Self-repairing electromagnetic polarity tool and discharging processing method

A technology of electric discharge machining and electromagnetic pole, which is applied in the field of self-repairing electromagnetic pole tools and electric discharge machining, can solve the problems that the loss compensation has not been well resolved, the production of formed electrodes, the difficulty of installation, and the increase in processing costs, etc., to solve the problem of electrode The problem of wear and tear, the technical means are simple and easy to implement, and the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiments of the present invention will be described in further detail below, but the embodiments of the present invention are not limited thereto.

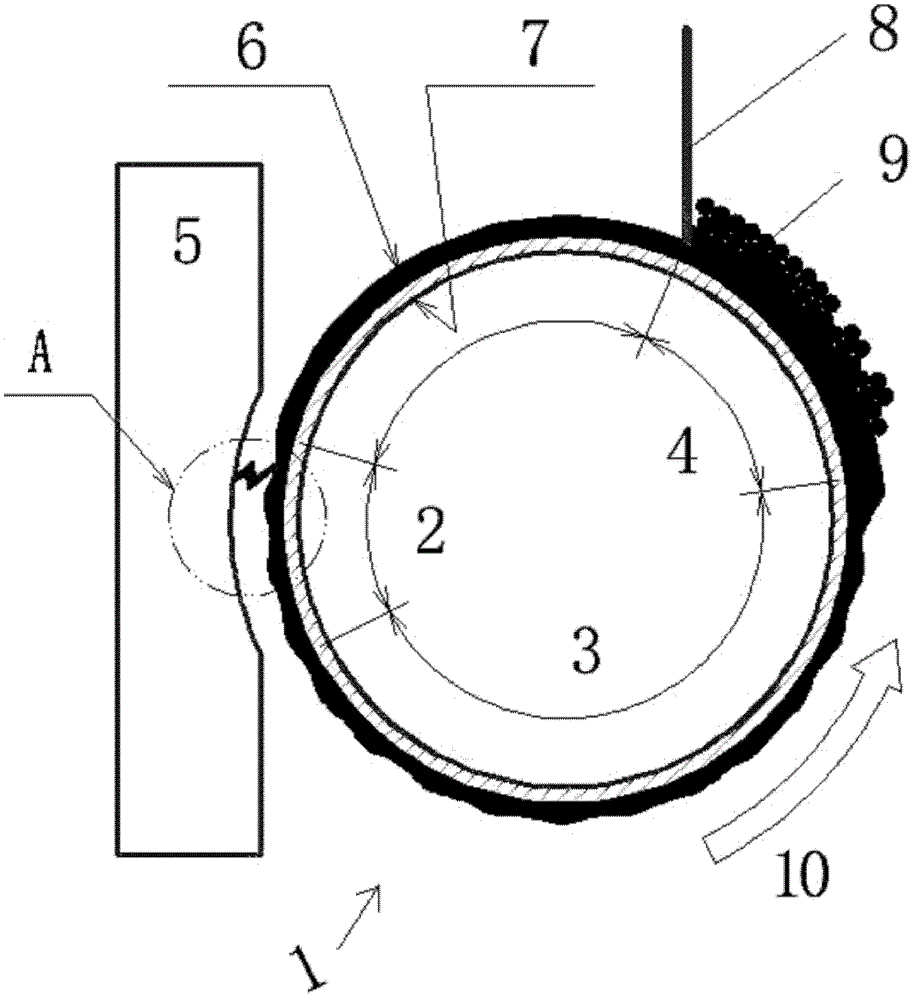

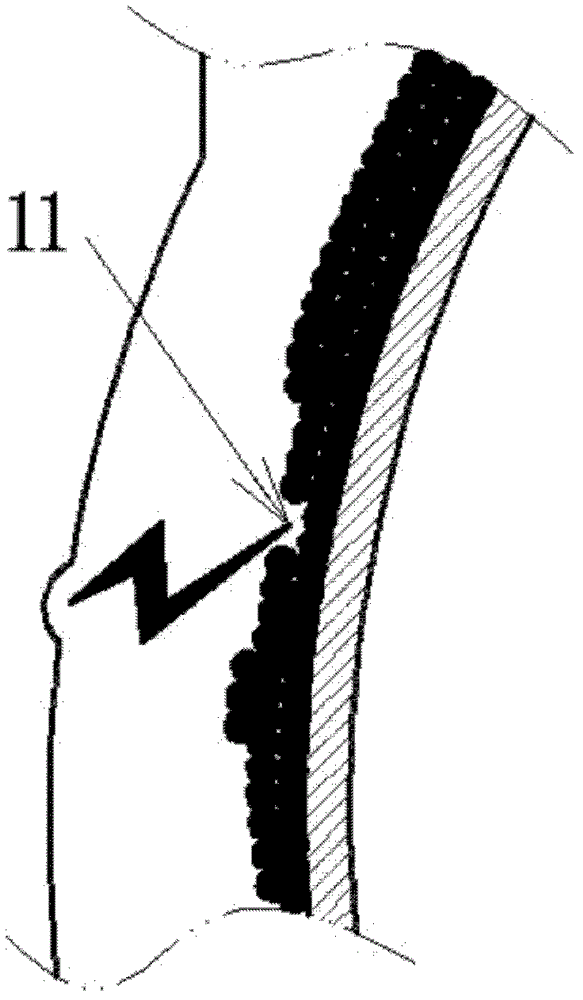

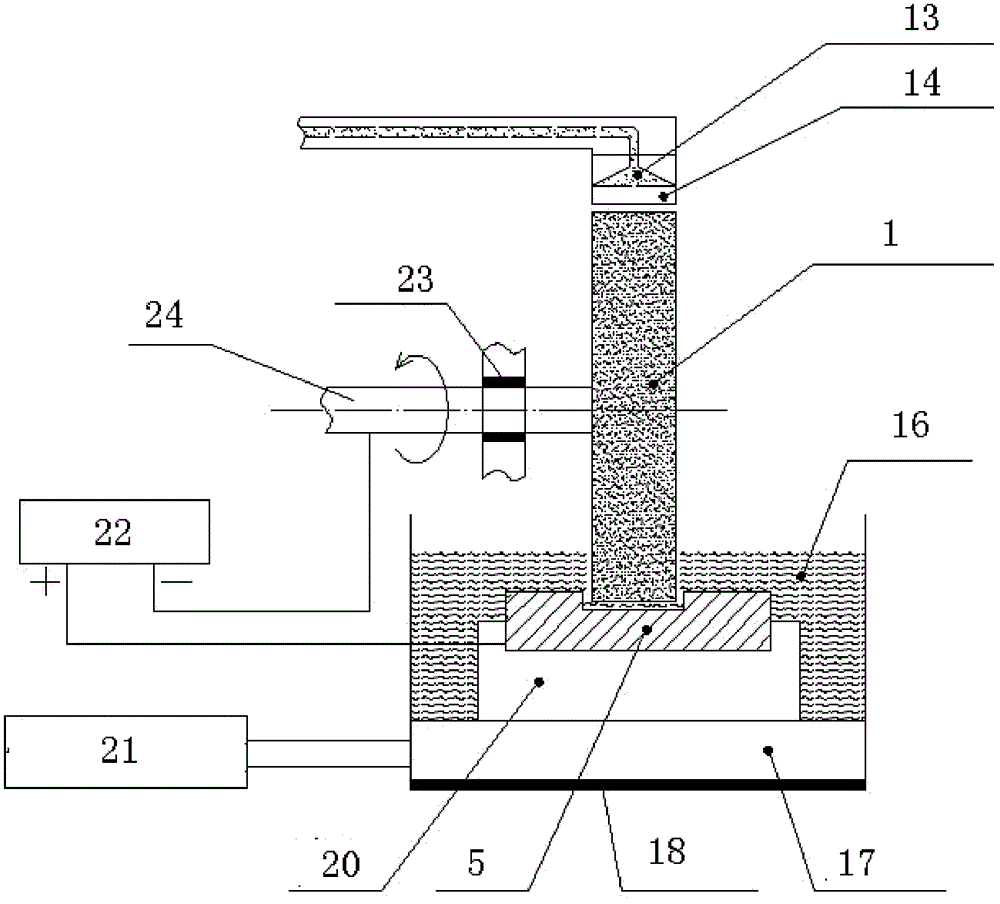

[0021] Such as figure 1 , figure 2 , image 3 As shown, the electrical discharge machining method of the self-repairing electromagnetic pole tool of the present invention comprises the following steps:

[0022] (1) Add a layer of magnetic powder layer 6 on the surface of the tool body 7 of the electromagnetic pole tool 1;

[0023] (2) During the processing of the workpiece 5, the electromagnetic pole tool 1 is connected to the negative pole of the rotating shaft 24 and connected to the power supply 22, and the workpiece 5 is connected to the positive pole of the power supply 22 (or according to the needs of actual processing, the electromagnetic pole tool 1 can also be connected to the rotating shaft 24 And connect the positive pole of power supply 22, and workpiece 5 connects the negative pole of power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com