Dust cup of cyclone centrifugal filtration type dust collector

A cyclone centrifugal and filtering technology, applied in suction filters and other directions, can solve the problems that the dust cup cannot maintain the dust suction effect for a long time, the fine dust is easy to block the filter, and the bottom cover is inconvenient to clean, etc., so as to achieve simple structure and extended use. Long life, good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

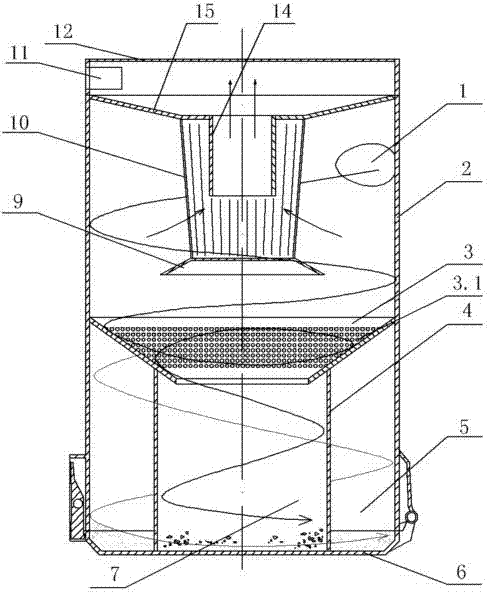

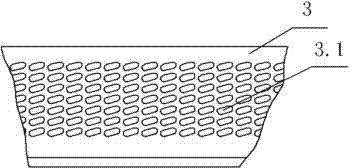

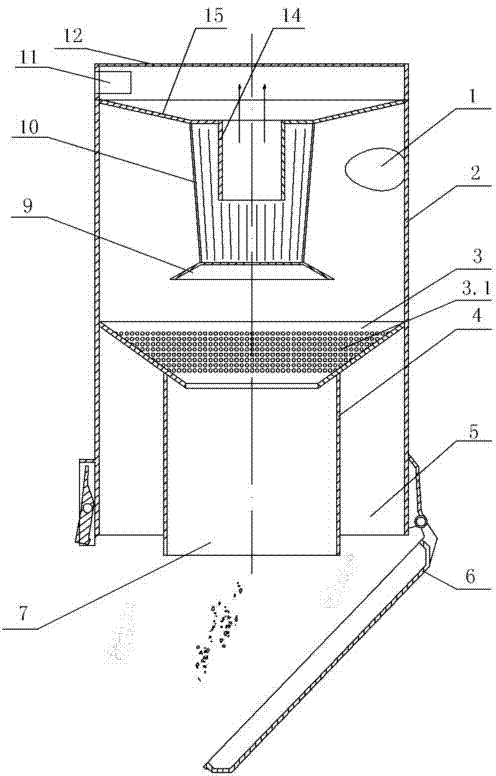

[0019] like figure 1 As shown, the present invention is a dust cup of a cyclone centrifugal filter vacuum cleaner, and its first embodiment includes a cup body 2 of the dust cup, an upper cover 12 and a bottom cover 6 of the cup body 2, and the upper cover 12 is fastened with the cup body 2 Or threaded connection, one side of the bottom cover 6 is hinged with the bottom of the cup body 2, and the other side of the bottom cover 6 is detachably connected with the bottom of the cup body 2 by means of an elastic lock. The upper side wall of the cup body 2 is provided with an air inlet 1 that is tangent to the peripheral wall of the cup body 2, and an air outlet 11 is provided on the upper cover 12. Dust and air are sucked through the air inlet 1, and the cyclone is rotated and centrifuged in the cup body 2. The dust is separated, and the clean air is discharged through the air outlet 11. A partition 15 is arranged between the cup body 2 and the upper cover 12, and the center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com