Electromagnetic fan clutch

An electromagnetic fan and clutch technology, applied in clutches, magnetic drive clutches, non-mechanical drive clutches, etc., can solve the problems of large volume, large wear of matching parts, and distance from the center of gravity, etc., and achieve compact overall structure, compact structure, and reduced wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

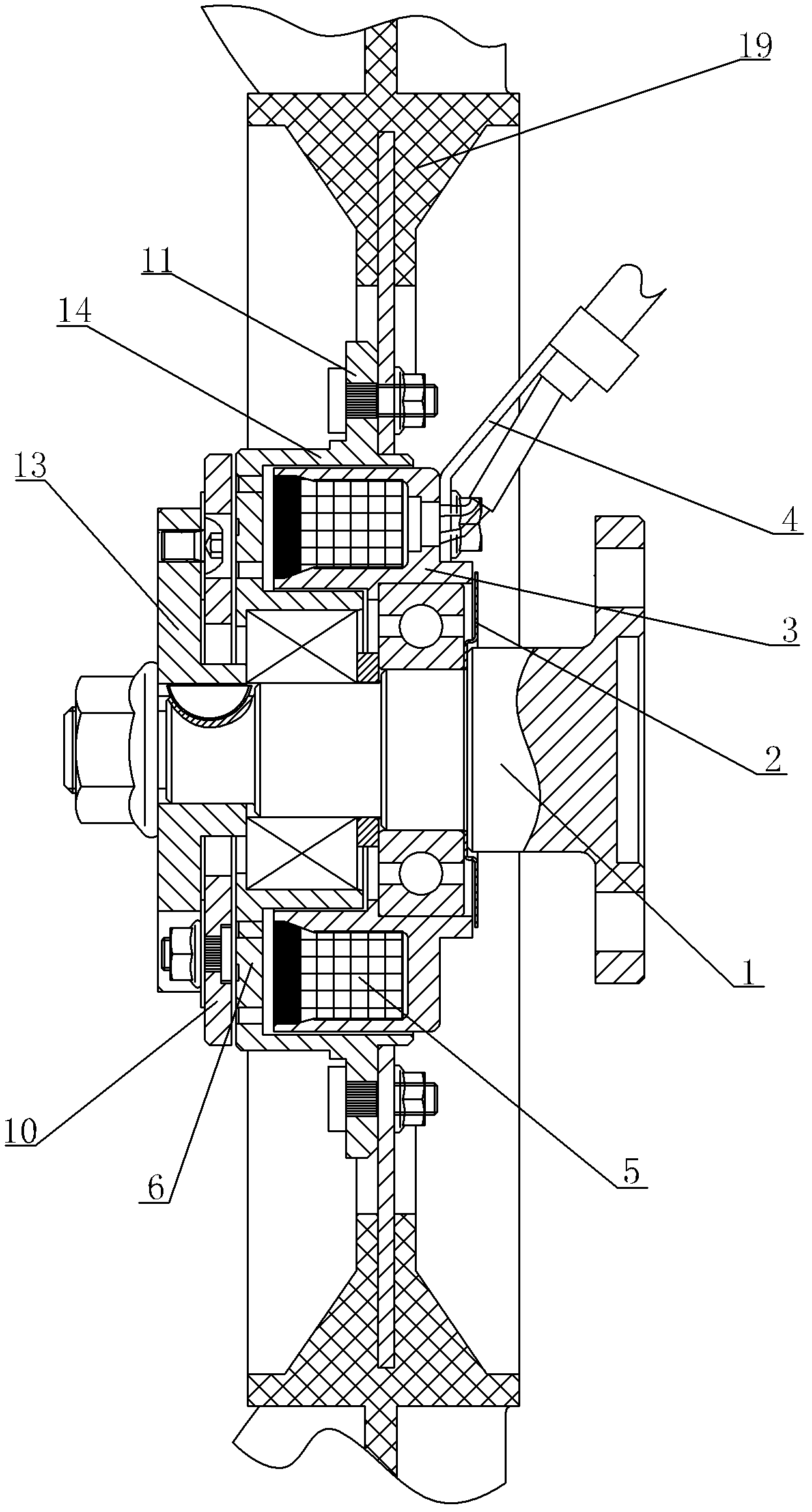

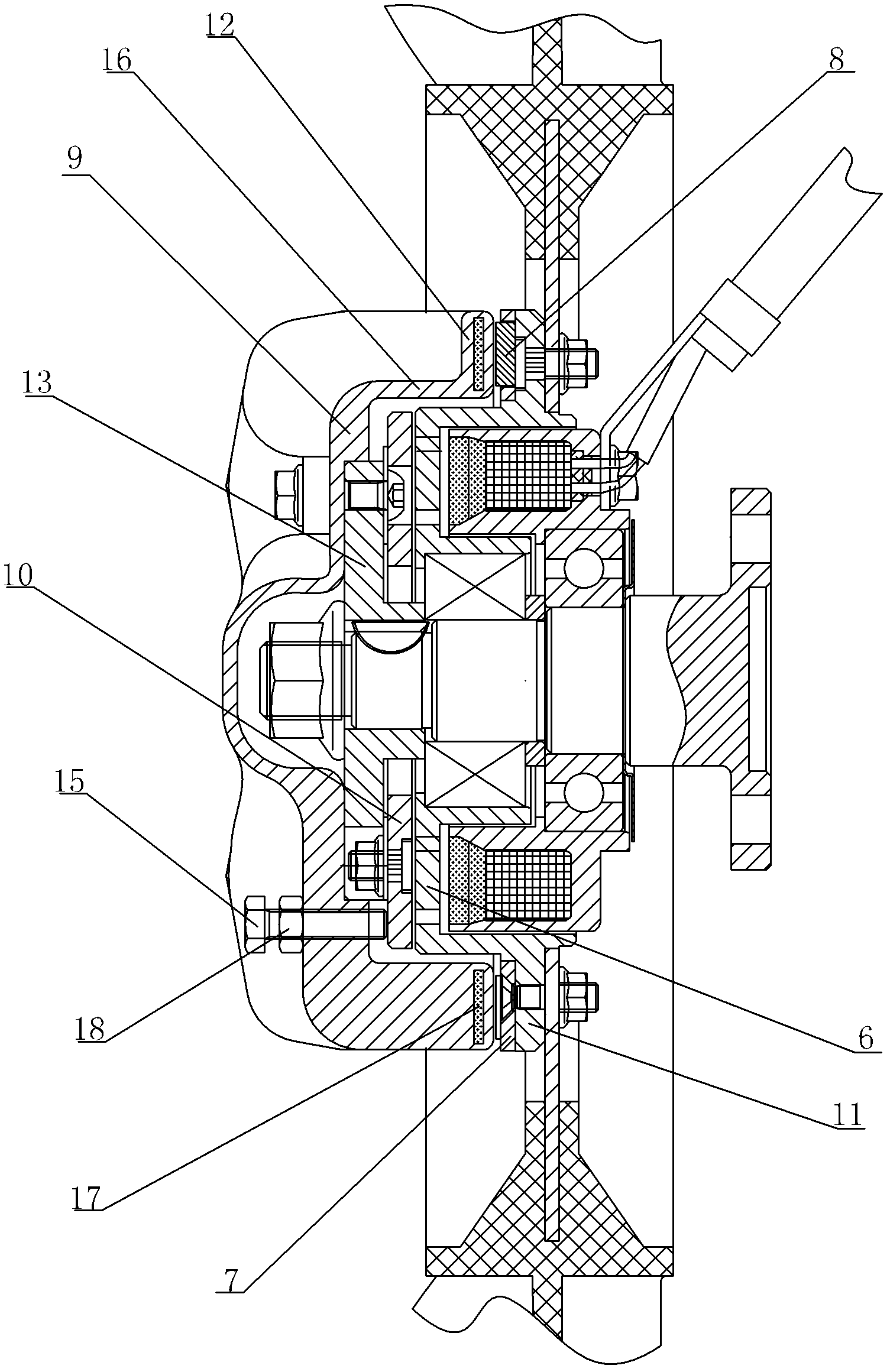

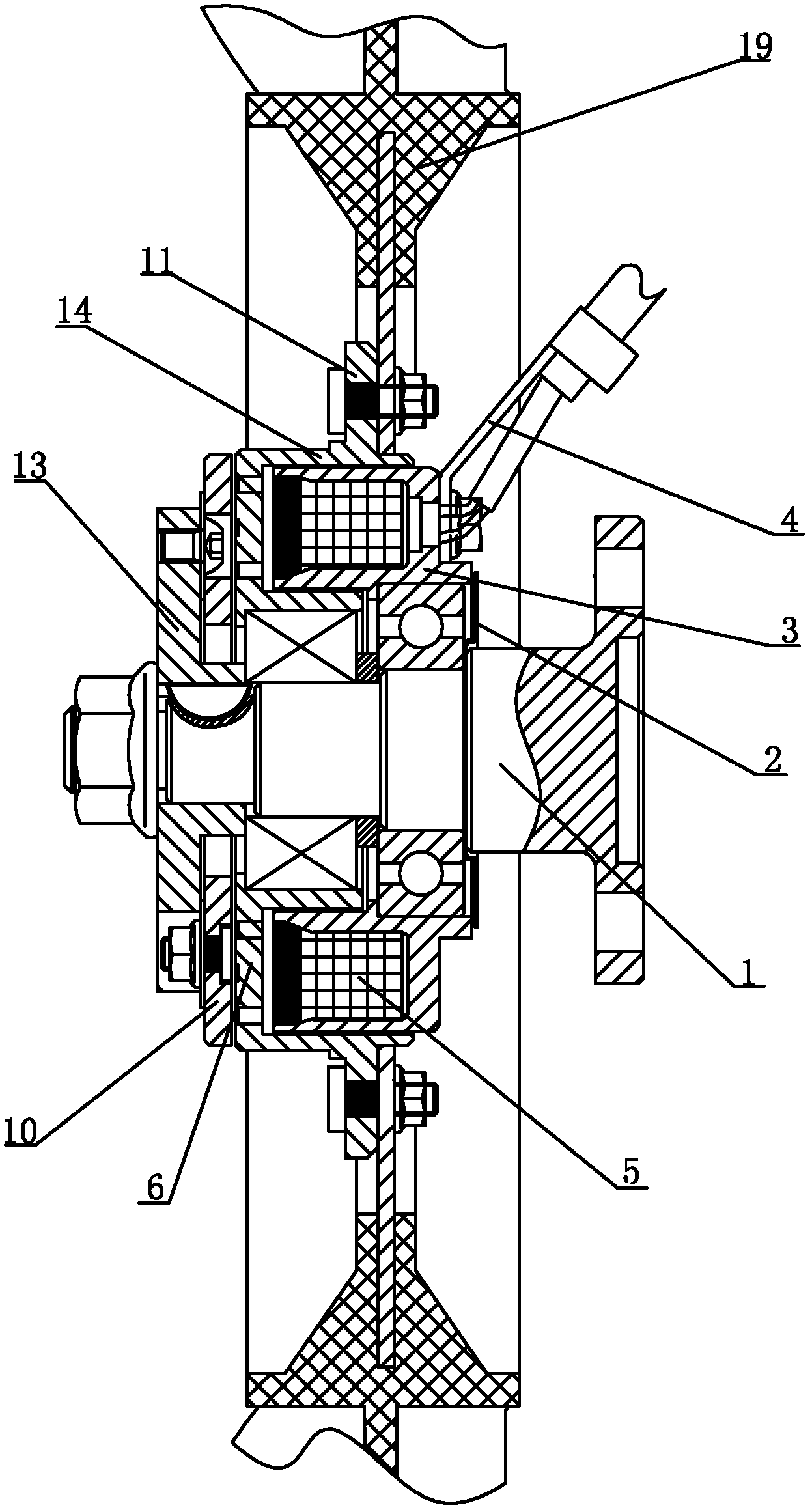

[0018] Such as figure 1 As shown, the electromagnetic fan clutch of the present invention includes a rotating main shaft 1, an electromagnet core 3 with a coil 5 embedded therein, a driven disc 6 that can rotate around the main shaft 1, and a driven disk that can rotate around the main shaft 1. The driving disc 13 that rotates with the main shaft 1 is provided with a suction disc 10 that can move in the axial direction between the driving disc 13 and the driven disc 6 , and the suction disc 10 and the driving disc 13 are connected by an elastic sheet.

[0019] The outer circumferential end surface of the driven disc 6 is axially provided with a first extension 14 toward the direction of the electromagnet core 3, the first extension 14 is radially located outside the electromagnet core 3, and the first extension 14 is on the outer wall near the free end A first skirt 11 is provided, and the first skirt 11 is perpendicular to the outer wall of the first extension 14 , and a fan ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com