Three-layer plastic automobile shell and rotational molding process of three-layer plastic automobile shell

A rotomolding, automotive shell technology, applied in coatings, vehicle parts, superstructures, etc., can solve the problems of heavy weight, strength, poor rigid heat insulation performance, etc., and achieve the effect of reducing the molding cycle and enhancing the heat insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

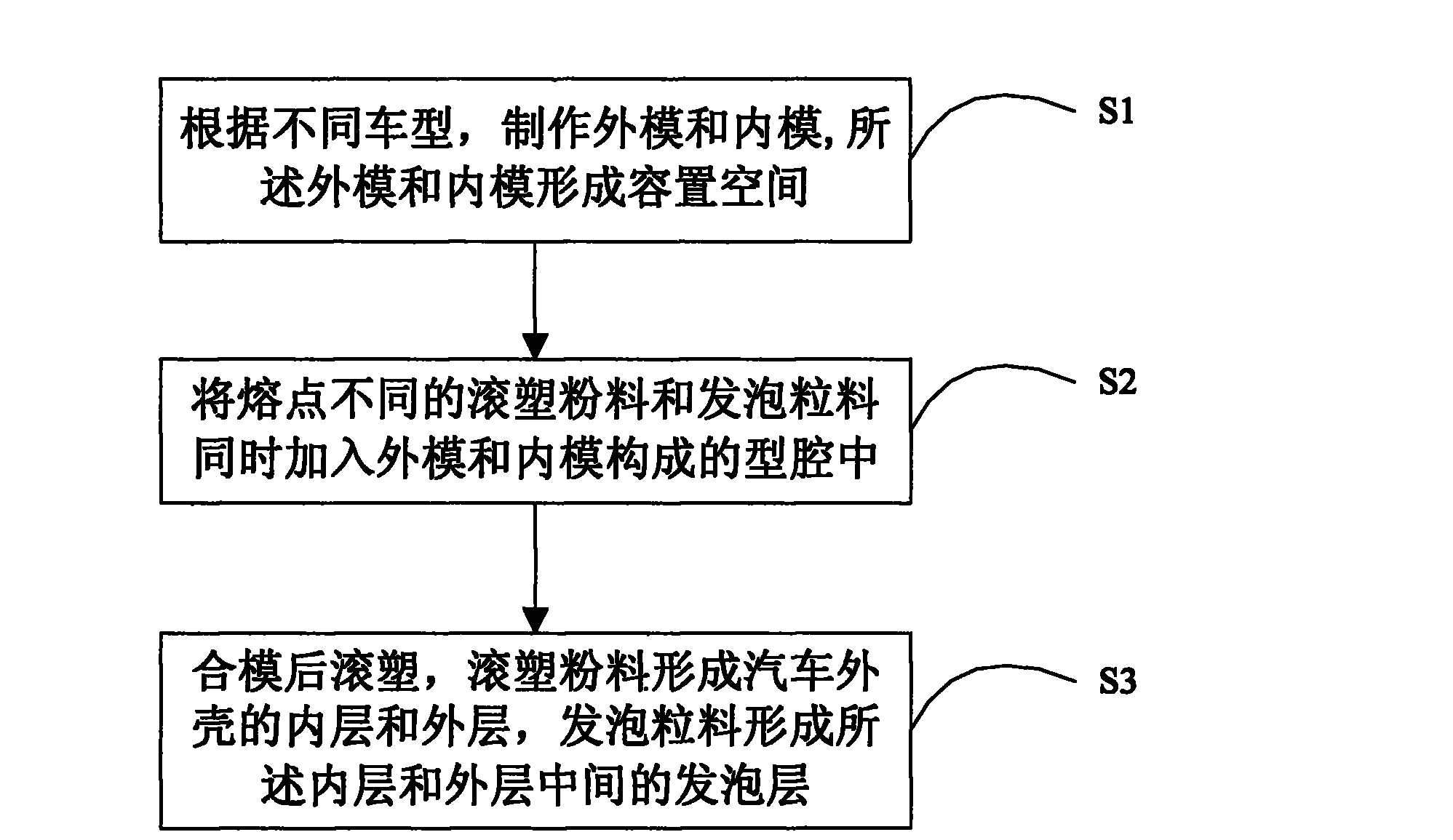

[0027] Such as figure 1 as shown, figure 1 It is a flow chart of the three-layer plastic automobile shell molding process of the present invention. The molding process of the three-layer plastic automobile shell of the present invention comprises steps:

[0028] S1: Make outer mold 1 and inner mold 2 according to different models.

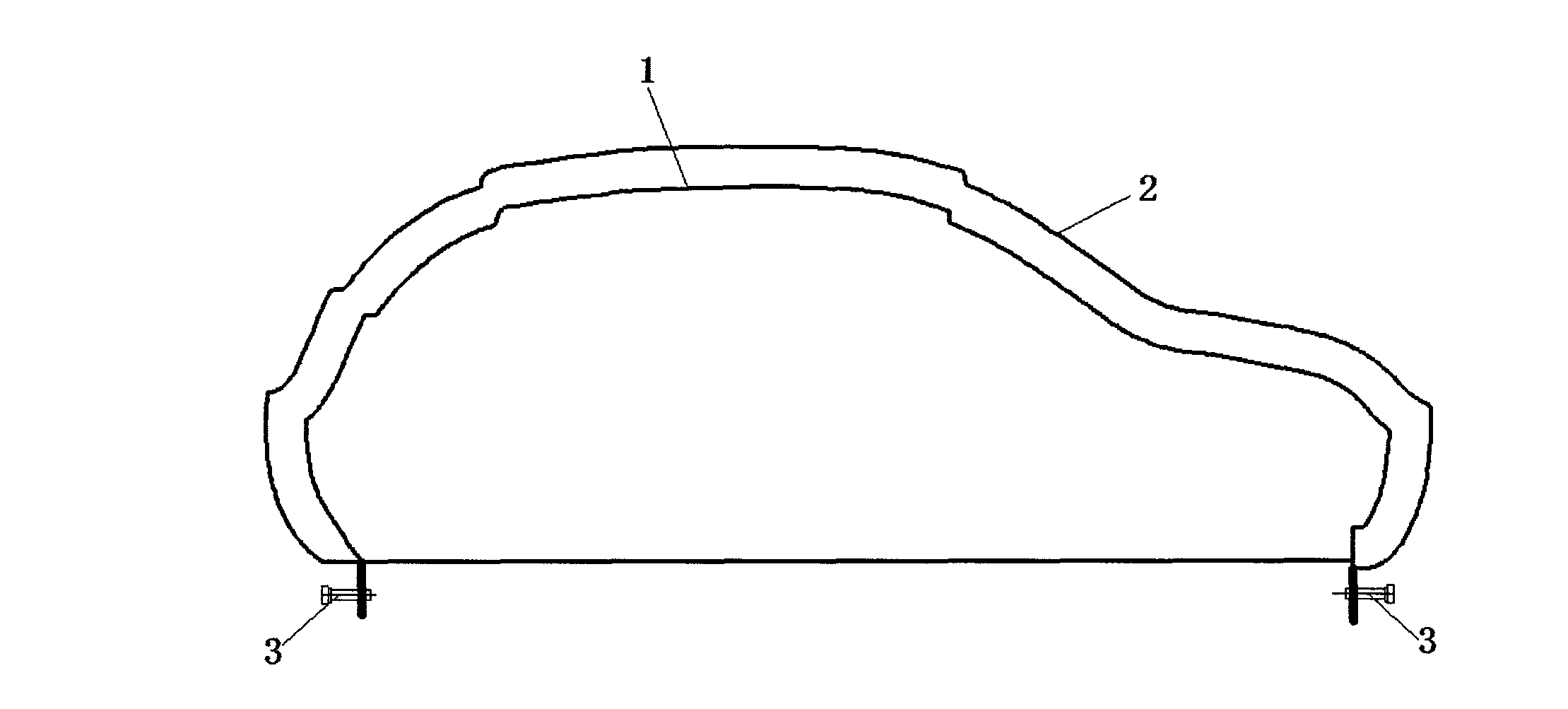

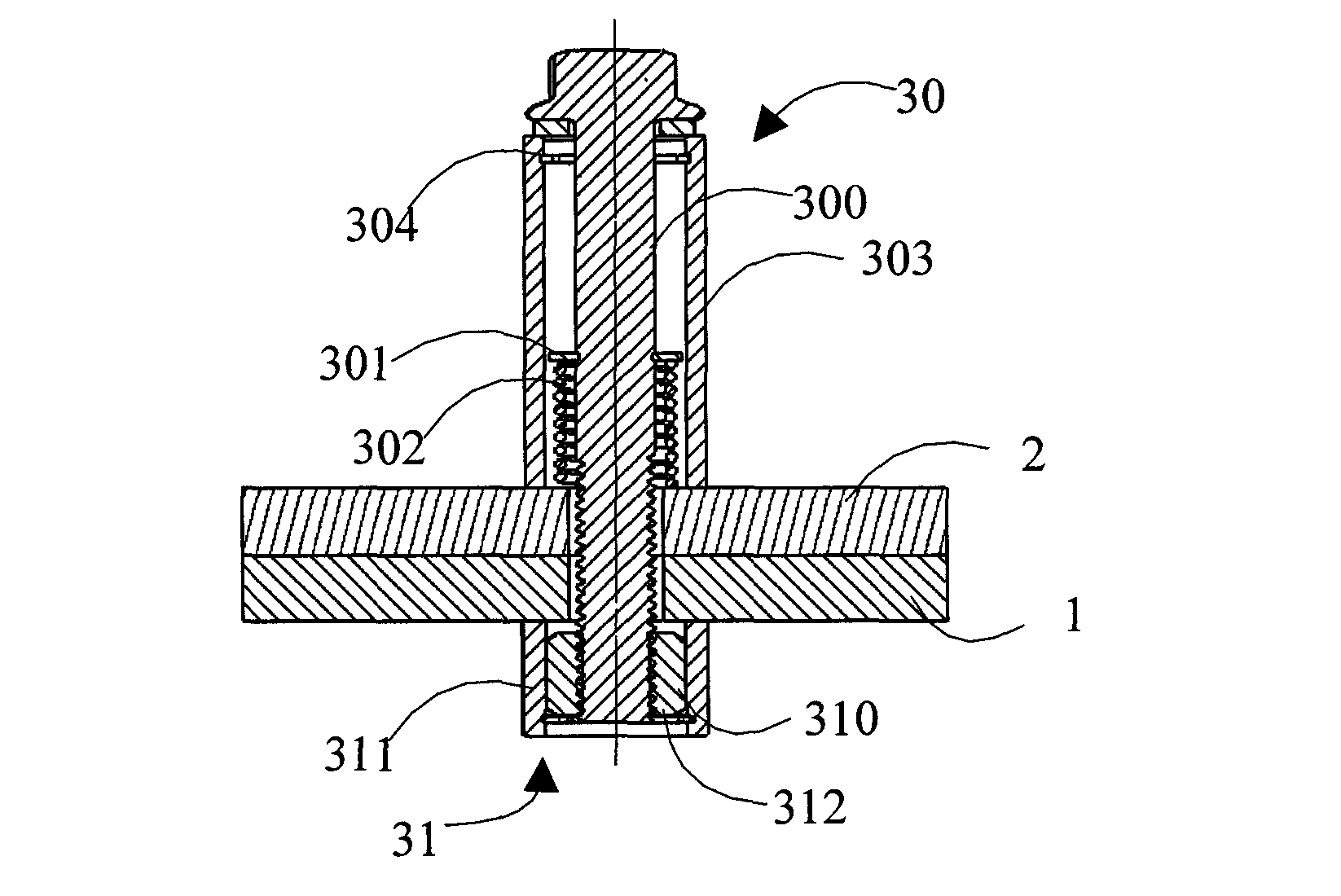

[0029] Such as figure 2 As shown, an accommodating space 10 is formed between the outer mold 1 and the inner mold 2 , and the outer mold 1 and the inner mold 2 are connected by a locking device 3 . The outer mold 1 and the inner mold 2 can be obtained by integral molding, or can be assembled by disassembling the outer mold 1 and the inner mold 2 into a plurality of parts, which are respect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap