Edge-lit backlight module and liquid crystal display device with same

A backlight module and side-light technology, applied in lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of broken and separated wires and connectors, complicated fixing structures, and poor display screens of liquid crystal display devices, etc. , to improve the display quality, simplify the cable management structure, and save the effect of sticking tape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

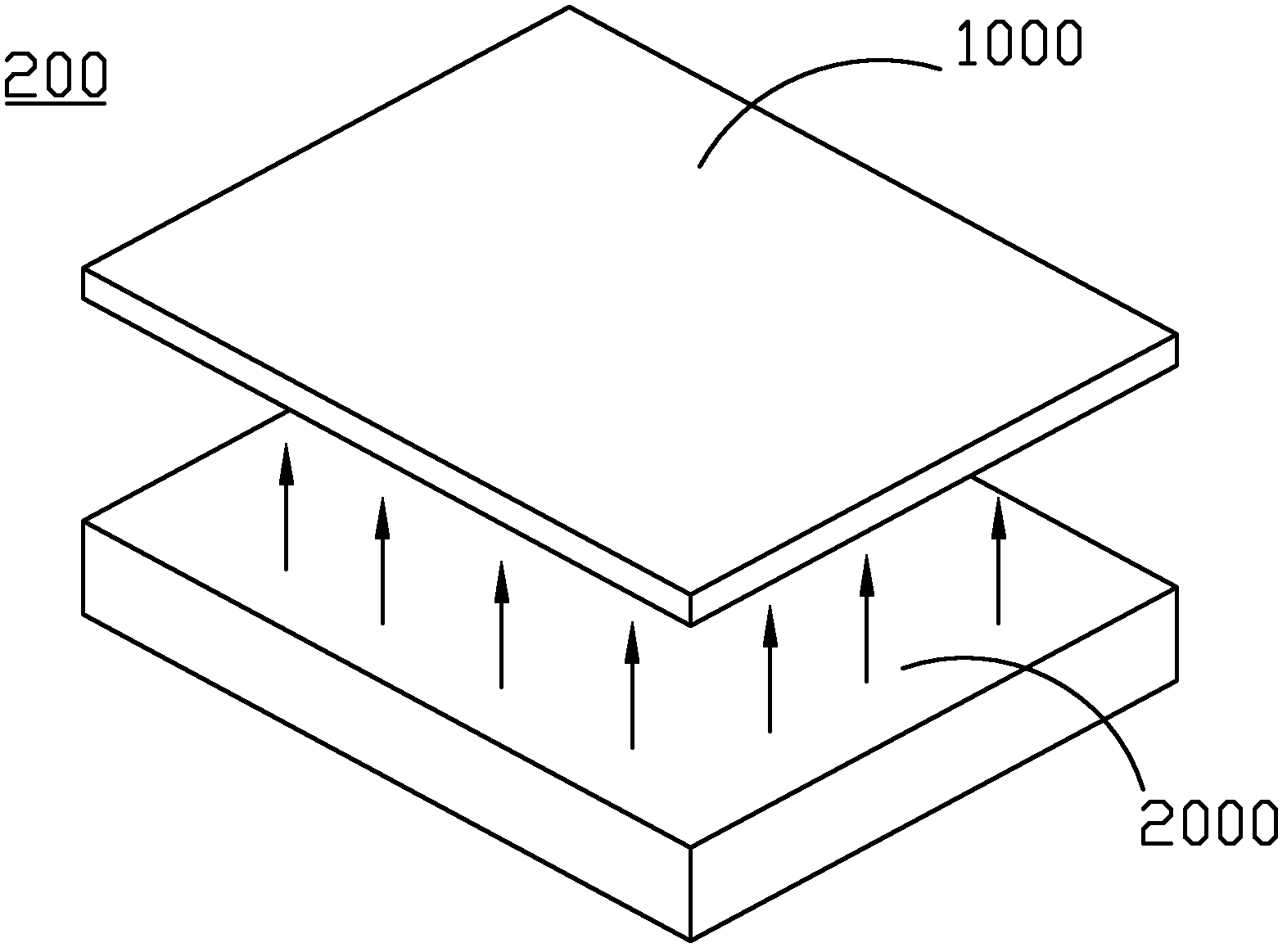

[0024] figure 2 It is a three-dimensional exploded schematic diagram of a liquid crystal display device 200 disclosed in an embodiment of the present invention. The liquid crystal display device 200 includes a liquid crystal display panel 1000 and an edge-lit backlight module 2000, wherein the liquid crystal display panel 1000 and the edge-lit backlight module The modules 2000 are stacked together, and the light is emitted from the side-light backlight module 2000 and then enters the liquid crystal display panel 1000 .

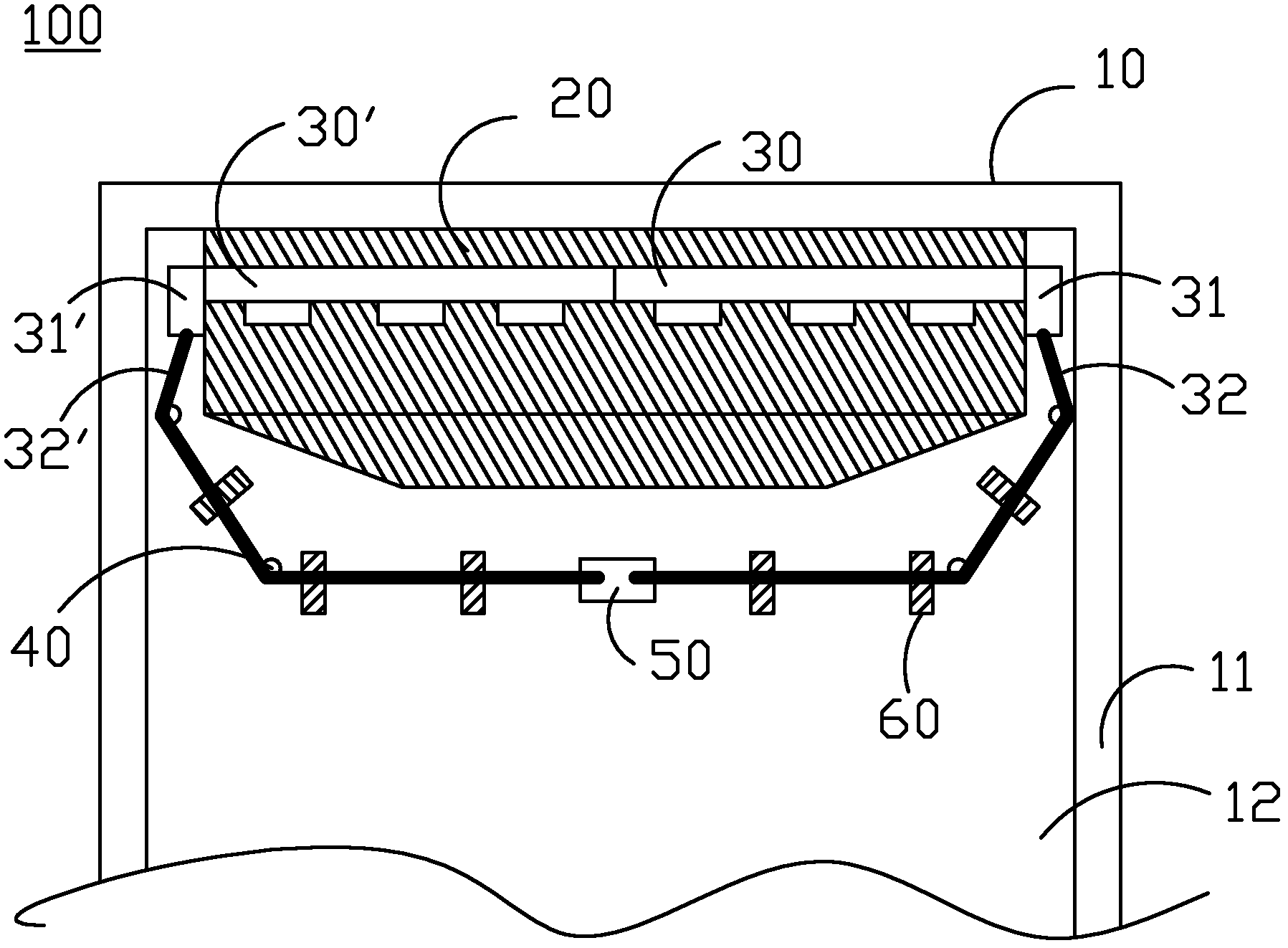

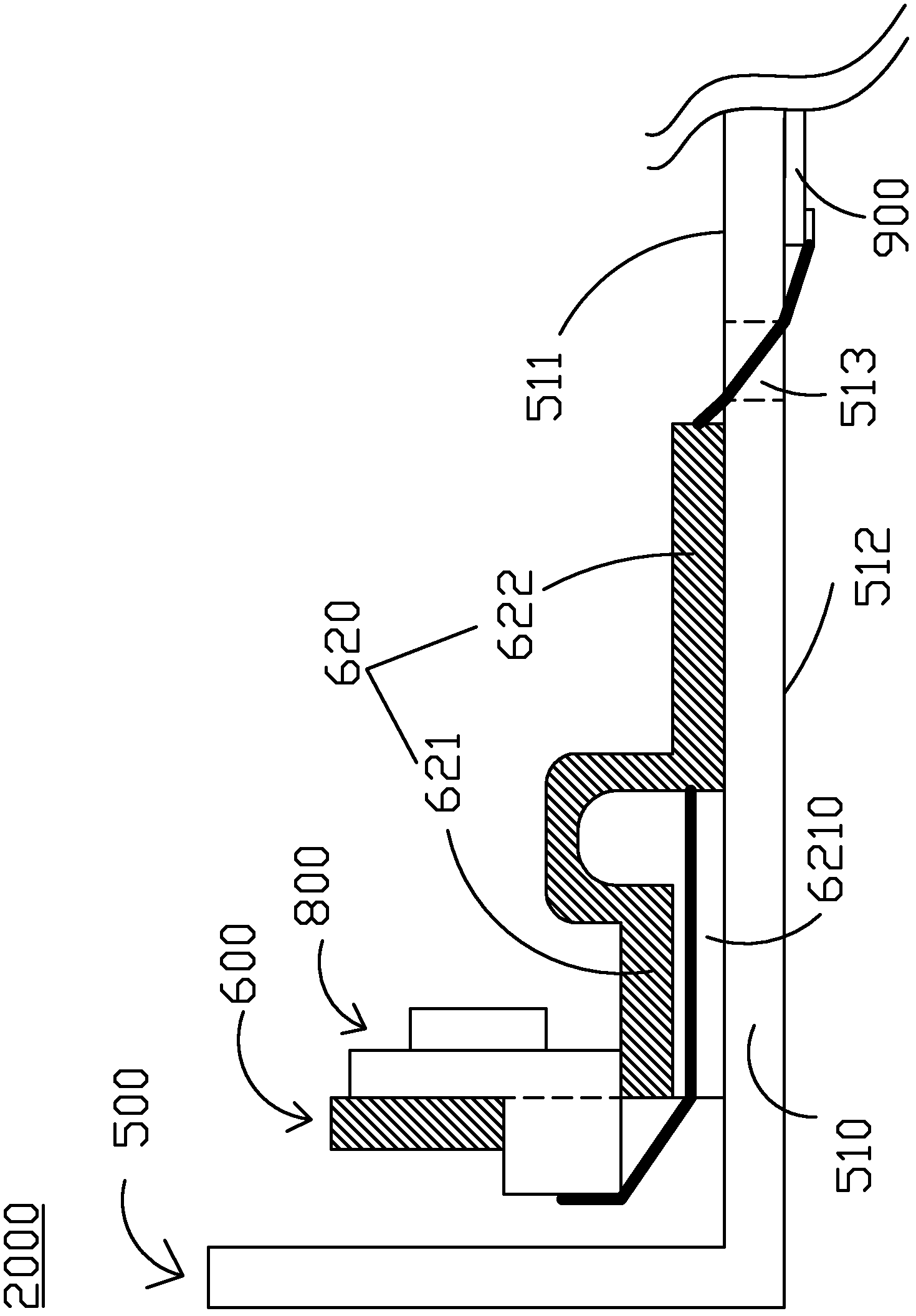

[0025] image 3 It is a partial cross-sectional view of the side of an edge-lit backlight module 2000 according to an embodiment of the present invention, Figure 4 It is a three-dimensional schematic diagram of some areas of the edge-lit backlight...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap