Automatic test tube cleaning equipment based on medical experiments

An automatic cleaning and medical experiment technology, applied in the field of medicine, can solve the problems of waste of disinfectant and complicated operation, and achieve the effect of avoiding waste, simple and rapid operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

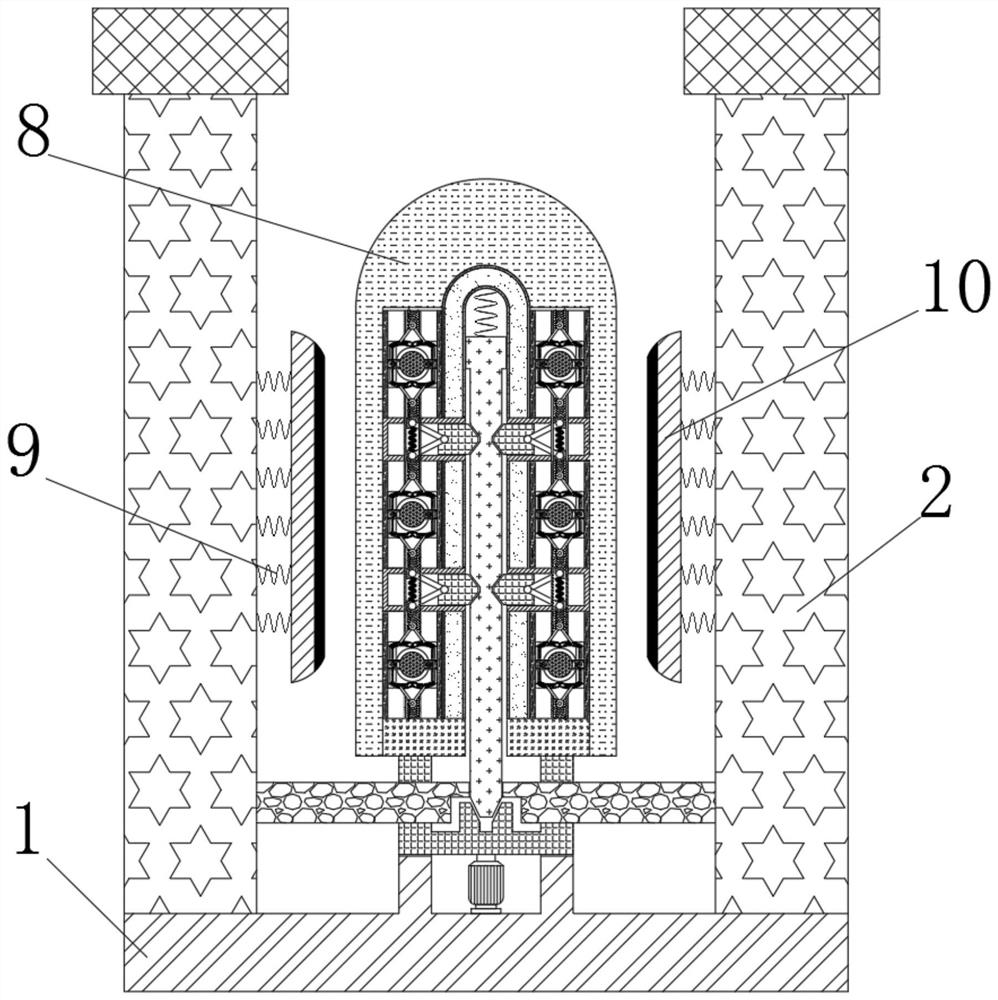

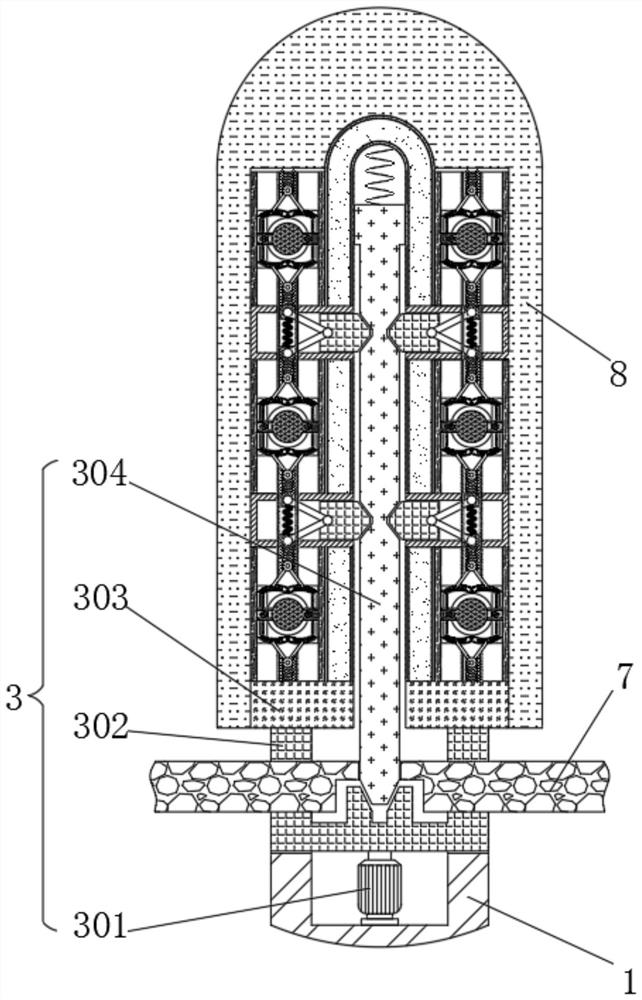

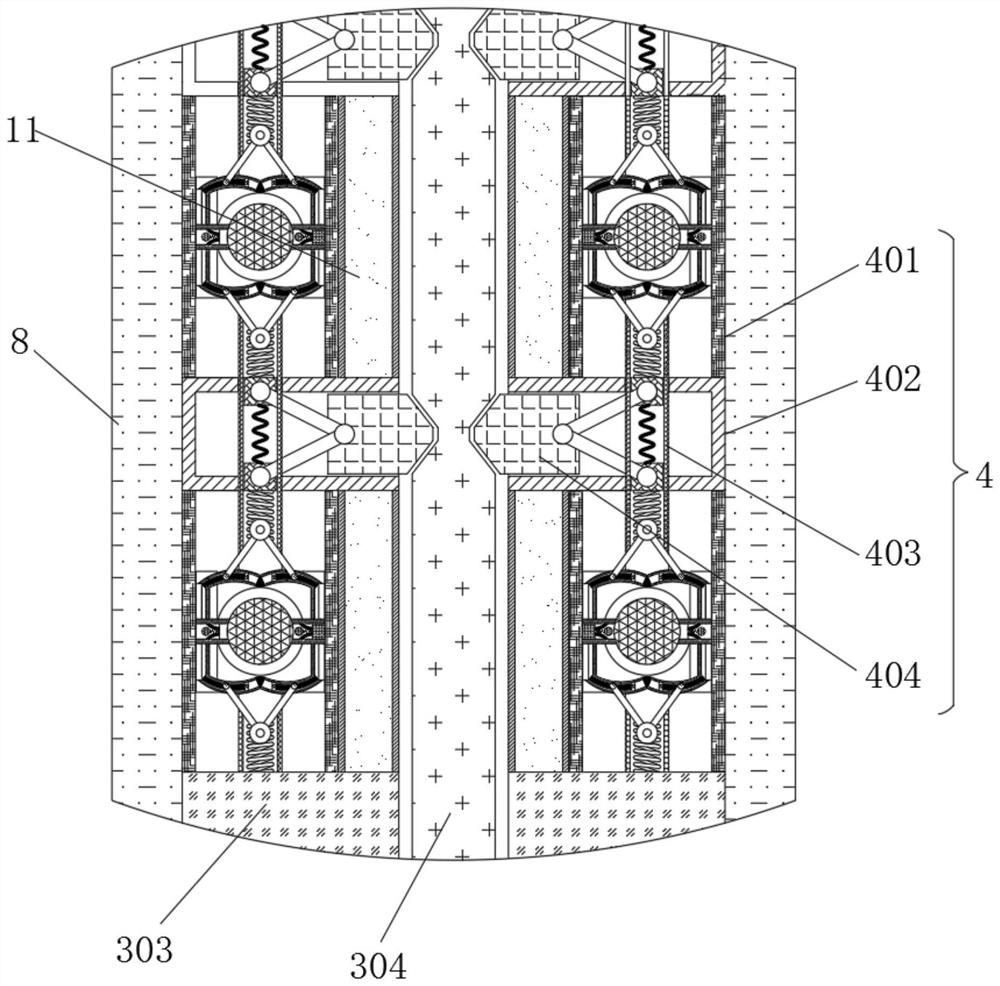

[0026] see Figure 1-5 , a test tube automatic cleaning device based on medical experiments, including a base 1, a side plate 2 is welded on the top of the base 1, a spring assembly 9 is welded on the outside of the side plate 2, and a stopper is welded on the end of the spring assembly 9 away from the side plate 2 Board 10, the top of the base 1 is fixedly equipped with a starting mechanism 3, the starting mechanism 3 includes a motor 301, the motor 301 is fixedly installed on the top of the base 1, the top of the motor 301 is fixedly installed with a connecting block 302, and the top of the connecting block 302 is welded with a support Plate 303, the top of the connecting block 302 and the vertical bar 304 is clamped between the two support plates 303, the vertical bar 304 is slidably connected to the outside of the limiting plate 7, and the top of the connecting block 302 is provided with a groove, the groove and The bottoms of the vertical rods 304 coincide, the top of the...

Embodiment 2

[0029] see Figure 1-5, a test tube automatic cleaning device based on medical experiments, including a base 1, a side plate 2 is welded on the top of the base 1, a spring assembly 9 is welded on the outside of the side plate 2, and a stopper is welded on the end of the spring assembly 9 away from the side plate 2 Board 10, the top of the base 1 is fixedly equipped with a starting mechanism 3, the starting mechanism 3 includes a motor 301, the motor 301 is fixedly installed on the top of the base 1, the top of the motor 301 is fixedly installed with a connecting block 302, and the top of the connecting block 302 is welded with a support Plate 303, the top of the connecting block 302 and the vertical bar 304 is clamped between the two support plates 303, the vertical bar 304 is slidably connected to the outside of the limiting plate 7, and the top of the connecting block 302 is provided with a groove, the groove and The bottoms of the vertical rods 304 coincide, the top of the ...

Embodiment 3

[0032] see Figure 1-5 , a test tube automatic cleaning device based on medical experiments, including a base 1, a side plate 2 is welded on the top of the base 1, a spring assembly 9 is welded on the outside of the side plate 2, and a stopper is welded on the end of the spring assembly 9 away from the side plate 2 Board 10, the top of the base 1 is fixedly equipped with a starting mechanism 3, the starting mechanism 3 includes a motor 301, the motor 301 is fixedly installed on the top of the base 1, the top of the motor 301 is fixedly installed with a connecting block 302, and the top of the connecting block 302 is welded with a support Plate 303, the top of the connecting block 302 and the vertical bar 304 is clamped between the two support plates 303, the vertical bar 304 is slidably connected to the outside of the limiting plate 7, and the top of the connecting block 302 is provided with a groove, the groove and The bottoms of the vertical rods 304 coincide, the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com