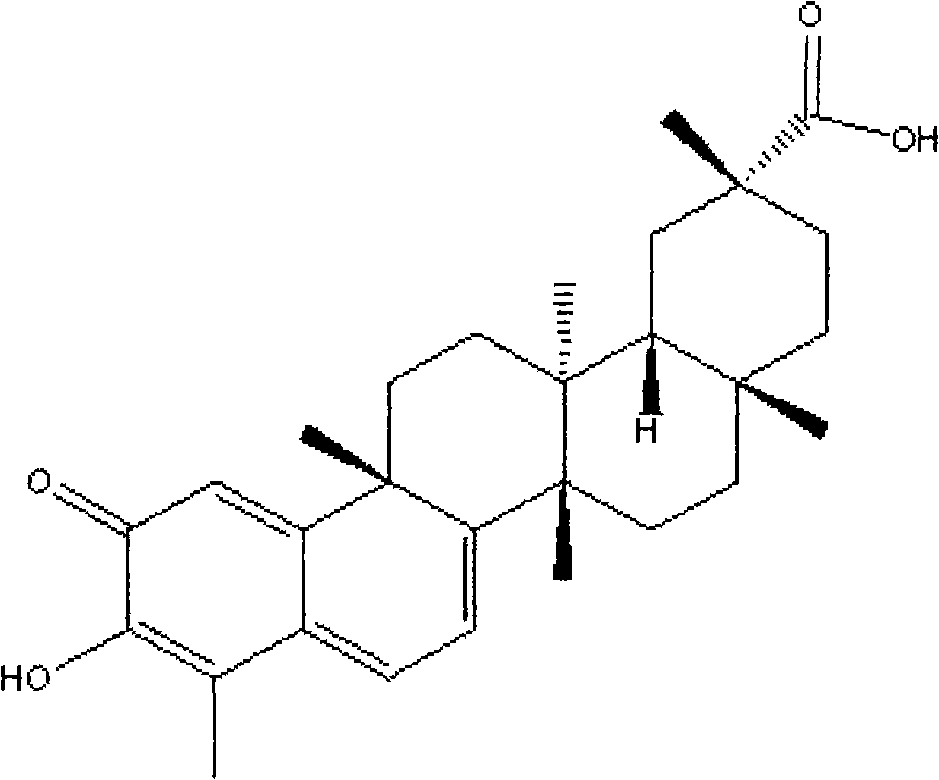

Preparation method of tripterine

A technology of tripterygium and tripterygium, applied in the field of natural medicinal chemistry, can solve the problems of small preparation amount and low degree of industrialization, and achieve the effects of low toxicity, high degree of industrialization and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The root of tripterygium twig is crushed, weighed 1kg, added 7 times the amount of 85% ethanol for reflux extraction for 1 hour, filtered the extract, added 5 times the amount of 85% ethanol solution for reflux extraction for 1 hour, combined the extract and added 100g of medicinal powdered activated carbon, 80 Decolorize at ℃ for 1 hour, filter out activated carbon, recover ethanol from the decolorization solution to an alcohol concentration of 55%, let it settle for 8 hours, filter out the precipitate, and obtain 32 g of precipitate, use 220ml of 70% ethanol solution (containing 0.4% sodium hydroxide), and stir thoroughly Dissolve, filter out the insoluble matter, adjust the pH to 3 with concentrated hydrochloric acid, place the precipitate, filter out the precipitate, then dissolve it with 100ml of 70% alcohol solution (containing 0.4% sodium hydroxide), filter to adjust the pH to neutral, place the precipitate, filter out the precipitate, and use acetic acid Ethyl es...

Embodiment 2

[0027] Pulverize the root of Tripterygium wilfordii, weigh 1kg, add 7 times the amount of 90% ethanol for reflux extraction for one hour, filter the extract, add 5 times the amount of 90% ethanol solution for reflux extraction for 1 hour, combine the extracts and add 150g of medicinal powdered activated carbon, 80 Decolorize at ℃ for 1 hour, filter out activated carbon, recover ethanol from the decolorized solution to an alcohol concentration of 65%, let it settle for 12 hours, filter out the precipitate to obtain 28 g of precipitate, use 140ml of 85% ethanol solution (containing 0.8% sodium hydroxide), and stir thoroughly Dissolve, filter out insoluble matter, adjust the pH to 5 with concentrated hydrochloric acid, place the precipitate, filter out the precipitate, then dissolve it with 80ml of 85% ethanol solution (containing 0.8% sodium hydroxide), filter to adjust the pH to neutral, place the precipitate, filter out the precipitate, and use acetic acid Ethyl ester was reflu...

Embodiment 3

[0029] Tripterygium twig root is pulverized, weighed 10kg, added 7 times the amount of 85% ethanol for reflux extraction for 1 hour, filtered the extract, added 5 times the amount of 85% ethanol solution for reflux extraction for 1 hour, combined the extract and added 1kg of medicinal powdered activated carbon, 80 Decolorize at ℃ for 1 hour, filter out activated carbon, reclaim ethanol from the decolorization solution to an alcohol concentration of 60%, place it for precipitation for 10 hours, filter out the precipitate, and obtain 306 g of precipitate, use 1.6L of 85% ethanol solution (containing 0.8% sodium hydroxide), fully Stir to dissolve, filter out insoluble matter, adjust pH3 with concentrated hydrochloric acid, place the precipitate, filter out the precipitate, then dissolve it with 1Lml85% ethanol solution (containing 0.8% sodium hydroxide), filter to adjust the pH to neutral place the precipitate, filter out the precipitate, and use Ethyl acetate is refluxed to disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com