Method for performing work on a rotor and related linings

A rotor and lining technology, applied in the field of operation, can solve the problems of inability to repair and time-consuming replacement, and achieve the effect of improving service life and improving contact conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

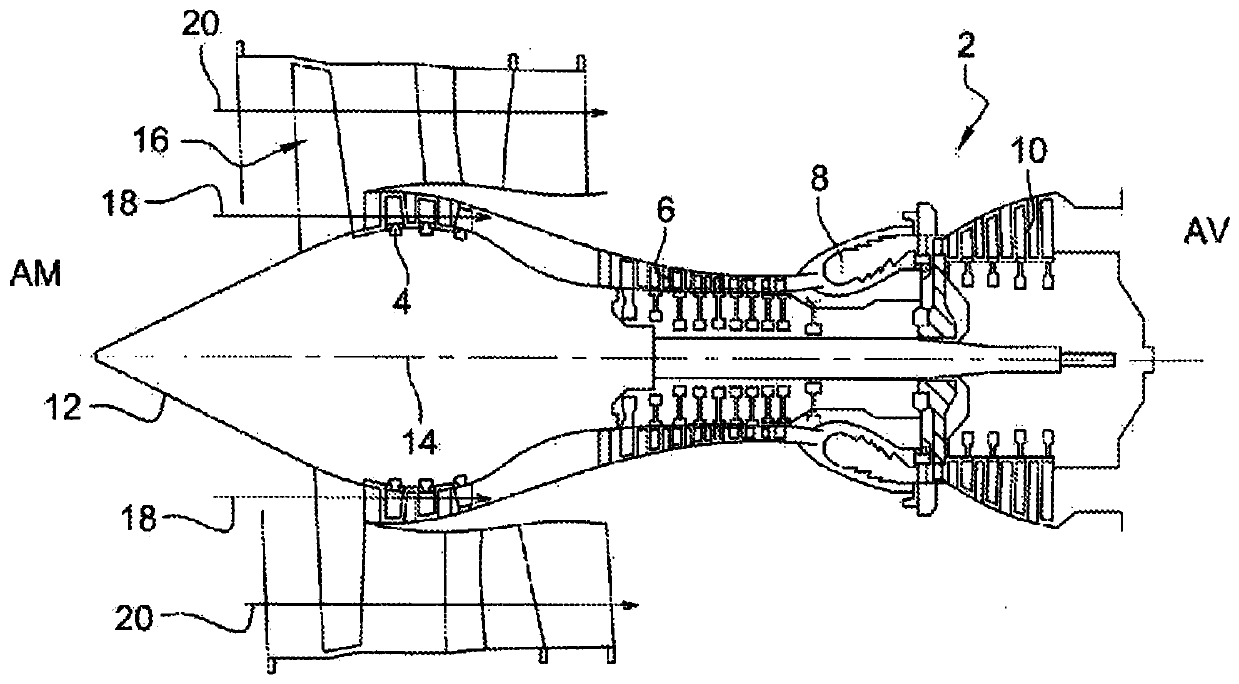

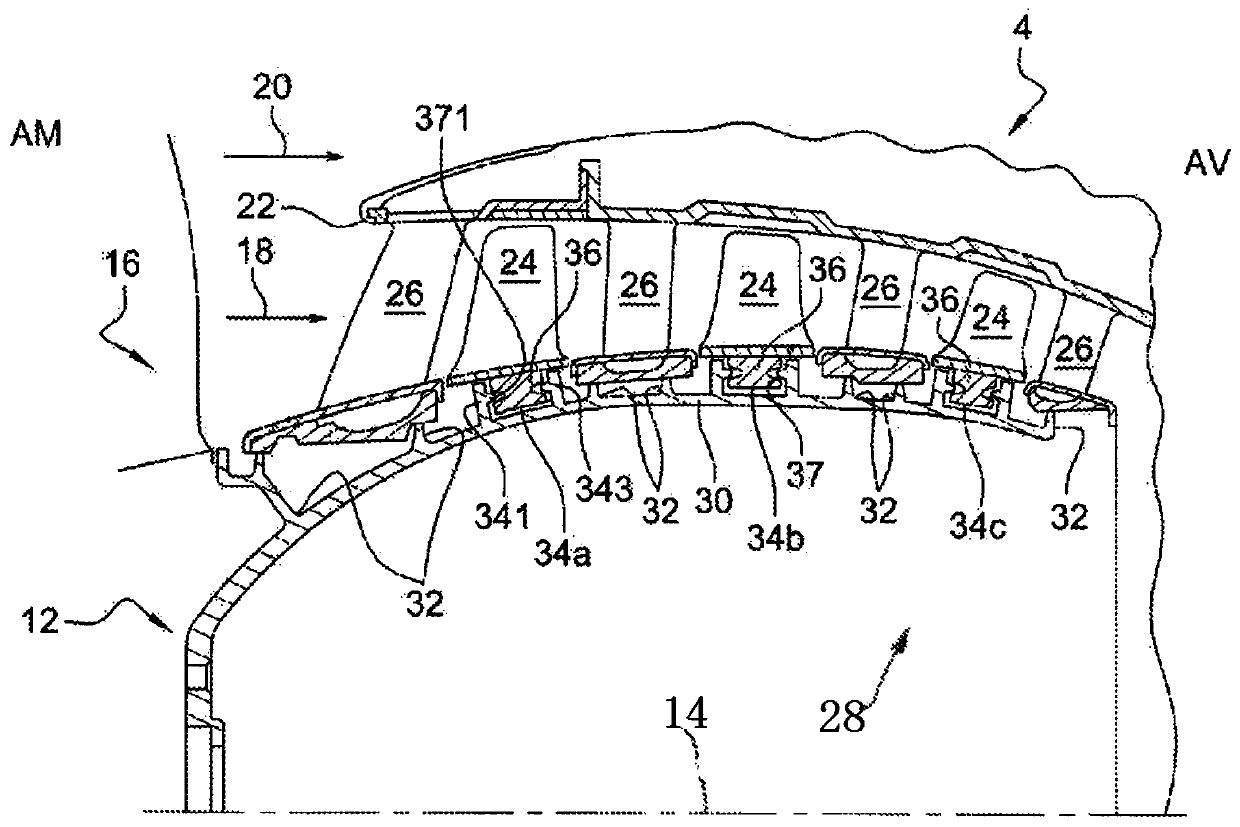

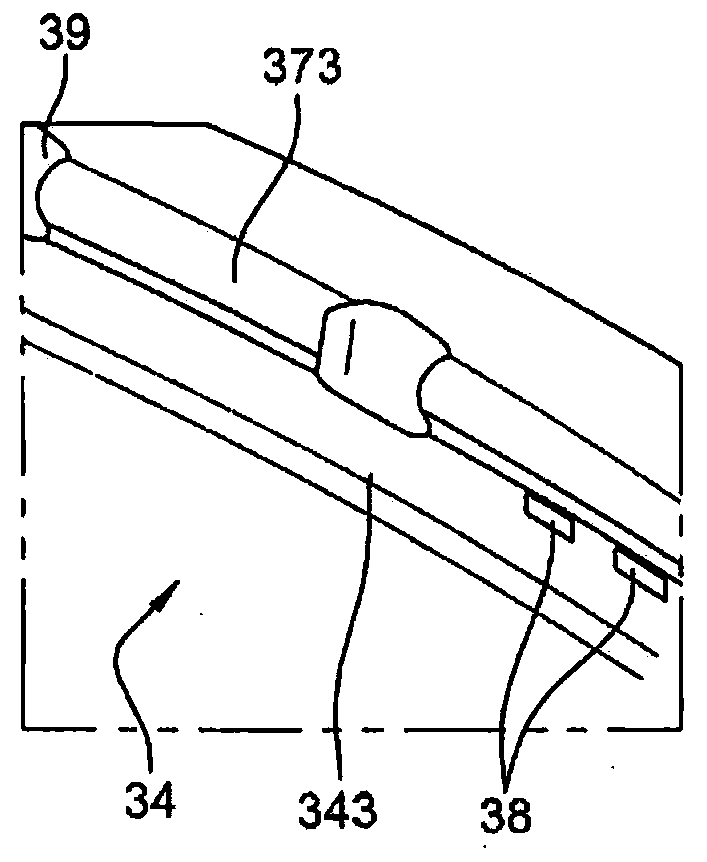

[0047] Before specifically introducing the present invention, therefore, according to the known state of the art in document EP2762681, when the rotor that is damaged and needs to be ground is a low-pressure compressor drum, figure 1 with figure 2 The operating environment of the present invention is shown.

[0048] In fact, the present invention is applicable to another rotor equipped with low-pressure compressor drum blades within the specified scope; however, because of its position, mass, volume, and constraints in the engine, this component They are all specific.

[0049] figure 1 A two-way turbine 2 is shown. Such a turbine 2 includes a low-pressure compressor 4, a high-pressure compressor 6, a combustion chamber 8 and one or more turbine stages 10 in order from upstream (AM) to downstream (AV) in the axial direction. In operation, the mechanical power of the turbine 10 transmitted to the rotor 12 via the central shaft drives the two compressors 4 and 6. Rotation of the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com