Automatic finishing and arranging pillow-type packaging line

An automatic sorting and packaging line technology, applied in packaging and other directions, can solve the problems of candy falling and difficulty in adjusting the direction of candy, and achieve the effect of improving work efficiency, reducing the amount of falling, and achieving good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

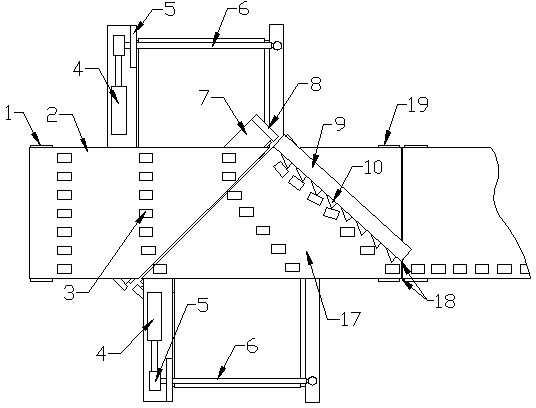

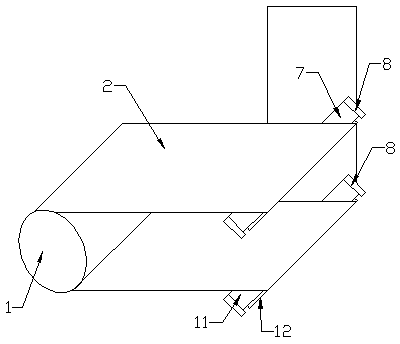

[0023] The structure of the automatic sorting and arranging pillow packaging line of the present invention includes a frame, a feeding mechanism, a sorting mechanism and a packaging mechanism, wherein the sorting mechanism includes a sorting structure and several conveyor belts, and the conveyor belts are sleeved on the driving roller 19 and the passive roller 1 , the driving roller 19 and the passive roller 1 are used to move the conveyor belt.

[0024] The conveyor belt comprises a front feed belt 2 and a finishing belt 17 which is located at a downstream position of the front feed belt 2 close to each other. The front feeding belt 2 is used to accept the lumps 3 released by the feeding mechanism. The lumps 3 on the front feeding belt 2 are arranged in the form of multiple columns and rows. The arrangement of the lumps 3 is on the finishing belt 17 completed.

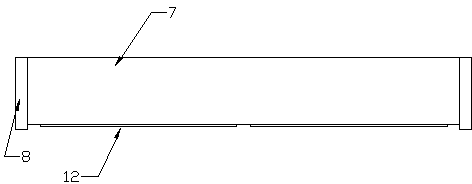

[0025]The finishing structure is arranged on the upper side of the finishing belt 17, and the finishing structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com