Corrugated pipe cut-off machine

A corrugated pipe cutting machine and cutting cylinder technology, which are applied in the direction of pipe shearing device, shearing device, accessories of shearing machine, etc., can solve the problems of low production efficiency, increase work labor intensity, work fatigue, etc., and achieve production efficiency. High, reduce labor hours per capita, eliminate errors and inconveniences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

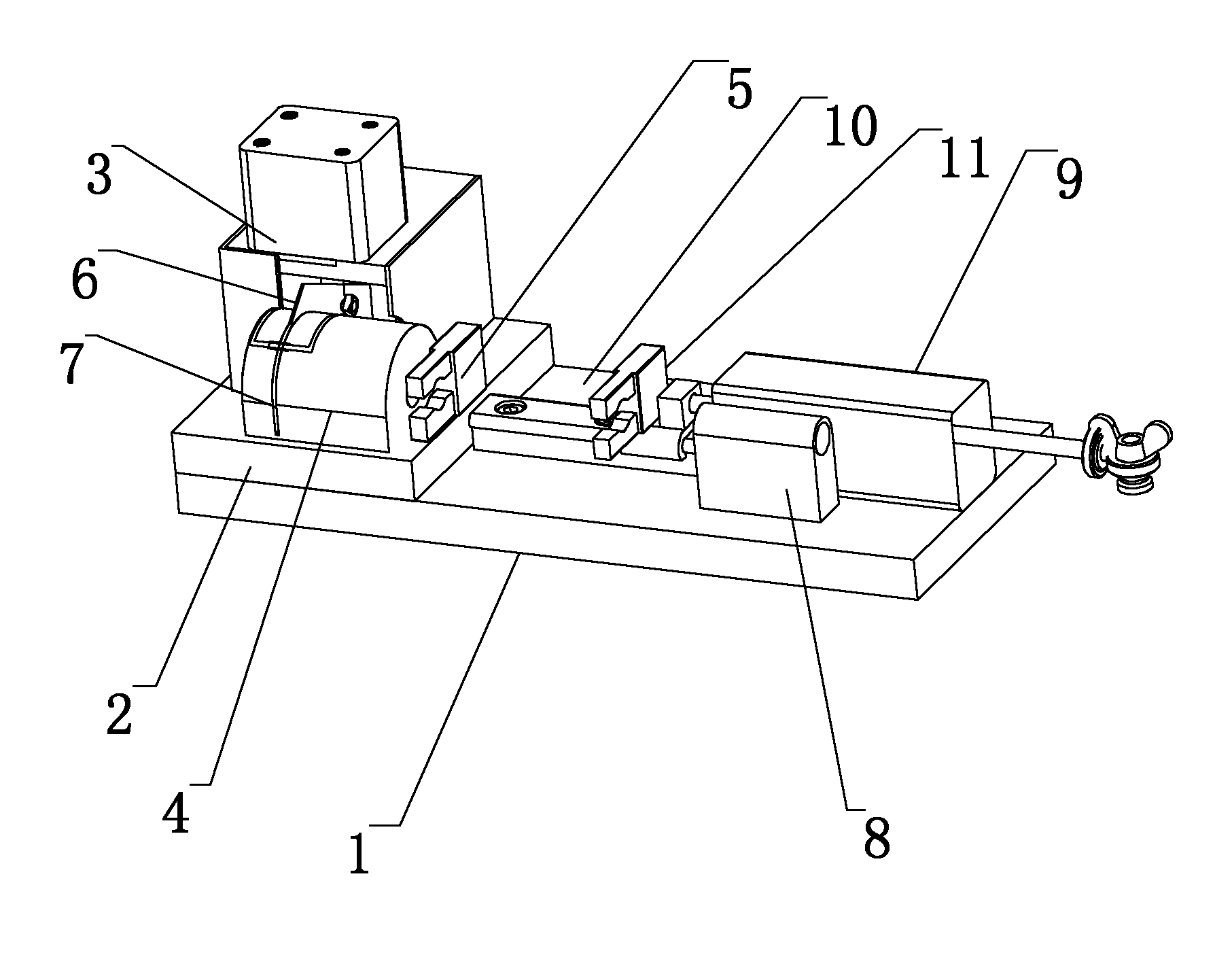

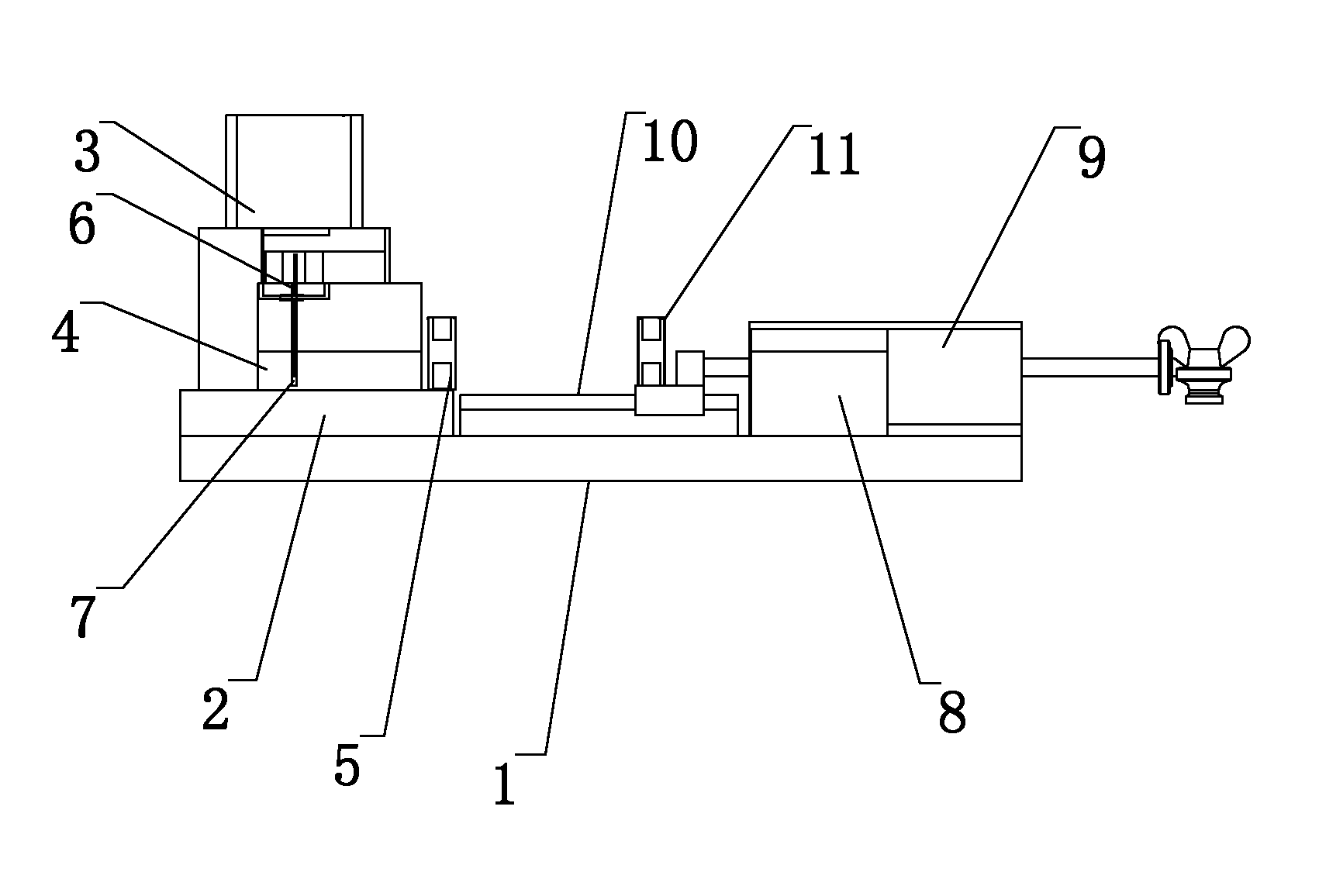

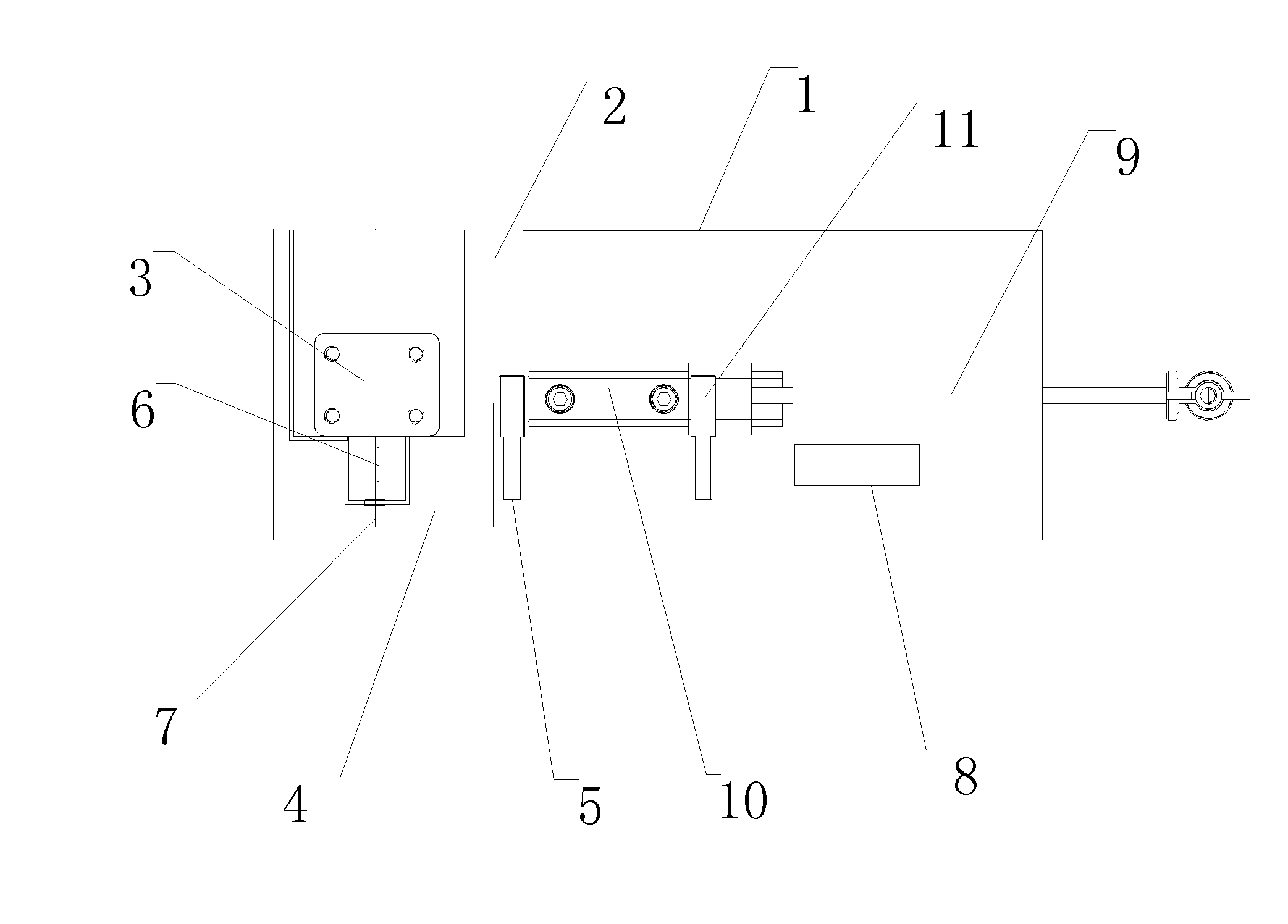

[0021] like Figure 1-4 As shown in and 6, a bellows cutting machine according to the embodiment of the present invention includes a machine base 1, one end of the machine base 1 is provided with a boss 2, and the boss 2 is provided with a cutting cylinder 3 and a conduit one 4 One side of the conduit one 4 is provided with a clamping cylinder two 5, the cutting cylinder 3 is connected with a cutter 6, the cutter 6 is matched with the groove 7 on the conduit one 4, and the other end of the base 1 is provided with a conduit two 8 and the adjustable cylinder 9, a linear guide rail 10 is arranged between the adjustable cylinder 9 and the cutting cylinder 3, and the linear guide rail 9 is provided with a clamping cylinder one 11.

[0022] like Figure 5 As shown, the clamping cylinder one 11 is connected with the solenoid valve one 12, the solenoid valve one 12 is connected with the relay one 13 (KM1) through the circuit, and the relay one 13 (KM1) is connected with the switch 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com