A Calculation Method of the Diameter and Optimum Explosive Consumption of Anti-Lying Blasting Pit

A blasting pit and explosive technology, which is applied in the field of engineering calculation to prevent ice disasters, can solve the problems of blind calculation of explosives, reduced work efficiency, hidden dangers, etc., and achieves the effect of saving funds and blasting funds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

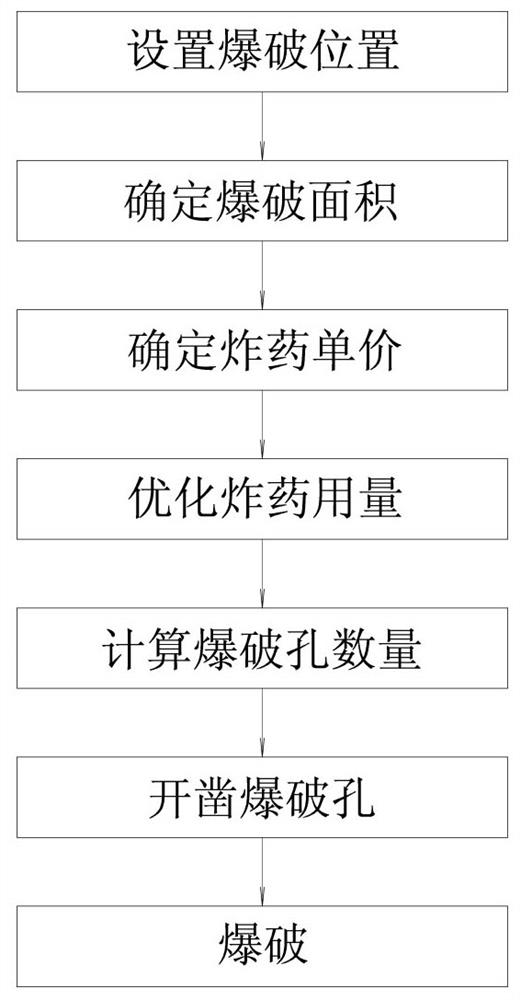

Method used

Image

Examples

Embodiment 1

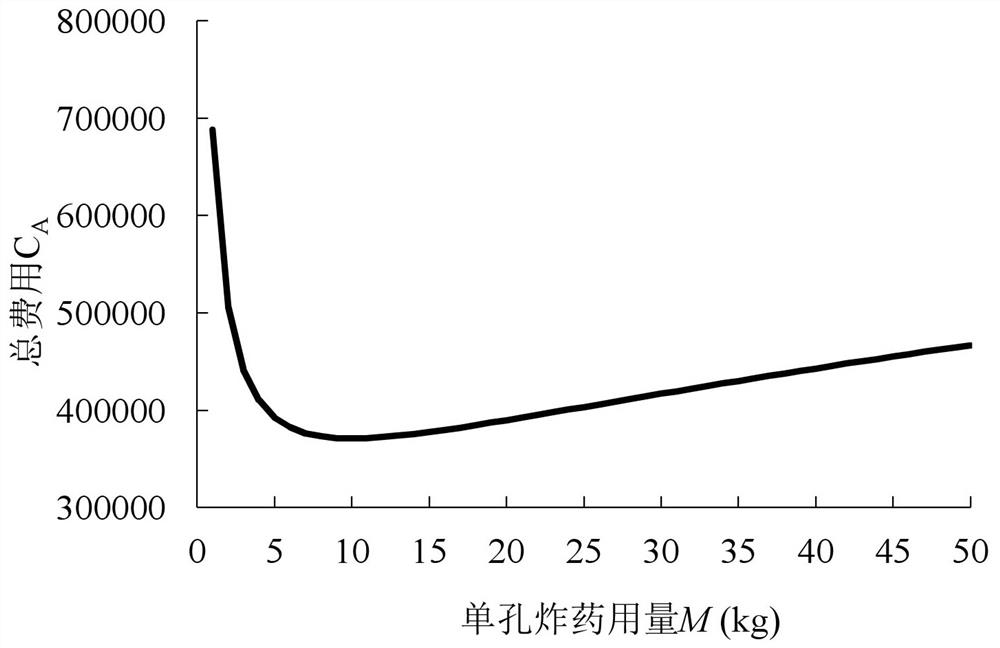

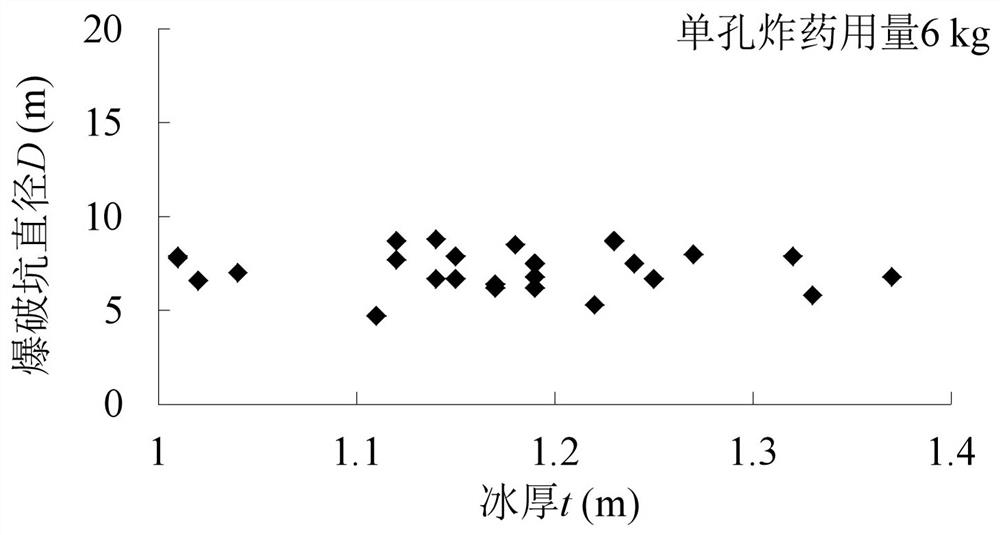

[0039] This embodiment is a method for calculating the diameter of the anti-bombing blasting pit and the optimal amount of explosives. In this embodiment, based on hundreds of groups of ice blasting data measured in the field, the relationship between the diameter of the blasting pit and the amount of single-hole explosive, the depth of water under the ice, and the installation position of the explosive is analyzed, and the relationship between the amount of single-hole explosive and the diameter of the blasting pit is analyzed. On the basis of the above analysis, a calculation method for the optimal single-hole explosive dosage in anti-bombing blasting is proposed. This method can be used to calculate the minimum blasting cost under the same blasting effect. Taking the 5km long river section in Heilongjiang as an example to prove that the method of this embodiment can save about 46% of the blasting cost under the same blasting effect. In terms of blasting effect, field protot...

Embodiment 2

[0095] This embodiment is an improvement of the first embodiment, and is a refinement of the blasting length of the river section in the first embodiment. The blasting length of the river section described in the present embodiment is 3-8km.

[0096] The length of the blasting river section is mainly determined according to the bearing capacity of manpower and material resources. If the blasting river section is too short, the thermal efficiency produced is not obvious enough. It is necessary to increase the density of the blasting river section. accepted. According to many years of actual blasting experiment experience, after analysis, the length of a blasting river section is generally about 5 kilometers, which is a better length choice, and multiple blasting river sections can be selected according to different actual conditions on a river.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com