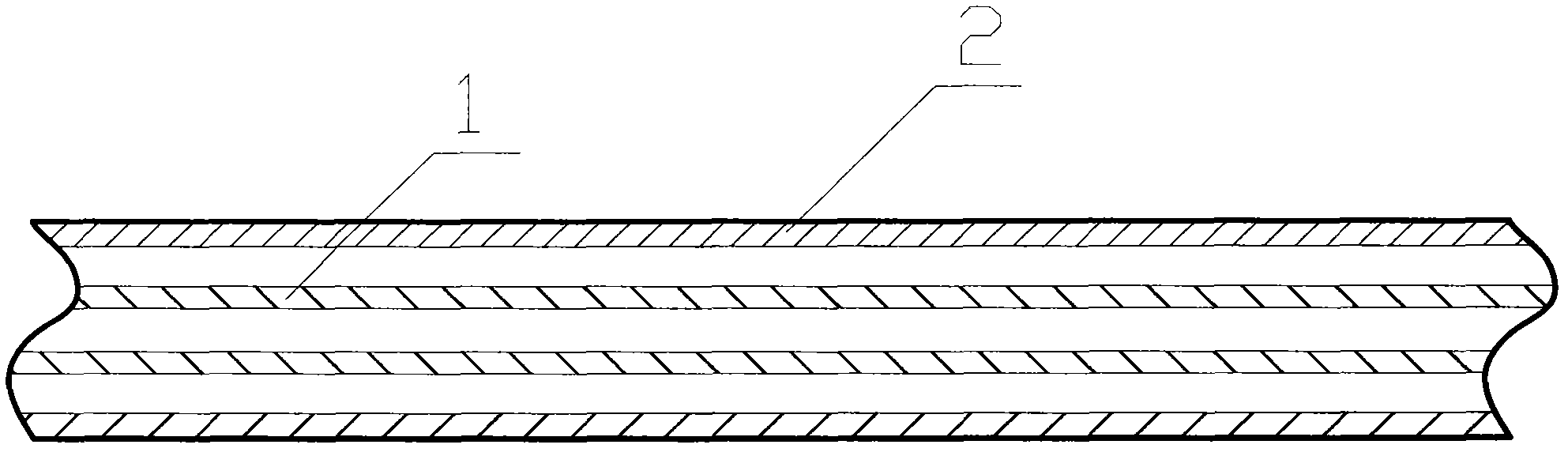

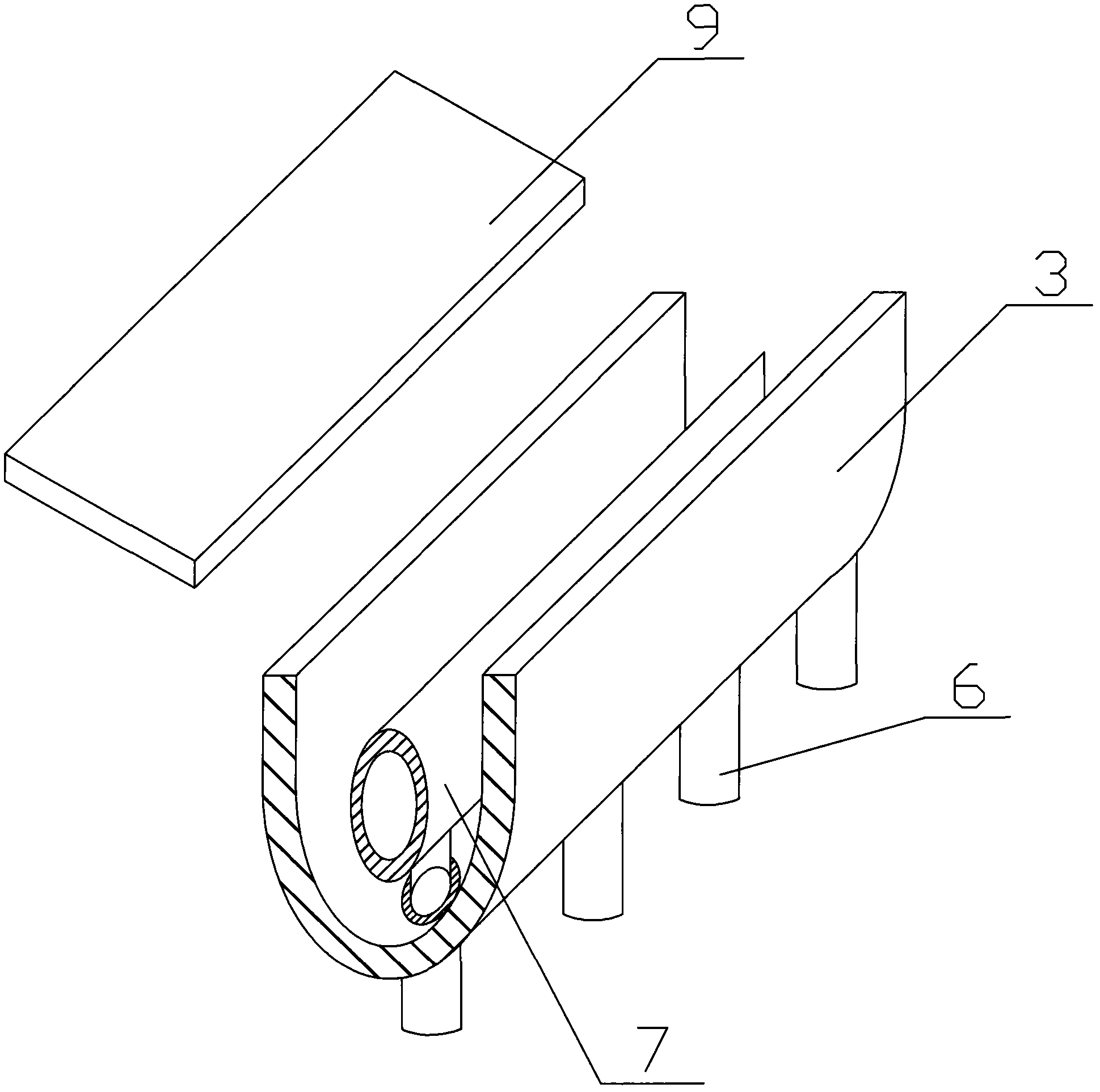

[0028] Such as figure 1 . As shown, a plastic double-sleeved capillary heat-resistant curtain, the system includes a double-sleeved inner tube 1, a double-sleeved outer tube 2, a composite header 3, a water polo 4, and a connecting hose 5, which is characterized in that the The connecting hose 5 is used to connect the inner tube 1 and the outer tube 2 of the double-tube capillary heat-resistant curtains in plastic double-tube heat-resistant curtains, respectively, and connect the heat-resistant curtains connected in groups to the cold and heat sources On the one hand, through the refrigerant with suitable water temperature and water quantity provided by the cold and heat so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com