Shield support and support method for bow pseudo-inclined fully mechanized coal mining face

A technology of fully mechanized mining face and shielding support, which is applied in the direction of mine roof support, mining equipment, earthwork drilling, etc. resistance, increased blocking, and reduced impact and squeezing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

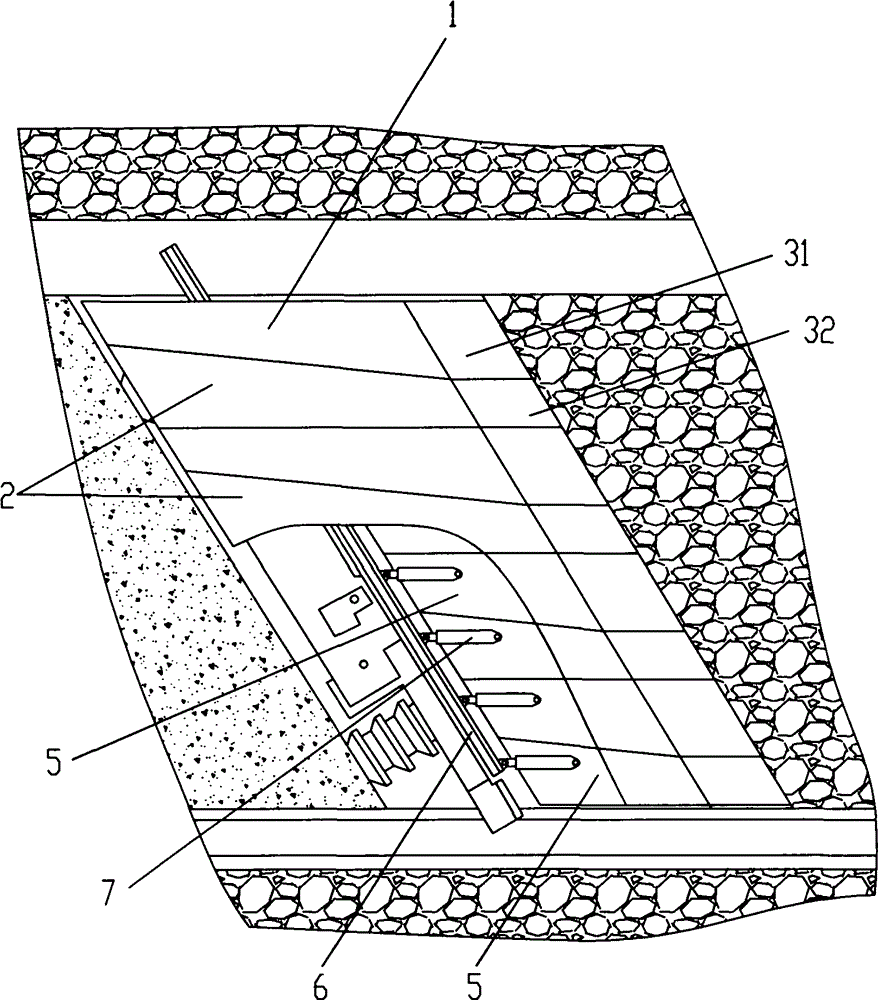

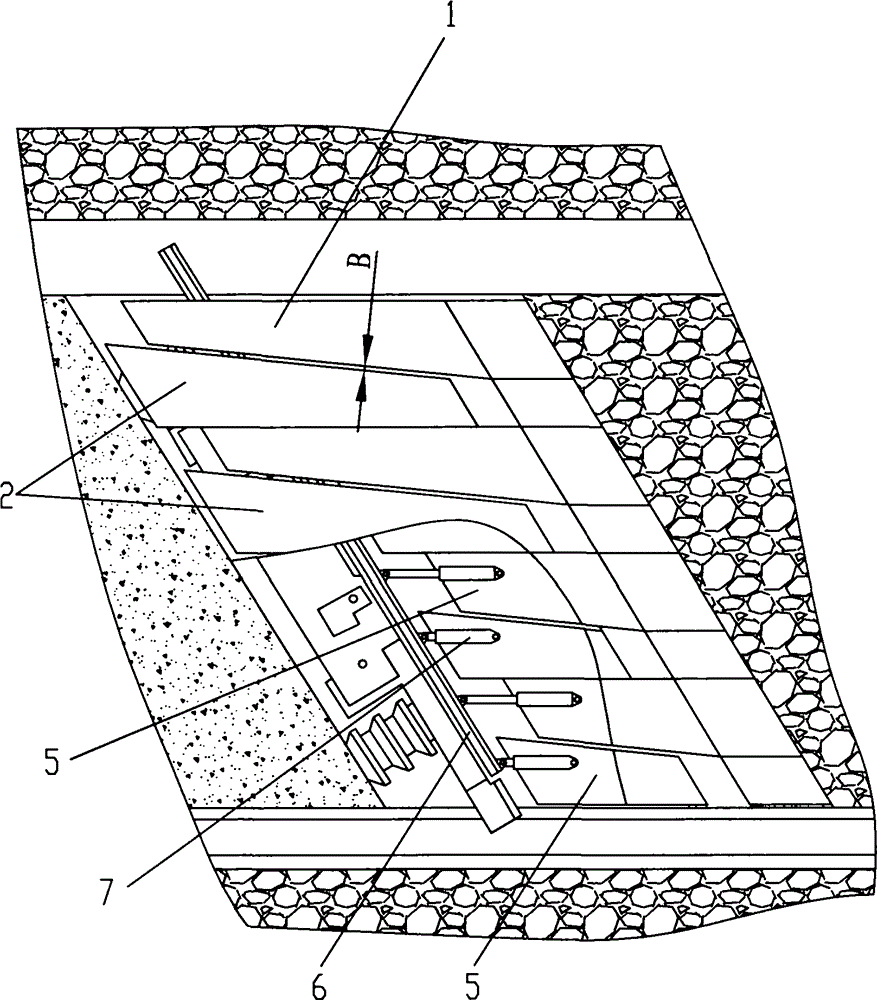

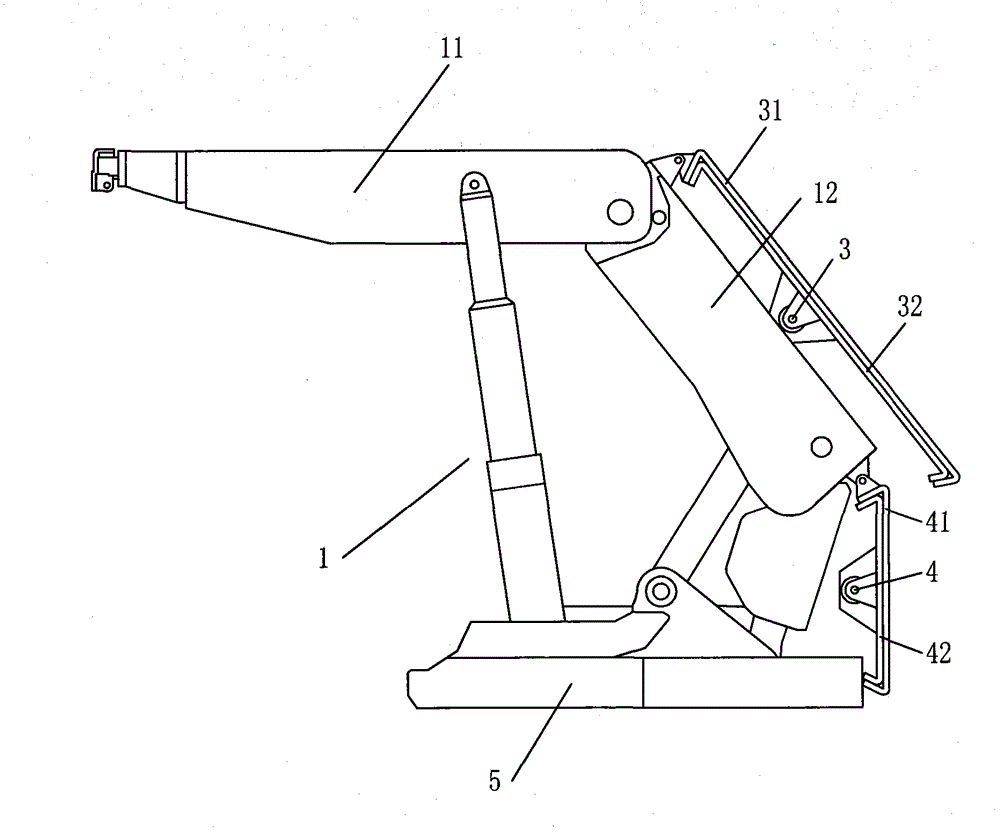

[0025] Example 1, see figure 1 , figure 2 , image 3 , Figure 4 , a shielding support for a fully-mechanized mining face with a downward pseudo-incline, the fully-mechanized mining support is composed of a first hydraulic support 1 and a second hydraulic support 2 in pairs, and the top beams of the first hydraulic support 1 and the second hydraulic support 2 have a top beam overlooking the profile Both trapezoids are trapezoidal, and the two trapezoids are combined to form a parallelogram. When the first hydraulic support 1 and the second hydraulic support 2 are arranged on the pseudo-inclined working face, one set of parallel sides of the parallelogram is parallel to the advancing direction of the working face, and the other A group of parallel sides is longitudinally parallel to the chute 6 of the coal mining equipment, and the first hydraulic support 1 is located above the second hydraulic support 2, and the trapezoidal upper bottom of the first hydraulic support 1 is l...

Embodiment 2

[0028] Example 2, see figure 1 , figure 2 , image 3 , Figure 4 , a support method for fully-mechanized working faces with dipped pseudo-inclines, characterized in that it comprises the following steps:

[0029] S1. Lay out the shield support: set a plurality of shield supports described in the technical solution for realizing the first purpose of the present invention in the fully mechanized mining face of the inclined pseudo-incline to form a support system for the working face, so that the gangue blocking device at the rear end of the first hydraulic support 1 It is located behind the second hydraulic support 2 and forms a barrier to the gangue in the goaf behind the first hydraulic support 1 and the second hydraulic support 2, and the first hydraulic support 1 and the second hydraulic support 2 are connected to the mining area by advancing the oil cylinder 7 respectively. The 6 connections of the coal equipment;

[0030] S2. Support: lift the top beam 3 of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com