Surfactant for polymerization reaction in supercritical carbon dioxide

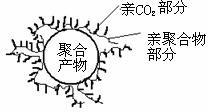

A surfactant and polymerization reaction technology, applied in the production of bulk chemicals, chemical instruments and methods, chemical/physical processes, etc. Agent working pressure, high cost of surfactants (such as fluorine-containing surfactants and most siloxane-based surfactants, etc., to achieve the effect of ensuring low toxicity, low cost, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] (1) Synthesis of methacryloyl chloride (MAC)

[0068] Below 10°C, add 10g of methacrylic acid, 0.05g of hydroquinone and a magnetic rotor to a 100mL three-necked flask equipped with a reflux condenser, a thermometer and a constant pressure dropping funnel, and slowly add them dropwise from the dropping funnel while stirring. 9 g thionyl chloride. Slowly raise the temperature until the reaction starts, and continue to raise the temperature to 60°C until the reaction is complete after the reaction rate decreases. Use 5% NaOH solution to absorb the HCl and SO generated in the reaction 2 gas. The crude product is distilled twice, the product at 87-103°C is collected in the first distillation, and the product at 95-96°C is collected in the second distillation, which is high-purity MAC.

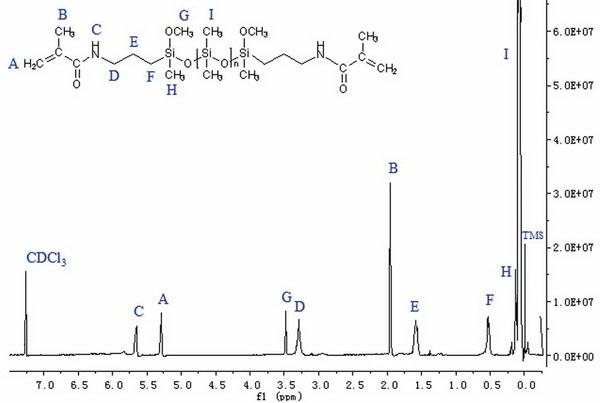

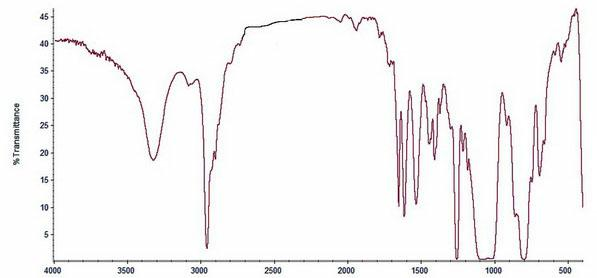

[0069] (2) Condensation of hydroxyl silicone oil and γ-aminopropyldimethoxymethylsilane

[0070] The reaction was carried out in a 100mL three-neck flask equipped with a reflux condenser...

Embodiment 2

[0076] In this embodiment, the polysiloxane-based surfactant of the present invention is applied to the dispersion polymerization reaction of methyl methacrylate (hereinafter referred to as MMA) in supercritical carbon dioxide.

[0077] MMA in ScCO 2 The dispersion polymerization in was carried out in a 50mL stainless steel reactor. The reactor was cleaned with DMC before the experiment. Add 5 g of MMA, 0.05 g of AIBN, 0.15 g of polysiloxane surfactant and a polytetrafluoroethylene rotor into the reactor, and seal the reactor. Slow passage of CO 2 After 5 minutes, heat and turn on the plunger pump to pressurize the system. When the experimental temperature reaches 65°C and the reaction pressure reaches 16MPa, start the stirrer and react for 4 hours. Stop heating and stirring, use an ice-water bath to cool the reaction kettle to room temperature, and slowly release the gas to normal pressure. Open the reactor to collect the white powdery product, which is the synthesized po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap