Comprehensive garbage sorting machine

A comprehensive separation and garbage technology, applied in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc. The effect of preventing clogging of the mesh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

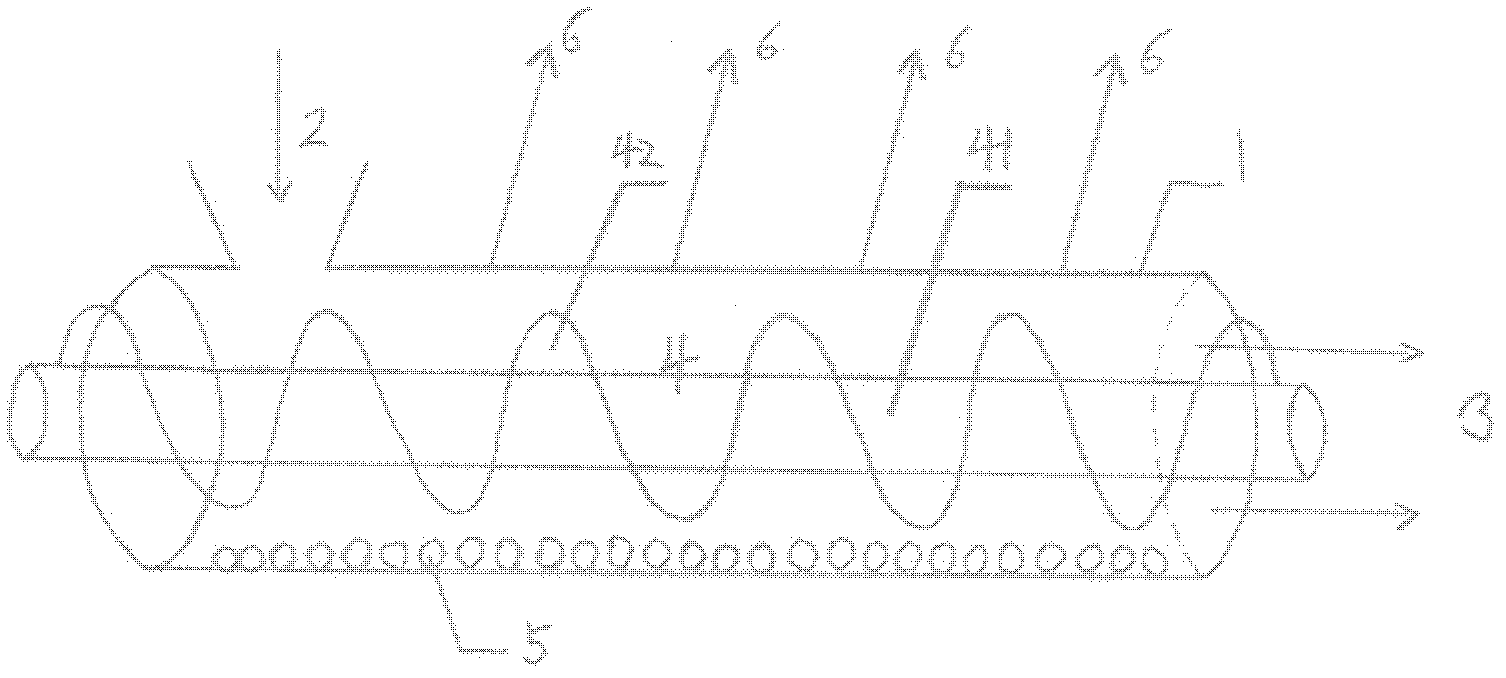

[0023] Embodiments of the present invention will be described below with reference to the accompanying drawings.

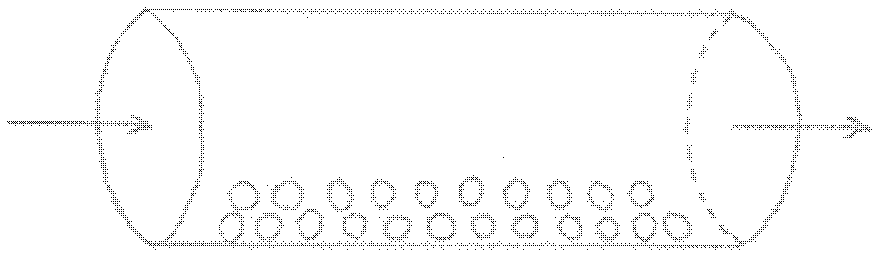

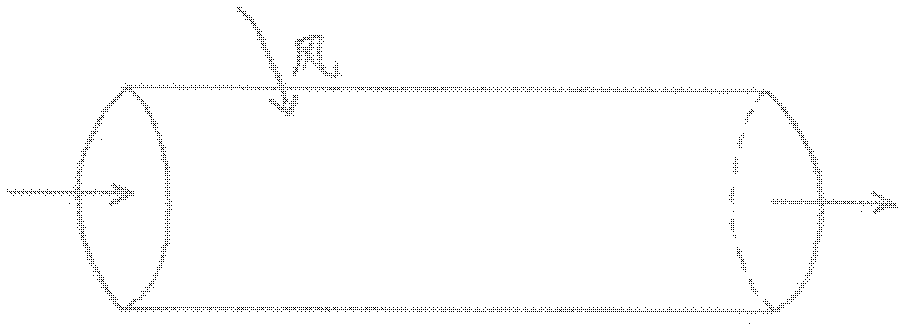

[0024] Such as image 3 As shown, the garbage comprehensive sorting machine provided by the present invention includes a drum-shaped housing 1, a feed port 2, and a discharge port 3. The middle part of the housing is provided with a screw pushing device 4, and the screw pushing device includes a screw 41, and The blade 42 extends helically along the screw axis, and the screw also has an adjustable reducer; a number of holes 5 are provided at the bottom of the housing, and n-level air suction ports 6 are provided at the upper middle of the housing, where 0<n< 6. n is 4 in this embodiment.

[0025] Further, there is a distance between the outer periphery of the screw of the screw pushing device and the upper and lower inner walls of the drum-shaped shell respectively. Preferably, the distance should ensure that the beer bottle cannot stand upright. This enables e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com