Coking coal blending method using high-expansion coking coal

A high-expansion, coal blending coking technology, used in coke ovens, petroleum industry, etc., can solve the problems of reduced hot and cold strength of coke, non-densification, loose coke, etc., and achieve the effect of reducing coal blending costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific examples.

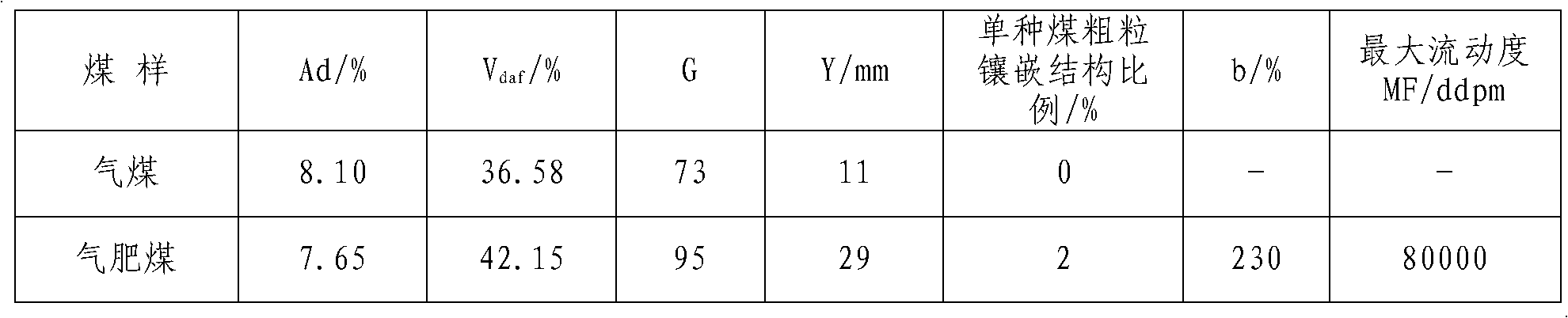

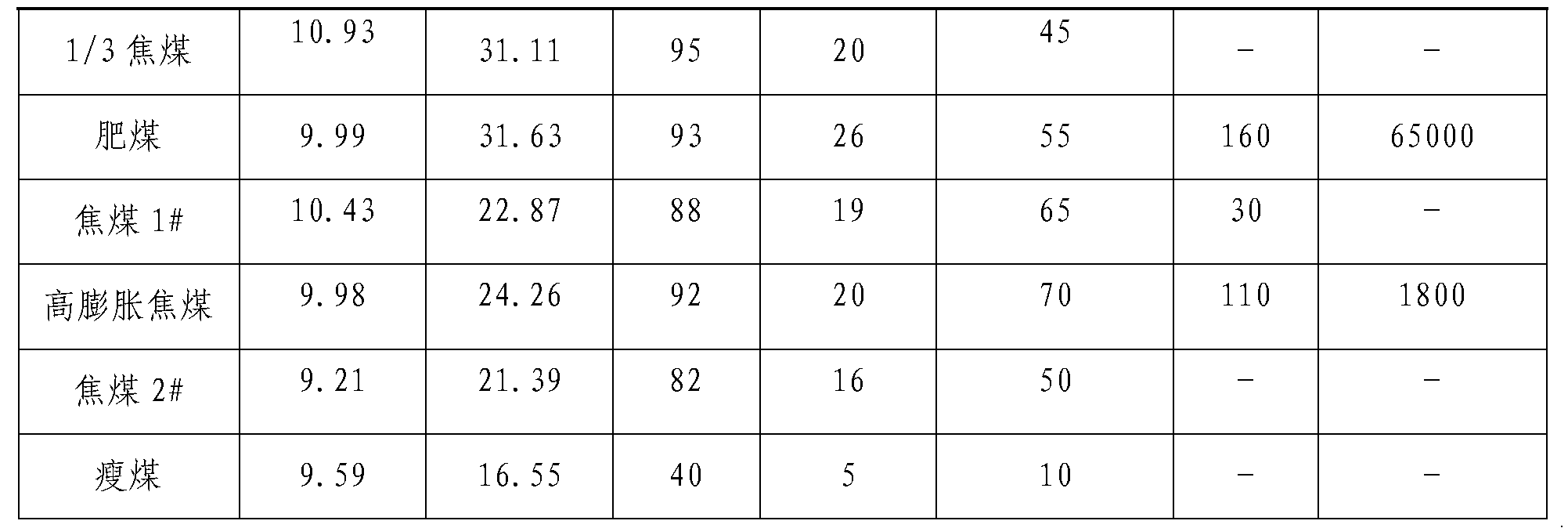

[0012] A coal blending and coking method for high-expansion coking coal of the present invention comprises the step of mixing individual coking coals, the single coking coals including gas coal, gas-fertilized coal, fat coal, 1 / 3 coking coal, high Expansion coking coal, coking coal 1#, coking coal 2#, lean coal. The industrial analysis results of each single coal are shown in Table 1.

[0013] Table 1 Analysis results of single coal quality

[0014]

[0015]

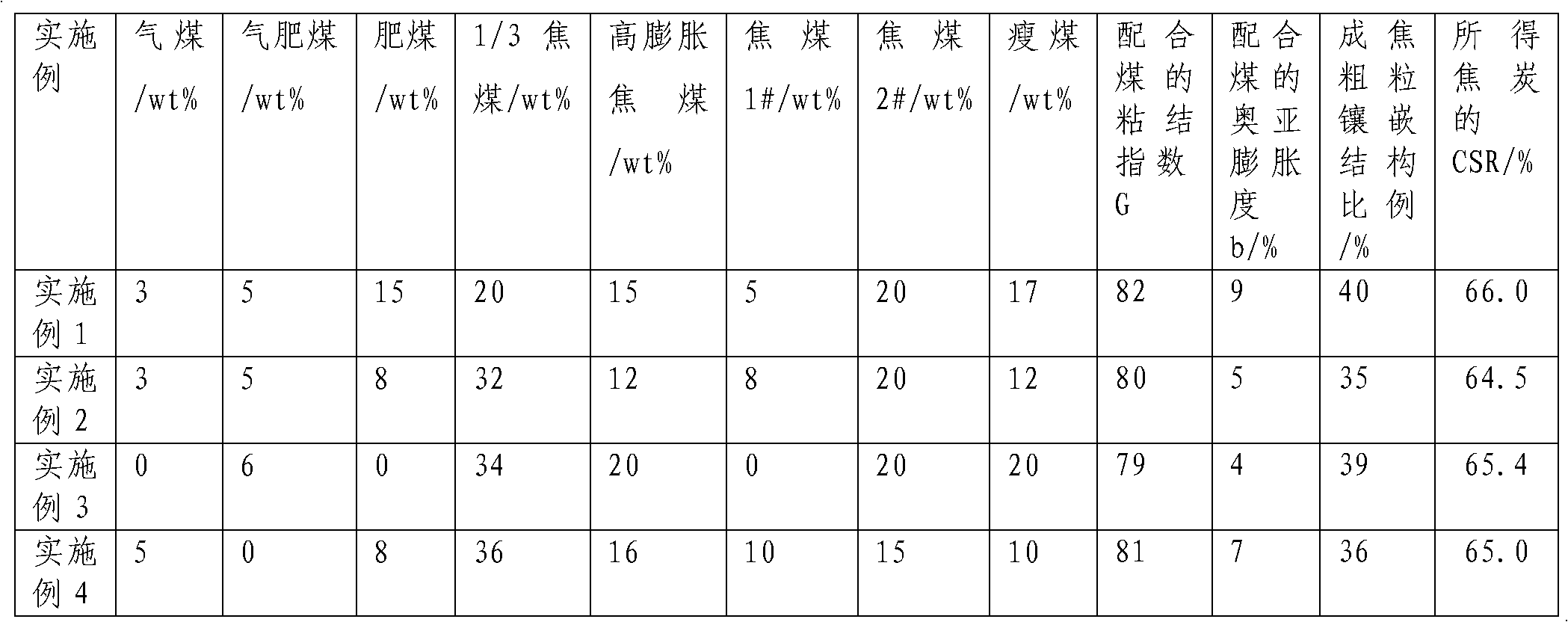

[0016] Among them, the weight percentage of high-expansion coking coal is 10-20%, the weight percentage of gas coal is 0-5%, the weight percentage of lean coal is 10-20%, and the sum of the weight percentage of gas coal and lean coal is 15-20% ; The weight percentage of fat coal is 0-15%; By adjusting the proportion of other single coking coals, the Aurora expansion degree b value of the mixed coal is <10%, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cohesion index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com