Automatic centering and clamping device

A clamping device and automatic centering technology, applied in the direction of expansion mandrel, etc., can solve the problems of workpiece and expansion sleeve rotation, affecting workpiece processing, cumbersome operation, etc., to ensure processing accuracy, reduce labor intensity, and expand evenly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

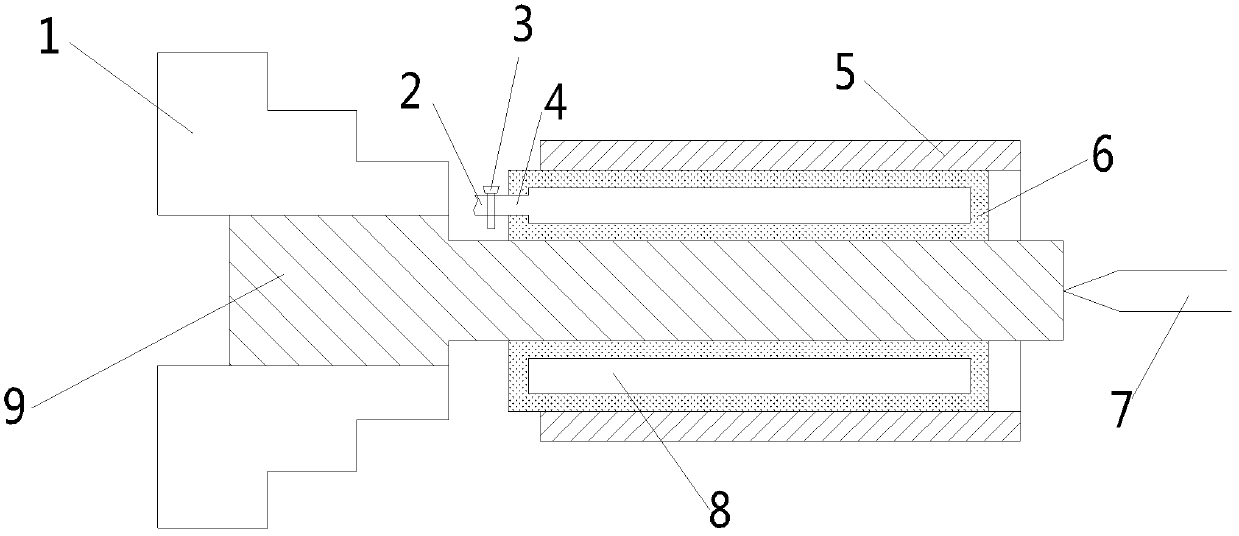

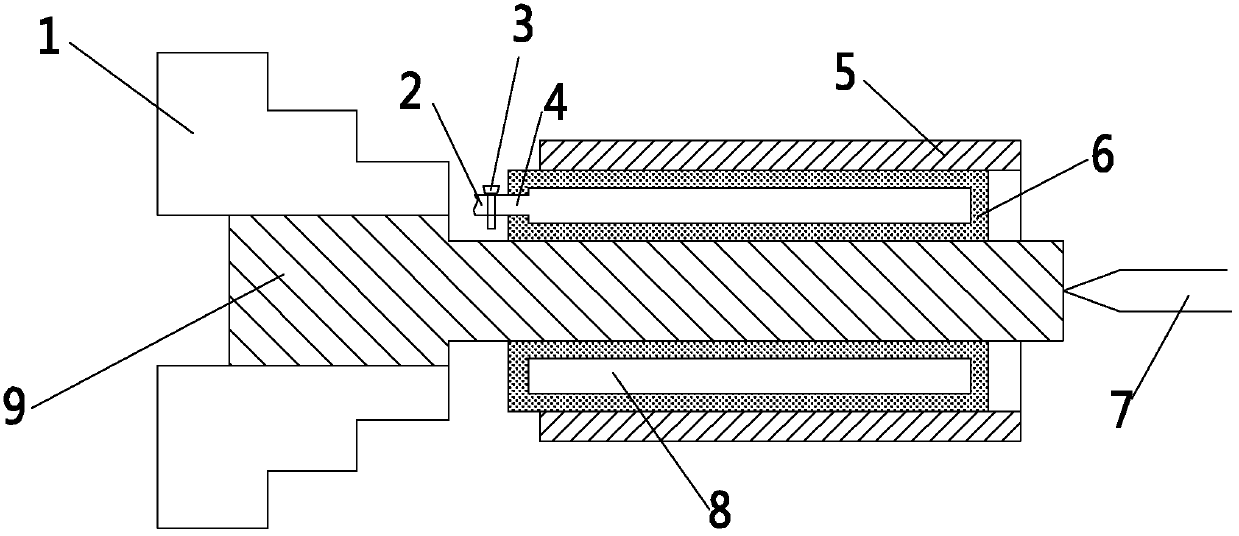

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] attached figure 1 It is an automatic centering clamping device according to the present invention, which includes a mandrel 9 and a carcass 6; the mandrel 9 is a cylinder, and one end of the mandrel 9 is fixed on the chuck 1; the bulge The carcass 6 is cylindrical, and the carcass 6 is sleeved on the mandrel 9; the inner sidewall of the carcass 6 is pasted on the mandrel 9; shaped cavity 8, and an air inlet 4 is arranged on one side of the chuck 1 on the expanded carcass 6; the air inlet 4 communicates with the cavity 8, and the outside of the air inlet 4 is connected to the air inlet pipe 2. The inlet pipe 2 is provided with a valve 3; the mandrel 9 is a stepped cylinder, and the diameter of one end of the mandrel 9 fixed on the chuck 1 is larger than the diameter of the other end.

[0014] When in use, put the workpiece 5 on the inflatable carcass 6, install the air intake pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com