Preparation method for frosted glass

A frosted glass and frosted powder technology, which is applied to the device for coating liquid on the surface, the pretreatment surface, the coating and other directions, can solve the problems of pollution and rough surface feel, improve the preparation quality, facilitate disassembly and replacement, and The effect of cleaning and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

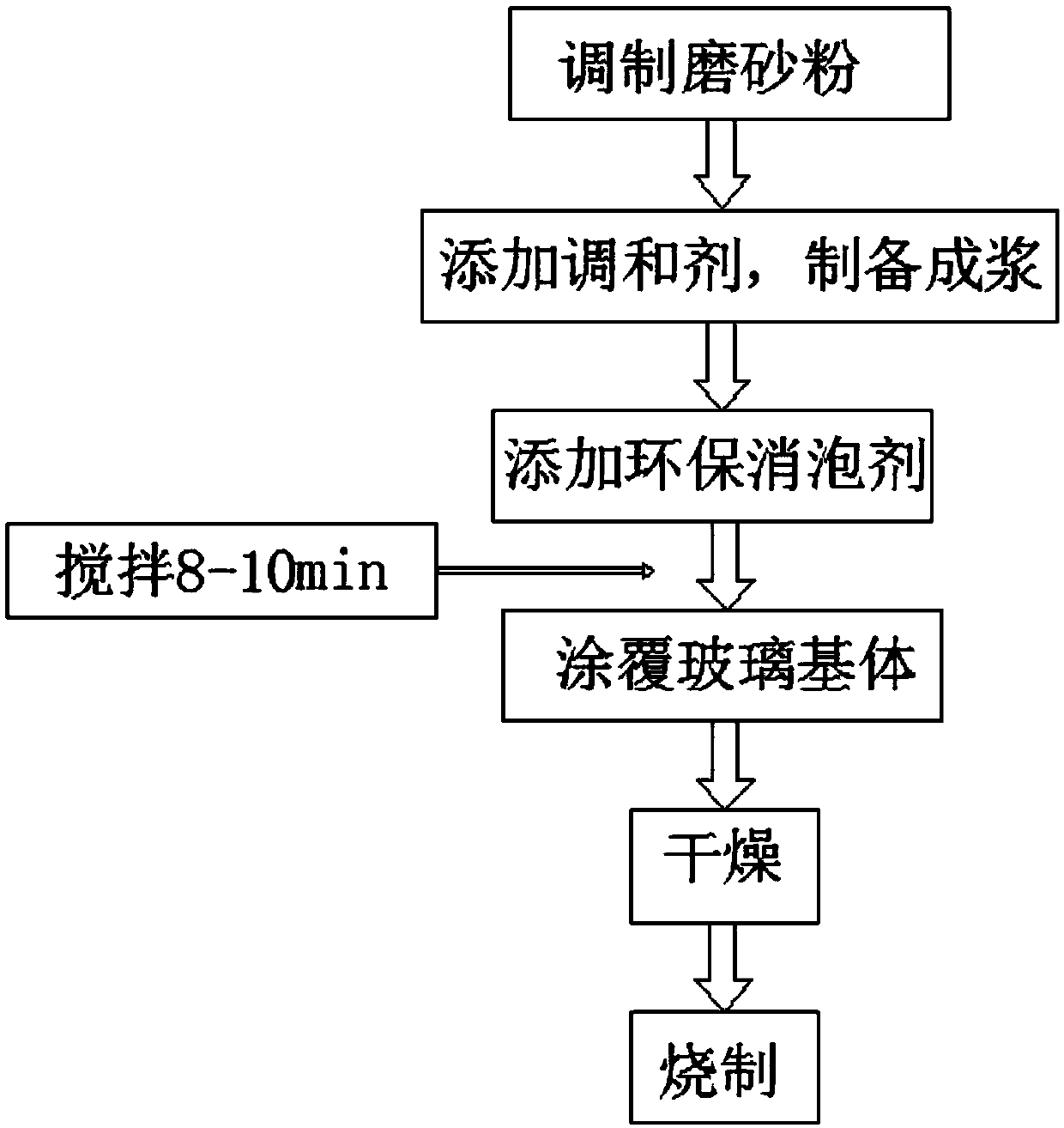

[0046] see figure 1 , a preparation method of frosted glass, the preparation method is:

[0047] S1: Prepare scrub powder;

[0048] S2: adding a blending agent to the prepared scrub powder to prepare a slurry;

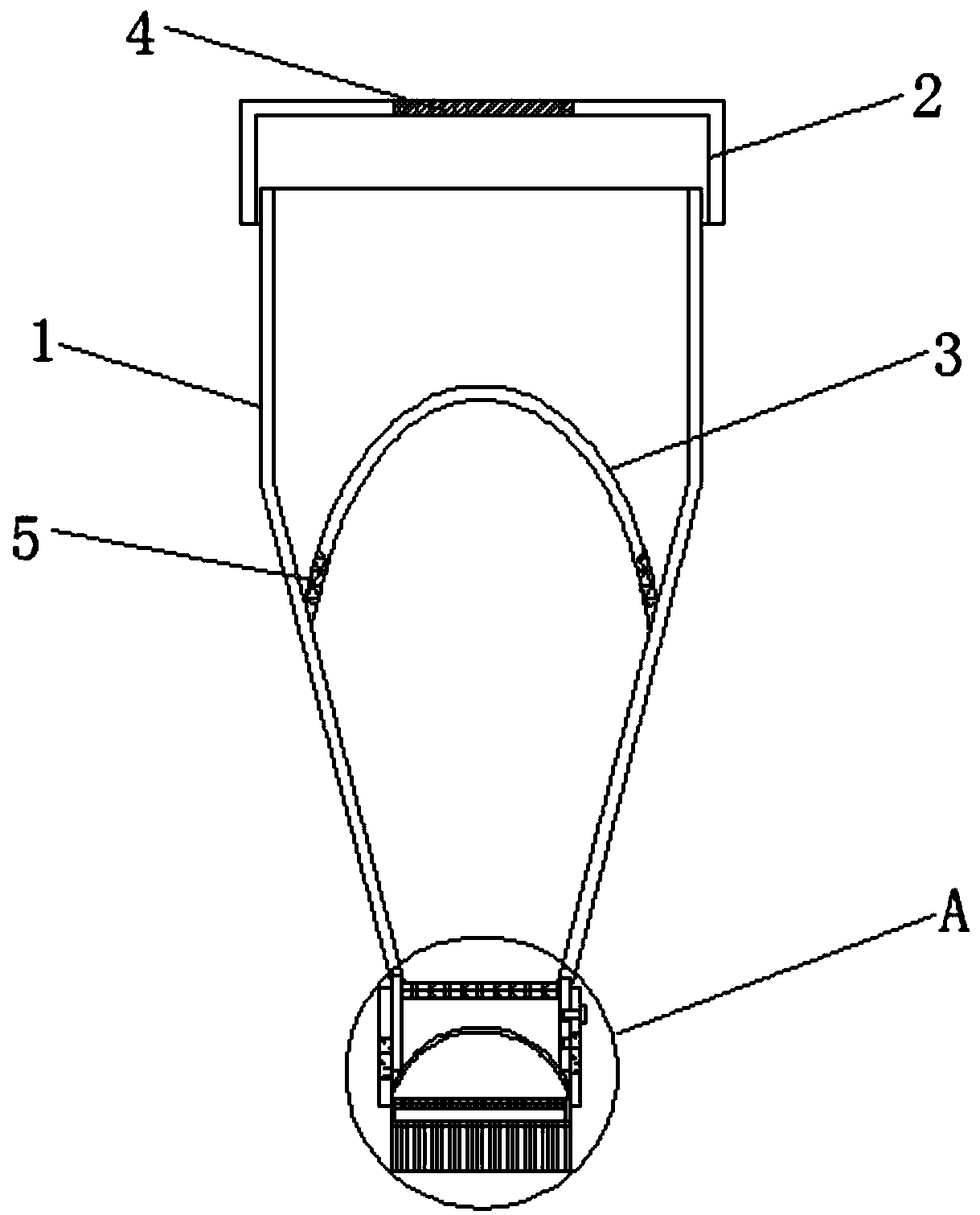

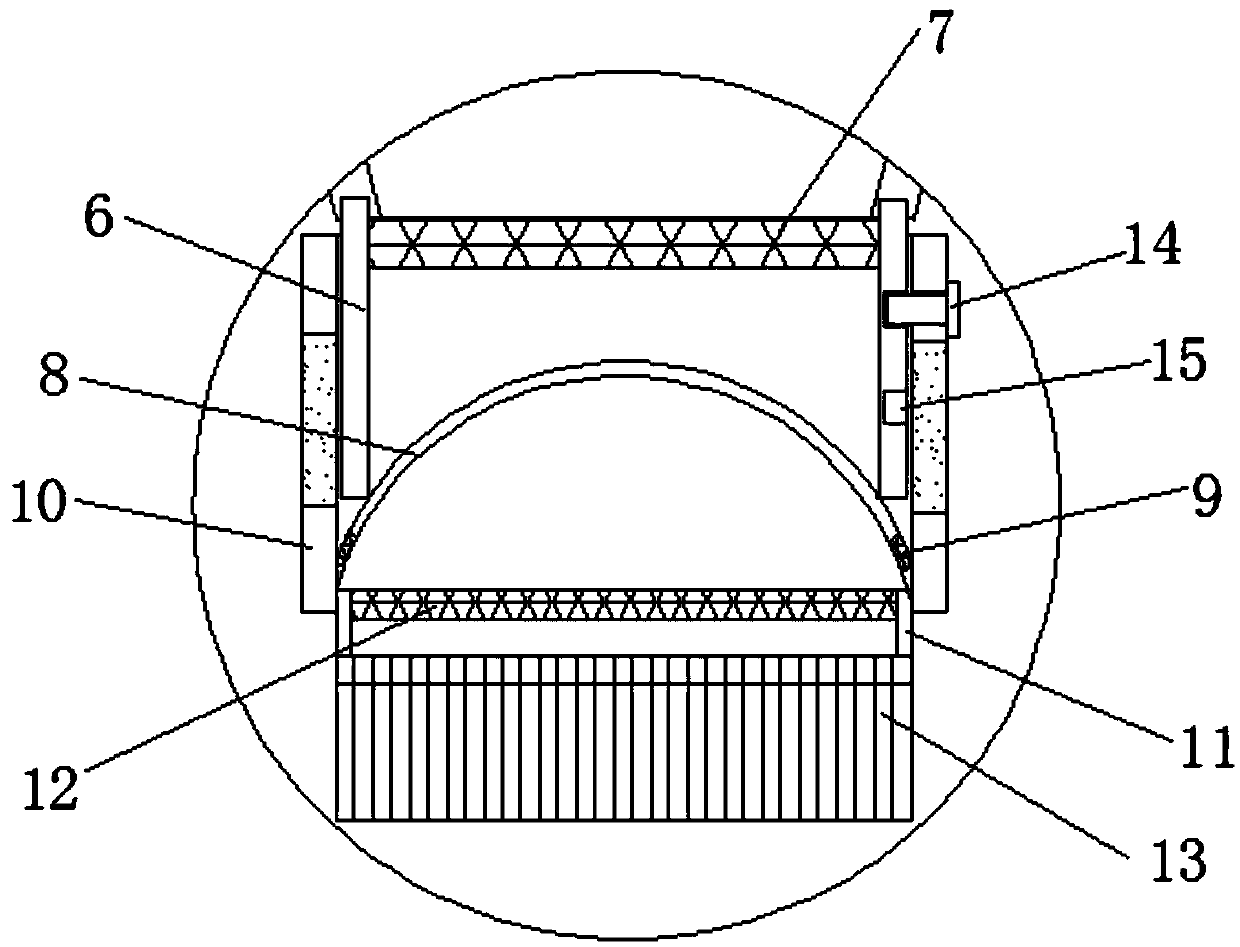

[0049] S3: apply the frosted slurry on the glass substrate with multiple defoaming brushes, and dry;

[0050] S4: Put the dried glass substrate with frosted slurry into a tempering furnace or a roller kiln for firing.

[0051] Multiple defoaming brushes can realize multiple defoaming of the frosted slurry during the coating process, effectively reduce the residual air bubbles in the frosted slurry, increase the density of the coating layer, and thus improve the preparation quality of the frosted glass.

[0052] Scrub powder includes the following components by weight percentage: SiO2: 60%; ZnO: 30%; CaO: 2%; BaO+SrO: 0.1%; B2O3: 8-30%; Al2O3: 0.1-8% ;TiO2: 0.5-8%; ZrO2: 0-5%; Na2O: 5-20%; K2O: 1-10%; Li2O: 0-8%; P2O5: 1-18%, above The scrub powder prepared from ra...

Embodiment 2

[0063] A preparation method of frosted glass, the preparation method comprising:

[0064] S1: Prepare scrub powder;

[0065] S2: Add a blender to the prepared frosting powder to prepare a slurry, then add an appropriate amount of environmentally friendly defoamer according to industry standards, and stir for 10 minutes. Using the environmentally friendly defoamer can eliminate the air bubbles inside the frosting powder slurry, which is convenient for subsequent coating work;

[0066] S3: apply the frosted slurry on the glass substrate with multiple defoaming brushes, and dry;

[0067] S4: Put the dried glass substrate with frosted slurry into a tempering furnace or a roller kiln for firing.

[0068] Scrub powder includes the following components in weight percentage: SiO 2: 45%; ZnO: 15%; CaO: 2%; MgO: 2%; BaO+SrO: 3%; B 2O 3: 8%; Al 2O 3: 0.1 %; TiO 2: 0.5%; ZrO 2: 2%; Na 2O: 5%; K 2O: 1%; Li 2O: 2%;

Embodiment 3

[0070] A preparation method of frosted glass, the preparation method comprising:

[0071] S1: Prepare scrub powder;

[0072] S2: Add a blender to the prepared frosting powder to prepare a slurry, then add an appropriate amount of environmentally friendly defoamer according to industry standards, and stir for 10 minutes. Using the environmentally friendly defoamer can eliminate the air bubbles inside the frosting powder slurry, which is convenient for subsequent coating work;

[0073] S3: apply the frosted slurry on the glass substrate with multiple defoaming brushes, and dry;

[0074] S4: Put the dried glass substrate with frosted slurry into a tempering furnace or a roller kiln for firing.

[0075] Scrub powder includes the following components in weight percentage: SiO 2: 40%; ZnO: 18%; CaO: 2%; MgO: 2%; BaO+SrO: 3%; B 2O 3: 10%; Al 2O 3: 1 %; TiO 2: 5%; ZrO 2: 3%; Na 2O: 5%; K 2O: 1%; Li2O: 4%;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com