Patents

Literature

35results about How to "Reduced drop amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

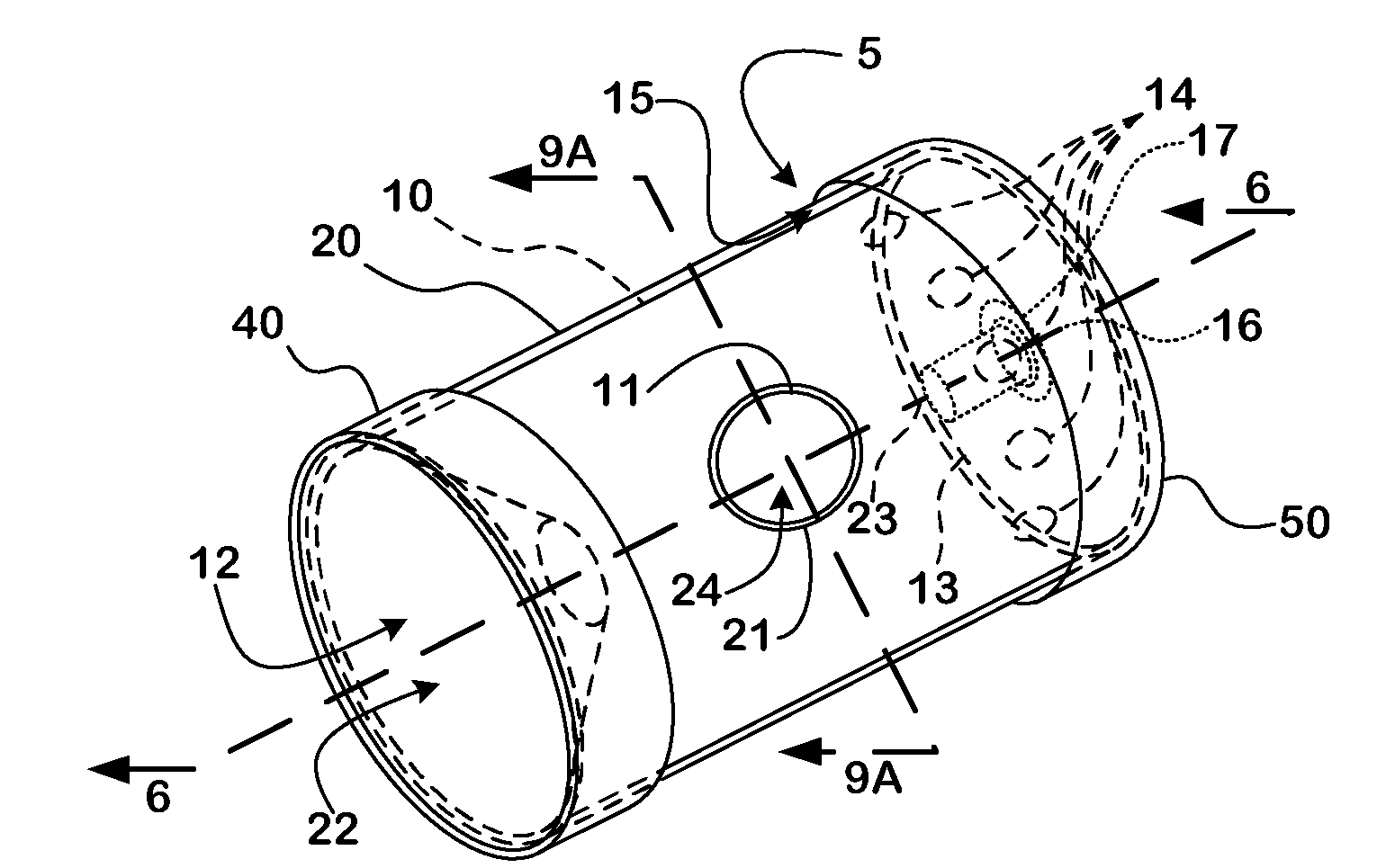

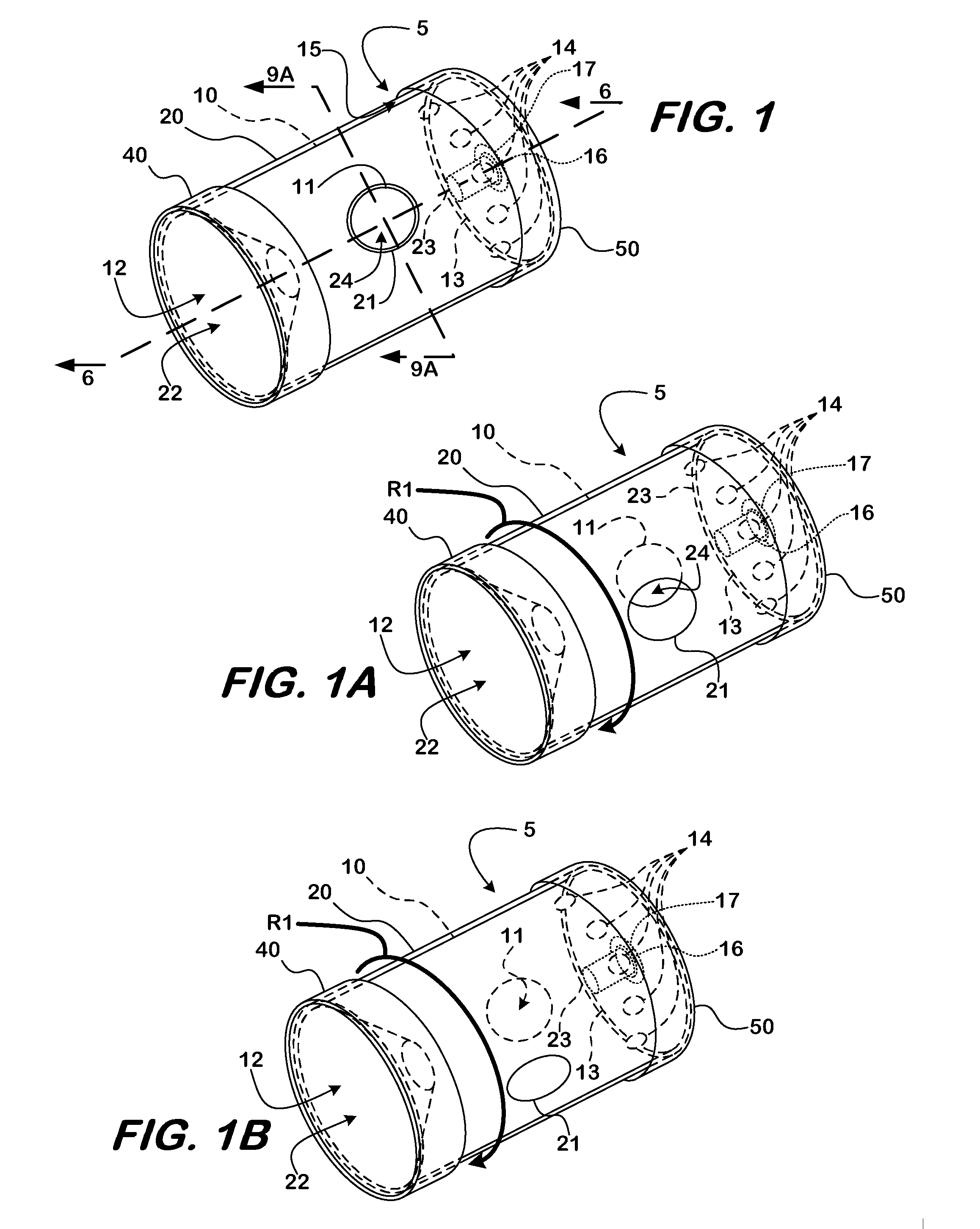

Pet exercise toy

InactiveUS20080083378A1Increase dispensing rateSmall sizeAnimal feeding devicesOther apparatusEngineeringCompanion animal

The invention relates to a pet toy that may be filled with food or scented material to attract and maintain the animal's interest while the pet tries to extract the material contained inside. The toy is preferably made with two nested housings with each housing containing one or more holes in the sidewall. Some of the holes in the housings may be adjustably aligned to create a opening in the side wall of the toy that permits materials inside the toy to fall out. The space between the housings is configured to trap crumbs or other particulate material that might create an undesirable mess if allowed to fall out of the toy.

Owner:PEARCE ROGER

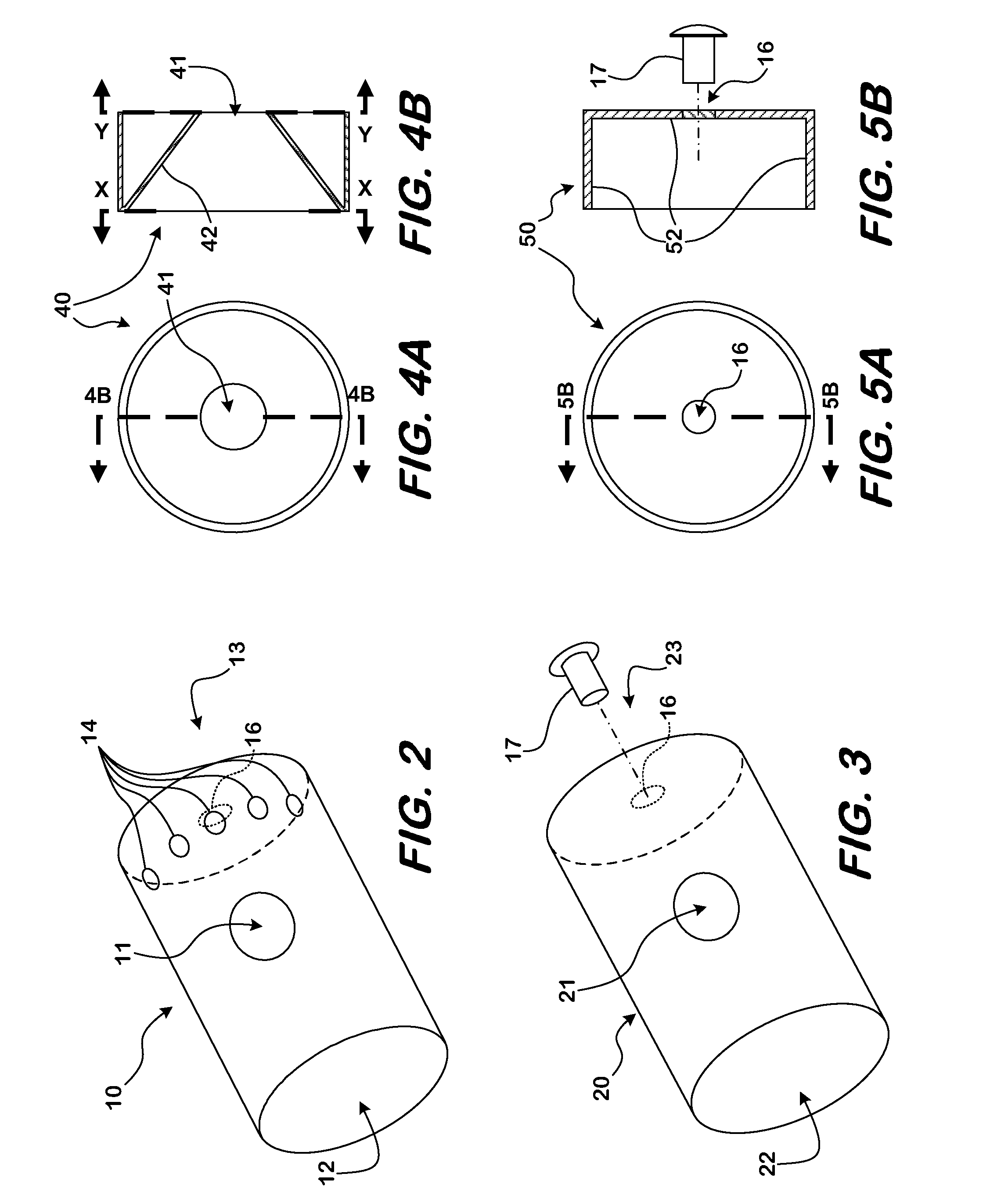

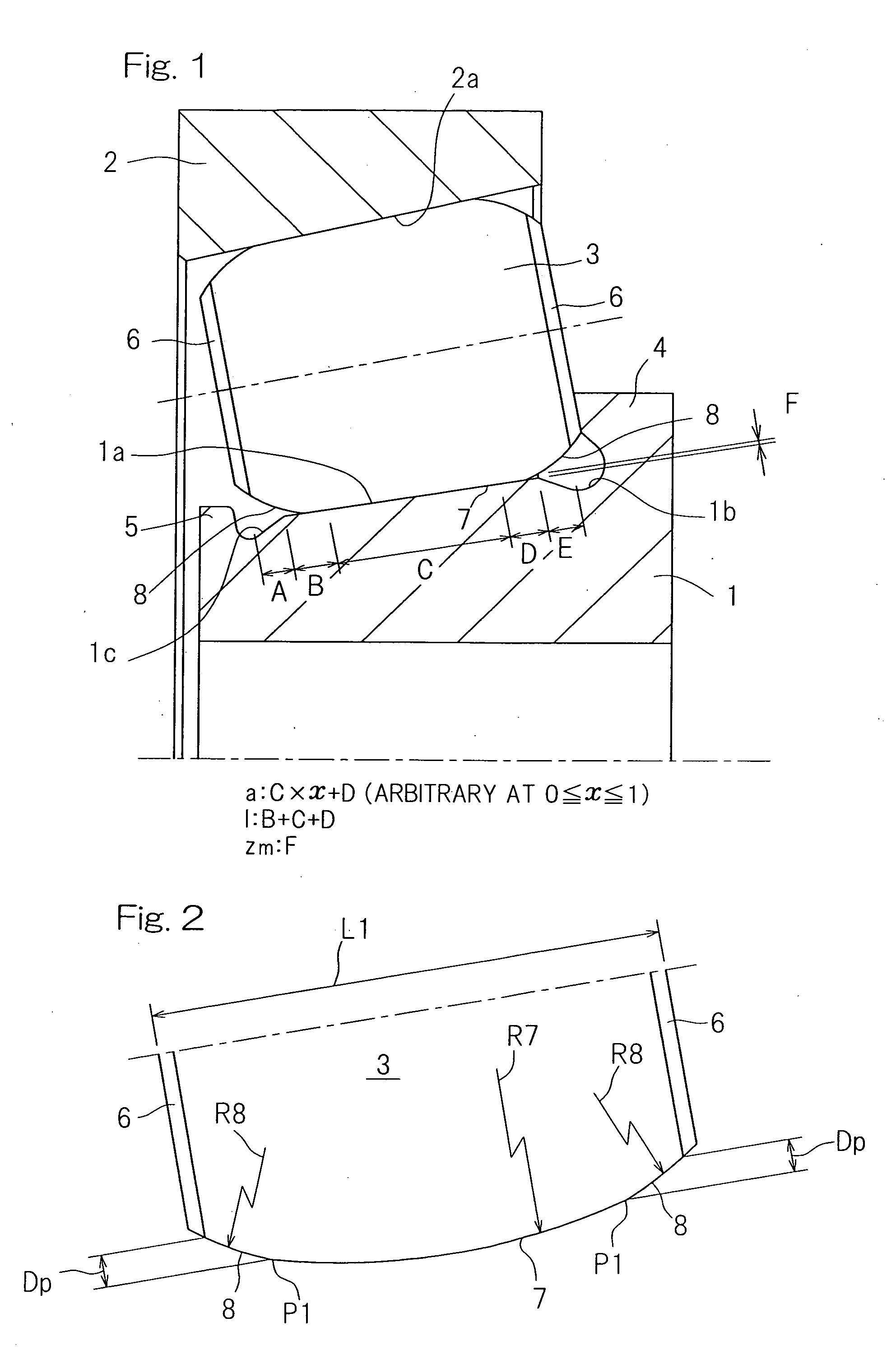

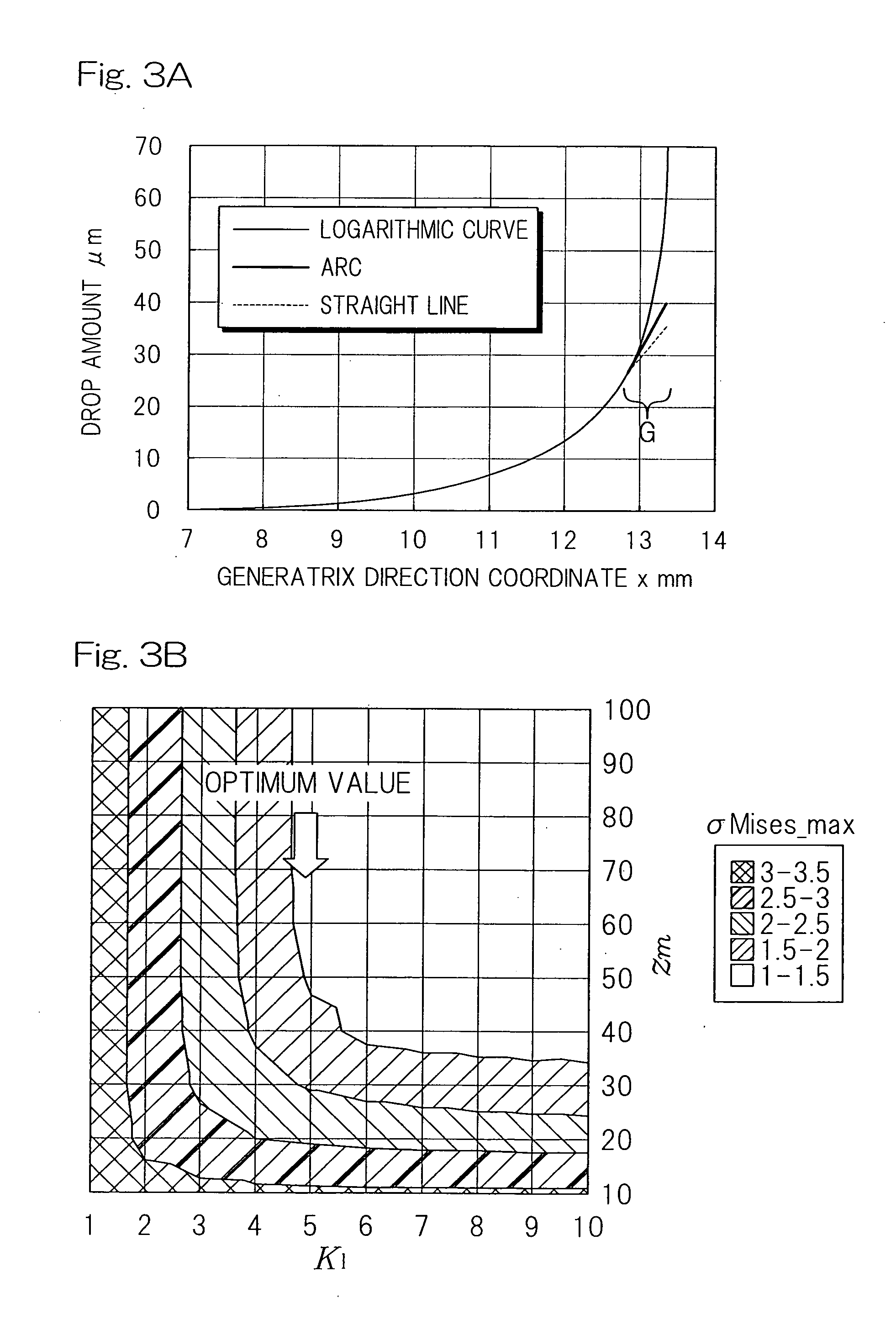

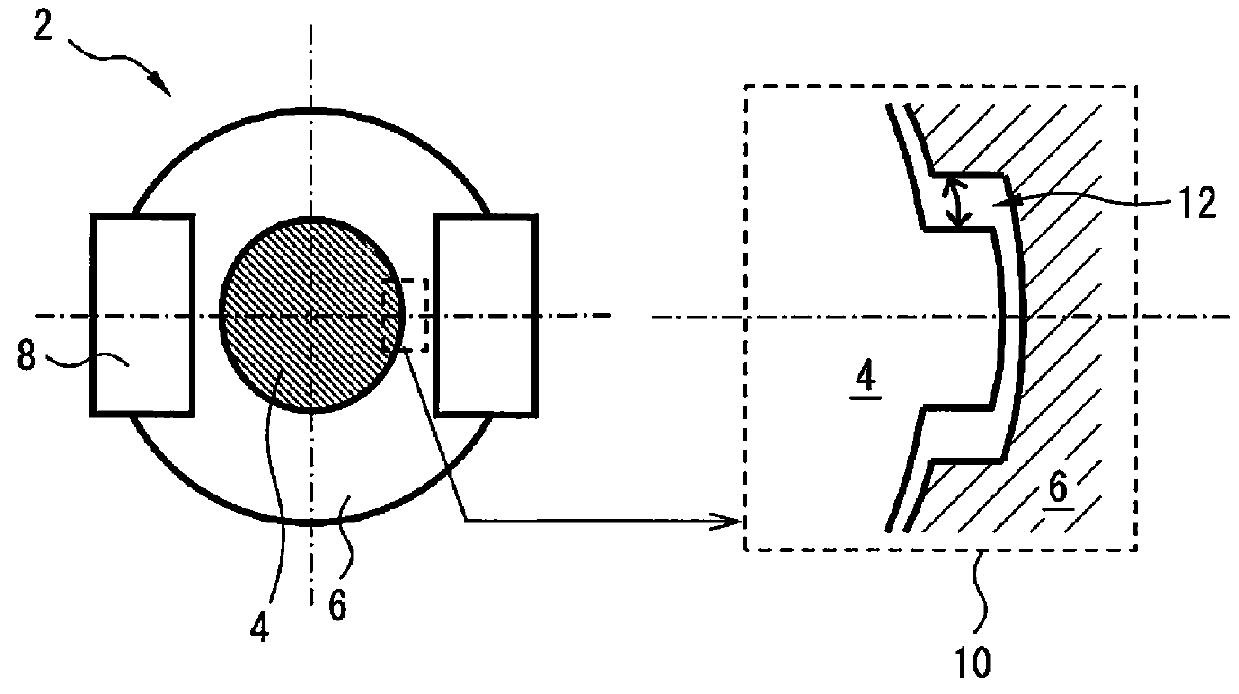

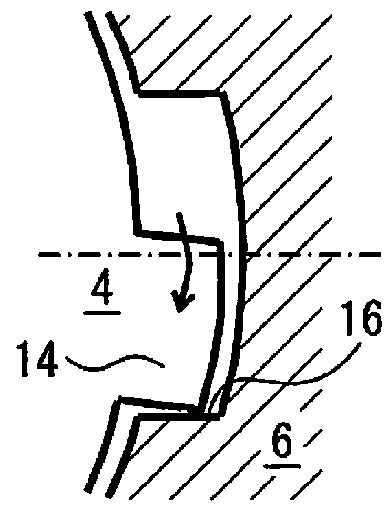

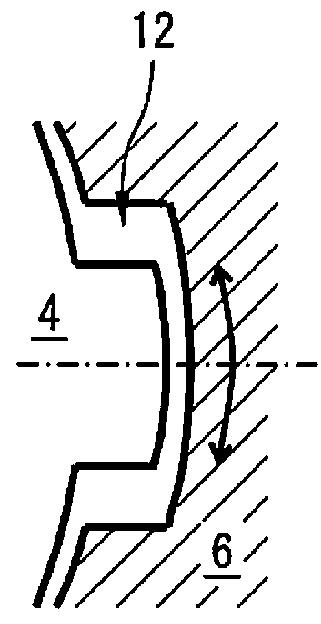

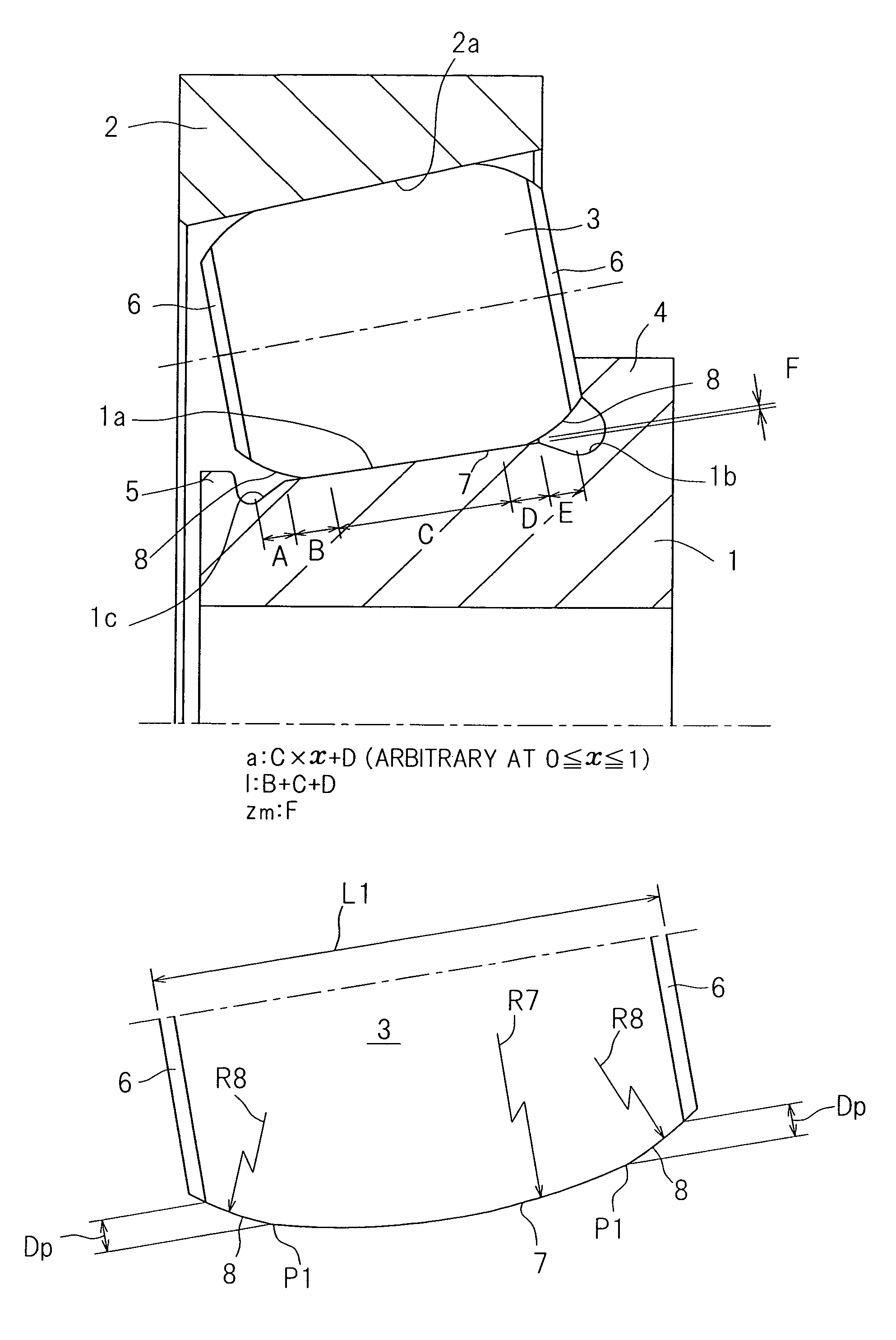

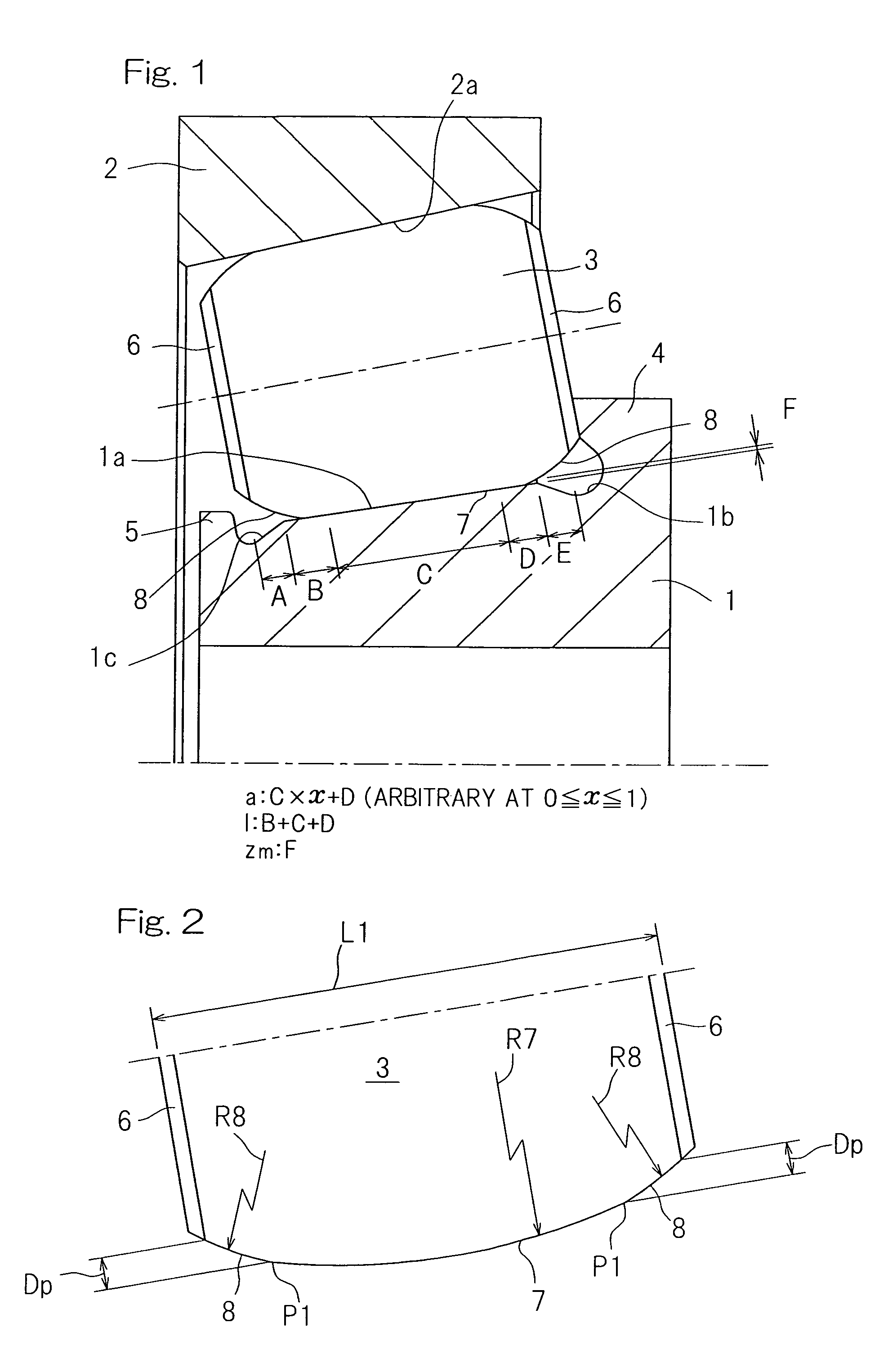

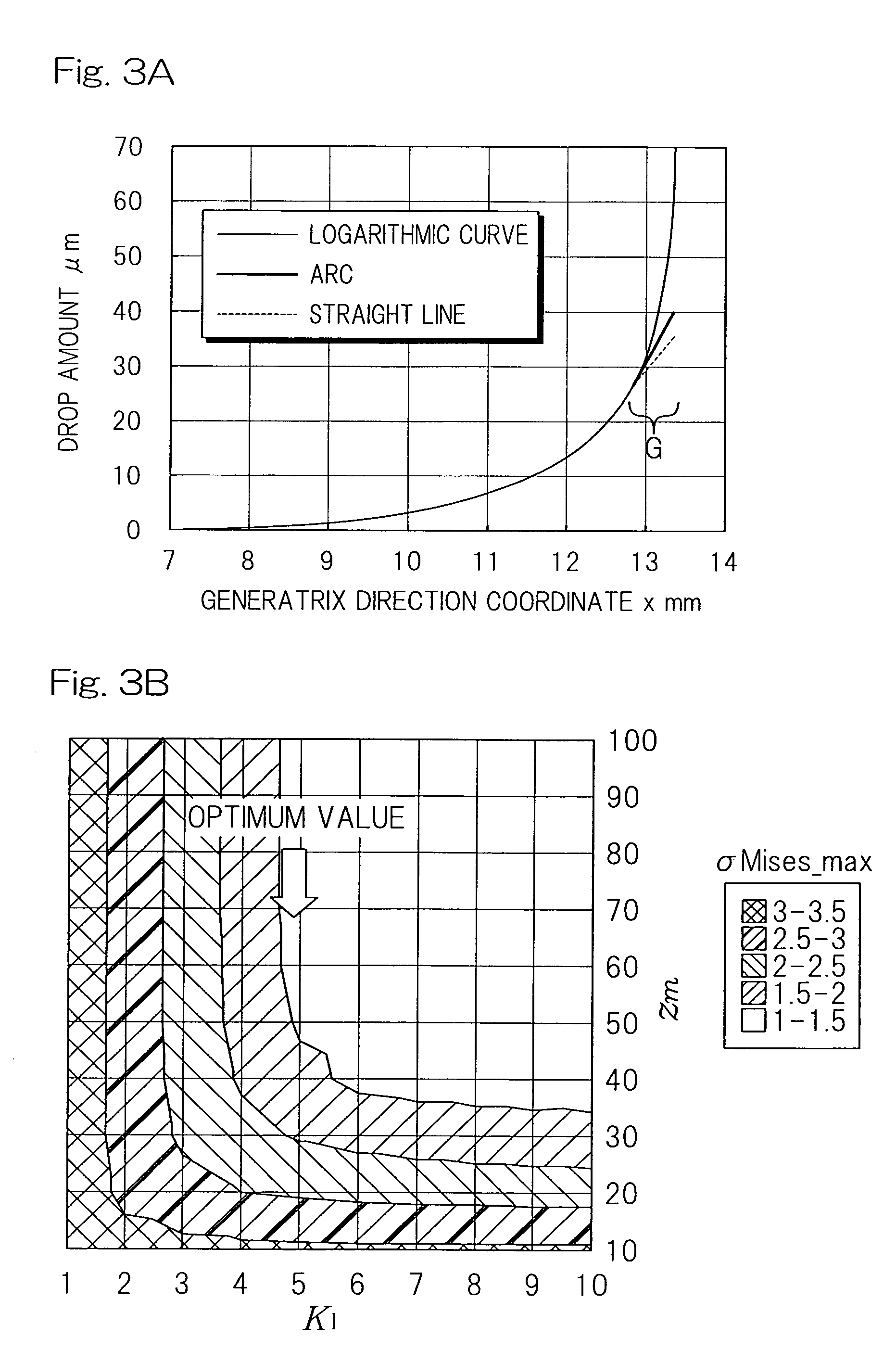

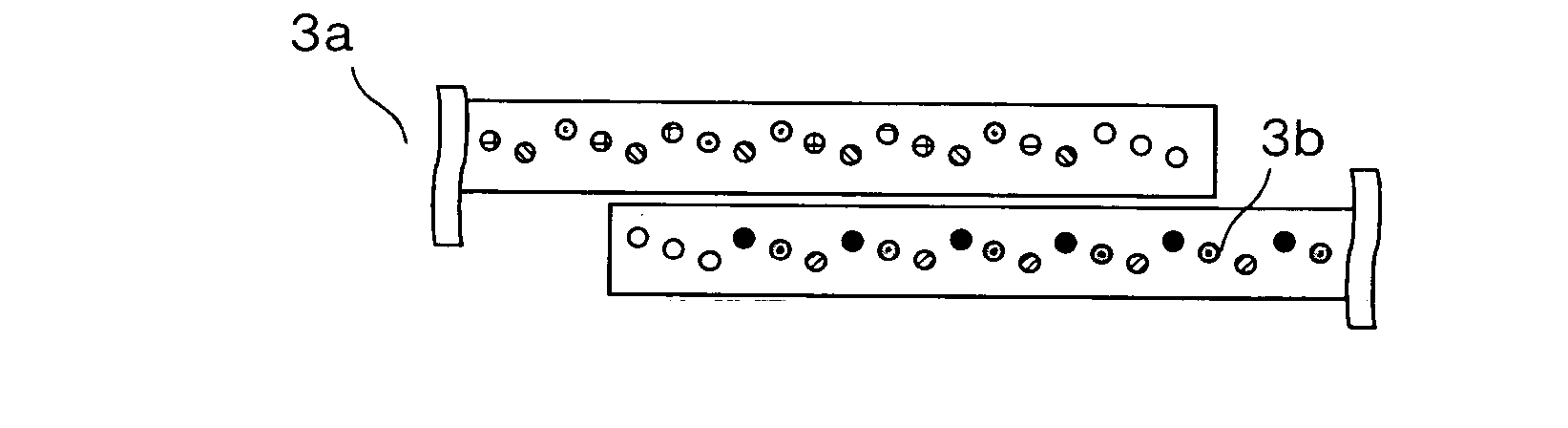

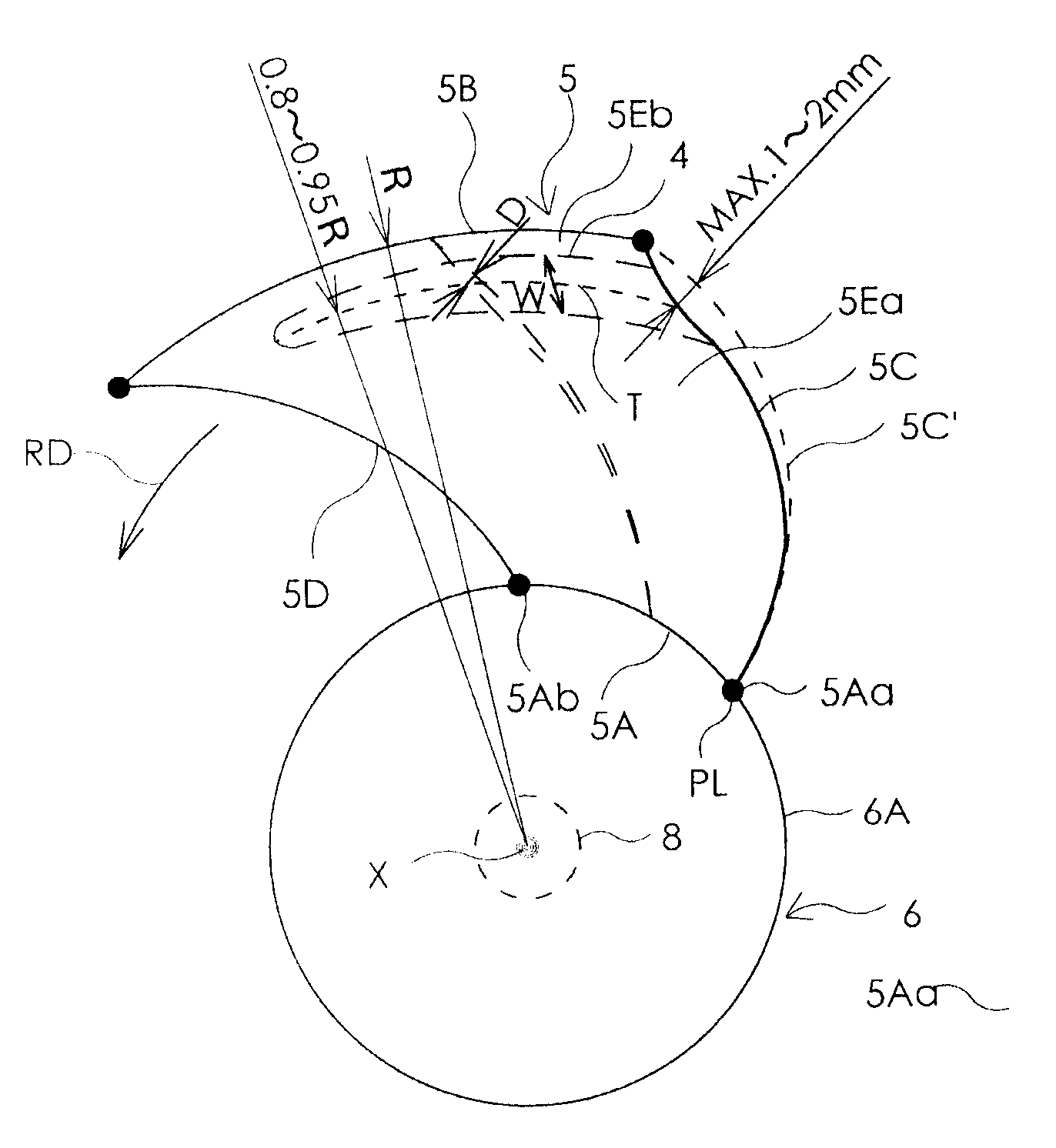

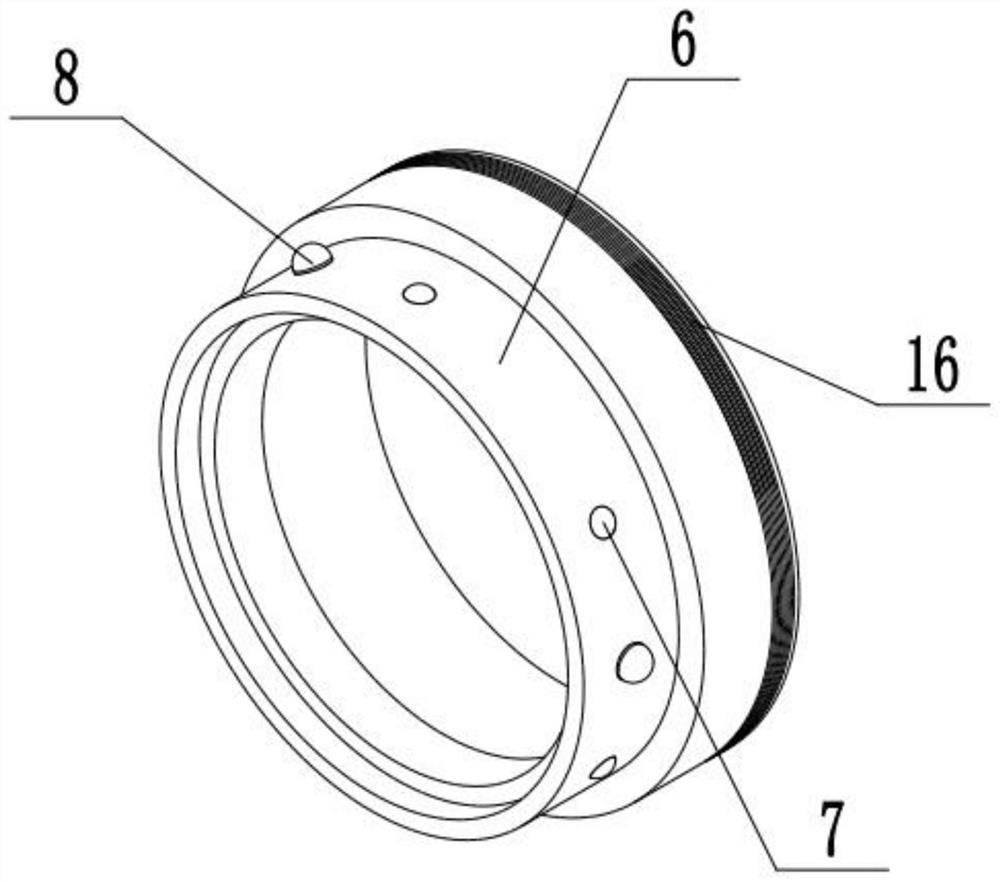

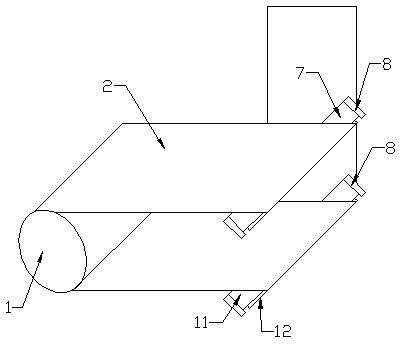

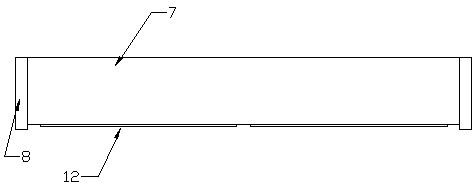

Tapered roller bearing and method of designing the same

ActiveUS20120033909A1Design be relatively longCost reductionRolling contact bearingsShaftsMechanical engineeringContact region

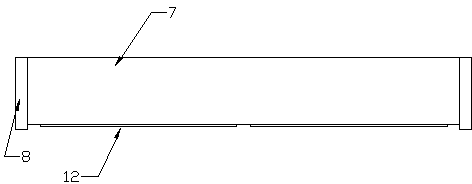

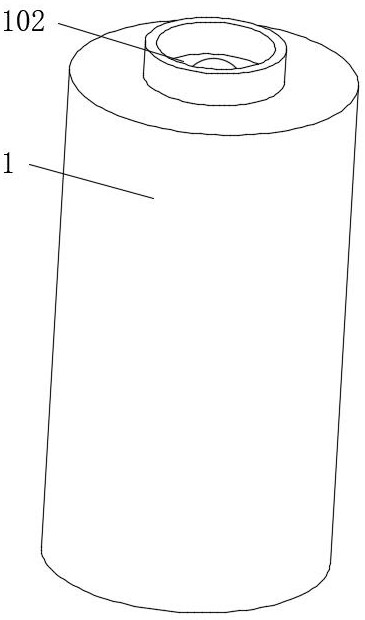

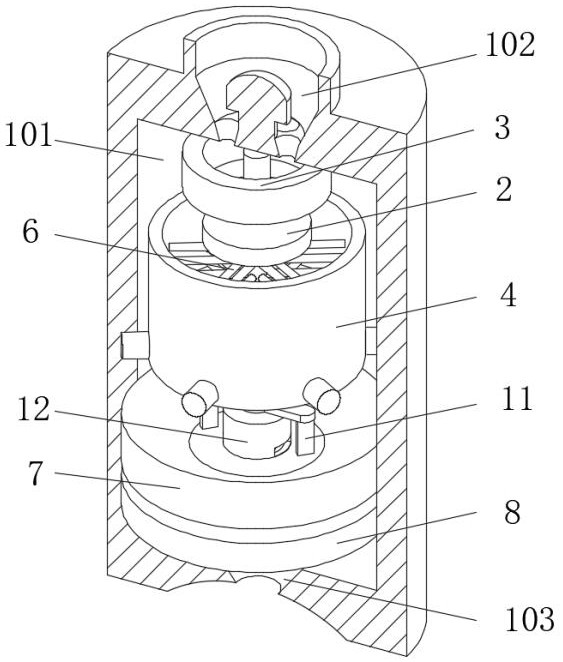

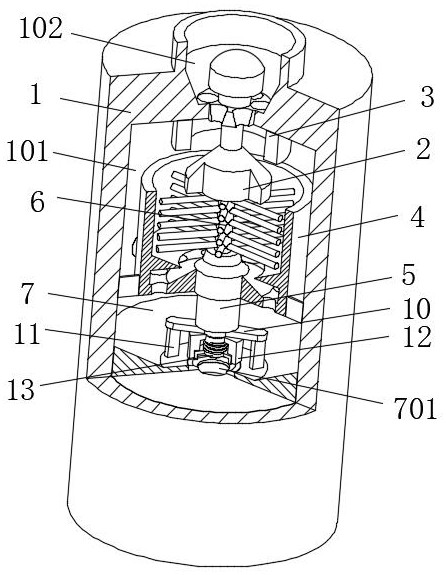

In a tapered roller bearing assembly, a crowning profile formed portion of the roller rolling surface is made up of a contact area crowned portion (7), which is held in contact with an inner ring raceway surface (1a), and a non-contact area crowned portion (8) which is held in non-contact with the inner ring raceway surface (1a). The contact area crowned portion (7) and the non-contact area crowned portion (8) have their generatrices extending in an axial direction of a roller (3), which generatrices are represented by corresponding continuous lines represented by different functions and continued smoothly at a point of connection, and the curvature of the generatrix of the non-contact area crowned portion (8) in the vicinity of the connection point is chosen to be smaller than the curvature of the generatrix of the contact area crowned portion (7).

Owner:NTN CORP

Servo controller having function for reducing dropping when braking

ActiveUS9334911B2Reduced drop amountAnti-hunting elementsBrake actuating mechanismsGravitational forceLimit value

A servo controller having a function for reducing an amount of dropping of a gravity axis provided with a machine. The Servo controller is configured to control a servomotor for driving a gravity axis of the machine, and includes a brake signal outputting part configured to output a brake activation signal and a brake release signal to a mechanical brake for holding the gravity axis; a torque command generating part which generates a torque command value for controlling the position of the servomotor; and a torque limiting value generating part which generates a torque limiting value for limiting the torque command value. The torque limiting value generating part continuously reduces the torque limiting value from a first value larger than a torque corresponding to the gravity force to a second value smaller than the torque corresponding to the gravity force, after the brake activation signal is output.

Owner:FANUC LTD

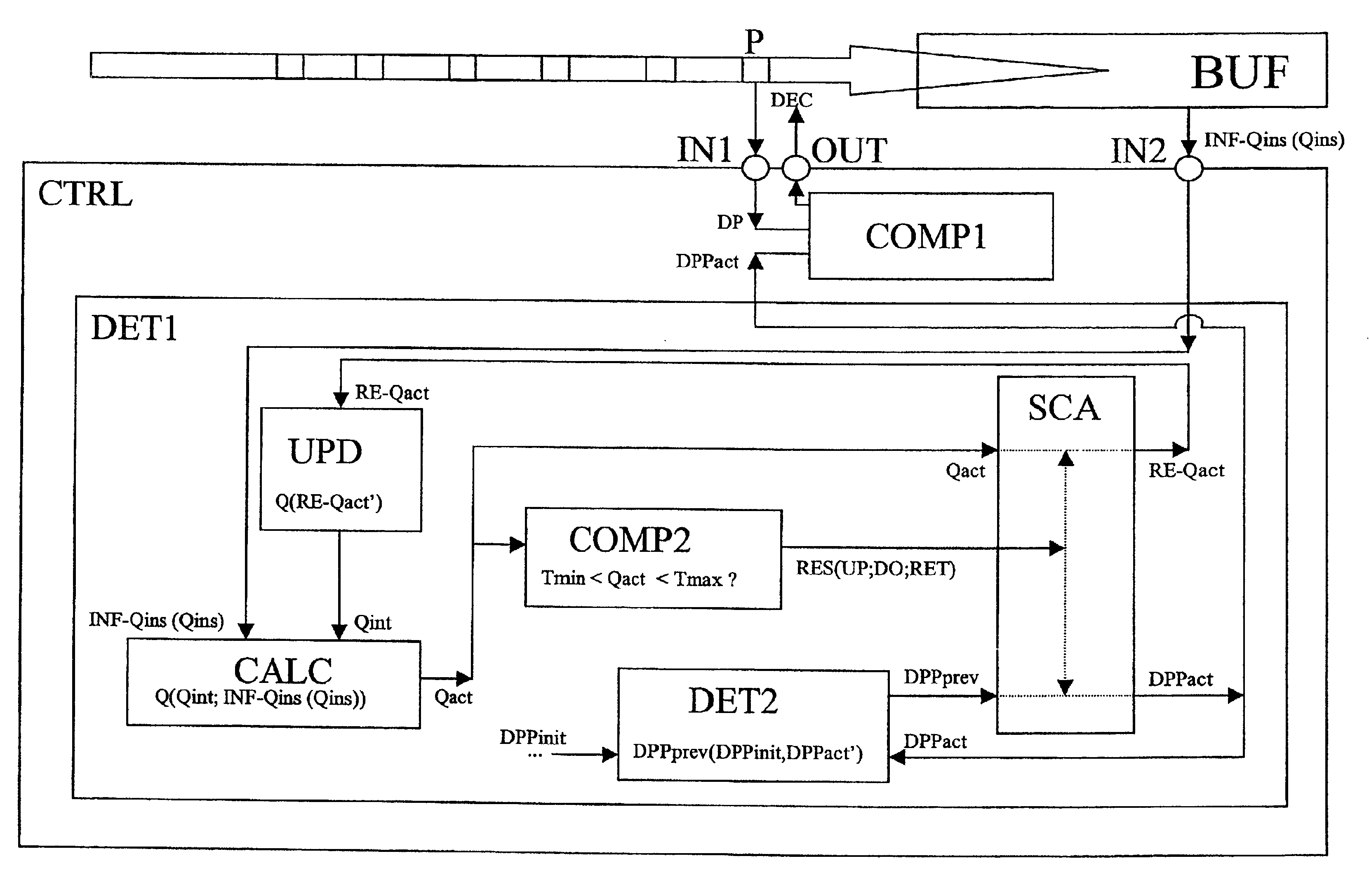

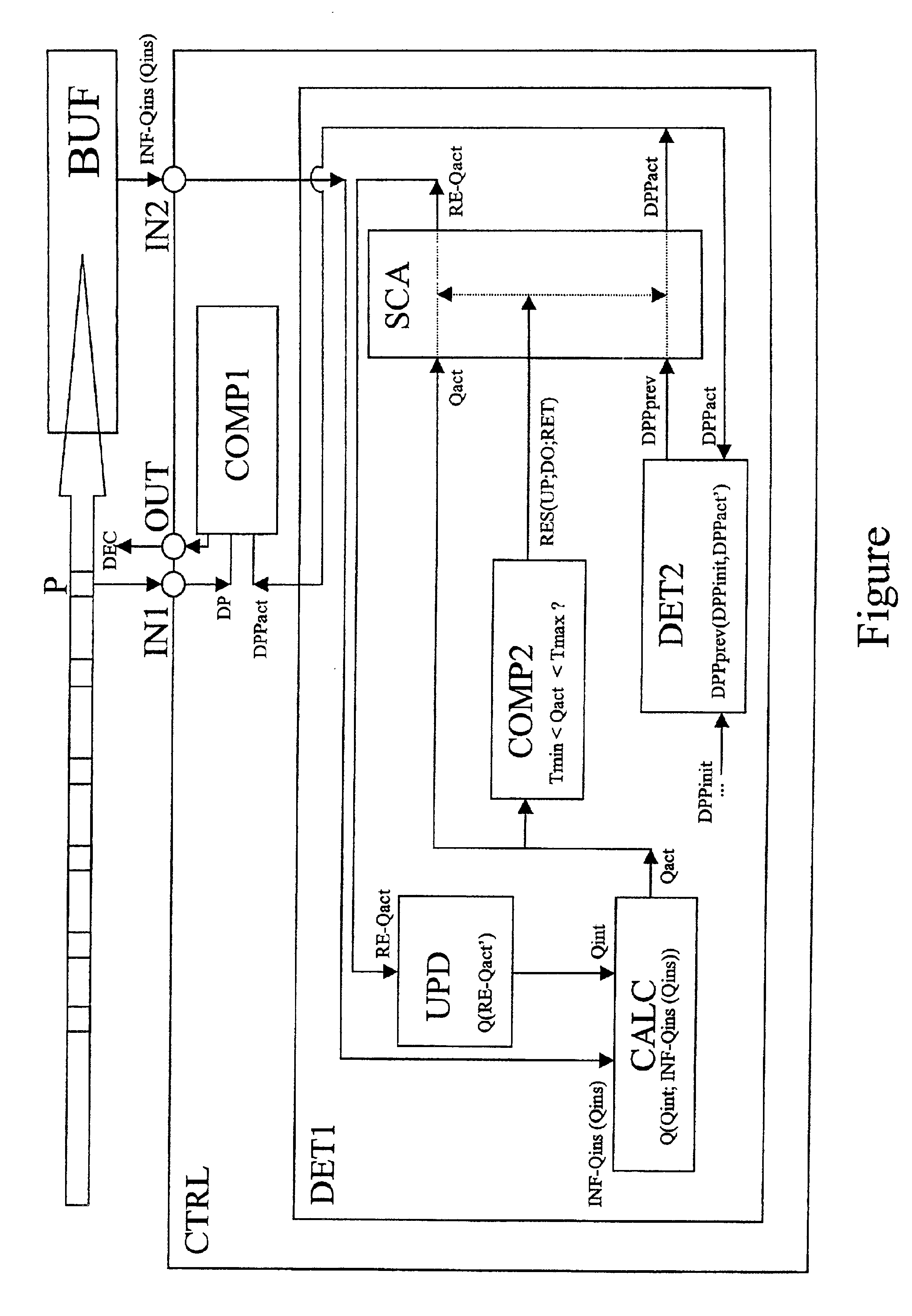

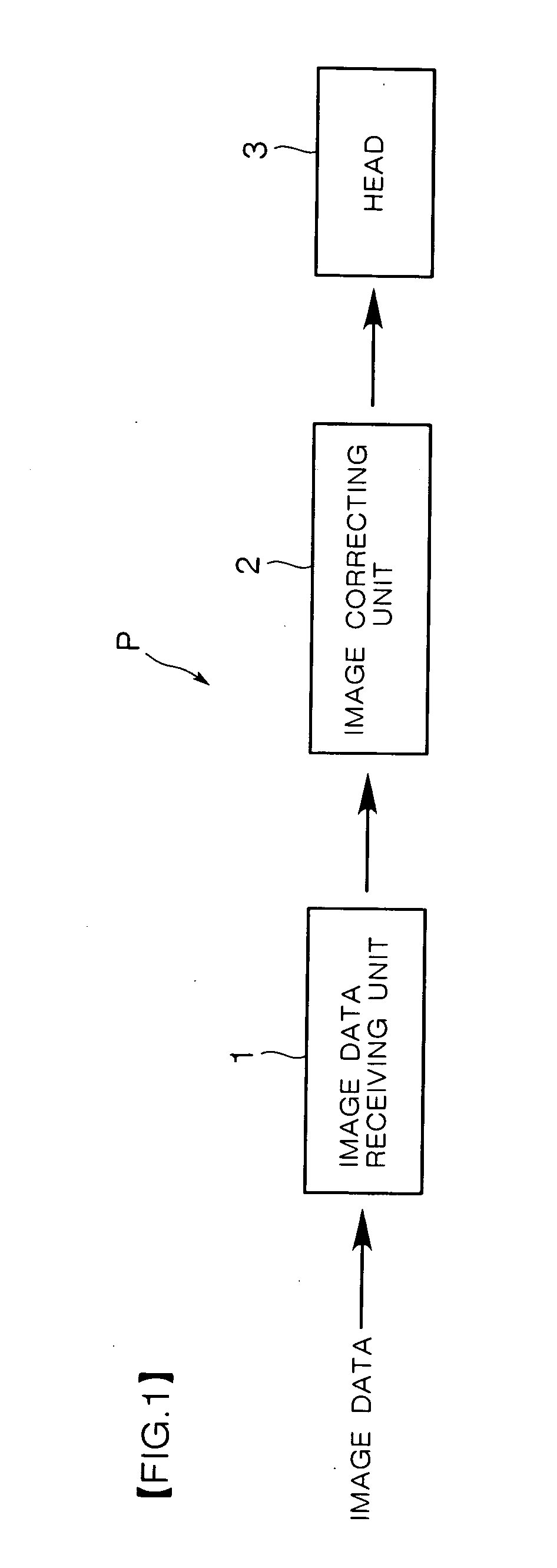

Method to generate an acceptance decision in a telecommunication system

InactiveUS6912226B2Easy to implementReduced drop amountError preventionTransmission systemsData streamComputer science

The invention relates to a method for use in a telecommunication system to generate an acceptance decision during a decision cycle that comprises whether to accept an incoming packet of a data stream or not in a buffer (BUF). The incoming packet (P) has a drop priority (DP) being one of a plurality of arranged drop priorities. The method comprises determining for a drop priority parameter (DPP) an actual drop priority parameter value (DPPact) out of the plurality of drop priorities; and comparing the drop priority parameter (DPP) with the drop priority (DP) of the packet (P) in order to generate the acceptance decision. The method further comprises that the step of determining the actual drop priority parameter value (DPPact) comprises determining a previous drop priority parameter value (DPPprev) by means of any one of an initial value (DPPinit) and a previous actual drop priority parameter value (DPPact′) having been determined during one of a previous decision cycle; and updating a queue occupancy variable (Q) as a function of a previous re-scaled queue occupancy value (RE-Qact′) having been determined during one of a previous decision cycle and providing thereby an intermediate queue occupancy value (Qint); and re-calculating the intermediate queue occupancy value (Qint) of the queue occupancy variable (Q) in function of instantaneous queue occupancy information (INF-Qins) of the buffer (BUF) and providing thereby an actual queue occupancy value (Qact); and comparing the actual queue occupancy value (Qact) with any one of a minimum threshold (Tmin) and a maximum threshold (Tmax) and providing thereby a result (RES (UP; DO; REM)); and according to the (RES (UP; DO; RET)) re-scaling the actual queue occupancy value (Qact) and the previous drop priority parameter value (DPPprev) and providing thereby, respectively, a re-scaled queue occupancy value (RE-Qact) and the actual drop priority parameter value (DPPact).

Owner:WSOU INVESTMENTS LLC

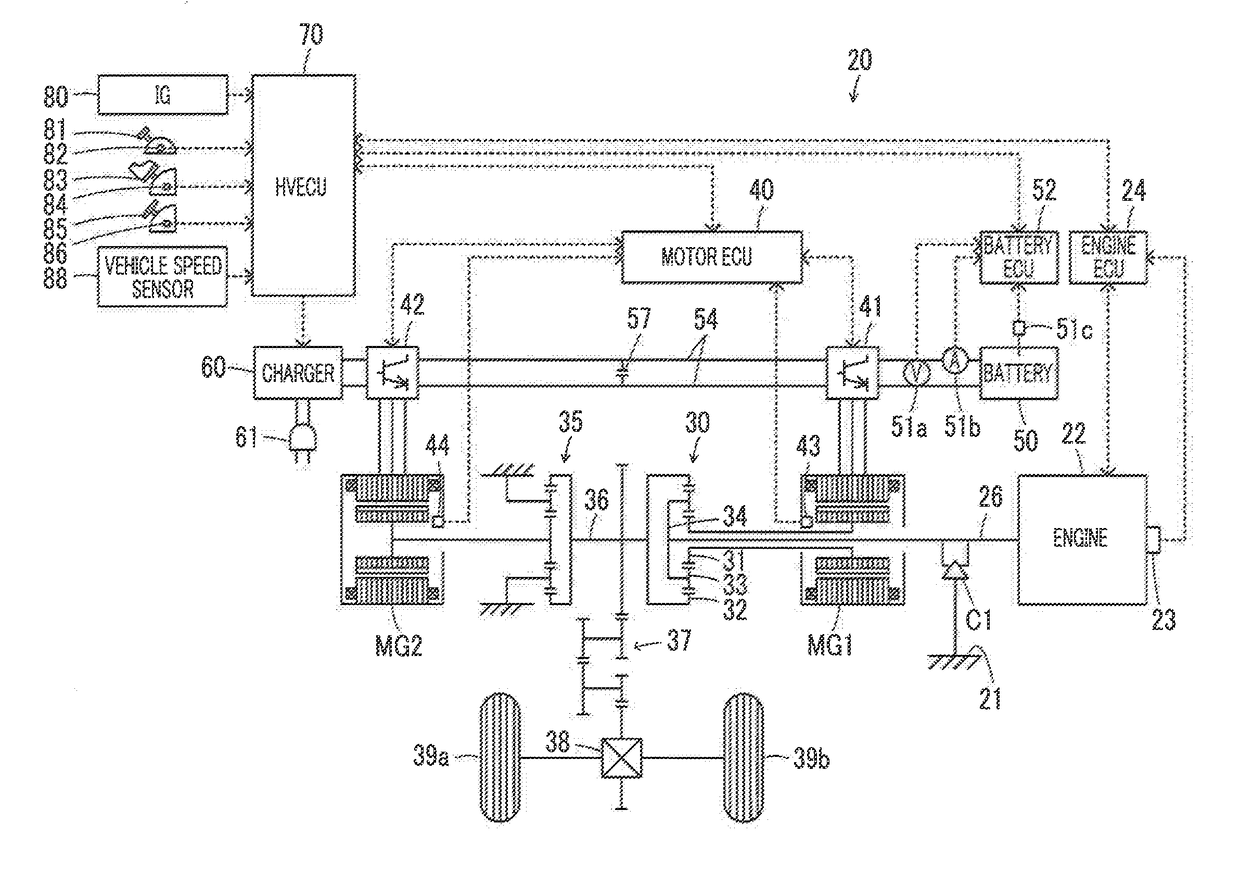

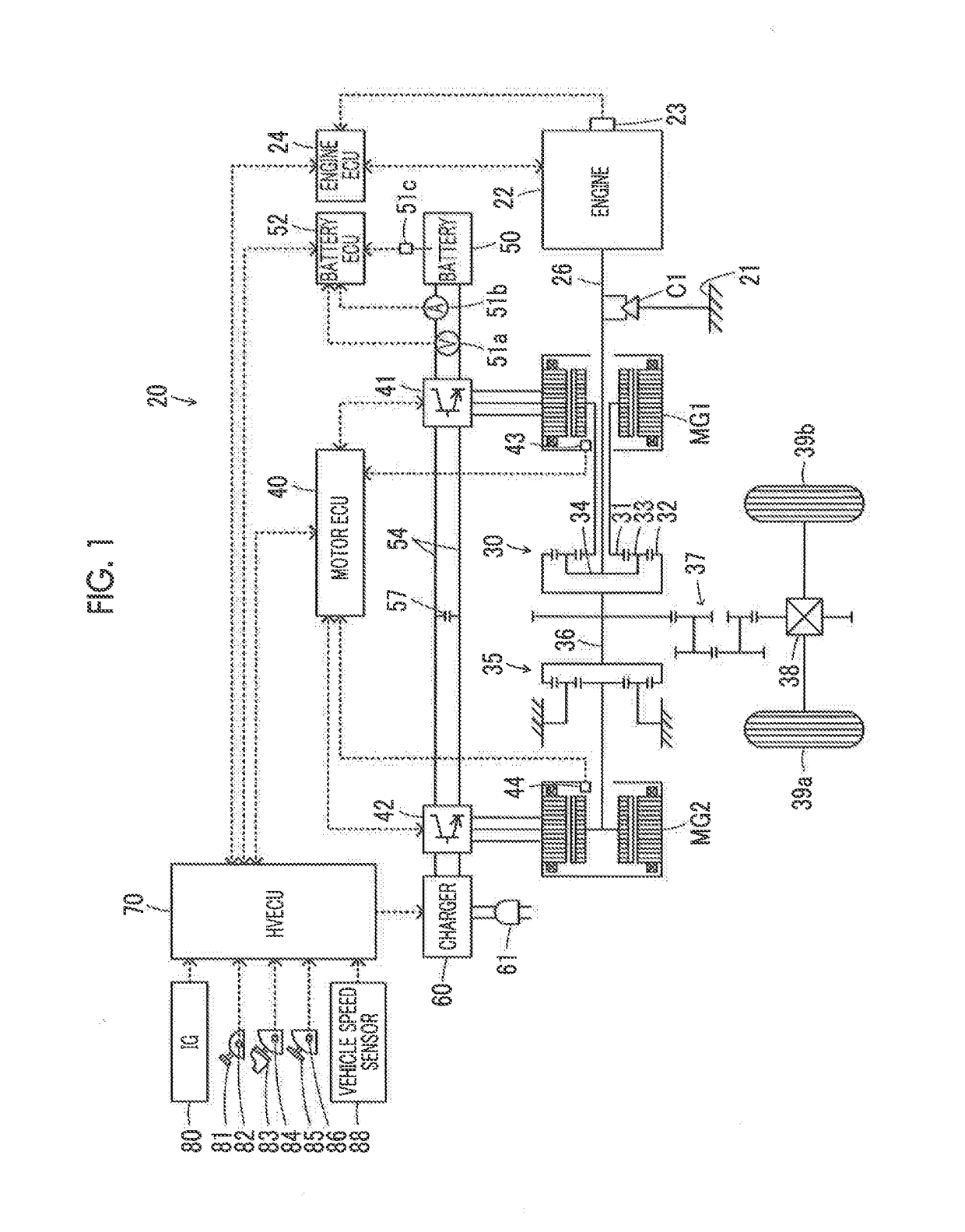

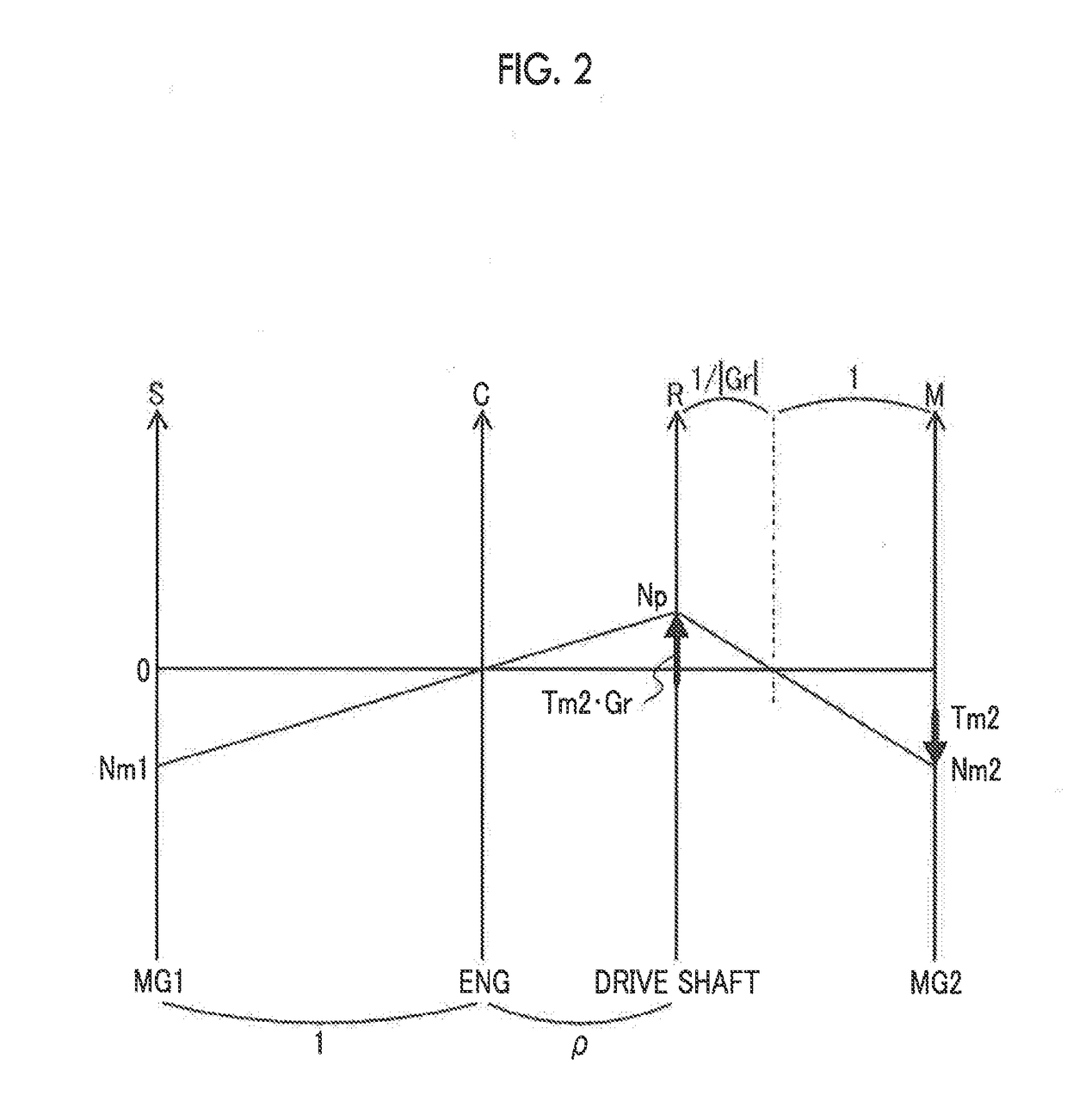

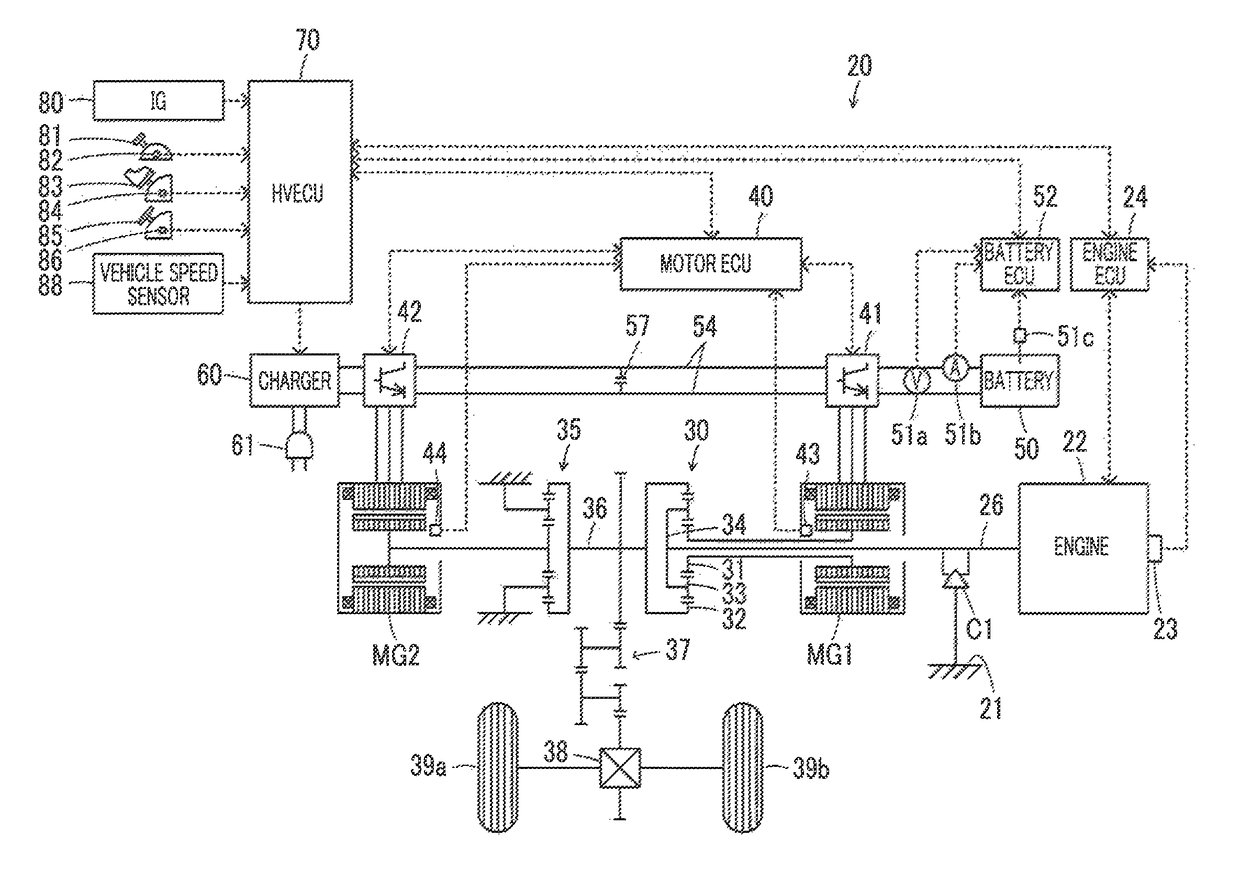

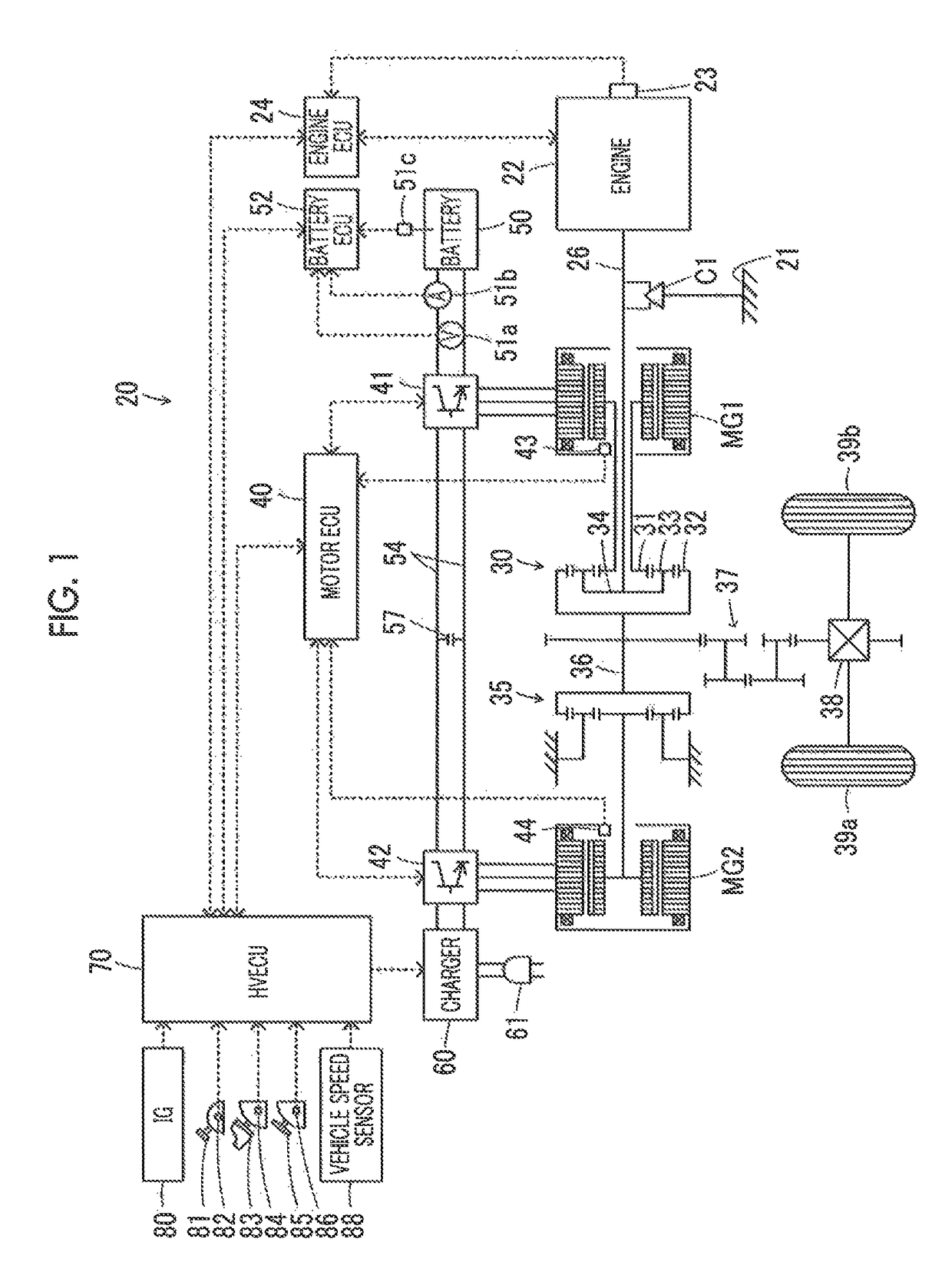

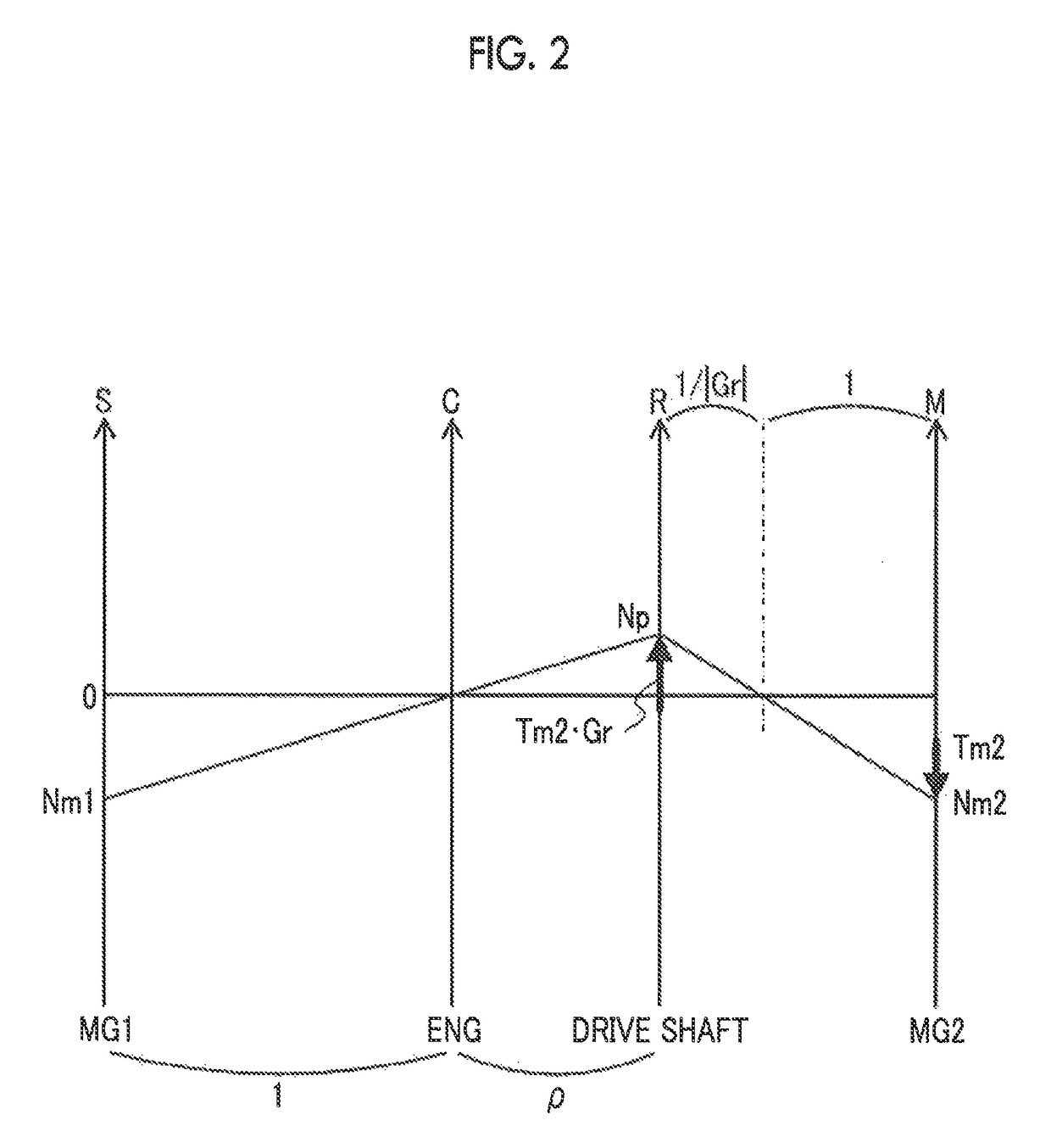

Hybrid vehicle and control method for hybrid vehicle

ActiveUS20170349157A1Improve degradation ratePrevented from feelingHybrid vehiclesInternal combustion piston enginesDrive shaftHybrid vehicle

When an output limitation value of a battery is equal to or less than a threshold, an electronic control unit determines that basic torque is able to be output from a second motor to a drive shaft. Then, the electronic control unit sets a predetermined value as a target motoring rotation speed for ending motoring of an engine by a first motor. When the output limitation value is greater than the threshold, the electronic control unit determines that the basic torque is unable to be output from the second motor to the drive shaft at the time of starting the engine, and sets a value smaller than the predetermined value as the target motoring rotation speed.

Owner:TOYOTA JIDOSHA KK +1

Tapered roller bearing and method of designing the same

ActiveUS8858088B2Convenience to workImprove machine efficiencyRoller bearingsShaftsCircular coneEngineering

In a tapered roller bearing assembly, a crowning profile formed portion of the roller rolling surface is made up of a contact area crowned portion, which is held in contact with an inner ring raceway surface, and a non-contact area crowned portion which is held in non-contact with the inner ring raceway surface. The contact area crowned portion and the non-contact area crowned portion have their generatrices extending in an axial direction of a roller, which generatrices are represented by corresponding continuous lines represented by different functions and continued smoothly at a point of connection, and the curvature of the generatrix of the non-contact area crowned portion in the vicinity of the connection point is chosen to be smaller than the curvature of the generatrix of the contact area crowned portion.

Owner:NTN CORP

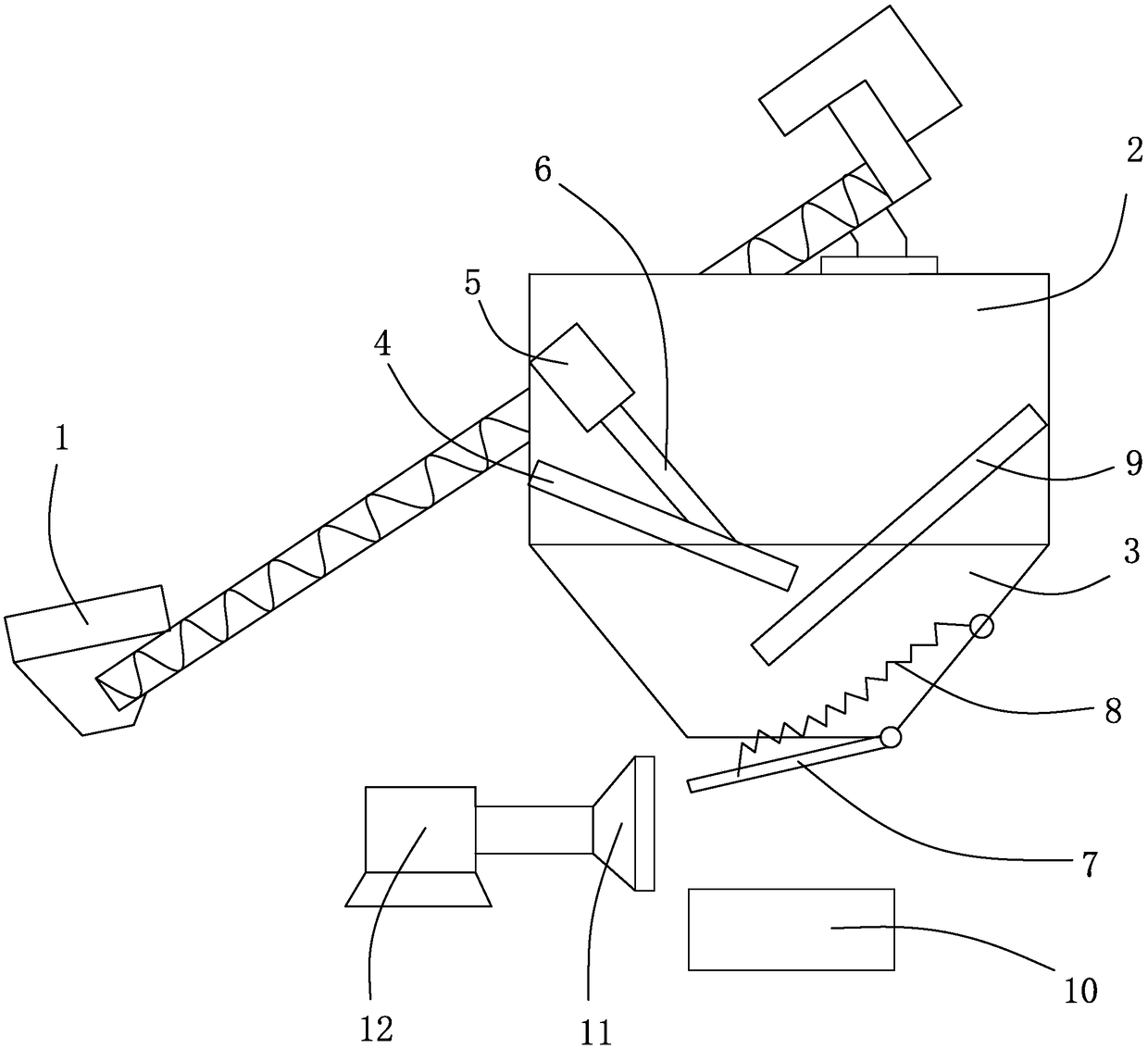

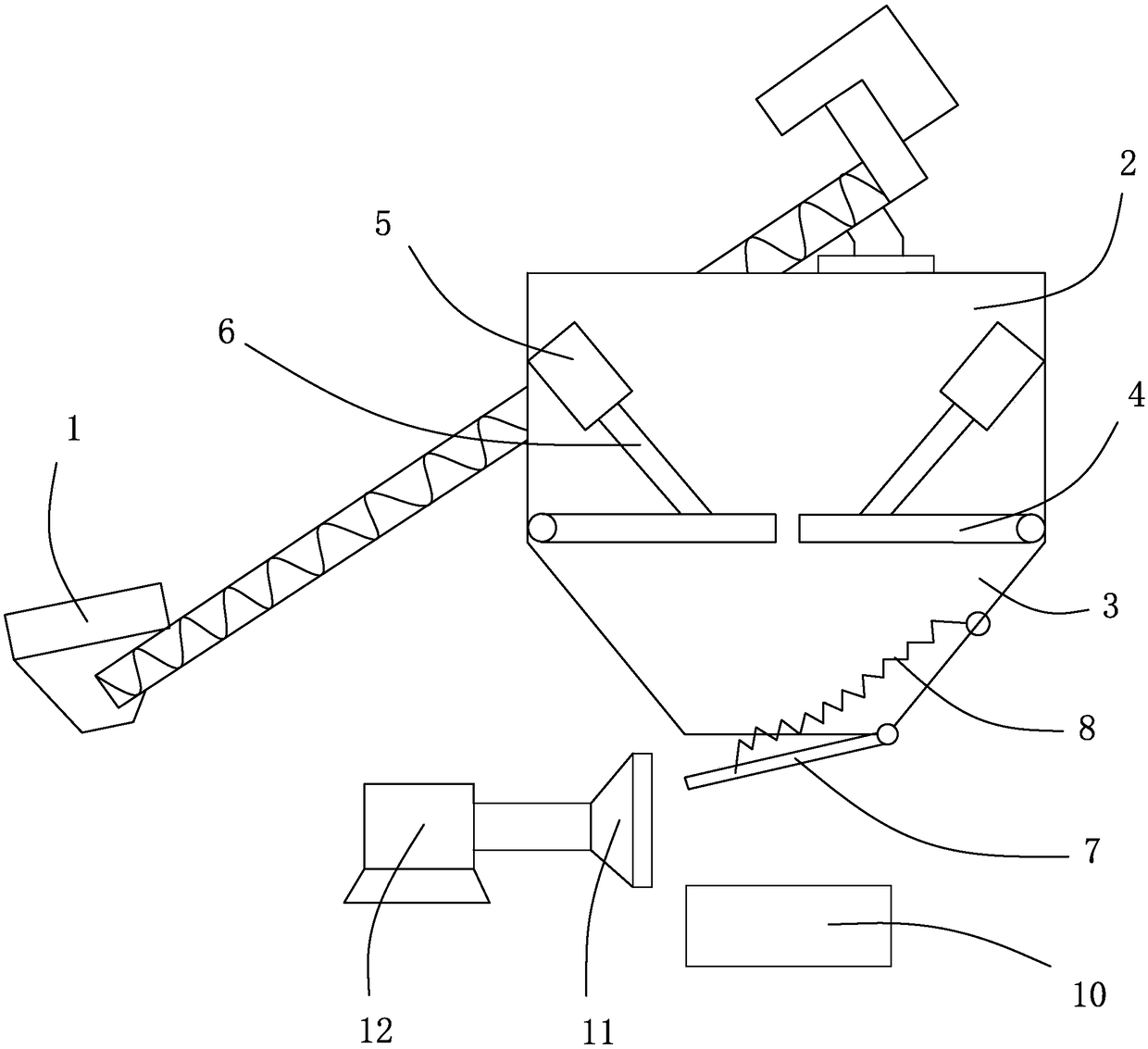

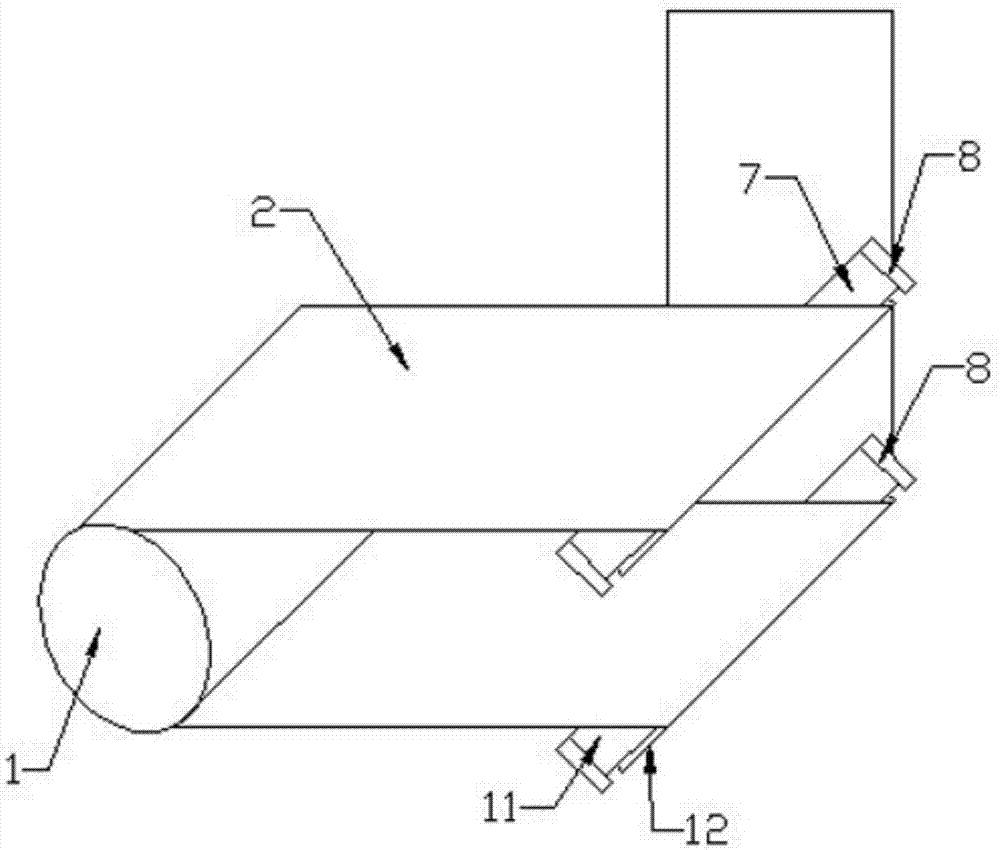

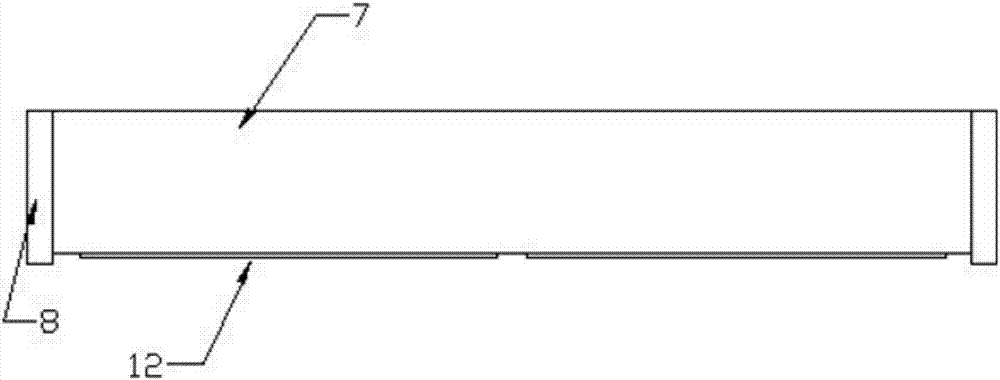

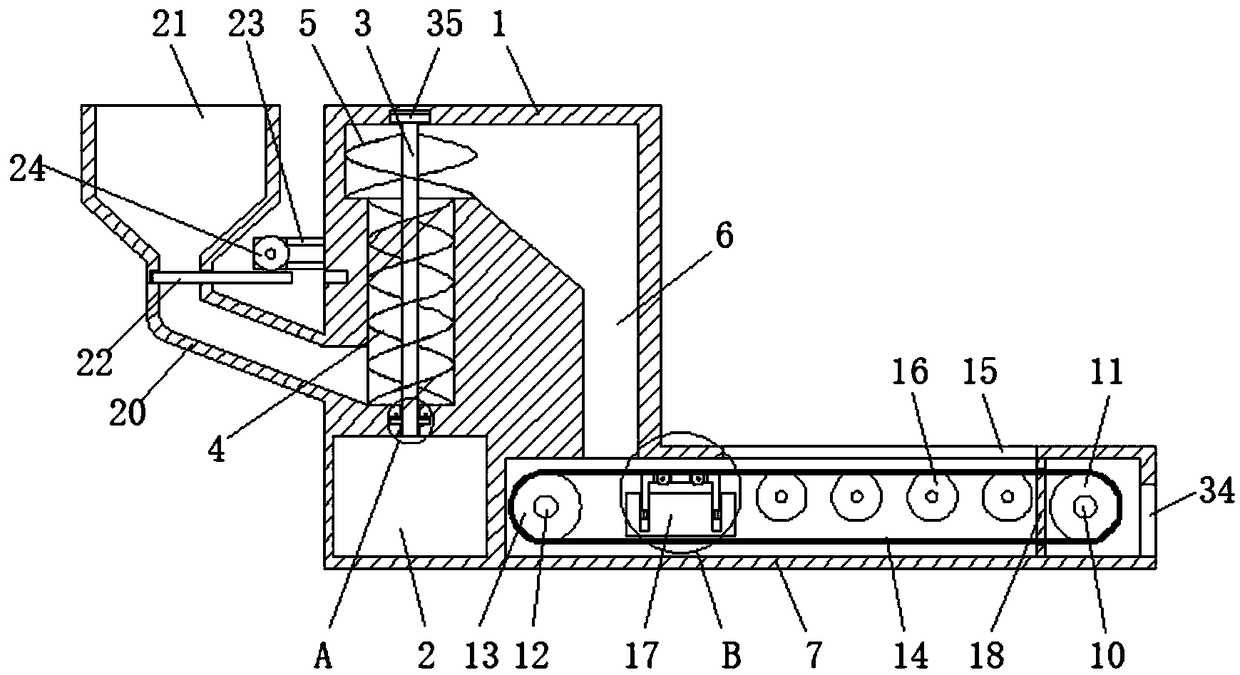

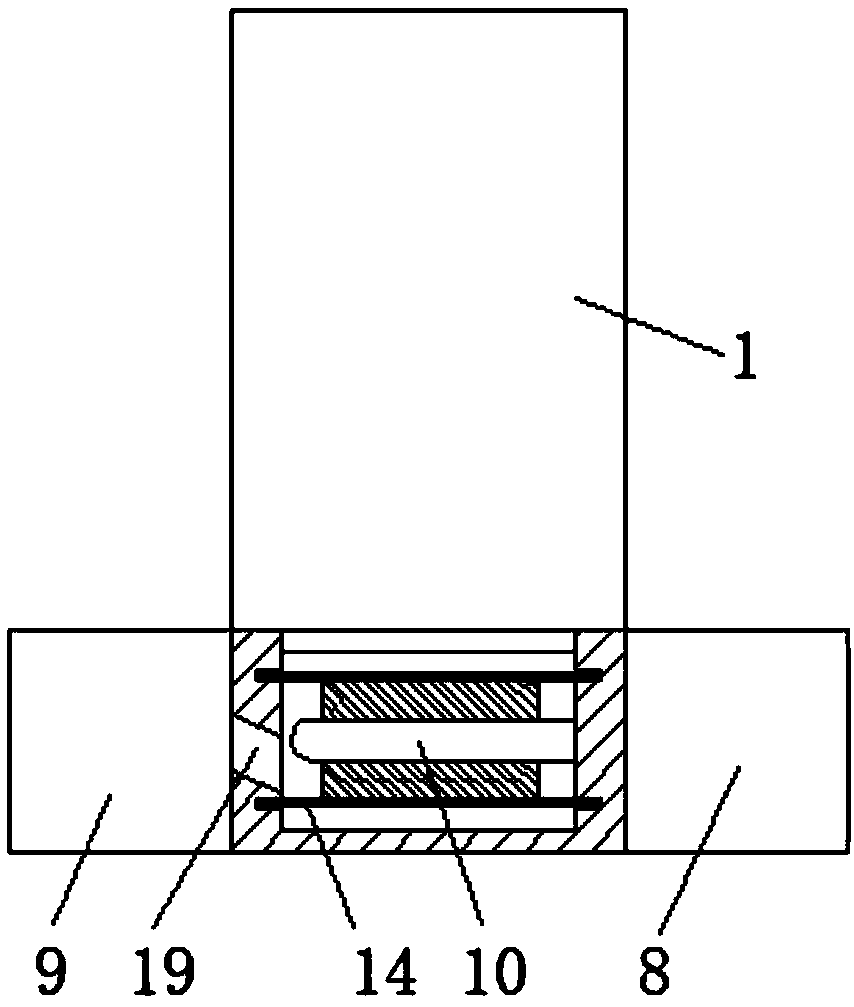

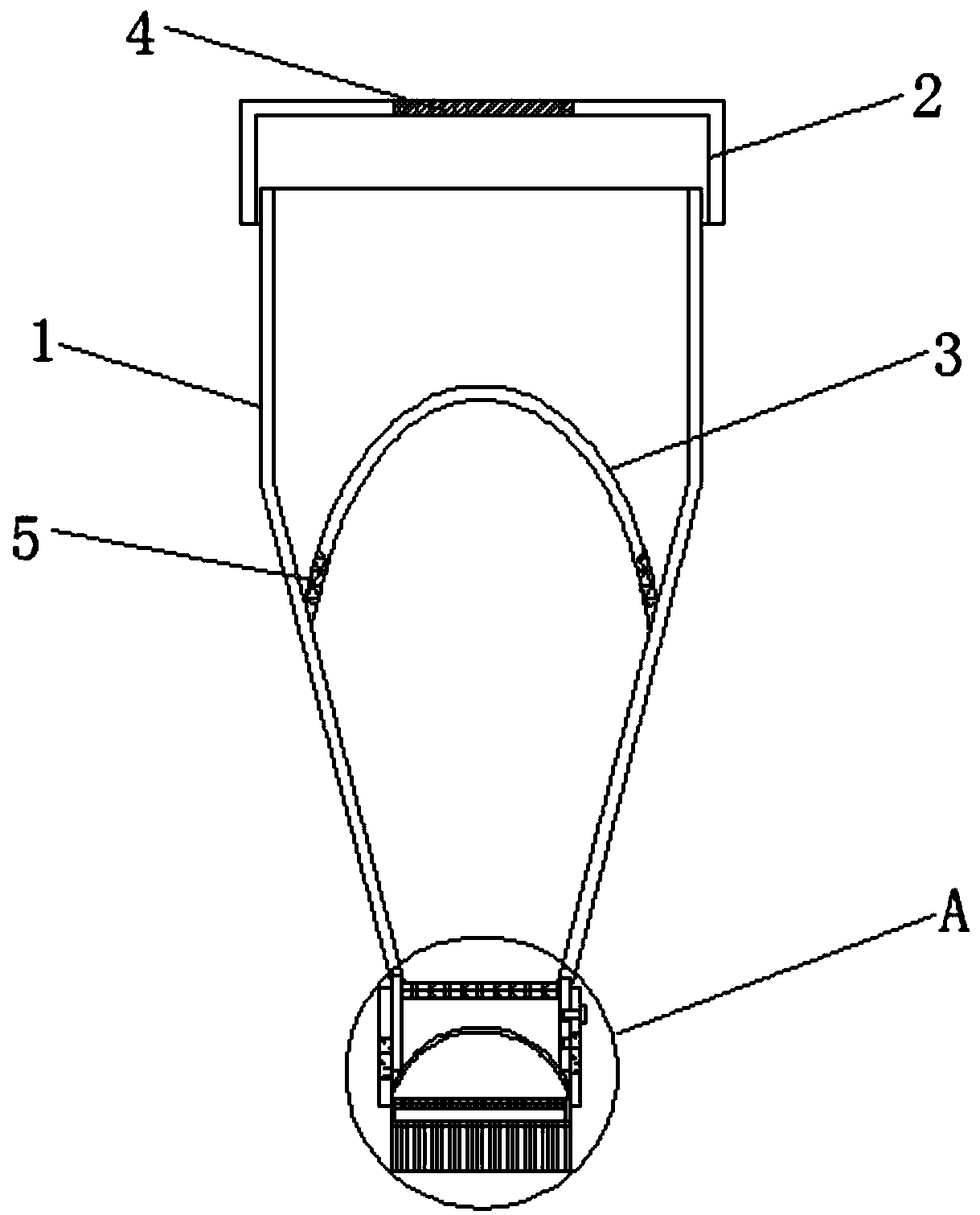

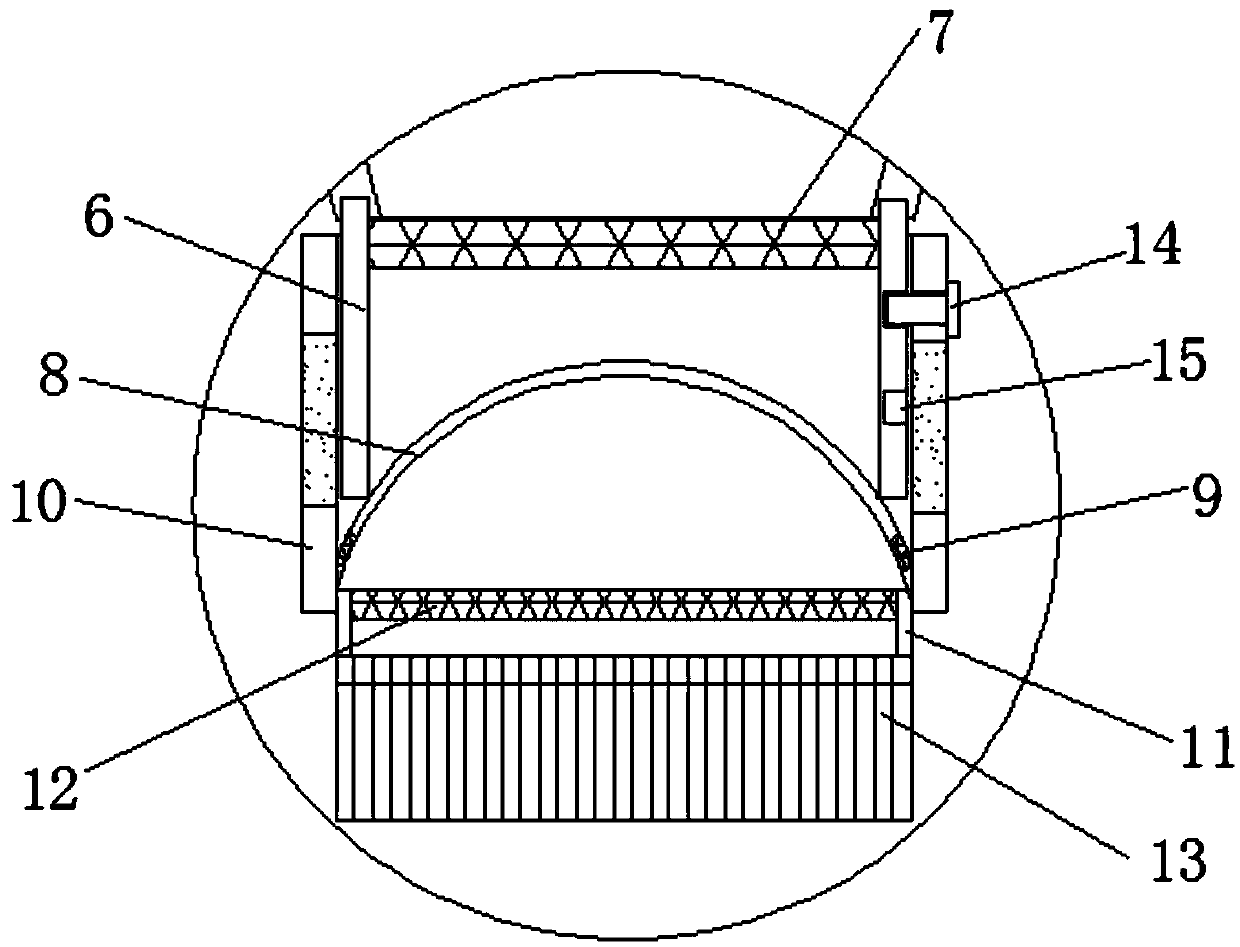

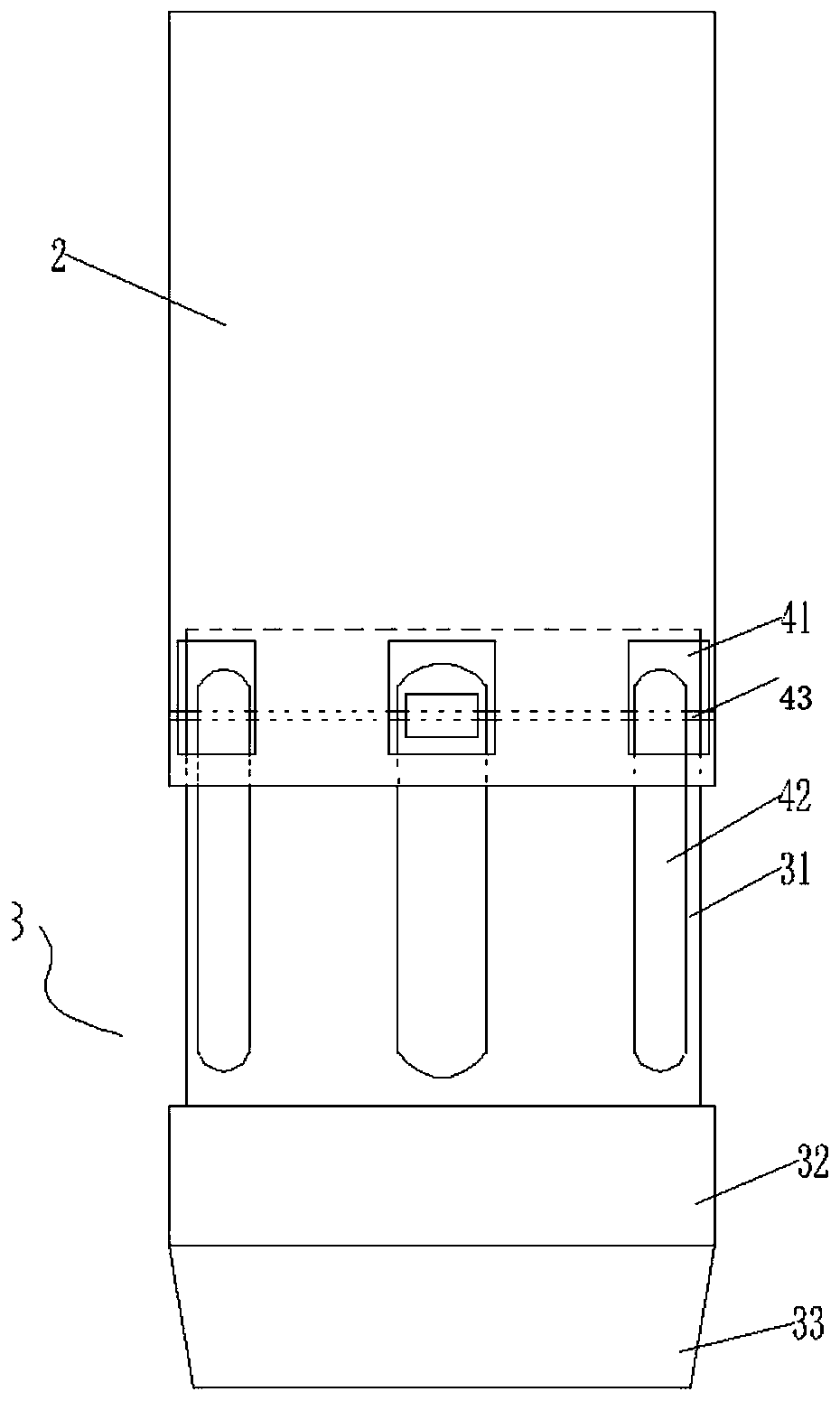

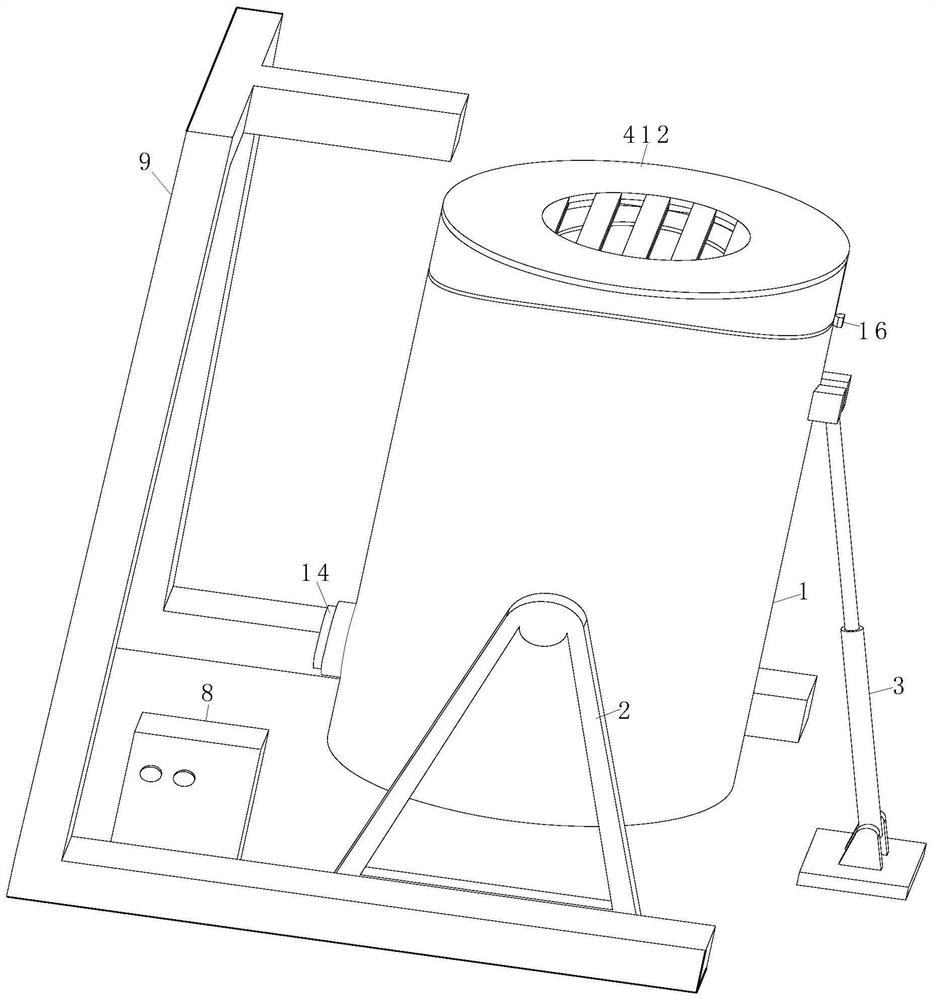

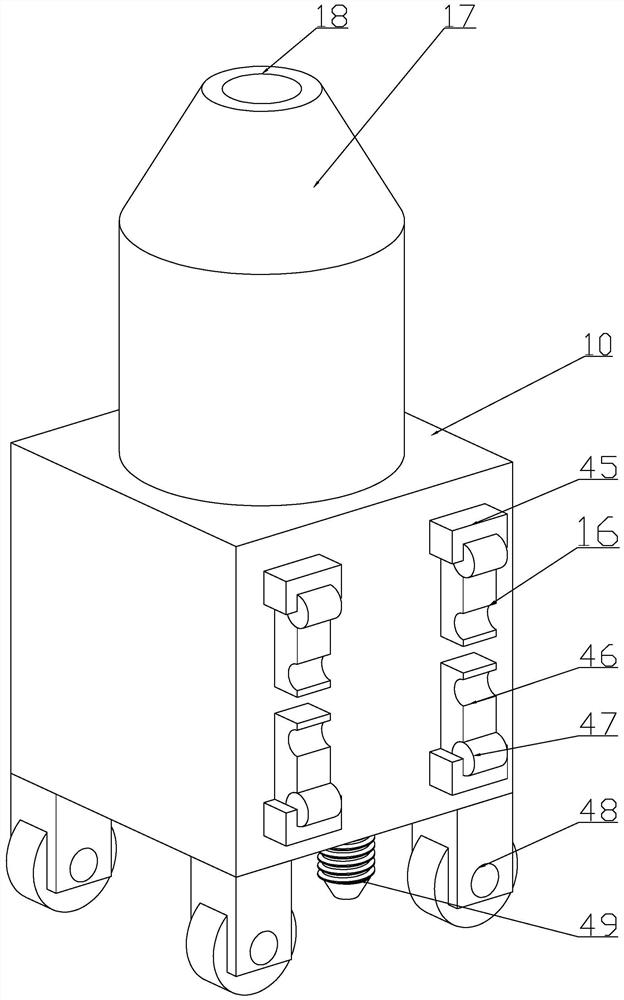

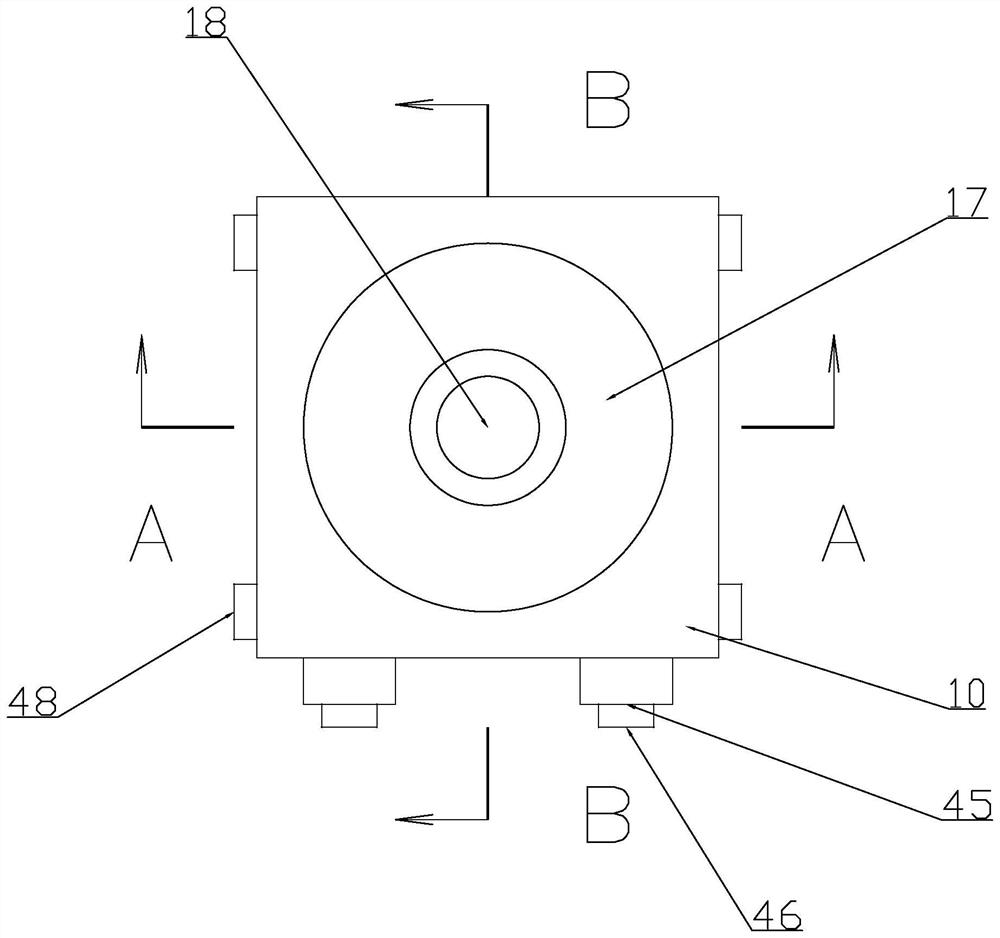

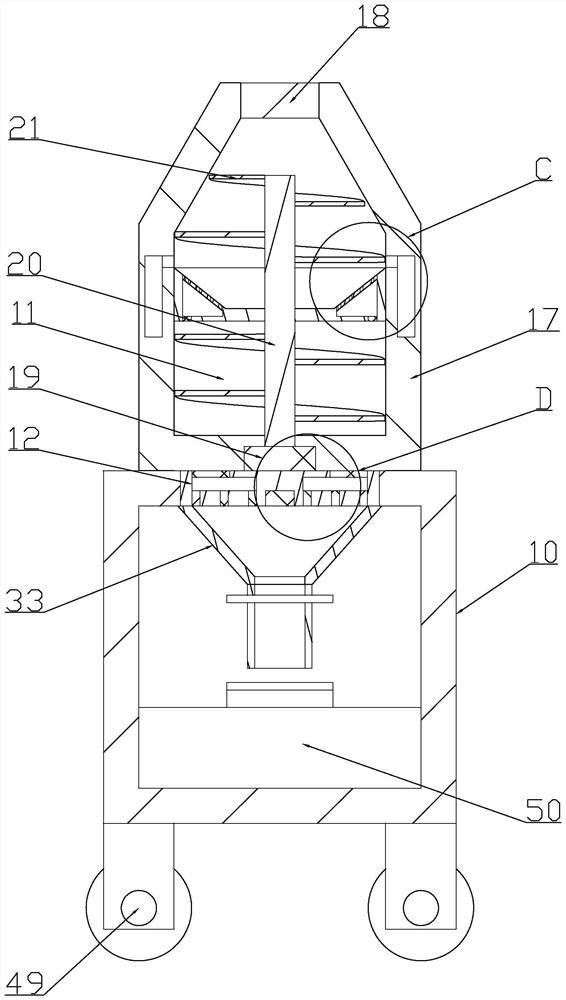

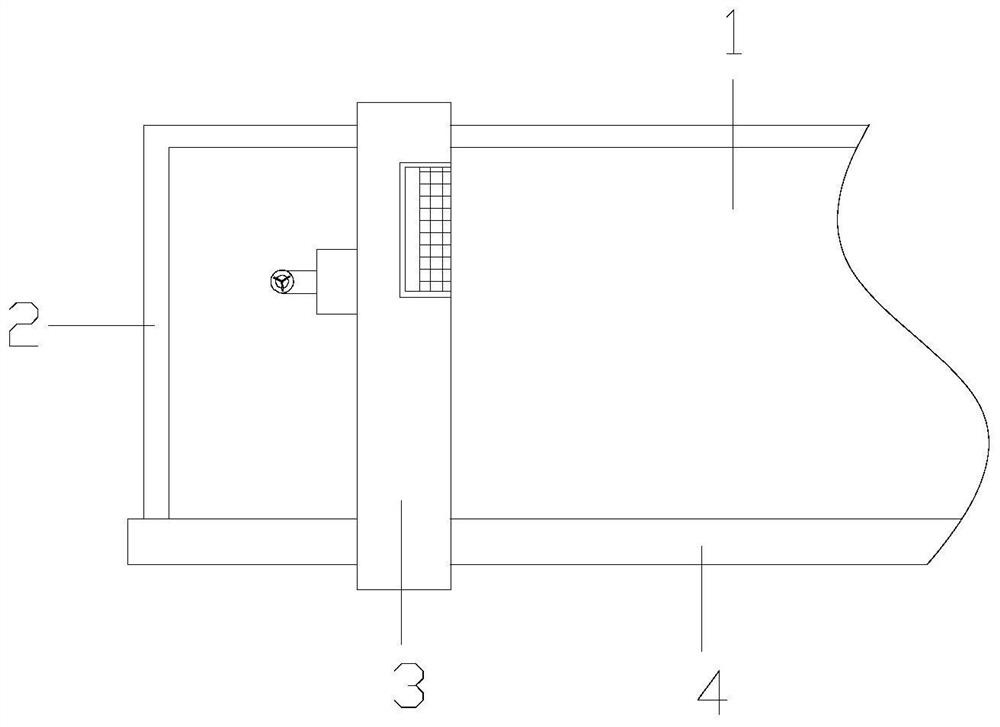

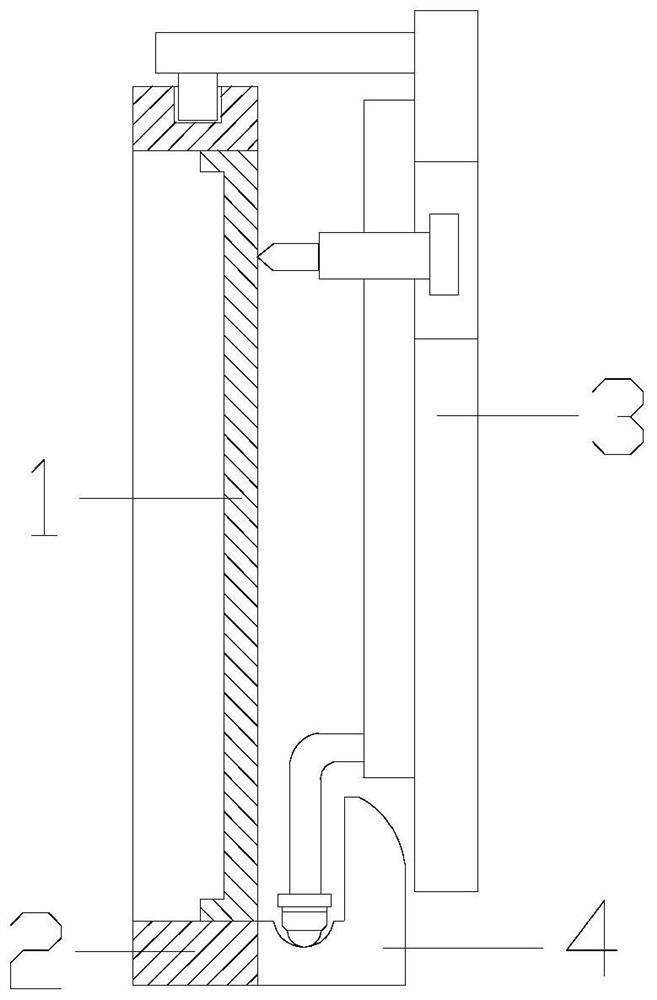

Feeding device capable of adjusting discharging amount

PendingCN109178457AReduced drop amountIncrease the amount of dropSolid materialEngineeringMechanical engineering

The invention discloses a feeding device capable of adjusting the discharging amount. The feeding device capable of adjusting the discharging amount comprises a feeding hopper, a screw conveying mechanism, a material bin and a control unit, wherein the material bin comprises a cylinder and a cone cylinder, the big end of the cone cylinder is upwards and is in communication with the cylinder, the large end of the conical cylinder is equal to the circular area of the section of the cylinder, a movable plate is hinged to the inner wall of the cylinder, the inner wall of the cylinder is fixedly connected with an air cylinder above the movable plate, the air cylinder is electrically connected with the control unit, a telescopic rod of the air cylinder is connected with one end, away from the hinged position, of the movable plate, the telescopic rod of the air cylinder acts, the movable plate is controlled to rotate so as to adjust the contact area of the movable plate and the falling material, a discharge hole is formed in the bottom of the material bin, one end of the discharge port is hinged to a bin door, one end, away from the hinged position, of the bin door is connected with an elastic piece, and the other end of the elastic piece is connected with the inner wall of the cone cylinder. The feeding device have the advantages that the material discharging amount can be adjusted,and the requirements of users can be met.

Owner:广东贝尤安新材料科技有限公司

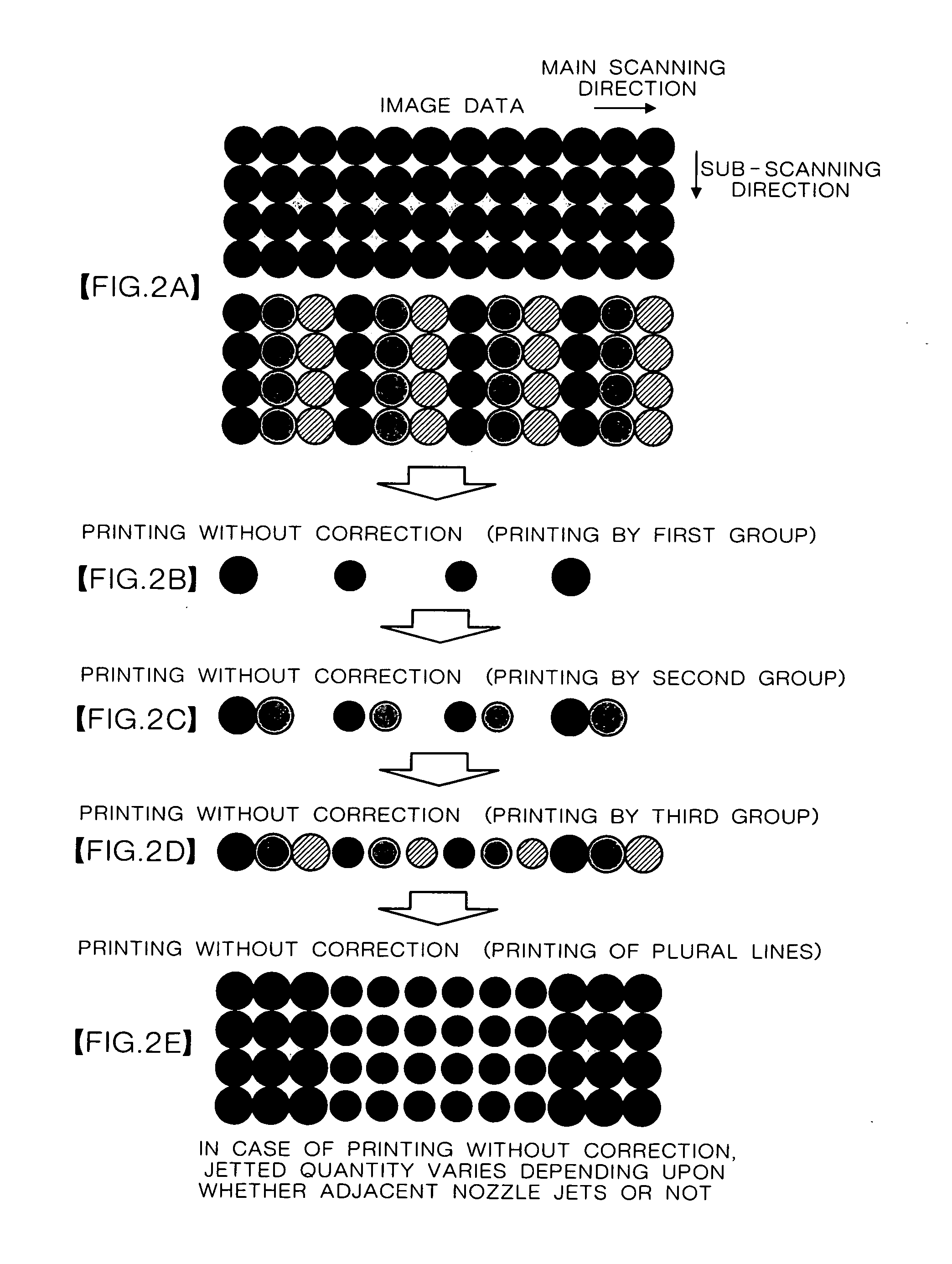

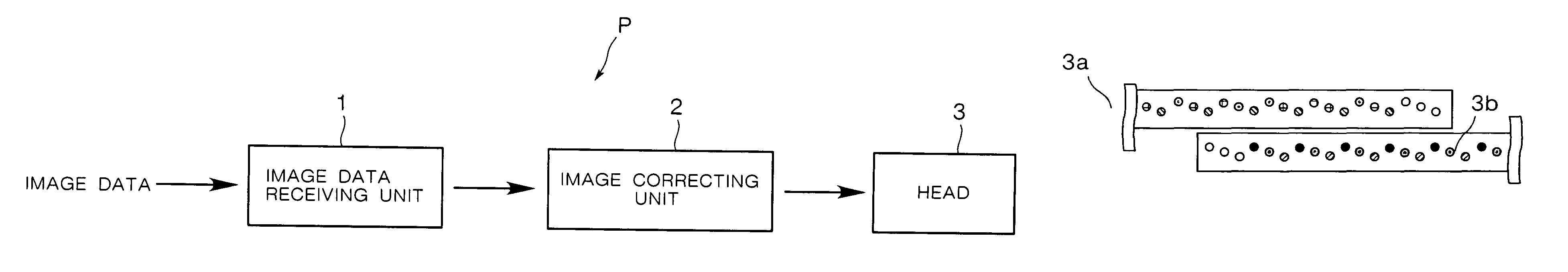

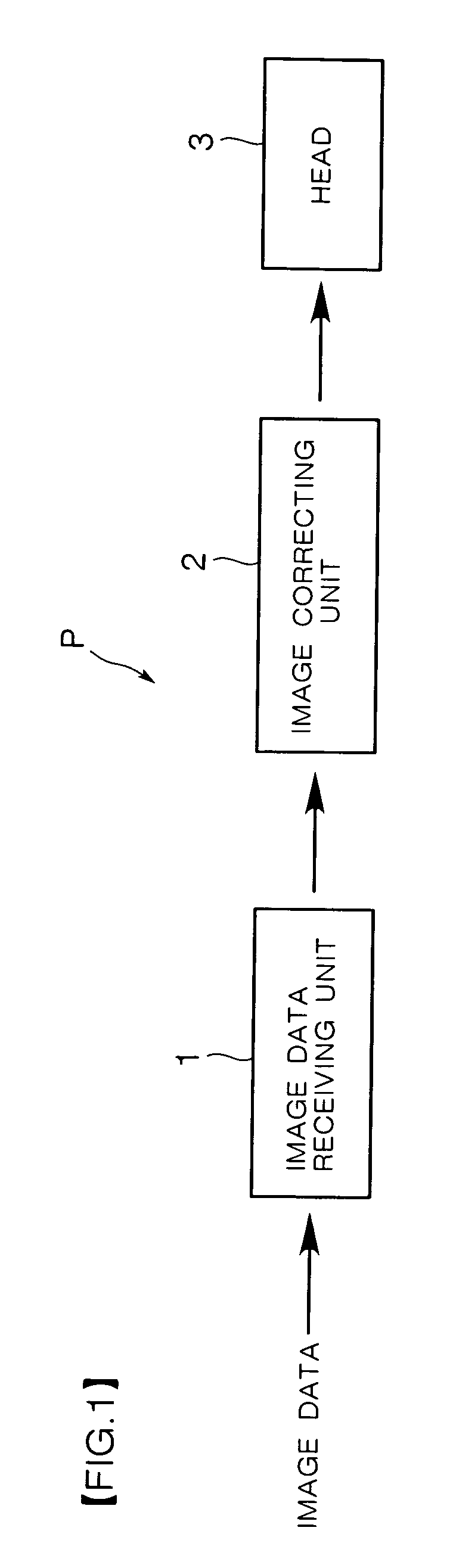

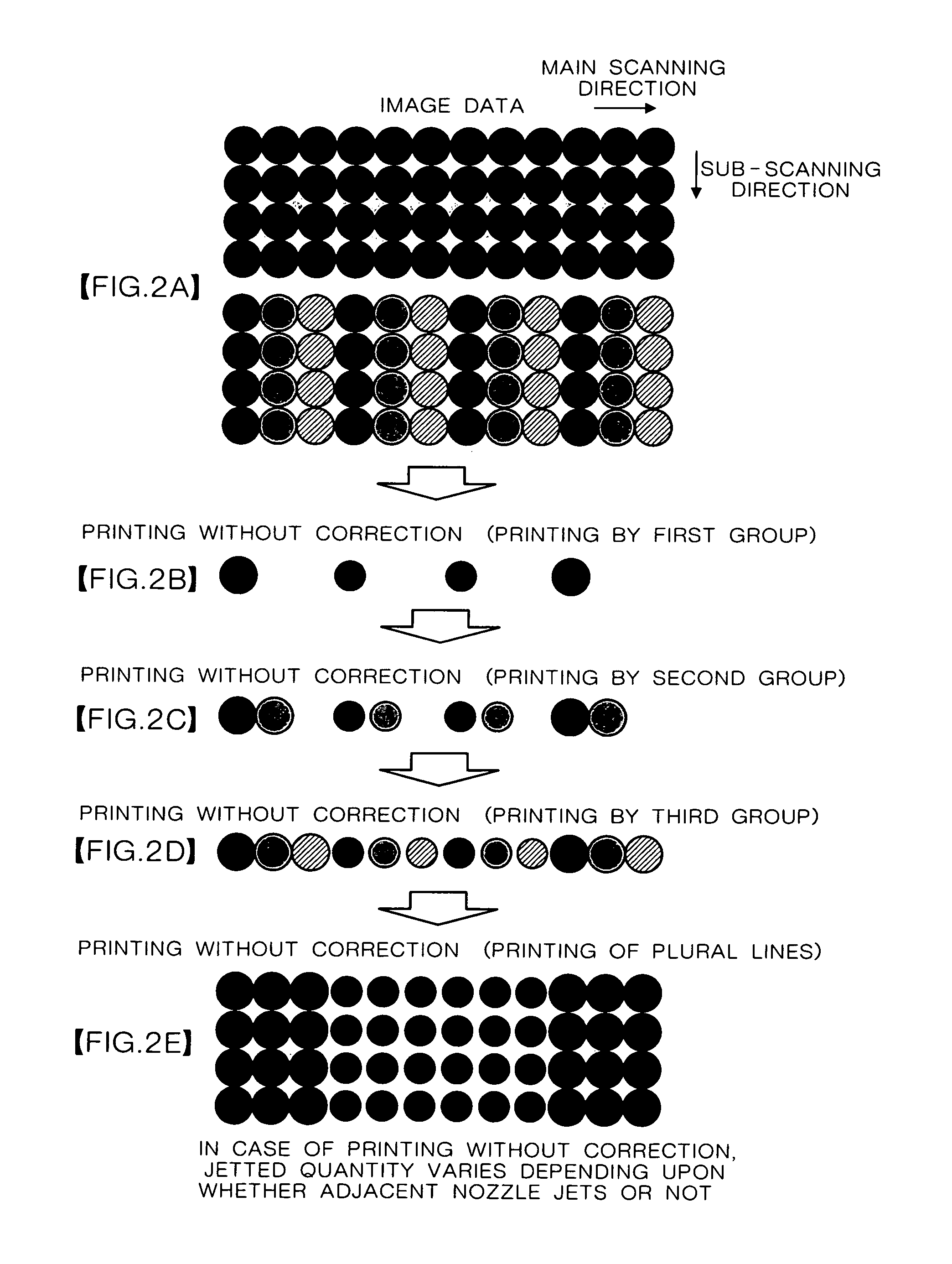

Ink jet printer

ActiveUS20070132798A1Reduce density unevennessReduced drop amountInking apparatusOther printing apparatusEngineeringMechanical engineering

The object of the invention is to settle a phenomenon that a quantity of jetted ink increases at the end of an image and a density increases in a share-mode ink jet head. In a three-split driven head, a first group prints so that a diameter of a dot is reduced by reducing the quantity of jetted ink as dots at both ends, a second group similarly prints, and a third group also similarly prints. Since each three dots at both ends in a main scanning direction of an acquired image are smaller than dots in the middle, a phenomenon that a quantity of jetted ink increases at the end of the image and density increases is reduced.

Owner:RISO KAGAKU CORP

Hybrid vehicle and control method for hybrid vehicle

ActiveUS10035502B2Improve failureShort timeHybrid vehiclesInternal combustion piston enginesDrive shaftEngineering

When an output limitation value of a battery is equal to or less than a threshold, an electronic control unit determines that basic torque is able to be output from a second motor to a drive shaft. Then, the electronic control unit sets a predetermined value as a target motoring rotation speed for ending motoring of an engine by a first motor. When the output limitation value is greater than the threshold, the electronic control unit determines that the basic torque is unable to be output from the second motor to the drive shaft at the time of starting the engine, and sets a value smaller than the predetermined value as the target motoring rotation speed.

Owner:TOYOTA JIDOSHA KK +1

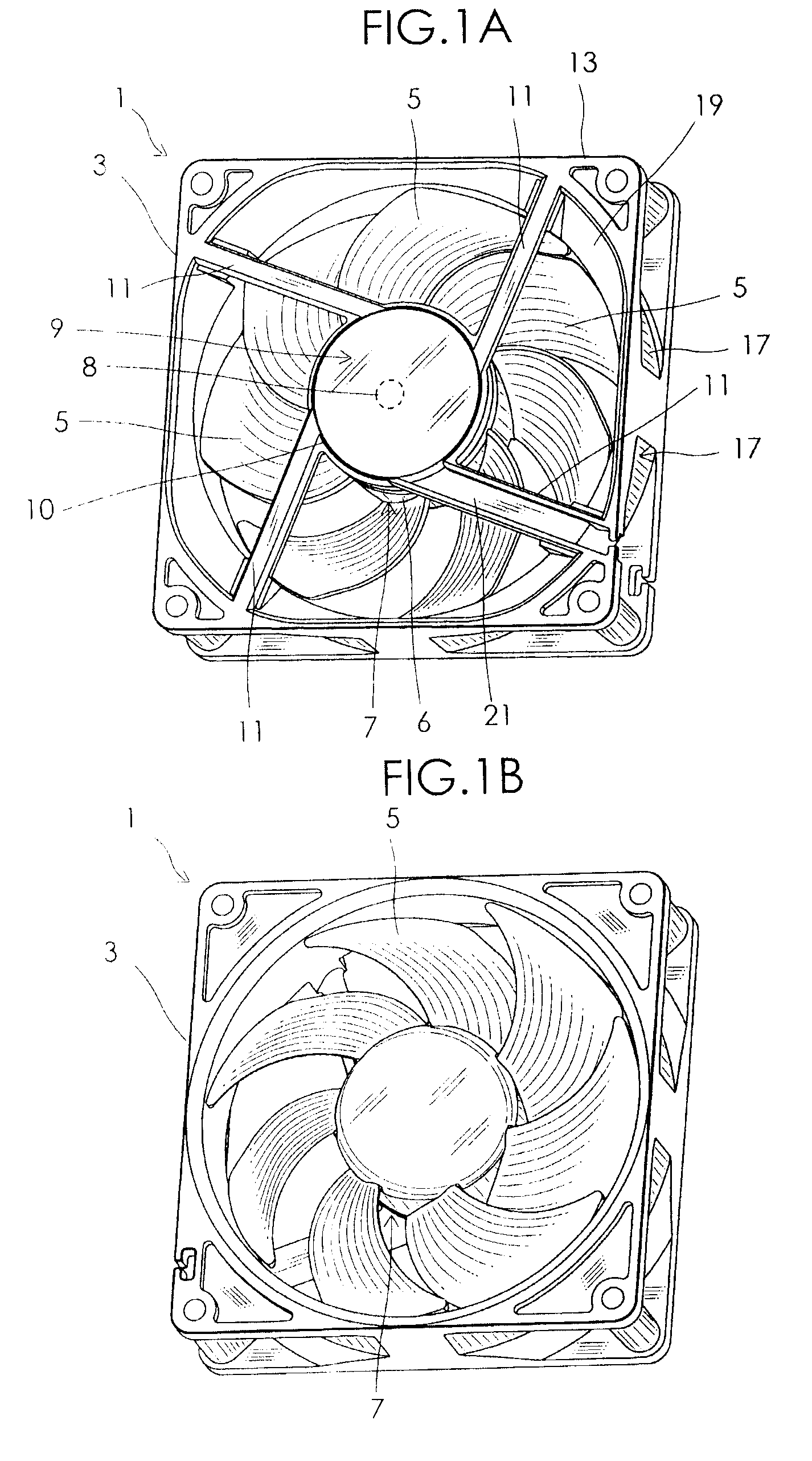

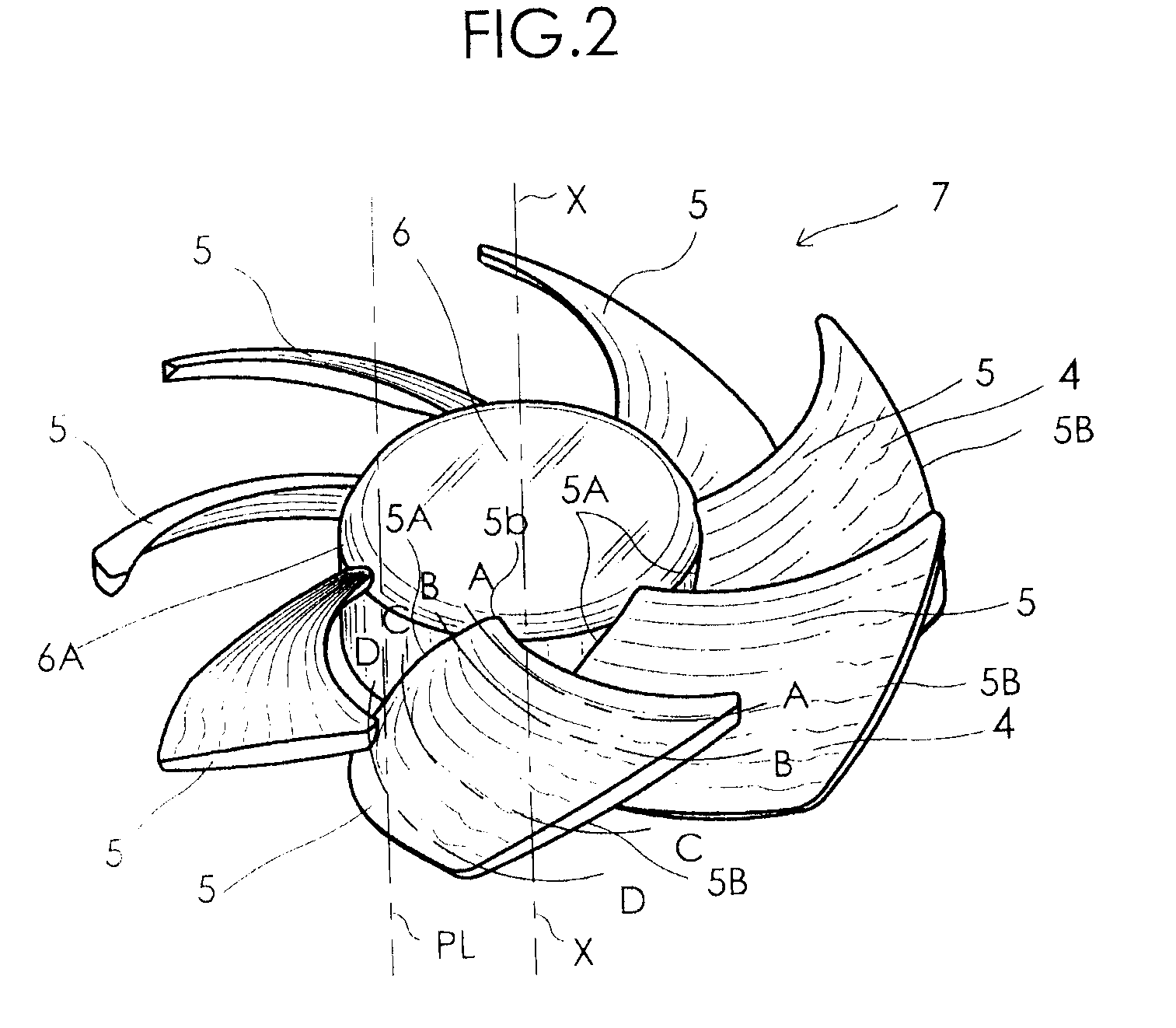

Axial flow fan

ActiveUS8770943B2Reduce pressureReduce noisePropellersPump componentsEngineeringMechanical engineering

An axial flow fan includes a blade having a curved portion formed in the vicinity of a radially outer end portion positioned opposite to the base portion in the radial direction of the peripheral wall portion of the hub. The curved portion is convex in the rotation direction, concave in the direction opposite to the rotation direction, and extends along the radially outer end portion of the blade. The curved portion extends from a rear end edge of the blade, positioned on a side where one end of the base portion of the blade is positioned, and extends in the radial direction of the hub to the vicinity of a front end edge of the blade, positioned on a side where the other end of the base portion of the blade is positioned and extending in the radial direction.

Owner:SANYO DENKI CO LTD

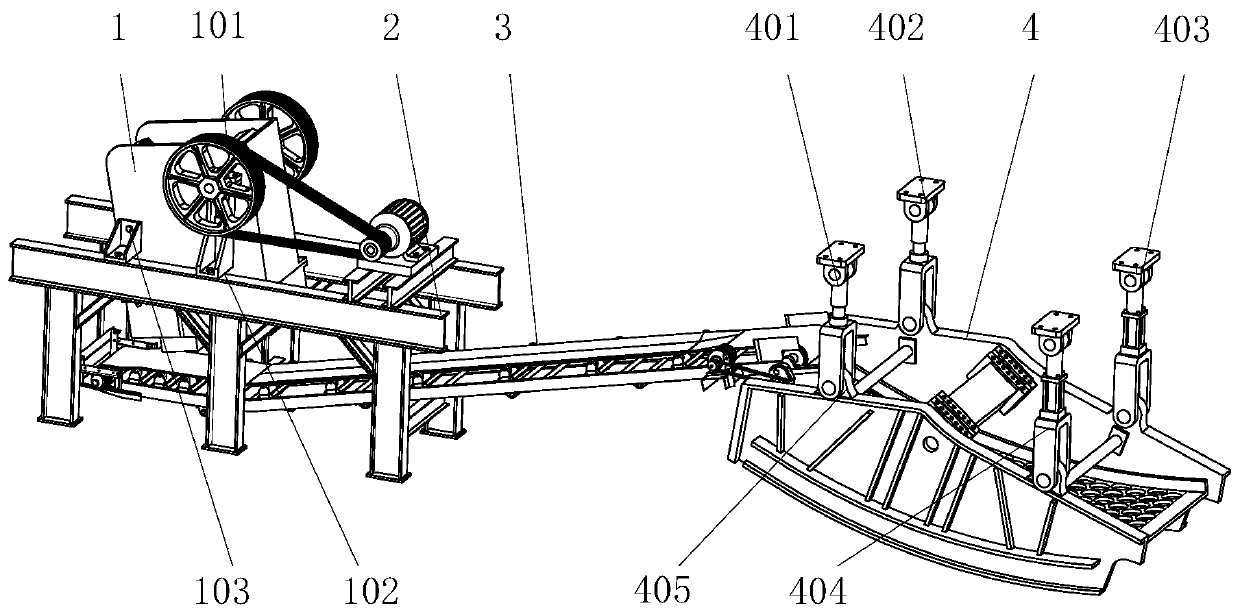

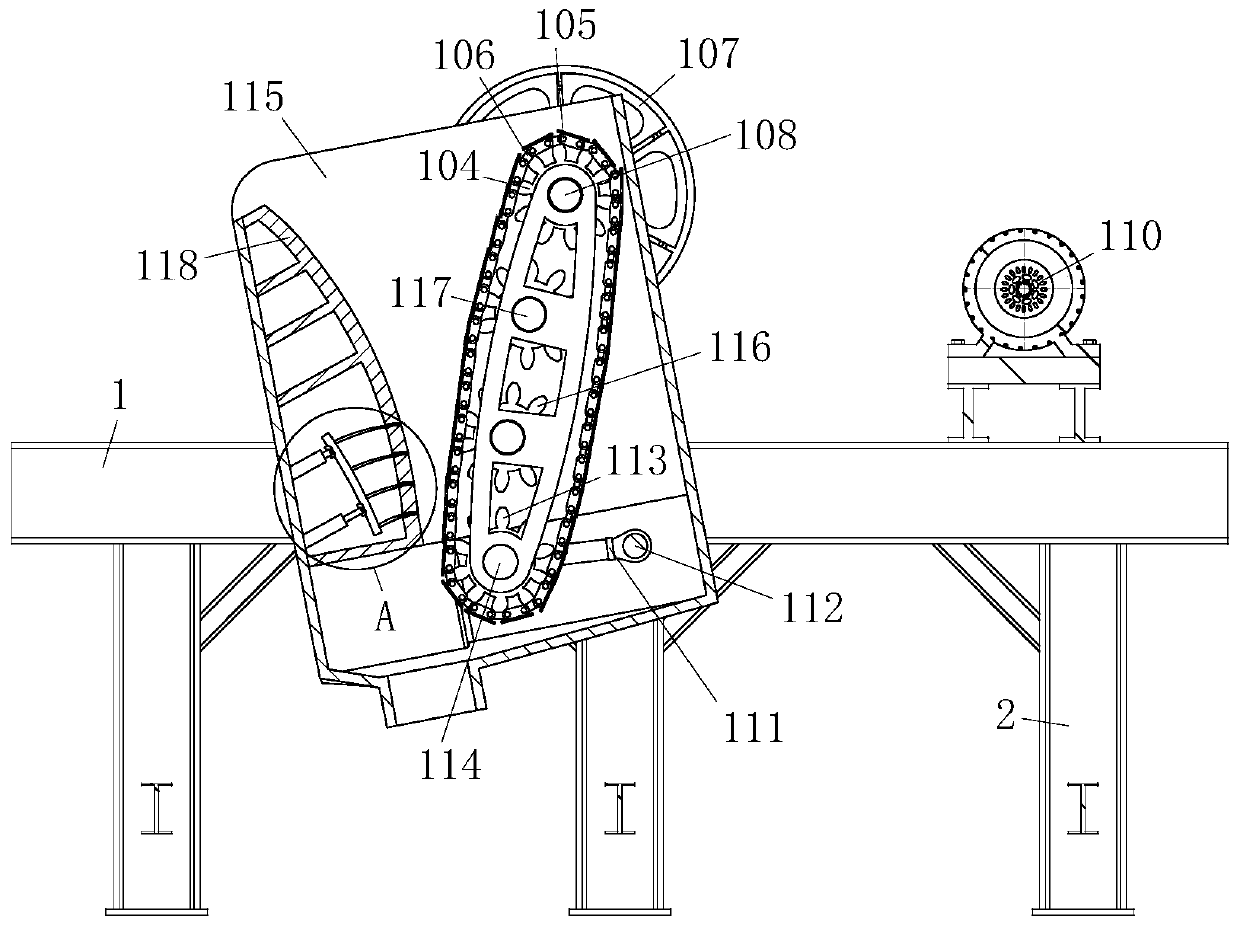

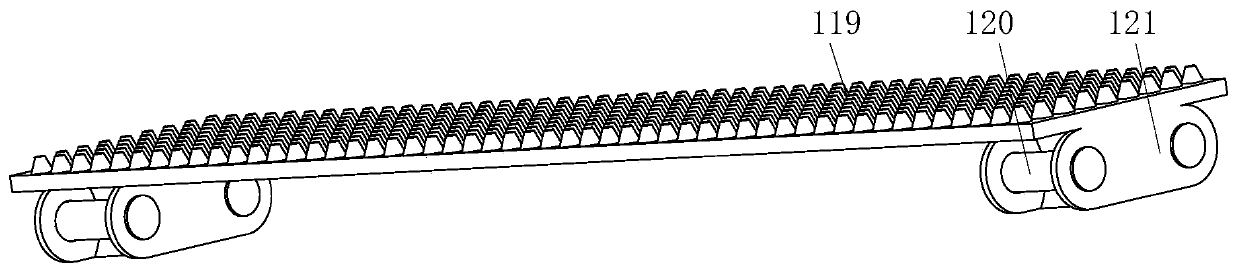

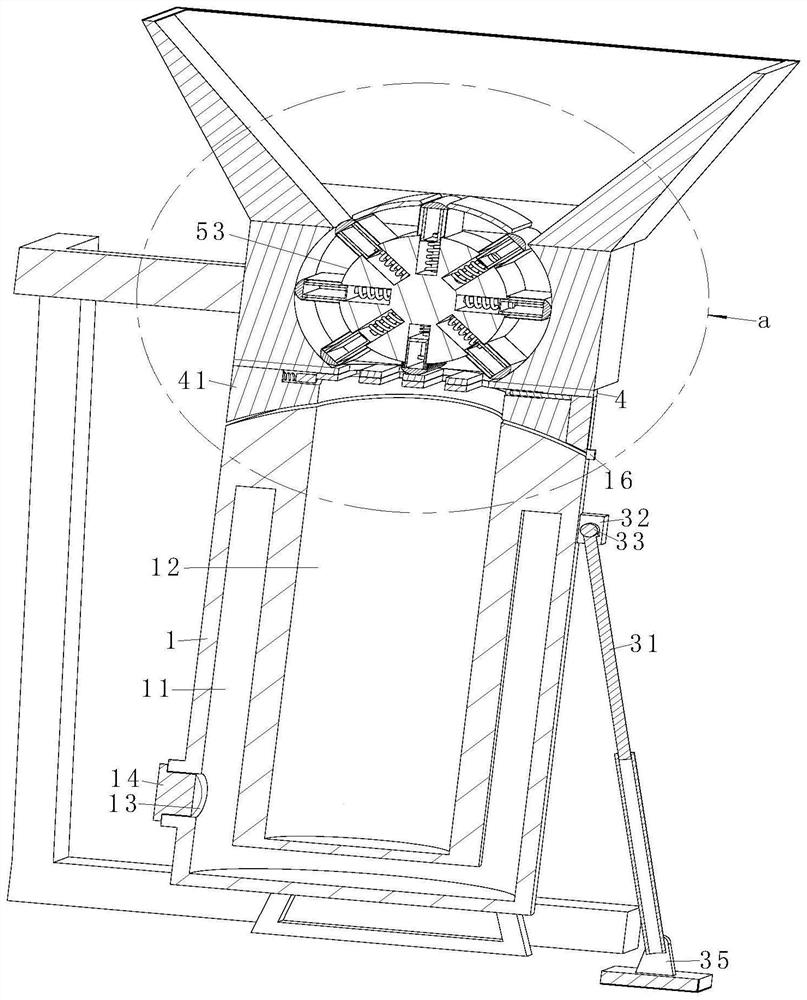

Crushing and screening device for coal mine

The invention belongs to the technical field of coal preparation machine, and particularly relates to a crushing and screening device for a coal mine. The crushing and screening device comprises a hinged crusher, a bracket, a belt conveyor and a parallel vibrating screen, and the hinged crusher comprises a driving shaft support, a box body support, a box body and a motor; both the box body supportand the driving shaft support are welded on the bracket, and the motor is installed on the bracket; and the box body is fixed to the support by a bolt, and the outer wall of the box body is providedwith a controller. According to the crushing and screening device, the crusher can be prevented from being damaged when large and hard gangues or other sundries can not be crushed; it is ensured thatthe crusher works properly, and lump coal can be extruded, split, broken, ground and crushed through a crushing hinge; crushing forms are diversified, and the crushing effect is good; when large-diameter gangues are separated, the falling amount of unbroken lump coal is reduced, and the workload for re-crushing the unbroken lump coal in the later period is reduced.

Owner:ANHUI UNIV OF SCI & TECH

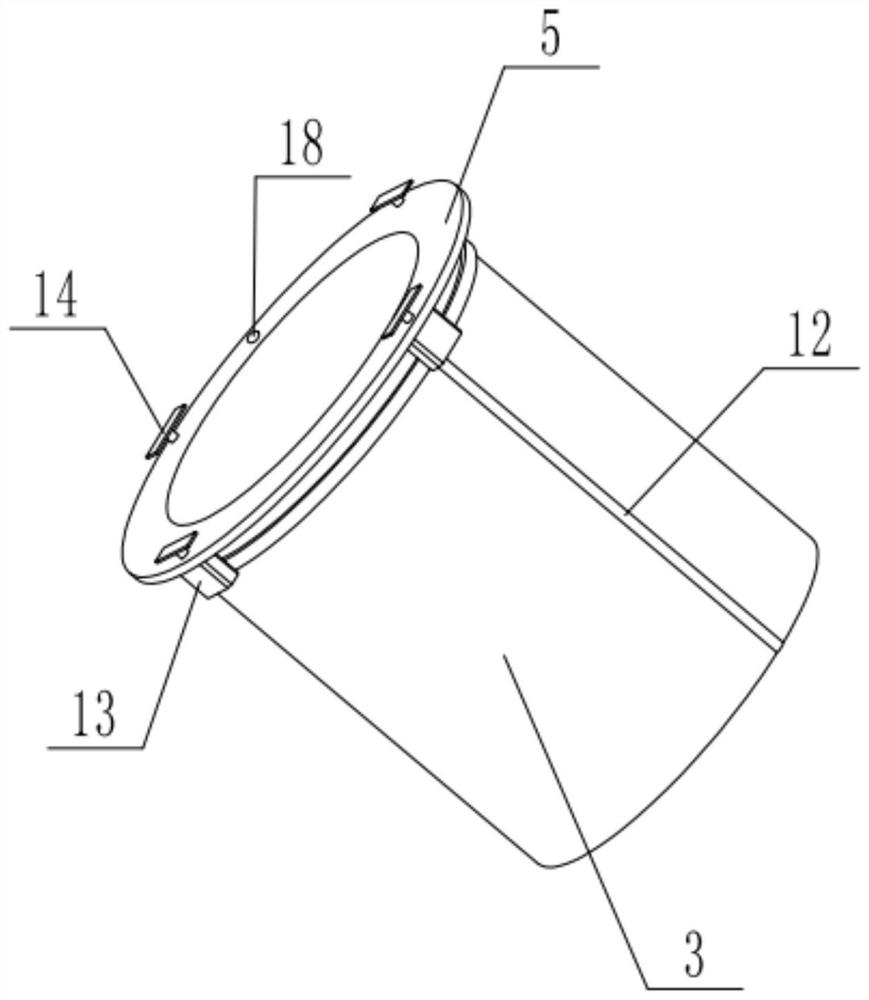

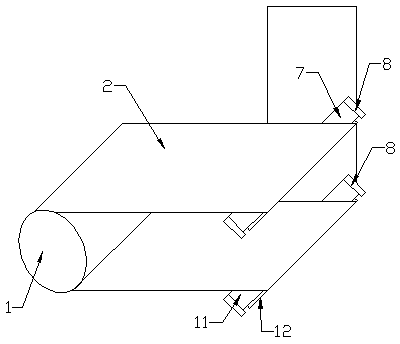

Medium-length hole charging and returned powder recycling device for blasting

PendingCN112880495AReduce the amount of dropImprove recycling efficiencyBlastingPistonEnvironmental geology

The invention relates to the technical field of blasting charging, and particularly discloses a medium-length hole charging and returned powder recycling device for blasting. The medium-length hole charging and returned powder recycling device for blasting comprises a positioning ring and a PLC, wherein the positioning ring can be placed in a blasting hole, an air guide ring is arranged inside the positioning ring, an air pump communicates with the air guide ring, a plurality of clamping pistons communicating with the air guide ring are arranged on the positioning ring, a recycling bag is arranged on the positioning ring, a limiting sleeve is arranged inside the recycling bag in a penetrating mode, a feeding pipe is slidably arranged inside the limiting sleeve, a compaction base is arranged at the end, located inside the blasting hole, of the feeding pipe, an air inlet pipe is arranged on the outer wall of the feeding pipe, a plurality of compaction air cylinders communicating with the air inlet pipe are arranged on the compaction base, the air inlet pipe communicates with the air pump, the compaction air cylinders and the air pump are both electrically connected with the PLC, and the working ends of the compaction air cylinders penetrate through the compaction base and are fixedly connected with auxiliary compaction plates. The medium-length hole charging and returned powder recycling device aims to solve the problem that when explosives are placed in a blasting hole in traditional mining blasting, the explosives are not recycled when falling out of the blasting hole.

Owner:庄培新

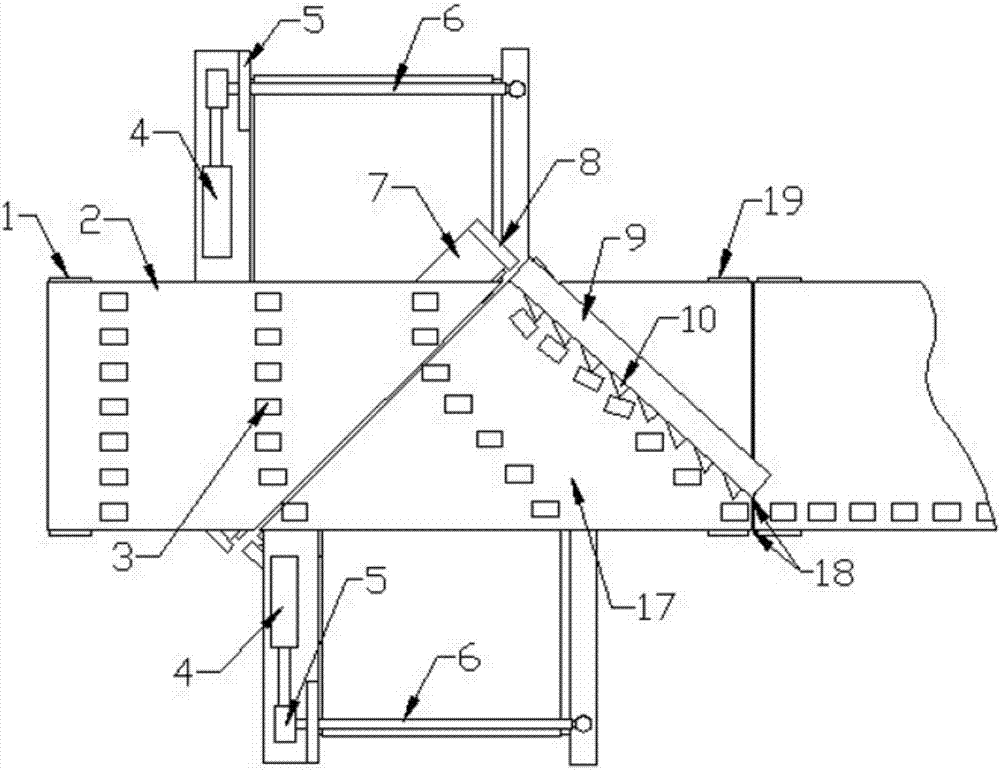

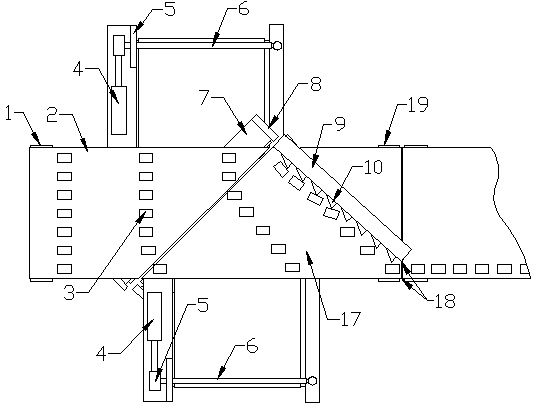

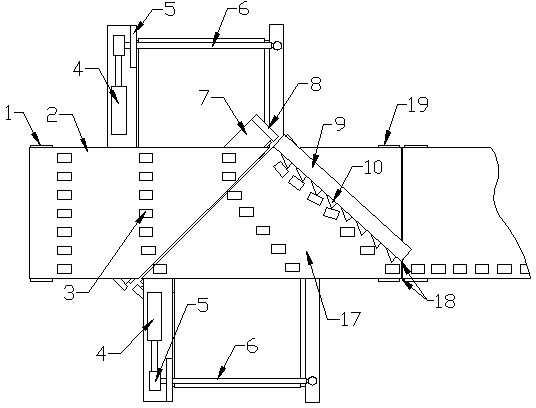

Pillow type packaging line achieving automatic sorting and arranging

InactiveCN107161397AGuaranteed uptimeNo accumulationConveyorsConveyor partsMechanical engineeringMoving speed

The invention discloses an automatic arranging and arranging pillow type packaging line, which solves the problem that the existing packaging line is inconvenient to adjust the direction of the block and the block is prone to fall to the outside of the conveyor belt. Problem, the technical solution adopted: an automatic sorting and arranging pillow packaging line, including a frame, a sorting mechanism and a packaging mechanism. The sorting mechanism includes a number of conveyor belts, driving rollers for moving the conveyor belts, passive rollers and a sorting structure , it is characterized in that, described conveyer belt comprises forward feeding belt and finishing belt, and finishing belt is positioned at the downstream of forward feeding belt; Two upper stop bodies are arranged side by side on frame, and described forward feeding belt and finishing belt are respectively Overlapped on an upper stop body; the upper stop body is arranged obliquely relative to the conveying direction of the conveyor belt; the moving speed of the finishing belt is greater than that of the forward feeding belt; the finishing structure is arranged on the finishing belt On the side, the finishing structure is arranged obliquely relative to the conveying direction of the conveyor belt, and a channel is formed between the finishing structure and one side edge of the finishing belt.

Owner:肇庆市端州区澳蒋科技有限公司

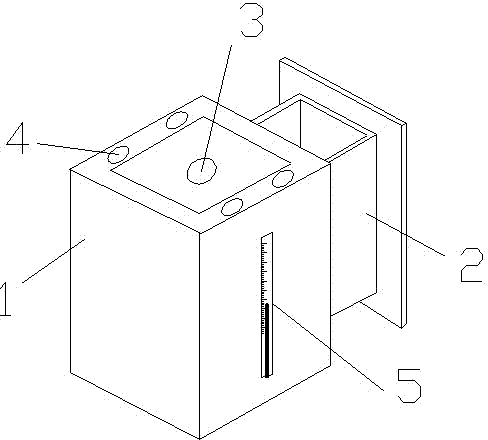

Anti-dust type pen barrel

InactiveCN103481710AReduced drop amountReal-time display of temperatureWriting accessoriesMechanical engineeringElectrical and Electronics engineering

The invention discloses an anti-dust type pen barrel which comprises a hollow barrel body, wherein an opening is formed in one side end surface of the hollow barrel body; a drawer capable of moving relative to the hollow barrel body is arranged at the opening; a through hole communicated with a hollow part is formed in the top of the hollow barrel body. By only remaining a through hole for storing a pen at the top of the barrel body of the pen barrel, when the pen in the pen barrel needs to be used again, the pen can be taken out by pulling out the drawer, so that the amount of fallen dust is greatly reduced; some frequently used pens can be inserted in pen holes in the barrel wall and do not need to be taken out of the drawer each time; an environmental temperature can be displayed in real time through a temperature meter to prompt a user.

Owner:王益明

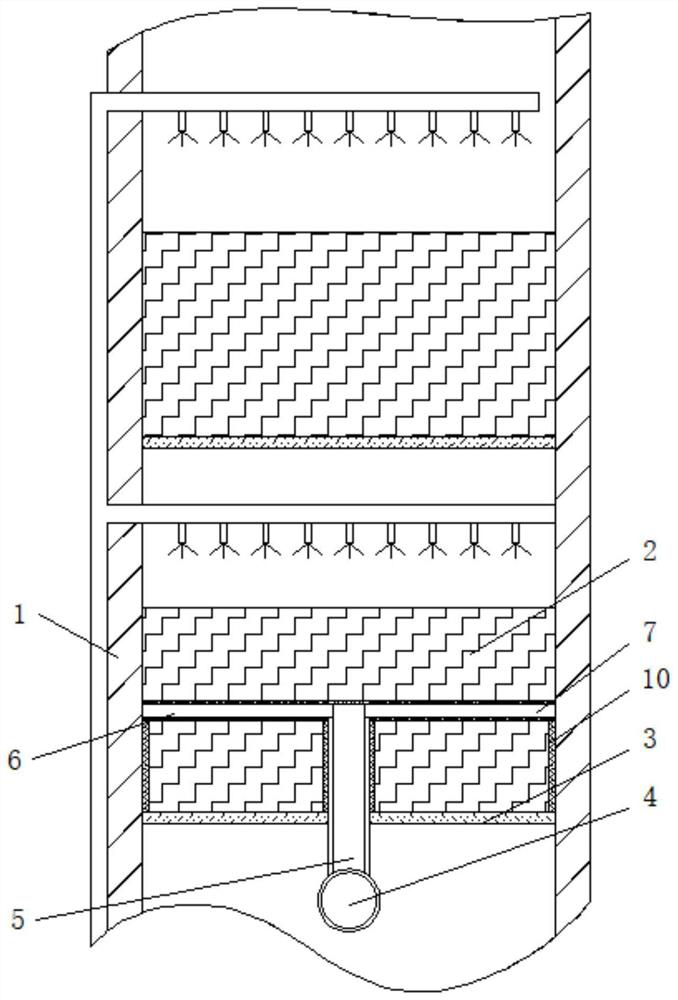

Organic waste gas filler absorption tower

InactiveCN113083001AImprove degradation efficiencyAvoid shockDispersed particle separationAir quality improvementBiofilmMicroorganism

The invention relates to the technical field of energy conservation and environmental protection, and discloses an organic waste gas packing absorption tower which comprises an absorption tower shell, a packing layer is fixedly installed in the absorption tower shell, a bearing plate is fixedly installed at the bottom of the packing layer and mainly used for bearing the packing layer, and an air pipe is arranged on the outer side of the absorption tower shell. According to the invention, an air pipe orifice which distributes air directly at the bottom of the filler layer originally extends into the filler layer through the through pipe, so that waste gas flow is prevented from directly impacting a microbial film at the bottom of the filler layer, and the probability that microorganisms at the bottom of the filler layer fall off is reduced; a biological film is impacted by up and down tubes, the falling amount of organisms at the upper end is reduced under the effect of adsorption force among the microorganisms at the lower end, and the microorganisms at the lower end are relatively large in friction force due to the action of adsorption force among the microorganisms, so that even if the microorganisms are subjected to gas-phase impact, the adsorption force among the microorganisms can also improve the wall hanging effect, and the degradation efficiency of the bottom of the filler layer is effectively improved.

Owner:董兆礼

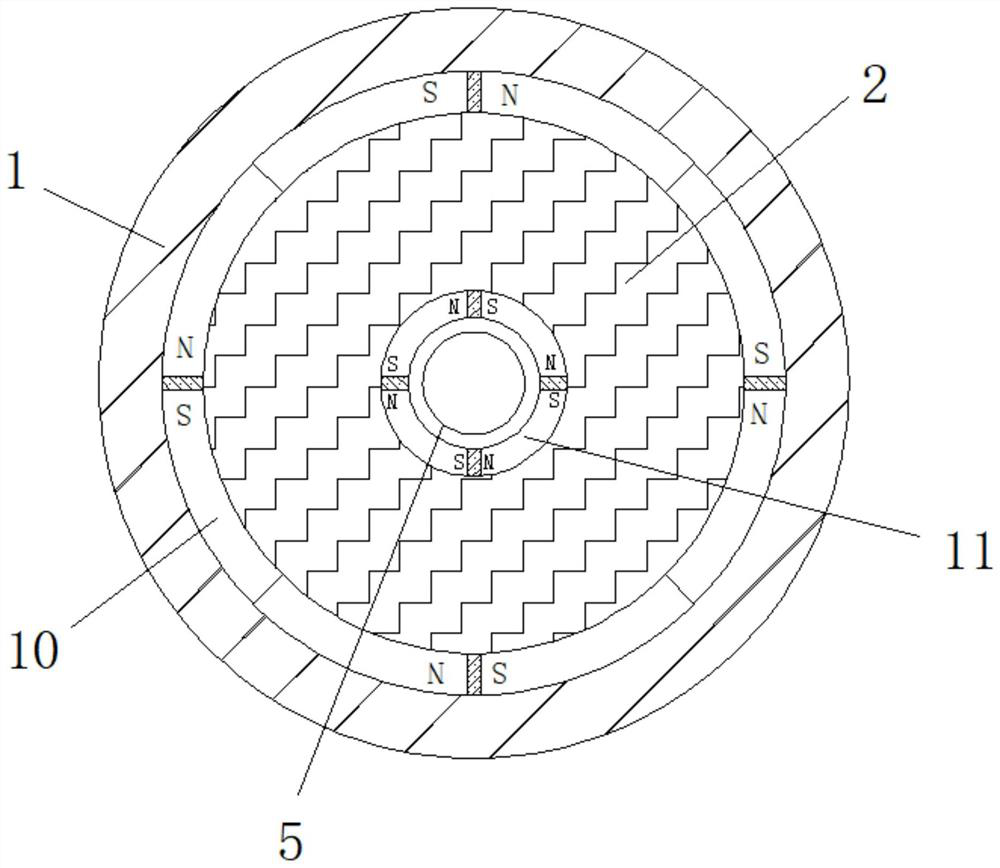

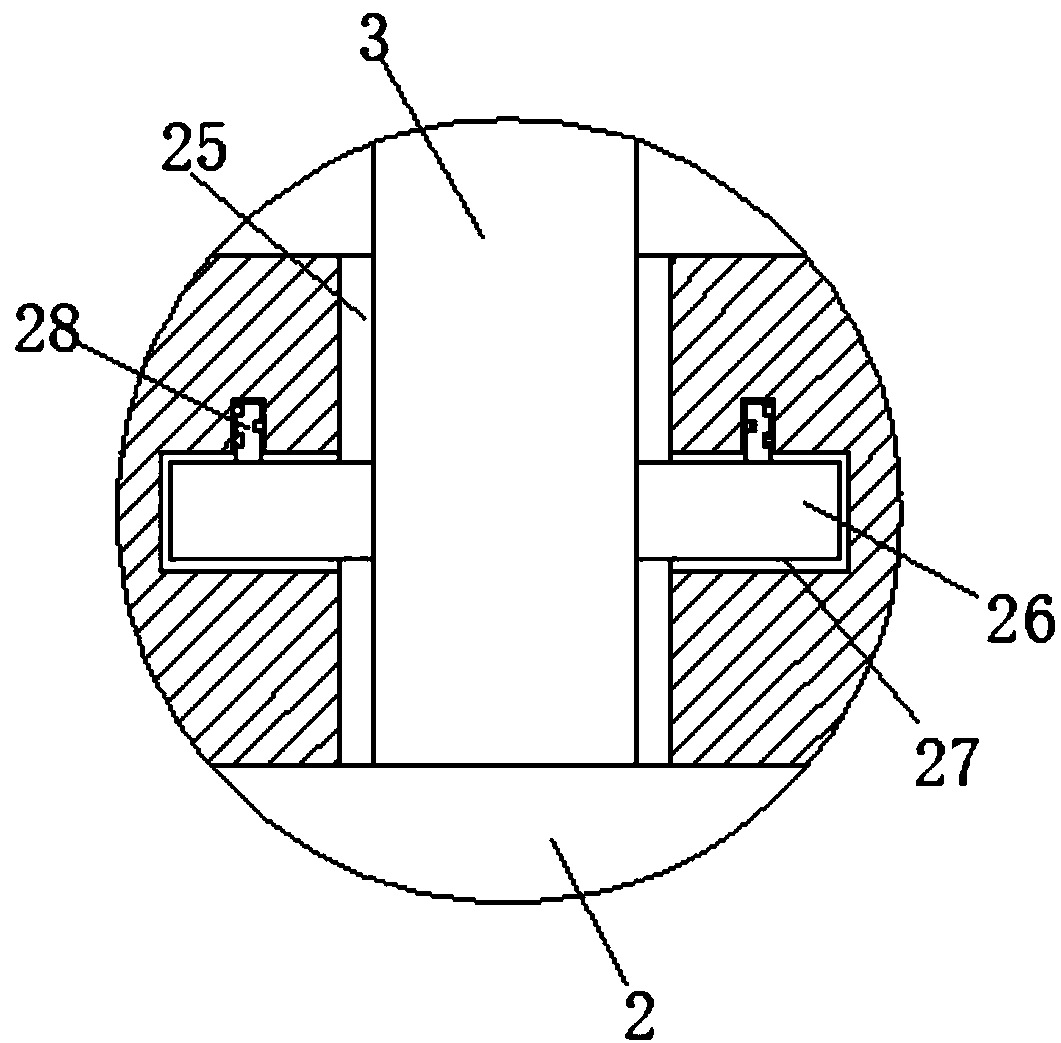

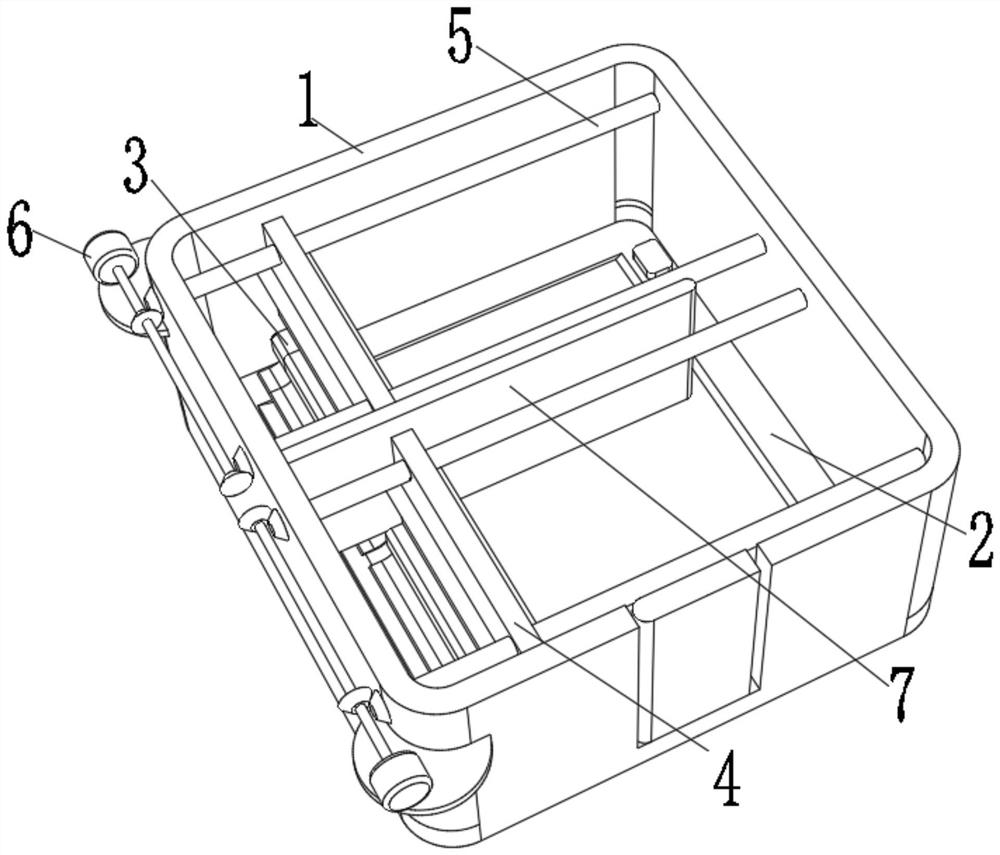

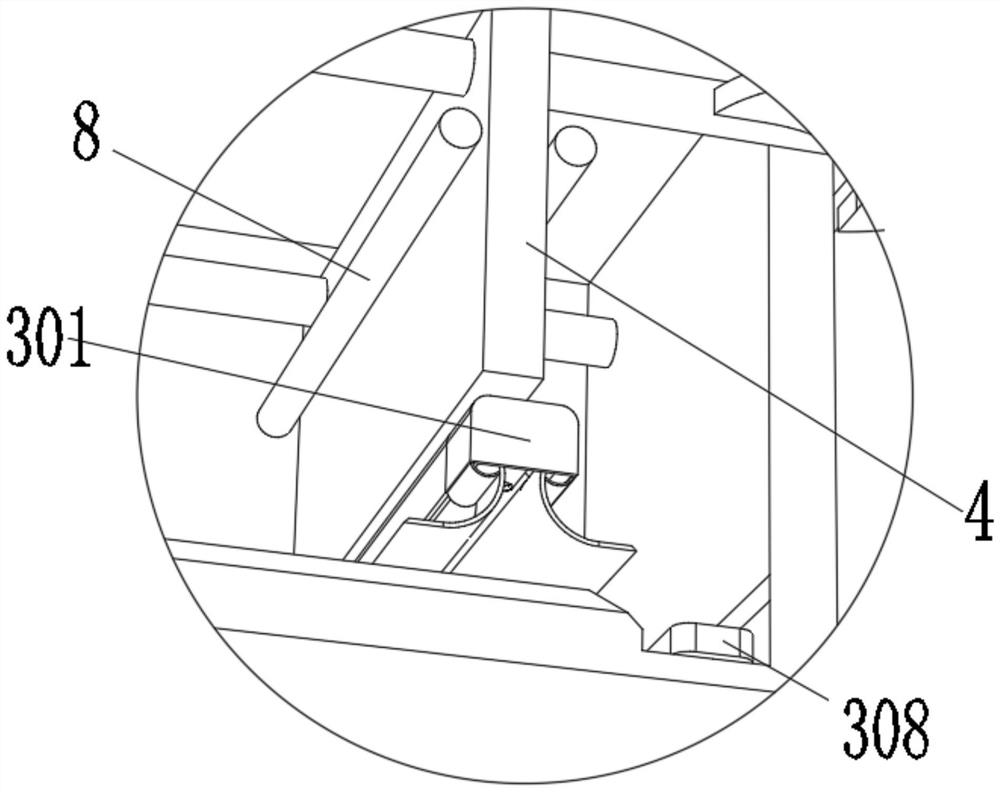

Coaxial annular feed trough transferring device

PendingCN108739467AReduced drop amountReduce automationAnimal feeding devicesEngineeringMechanical engineering

The invention discloses a coaxial annular feed trough transferring device which comprises a feeding base, wherein a mounting groove is formed in the bottom of the feeding base; a first servo motor ismounted inside the mounting cavity; a rotating rod is mounted at the driving end of the first servo motor; a conveying pipeline is arranged on the upper side of the mounting cavity; a discharge pipeline is arranged on the upper side of the conveying pipeline; the rotating rod penetrates through the top wall inside the mounting cavity and is inserted into the top wall inside the discharge pipeline;a vertical conveying helix and a discharge helix are respectively mounted on the rotating rod; the vertical conveying helix is positioned inside the conveying pipeline. The coaxial annular feed trough transferring device is simple in structure and easy to achieve, feed can be uniformly fed through the coaxial annular feed trough transferring device smartly, meanwhile the feeding amount of the feed can be detected and controlled by using a controller, automatic operation of feed feeding can be effectively achieved, labor investment can be reduced, and the coaxial annular feed trough transferring device is efficient and convenient and wide in application range.

Owner:安徽良木农业发展有限公司

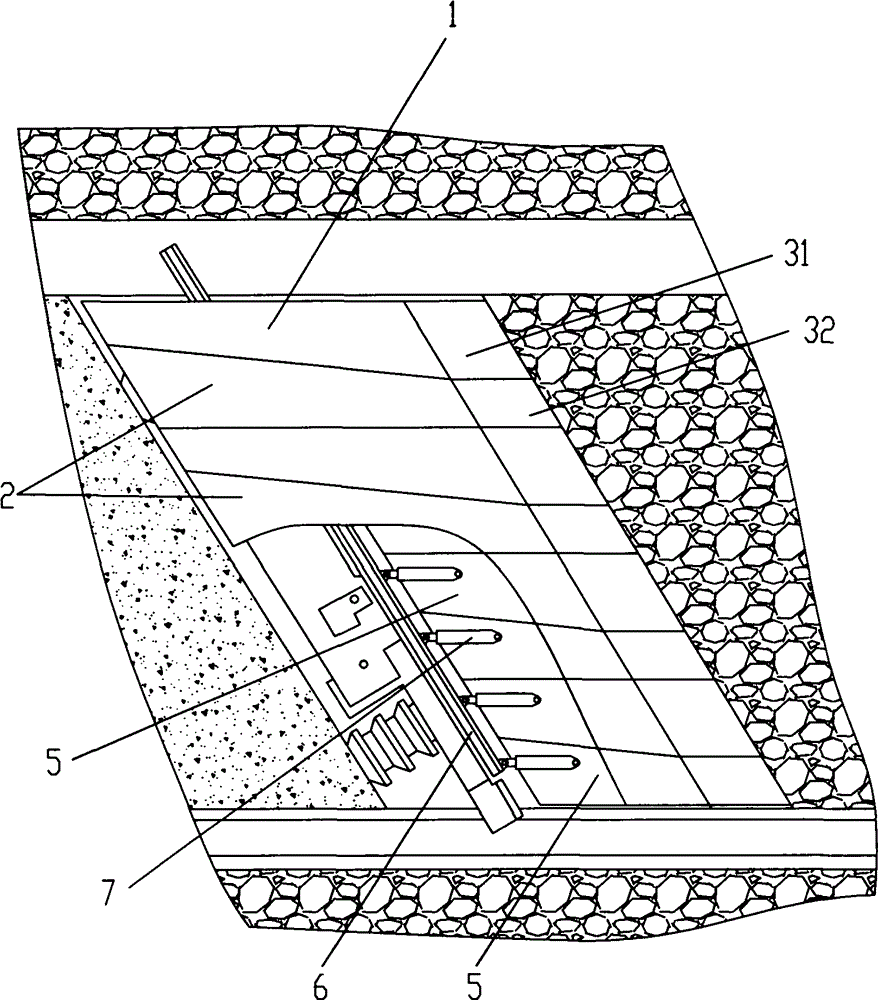

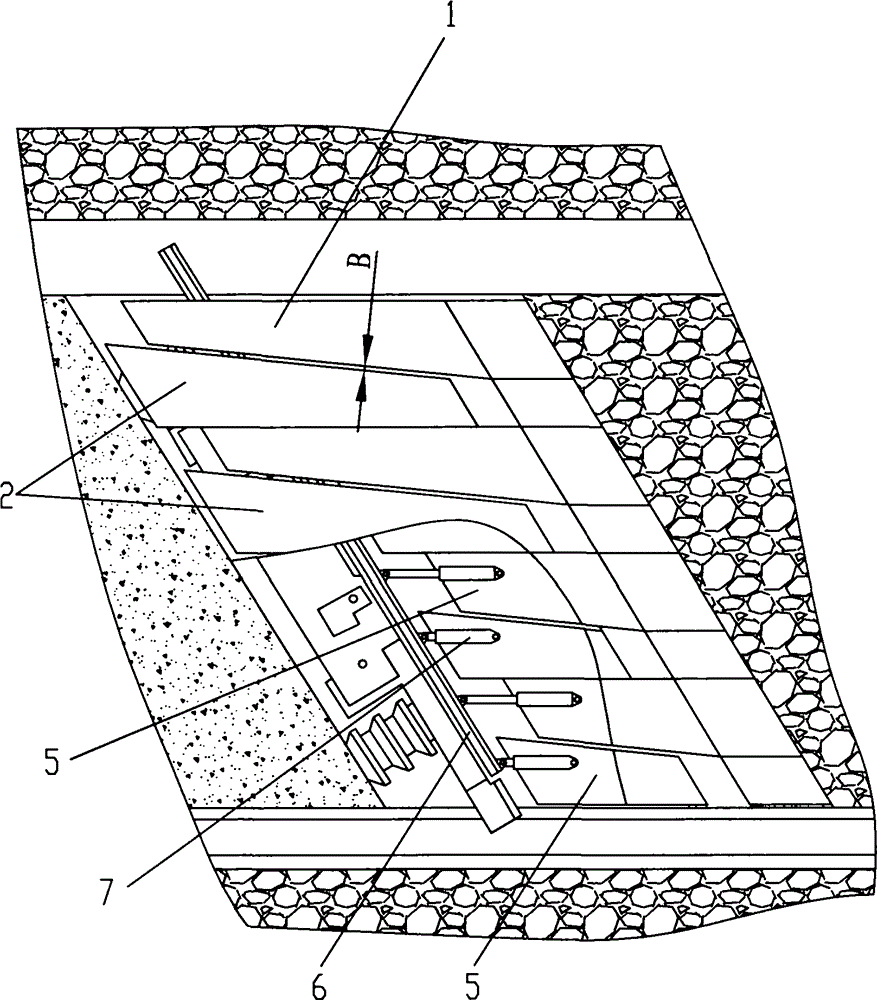

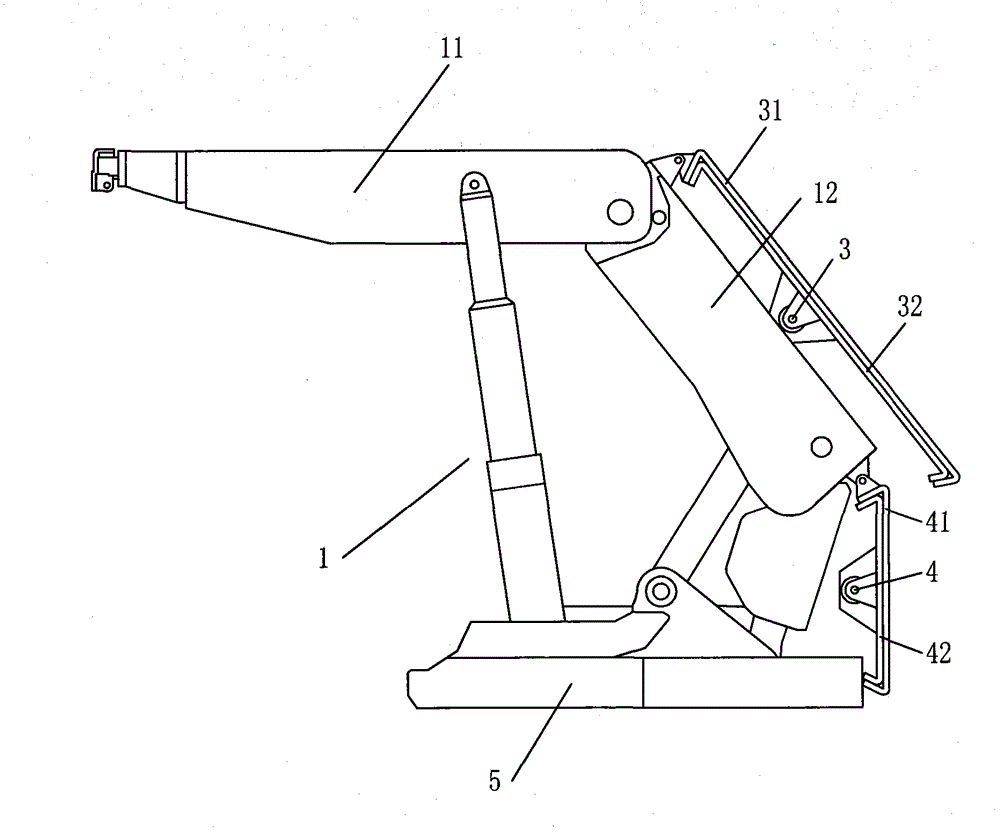

Shield support and support method for bow pseudo-inclined fully mechanized coal mining face

InactiveCN104314598AReduce propulsion energy consumptionEnsure support stabilityMine roof supportsCoal miningMining engineering

The invention discloses a shield support and a support method for a bow pseudo-inclined fully mechanized coal mining face. The fully mechanized coal mining support takes the shape of an overlook parallelogram which is constituted by first trapezoidal hydraulic supports and second trapezoidal hydraulic supports in pairs; the first hydraulic supports are positioned above the second hydraulic supports; the rear ends of the first hydraulic supports are provided with waste rock stop devices of which the waste rock stop amplitude in the height direction increases and decreases along with rise and fall of a top beam of the first hydraulic supports; the waste rock stop devices have waste rock stop width extending to the support width of the second hydraulic supports. The method comprises the steps of arranging the shield support, supporting, pushing and advancing the support, wherein the step of arranging the shield support comprises a sub-step of arranging a plurality of shield supports in the bow pseudo-inclined fully mechanized coal mining face, so that the waste rock stop devices of the first hydraulic supports are positioned on the rear sides of the second hydraulic supports to form stop for waste rocks at gobs on the rear sides of the shield supports. The shield support and the support method have the beneficial effects that the supports are formed in pairs and the waste rock stop devices are formed on the upper supports, and the shield support method guarantees stable supporting in a sequential descending and ascending staggered advancing mode.

Owner:四川省华蓥山煤业股份有限公司李子垭南煤矿

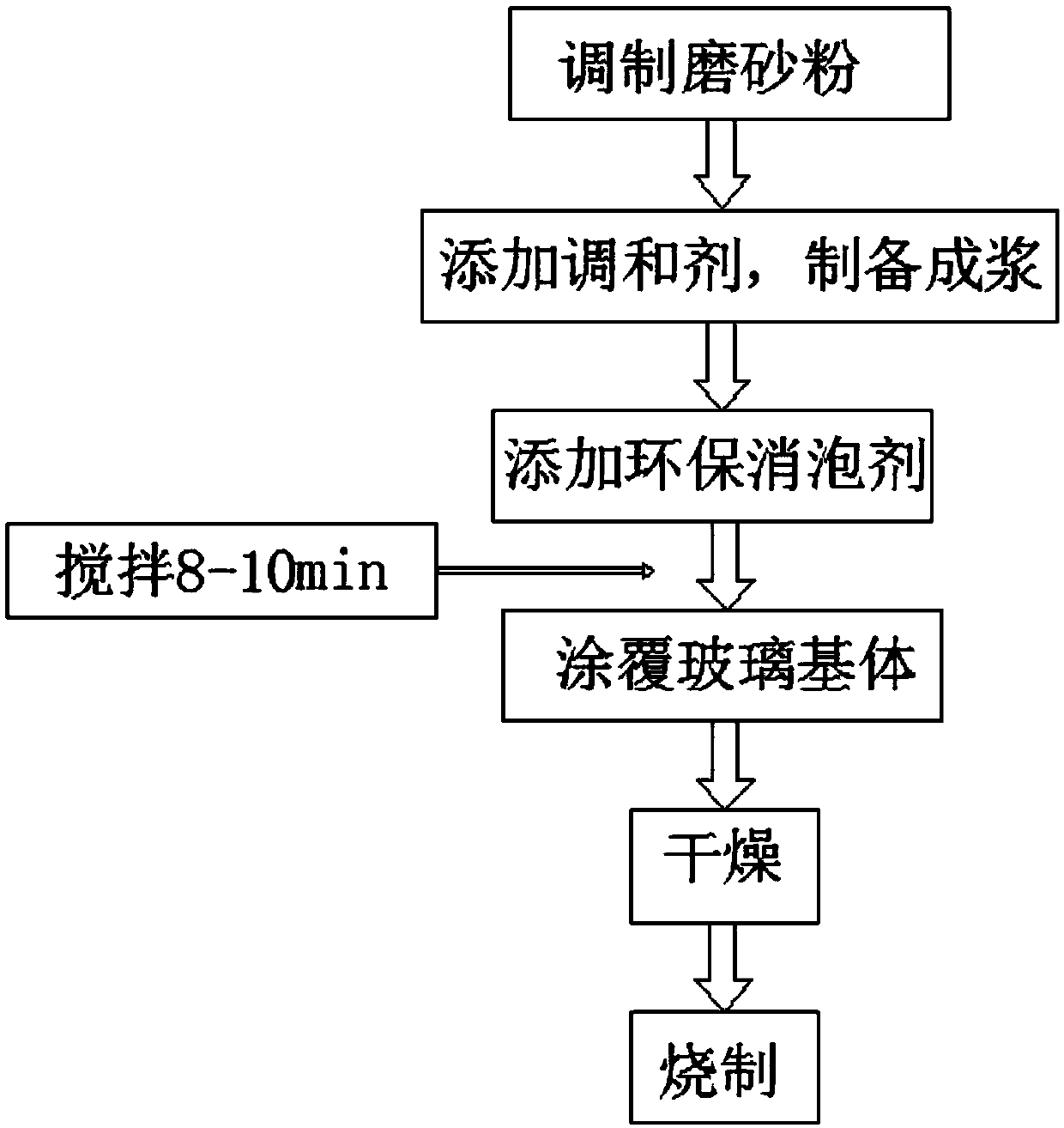

Preparation method for frosted glass

InactiveCN109604123AHigh densityImprove preparation qualityPretreated surfacesCoatingsFrosted glassAir bubble

The invention discloses a preparation method for frosted glass, and belongs to the field of glass processing. The preparation method for the frosted glass comprises the following steps that S1, frosted powder is proportioned and prepared; S2, a blender is added into the proportioned and prepared frosted powder so as to prepare the pulp; S3, the frosted powder pulp coats a glass base body by usingmultiple defoaming brushes, and drying is performed; and S4, the dried glass base body with the frosted powder pulp is placed into a toughening furnace or a roller kiln to be sintered. The multiple defoaming brushes comprise powder pulp cylinders and brush heads, detachable connecting pieces are connected between the powder pulp cylinders and the brush heads, the pulp cylinders are used for loading the frosted powder pulp, the surface of the glass base body is coated through the brush heads, the detachable connecting pieces are convenient to detach, replace and clean, multiple defoaming can beperformed on the frosted powder pulp in the coating process through the multiple defoaming brushes, residual air bubbles in the frosted powder pulp can be effectively reduced, the density of the coating layer can be improved so that the preparation quality of the frosted glass can be improved.

Owner:李丹

Method for processing and packaging chrysanthemum tea

The invention discloses a method for processing and packaging chrysanthemum tea. In the conventional processing and packaging method, the drop amount of petals is large and the preservation time is short. The method for processing and packaging chrysanthemum tea comprises the following steps of: selecting the picked chrysanthemum, and removing metamorphic and incomplete chrysanthemum; cooking the chrysanthemum for 8-15 minutes, and drying for 6-10 hours through hot wind airflow so as to enable the water content to be 10-15%; sorting the chrysanthemum based on the quality and encapsulating into plastic packaging bags; introducing nitrogen equal to 1-2 barometric pressure into the plastic packaging bags. By adopting the processing and packaging method, the drop amount of petals is small, and the preservation time is long.

Owner:KUNSHAN HAOLIDA PACKING CO LTD

Preparation method of crisp broad beans

The invention discloses a preparation method of crisp broad beans. The method includes the following steps: (1) pretreatment; (2) flavoring; (3) freezing; (4) frying; (5) slurry coating; (6) residue sieving; and (7) detection. The processing method of the present invention can reduce the drop amount of broad bean crumbs during the packaging of broad bean finished products after residue sieving treatment.

Owner:QINGDAO JINLONGYI FOOD

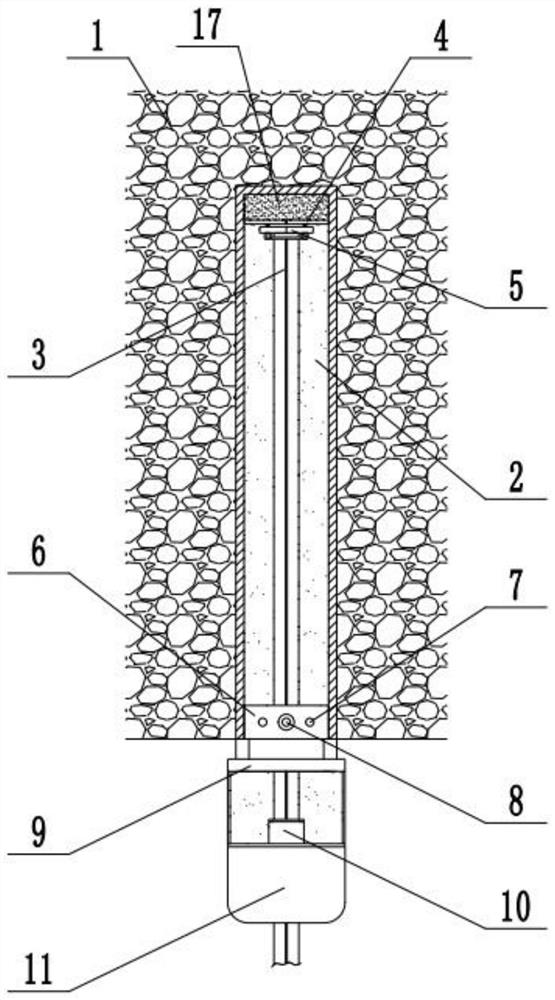

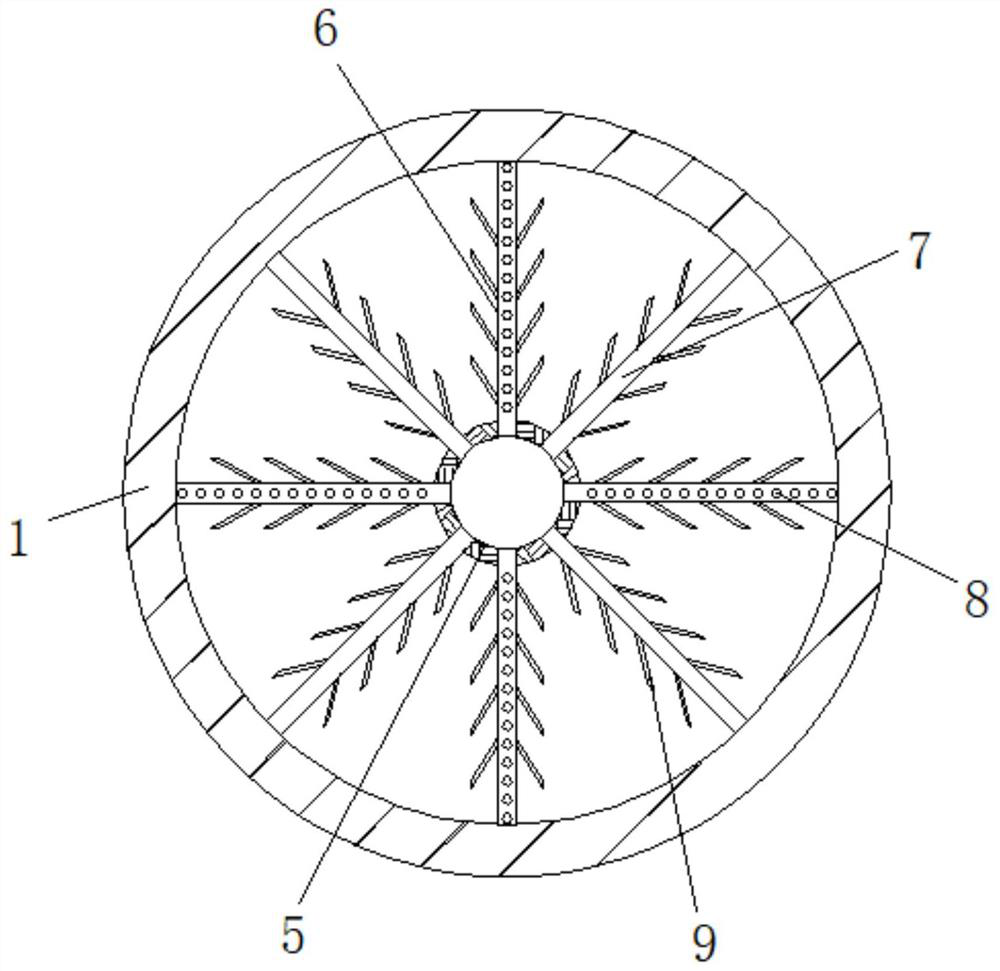

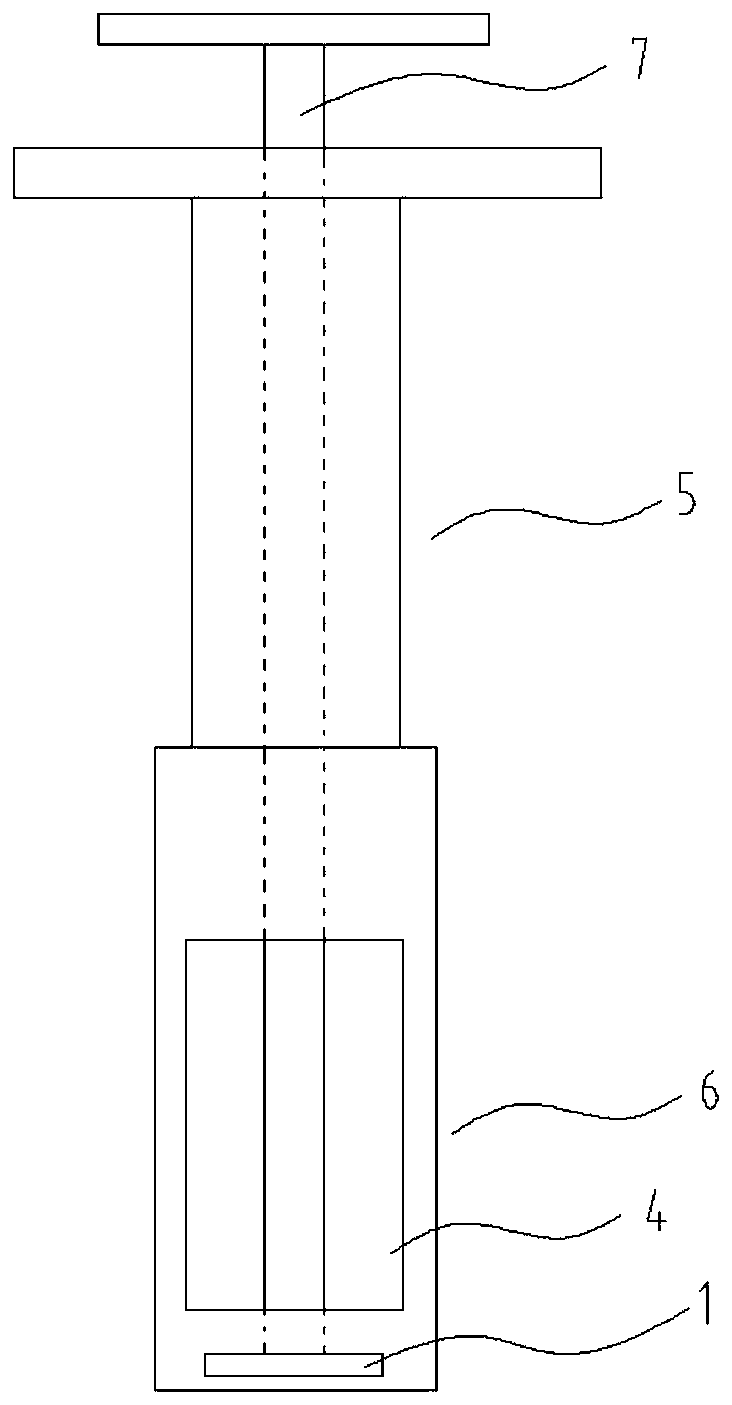

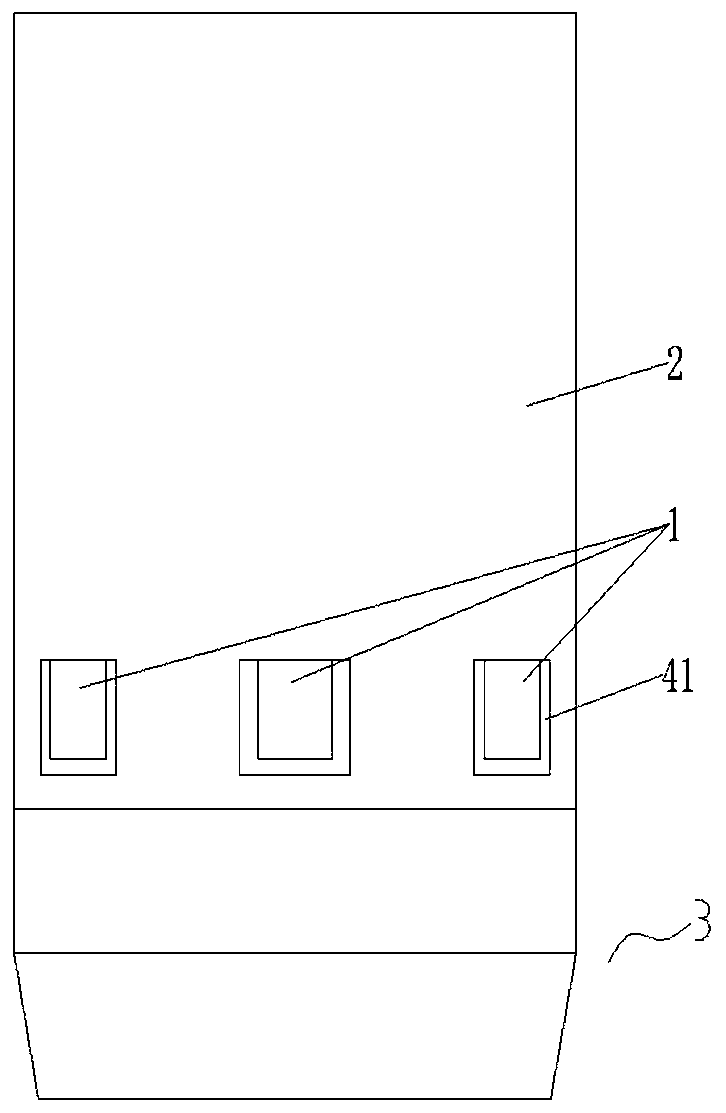

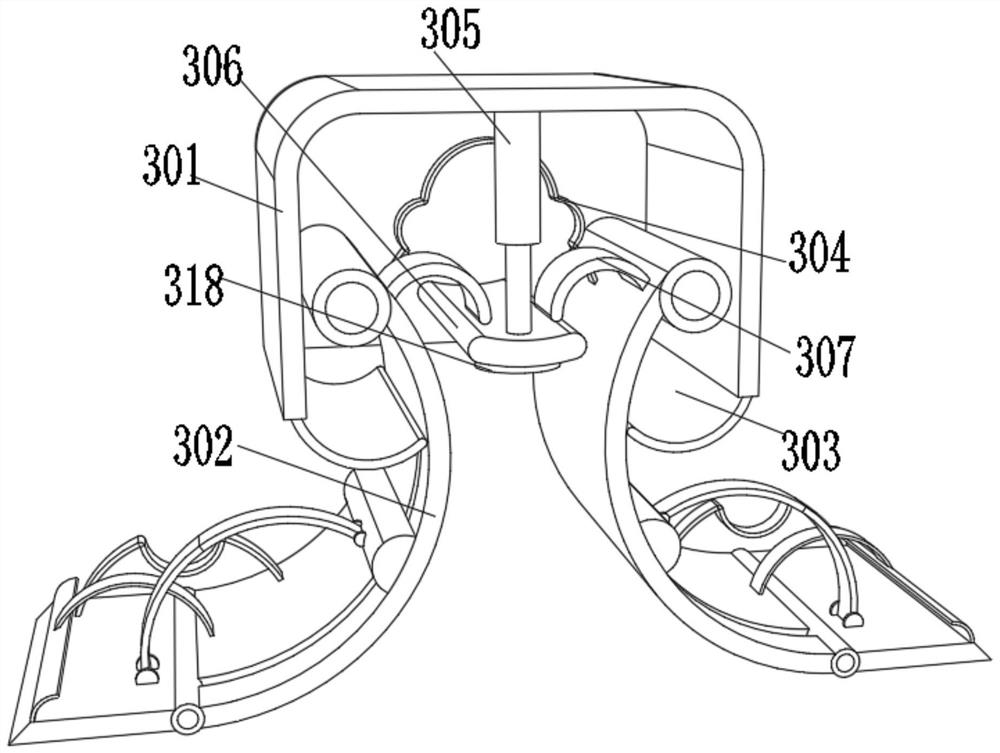

Telescopic drill bit for collecting columnar soil samples and soil collection method

PendingCN111473996AReduced drop amountImprove soil extraction efficiencyWithdrawing sample devicesSoil scienceEngineering

The invention discloses a telescopic drill bit for collecting columnar soil samples and a soil collection method. Columnar soil sample collection can be realized, automatic blocking of the blocking piece can be realized and soil drop can be reduced. The telescopic drill bit comprises a hollow columnar shell with an opening in the bottom, blocking pieces for preventing soil from falling out is arranged in the shell, and the blocking pieces are rotationally arranged in the shell; shell is of a telescopic structure and comprises a fixed shell and a movable shell arranged in the fixed shell in a sleeved mode. The movable shell and the fixed shell are relatively telescopically connected; a plurality of blocking pieces are uniformly and circumferentially arranged along the side wall of the shell; one end of the blocking pieces is rotationally arranged on the side wall of the shell and rotates under the telescopic effect of the movable shell so that the other end of the blocking pieces is enabled to block in the middle of the shell; the soil collection method comprises the steps that soil enters the shell along the opening in the bottom of the shell, the shell generates driving force during telescopic movement, the blocking piece rotates under the action of the driving force, and when the blocking piece rotates downwards to be in an open state, the soil is blocked in the shell.

Owner:江苏华东地质工程有限公司(江苏省有色金属华东地质勘查局八一〇队)

Automatic cleaning and pollution discharge room for pig raising

InactiveCN114532235AGood for fallingAvoid manual cleaningAnimal housingPig breedingMechanical engineering

The invention discloses an automatic cleaning and pollution discharge room for pig raising, and relates to the technical field of pig raising devices. The automatic cleaning and pollution discharge room for pig raising comprises a room body, a pollution discharge groove with an inclined edge is formed in the edge of the ground of the room body and communicated with the room body, a partition plate is fixedly connected to the center of the room body, driving plates are arranged in the room body and located on the two sides of the partition plate, and when the driving plates move, the driving plates are driven to rotate. A collecting plate is attached to the ground of the room body, then pig manure is collected into the collecting plate, the link of manual pig manure cleaning is avoided, when a driving plate moves to a sewage discharging groove, through magnetic repulsive force of a first magnetic part and a second magnetic part, an extrusion plate upwards pushes an extrusion frame, and then the collecting plate rotates; the pig manure collected above the collecting plate can conveniently fall into the dirt discharge groove, so that the pig manure can be discharged out of the house body through the dirt discharge groove, and the pig manure and impurities in the house body can be automatically cleaned.

Owner:衡阳宏鑫农业发展有限公司

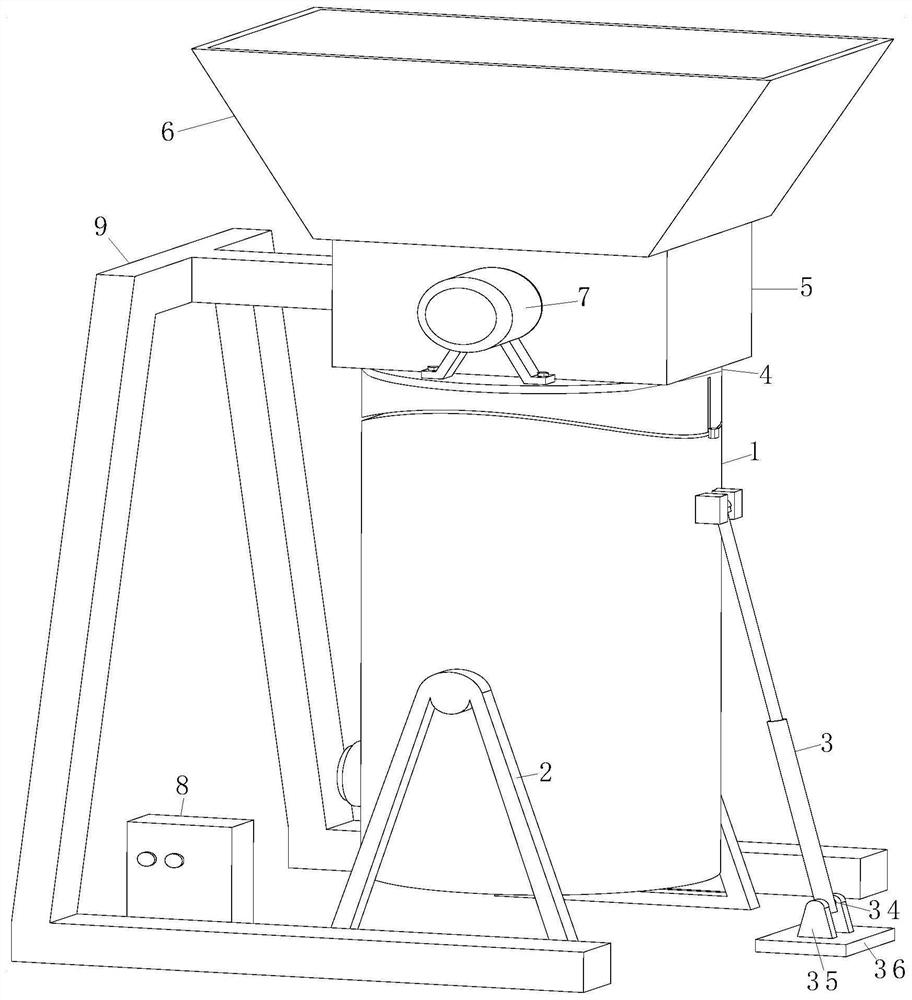

Aluminum profile smelting furnace

InactiveCN114440634AReduce labor intensityIncrease productivityCrucible furnacesThermodynamicsCombustion chamber

The invention relates to the field of aluminum profile smelting furnaces, in particular to an aluminum profile smelting furnace which comprises a smelting furnace body, a combustion chamber, a smelting chamber and a fuel port are formed in the smelting furnace body, a plug is inserted into the fuel port, and a wedge block is fixed to the outer wall of the smelting furnace body. The outer wall of the smelting furnace body is rotationally connected with two tripods through two first shafts correspondingly, a telescopic rod device is installed on the outer wall of the smelting furnace body, a monitoring device is installed above the smelting furnace body, a discharging device is installed above the monitoring device, a motor is installed on one side of the discharging device, and a discharging device is installed above the motor. A frame is installed on the other side of the discharging device, a hopper is installed above the discharging device, an electric cabinet is installed on one side of the frame, and the monitoring device can control whether aluminum profiles need to be added into the smelting chamber or not by monitoring whether the smelting furnace body turns over or not. The discharging device can control the falling amount of the aluminum profiles in the hopper.

Owner:杨柳

Pulverizer for fine grinding of cosmetic raw materials

The invention relates to the technical field of cosmetic production and processing, and discloses a pulverizer for fine grinding of cosmetic raw materials, a conical head is fixedly mounted in the middle of the top wall of a grinding cavity, a crushing cylinder is fixedly mounted at the bottom of the conical head in a machine body, and a guide ring is fixedly mounted at the bottom of a double-shaft motor on the inner wall of the machine body; a rotating rod is fixedly installed in the machine body, guide rods are fixedly installed at the bottoms of the two ends of the rotating rod, a discharging ring is fixedly connected to the bottom end of the double-shaft motor, guide openings are symmetrically formed in the two sides of the bottom of the discharging ring, an inner ring of the discharging ring is movably sleeved with an adjusting disc, and an electromagnet is fixedly installed on the inner top wall of the discharging ring. And a material guide ring is arranged at the bottom of the crushing barrel, a rotating rod and a discharging ring are installed at the bottom of the double-shaft motor, a movable cavity is formed in the grinding disc, and a strip-shaped magnet is installed in the movable cavity to be matched with a cylindrical magnet, so that the grinding quality and effect are improved, and the service life of the grinding roller is prolonged.

Owner:葛军辉

Mining filter

PendingCN114768337AImprove work efficiencyAvoid failureStationary filtering element filtersInlet valveElectric machinery

The invention belongs to the technical field of filters, and particularly relates to a mining filter which comprises a box body, a fixed cylinder is fixedly arranged at the upper end of the box body, an inlet valve is fixedly arranged at the upper end of the fixed cylinder, and an impurity removal part is arranged in the fixed cylinder; the impurity removal part comprises a motor, the motor is fixed to the lower end of the interior of the fixed cylinder, a rotating column is fixedly arranged at the upper end of the motor, the circumferential surface of the rotating column is sleeved with a rotating disc, a centrifugal cavity is formed in the rotating disc, two filtering plates are fixedly arranged on the portions, on the two sides of the centrifugal cavity, in the rotating disc, and two impurity removal cavities are formed in the portions, on the two sides of the rotating disc, in the fixed cylinder; and two channels are connected between the two impurity removal cavities and the centrifugal cavity. Large impurities in water can be quickly removed and blocked while water is driven to uniformly fall, filter cotton cloth is cleaned in time and recycled, the water falling amount is reduced while the filter cotton cloth is replaced, water is continuously filtered, and the water quality is improved. And the working efficiency is improved, and the processing quality is ensured.

Owner:瑞安市皓威机械有限公司

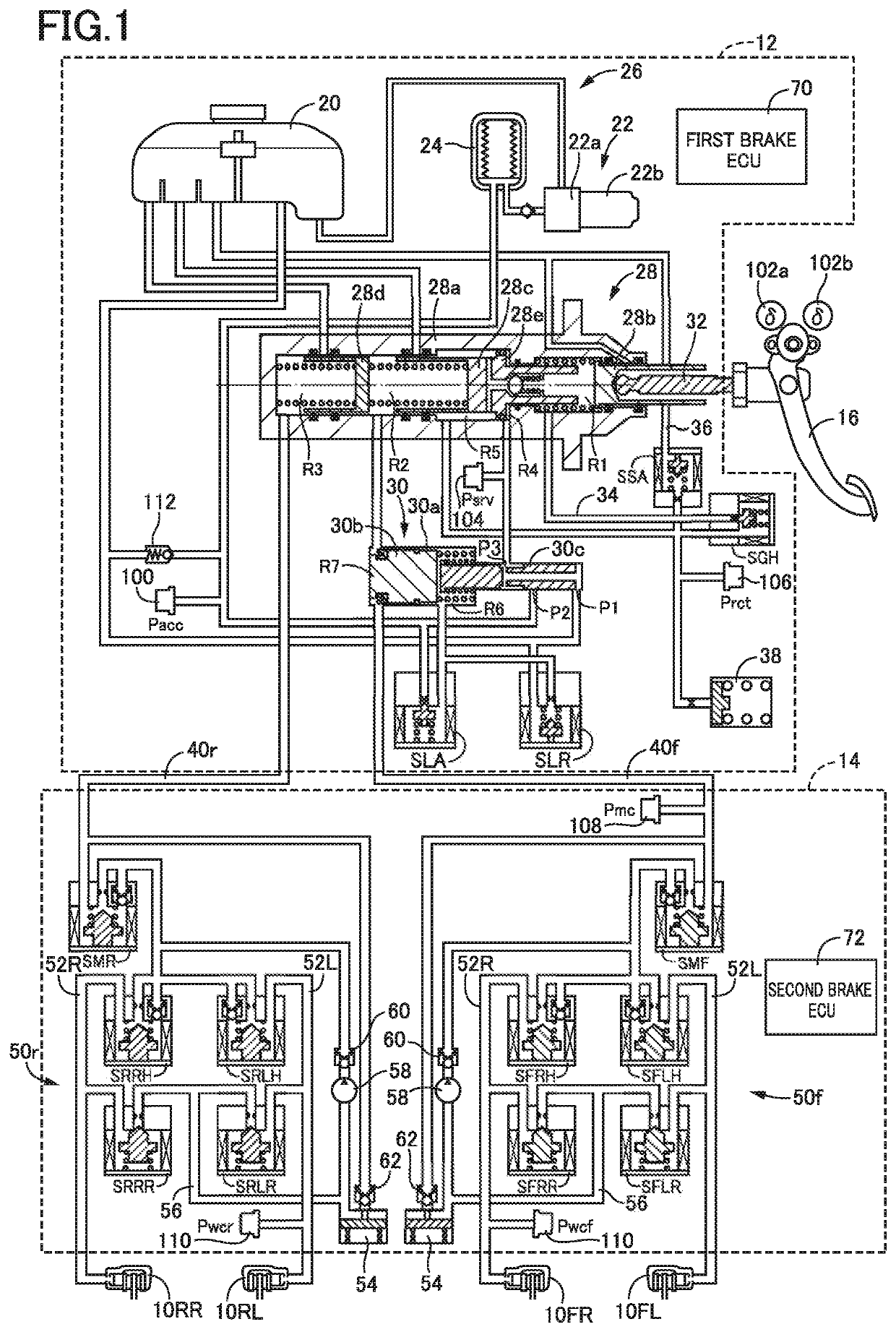

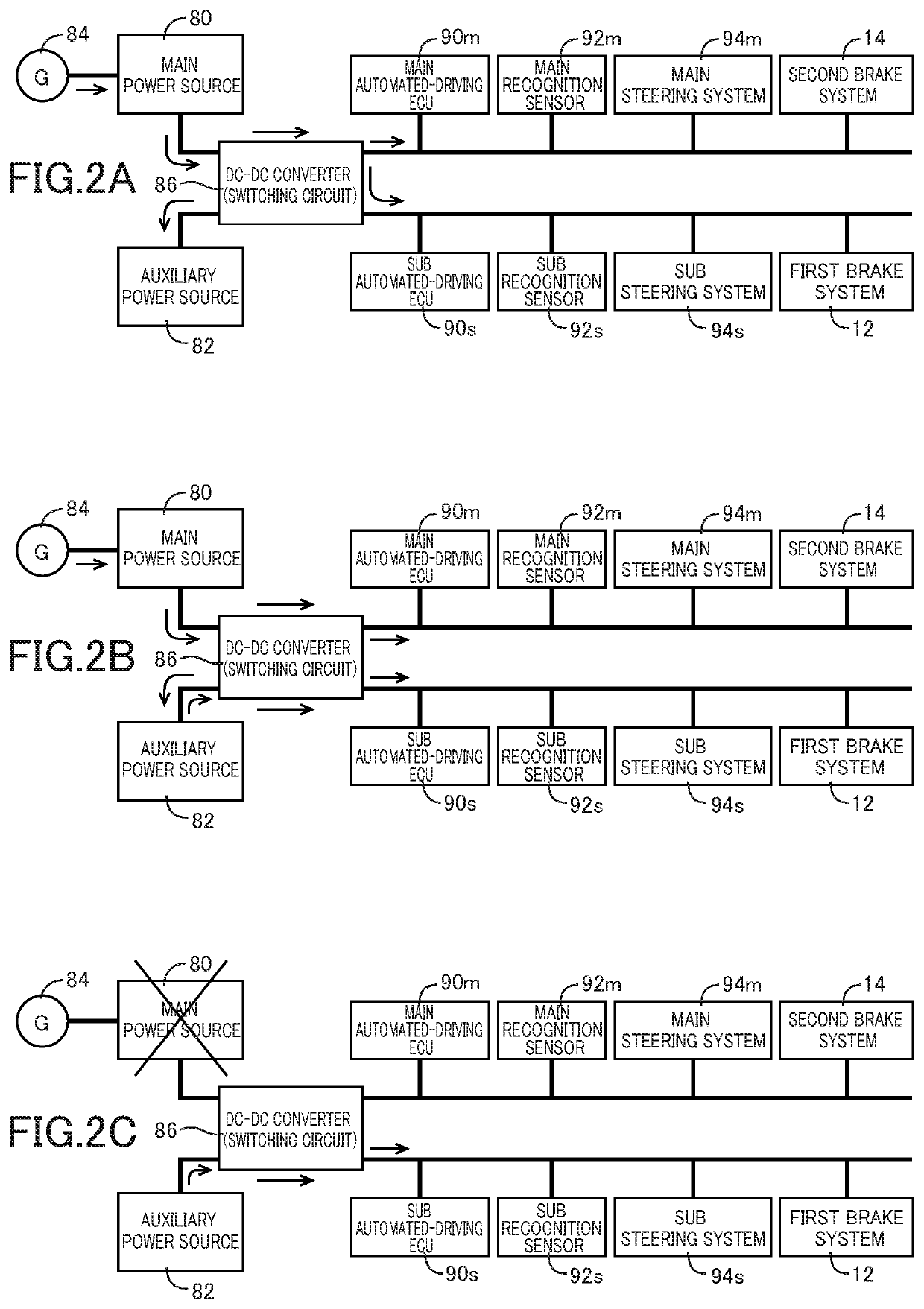

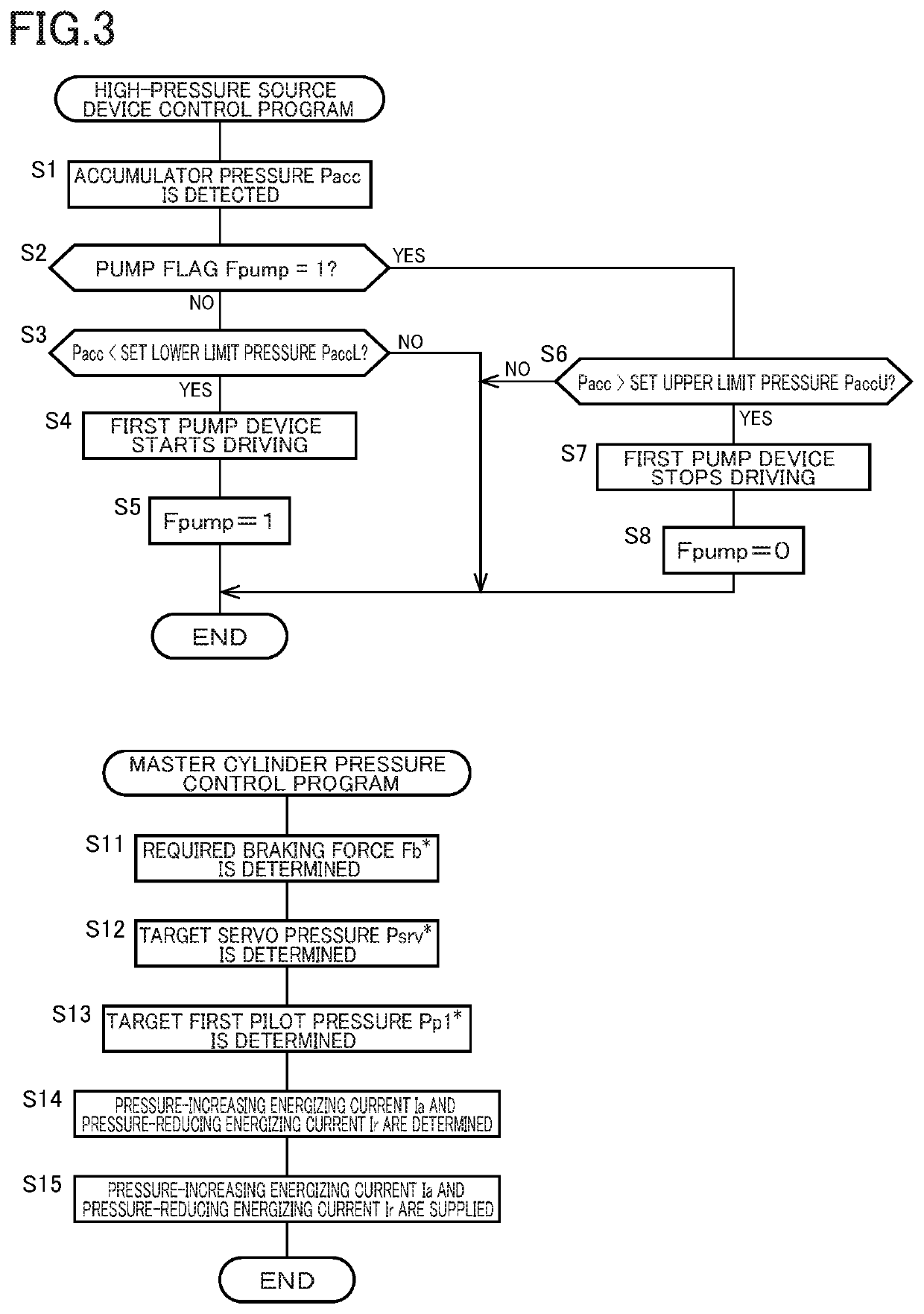

Hydraulic brake system

PendingUS20220227337A1Increase profitHigh utilityAxially engaging brakesBraking action transmissionWorking fluidPressure generation

A hydraulic brake system for a vehicle, including: a wheel brake device configured to generate a braking force based on a pressure of a working fluid; a first brake system including a high-pressure source device including an accumulator and a first pump device that is driven intermittently such that a pressure of the working fluid in the accumulator is not lower than a set lower limit pressure and not higher than a set upper limit pressure; a second brake system including a second pump device; and a main power source that supplies electricity to the first and second brake systems, wherein the hydraulic brake system includes an auxiliary power source that supplies electricity to the first brake system when a failure occurs in the main power source, and wherein the first pump device is continuously driven when the failure occurs irrespective of the pressure in the accumulator.

Owner:TOYOTA JIDOSHA KK +1

Intelligent education robot

InactiveCN112927568ACircumstances to reduce impactAvoid floating aroundBoard cleaning devicesWriting connectorsRespiratory tract diseaseSimulation

The invention discloses an intelligent education robot. The intelligent education robot structurally comprises a blackboard, a fixing frame, an intelligent writing device and a dust falling groove plate. According to the intelligent education robot, the intelligent writing device is utilized; a writing mechanism in the intelligent writing device is utilized, so that a teacher can use an external computer to operate according to the class requirement, so that the situation that the teacher is influenced by chalk dust is reduced; meanwhile, chalk characters on the surface of the blackboard are removed through a cleaning brush plate; by means of the ejection of a telescopic column, a scraper contacts with the blackboard, so that the chalk dust enters a dust collecting pipe from a suction cavity shell through movement, and therefore, the phenomenon that the chalk dust drifts around is avoided; and by means of the writing mechanism, through a clamping rod in the writing mechanism, a chalk is placed in a nesting hole and fixed through a movable extrusion column, it is ensured that the chalk cannot fall off during writing, and therefore the situation of respiratory diseases and eye discomfort of the teacher caused by the fact that the teacher inhales chalk dust or the chalk dust flows into the eyes is avoided.

Owner:李智勇

Ink jet printer

ActiveUS7874632B2Reduce density unevennessReduced drop amountInking apparatusOther printing apparatusInk printerEngineering

In order to settle a phenomenon that a quantity of jetted ink increases at the end of an image and a density increases in a shear-mode ink jet head, in a three-split driven head, a first group prints so that a diameter of a dot is reduced by reducing the quantity of jetted ink as dots at both ends, a second group similarly prints, and a third group also similarly prints. Since three dots at both ends in a main scanning direction of an acquired image are smaller than dots in the middle, the phenomenon that a quantity of jetted ink increases at the end of the image and density increases is reduced.

Owner:RISO KAGAKU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com