Mining filter

A filter and mining technology, applied in the field of filters, can solve the problems of affecting water use, high cost, long replacement time, etc., and achieve the effects of improving work efficiency, preventing equipment failure, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and the accompanying drawings to further describe the technical solutions of the present invention, but the present invention is not limited to these embodiments.

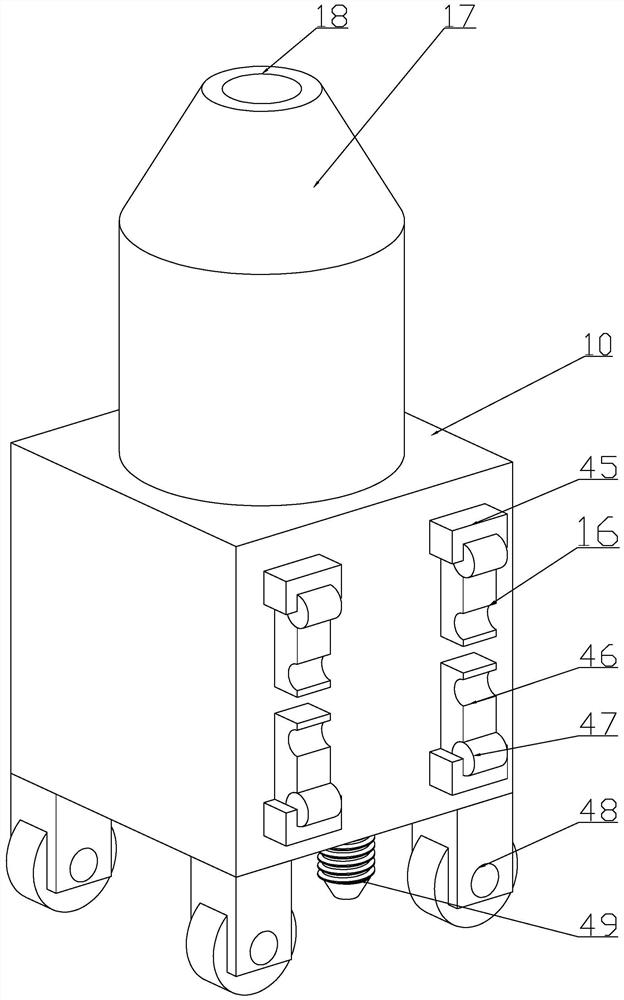

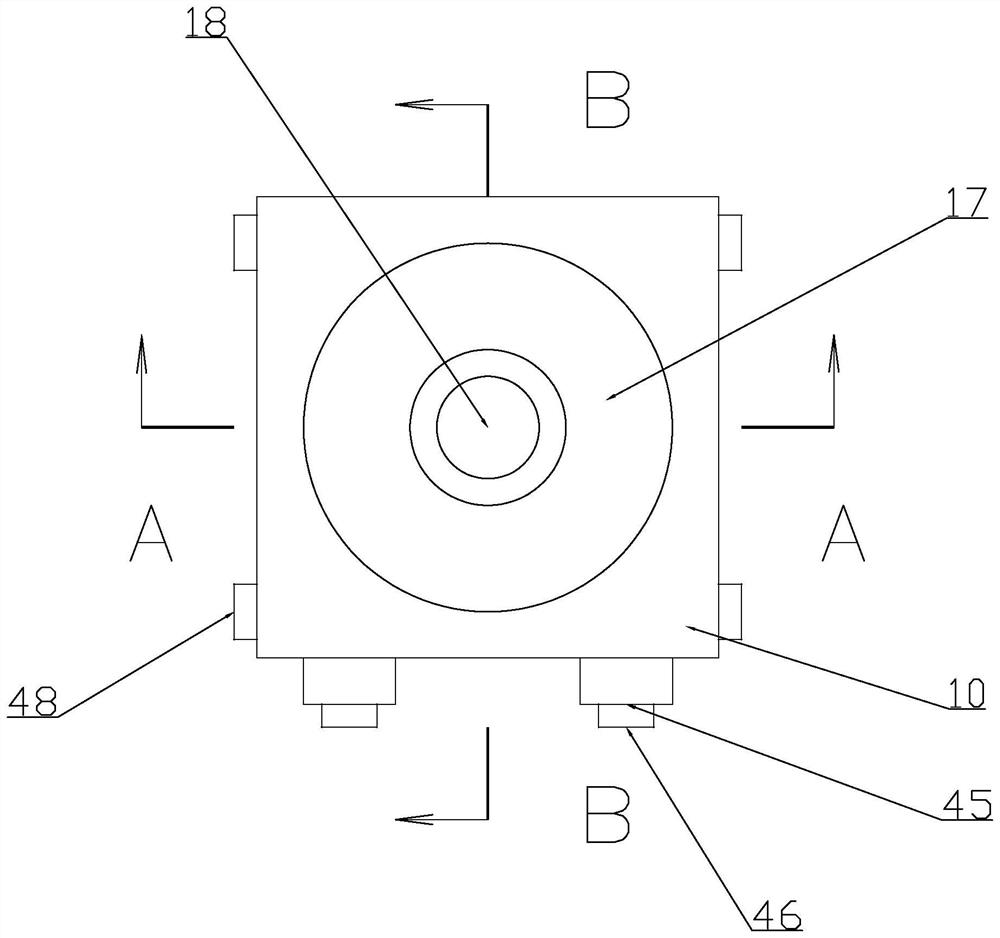

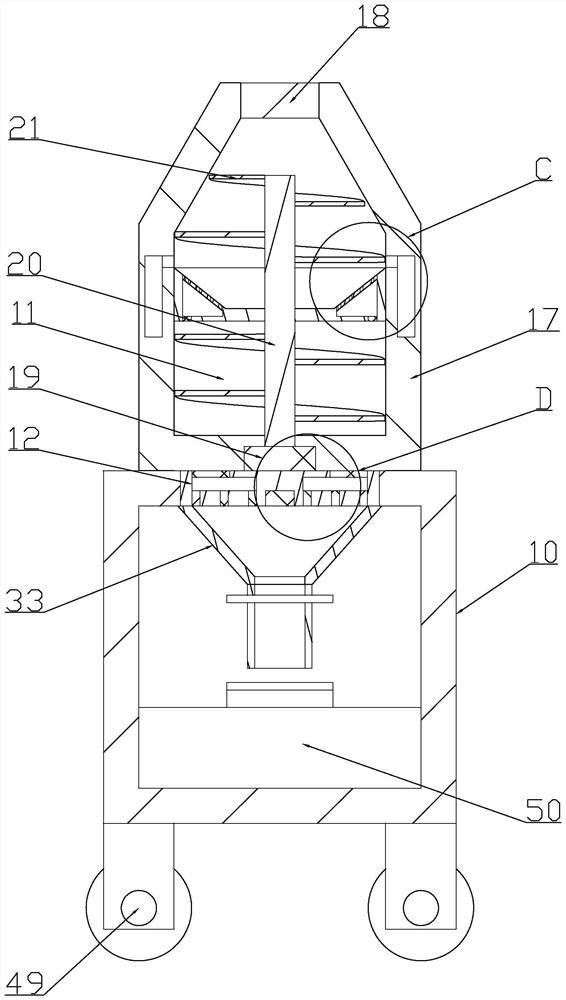

[0028] combine Figure 1-9 , a filter for mining, including a box body 10, the upper end of the box body 10 is fixed with a fixed cylinder 17, the upper end of the fixed cylinder 17 is fixed with an inlet valve 18, and the interior of the fixed cylinder 17 is provided with an impurity removal part 11; The miscellaneous parts 11 include a motor 19, the motor 19 is fixed on the inner lower end of the fixed cylinder 17, the upper end of the motor 19 is fixed with a rotating column 20, a rotating plate 22 is sleeved on the circumferential surface of the rotating column 20, and the interior of the rotating plate 22 is provided with In the centrifugal cavity 23, two filter plates 24 are fixed inside the rotating disc 22 on both sides of the centrifuga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com