Three-level type automatic ammunition-filling ammunition-pressing production line

A three-stage, production line technology, applied in the direction of ammunition, weapon accessories, offensive equipment, etc., can solve the problems of many safety hazards, casualties, property losses, etc., and achieve the effect of fewer types of equipment, ensuring safety, and fast transmission speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

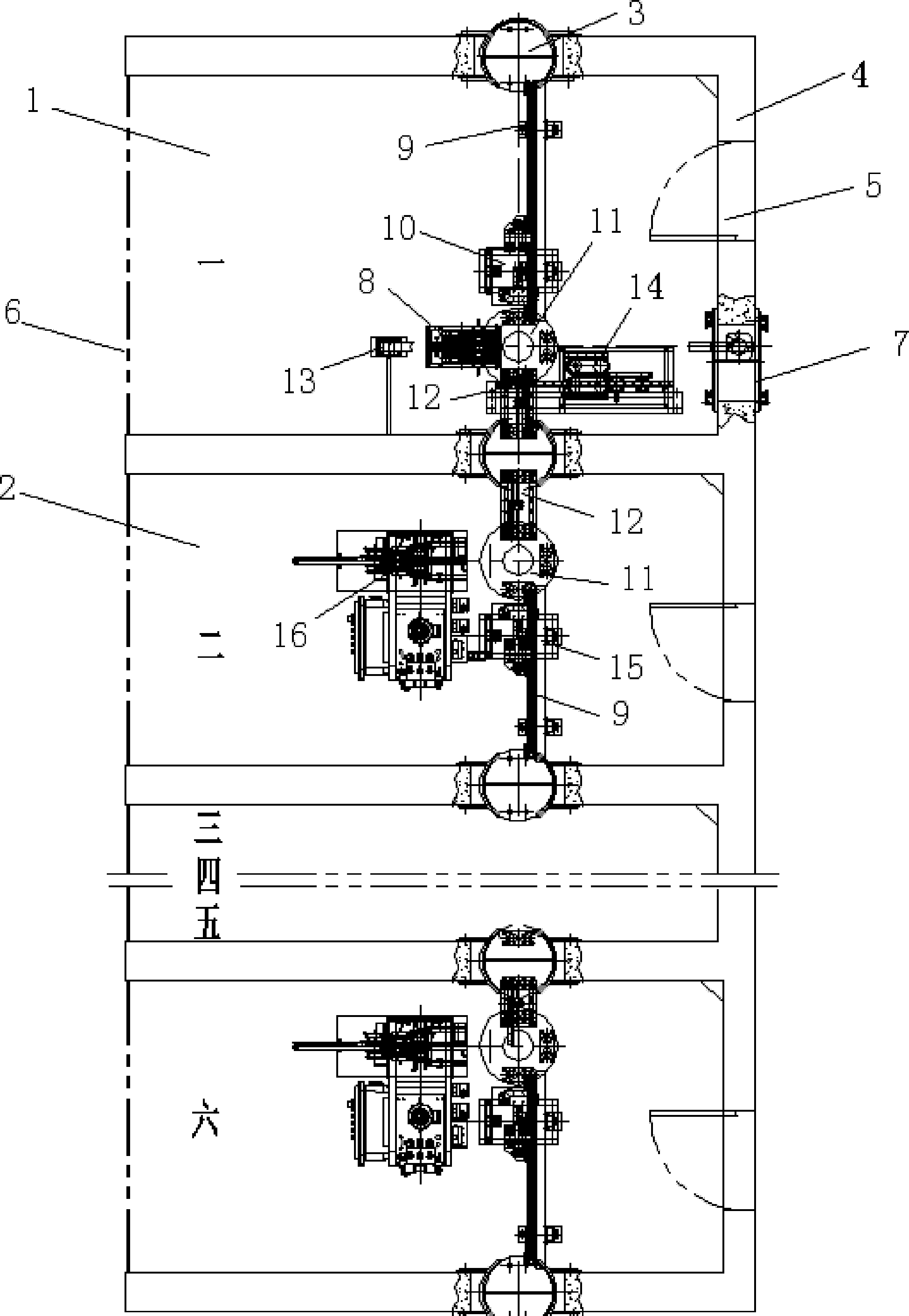

[0029] Such as figure 1 As shown, the present invention includes six antiknock rooms composed of three charge rooms 1 and three pressurized rooms 2 arranged in a staggered manner, between each antiknock room and between two antiknock rooms at both ends and the outside world On the anti-blast wall, a rotating anti-blast door 3 is respectively arranged, and on the side wall 4 perpendicular to each wall body where the rotating anti-blast door 3 is arranged, an employee access anti-blast door 5 is provided. The body of wall opposite the explosion door 5 is an integral explosion venting window 6. Adjacent to the staff access anti-blast door 5 of each charging room 1 is a gate-type anti-blast door 7 for delivering medicine from the outside.

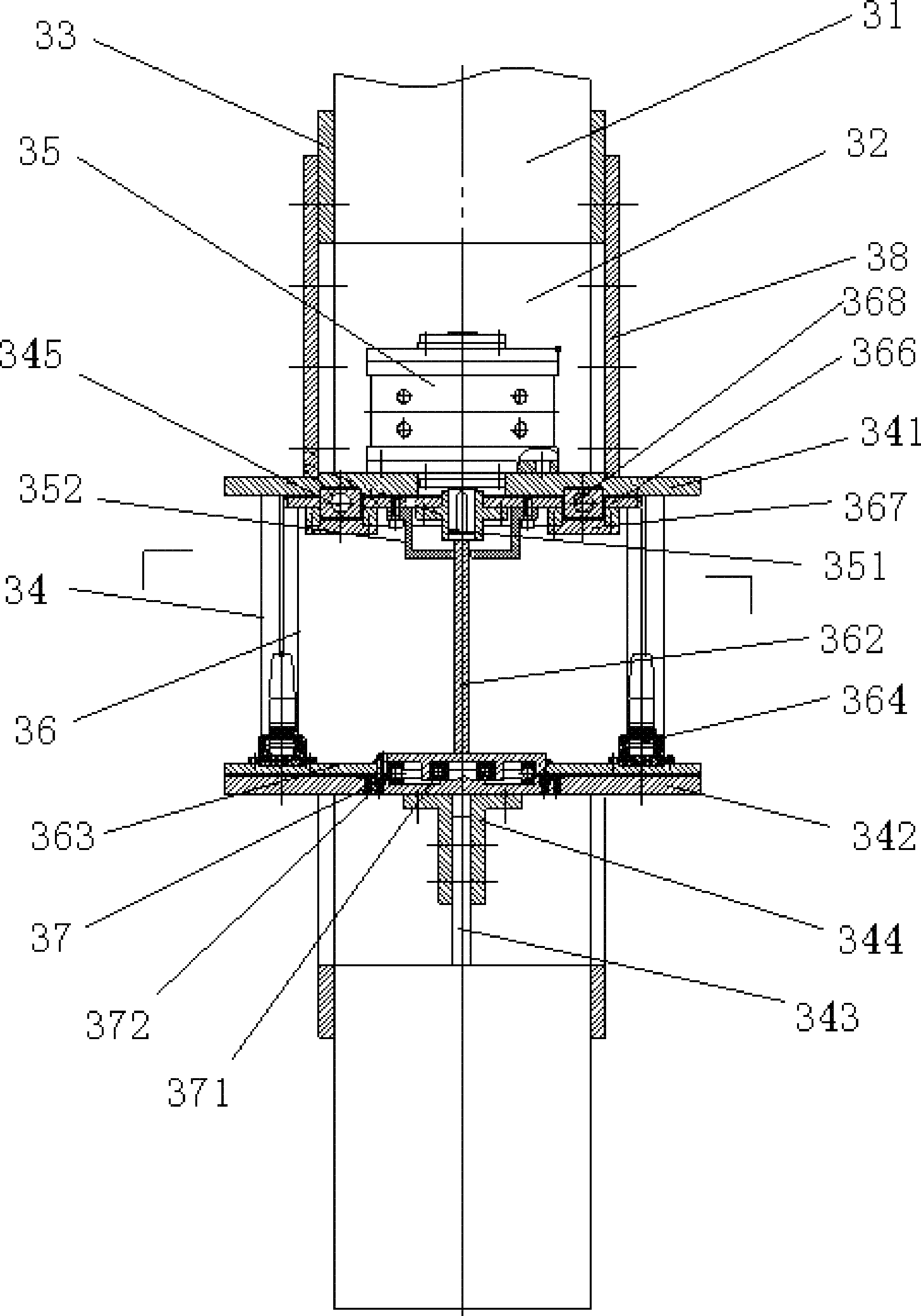

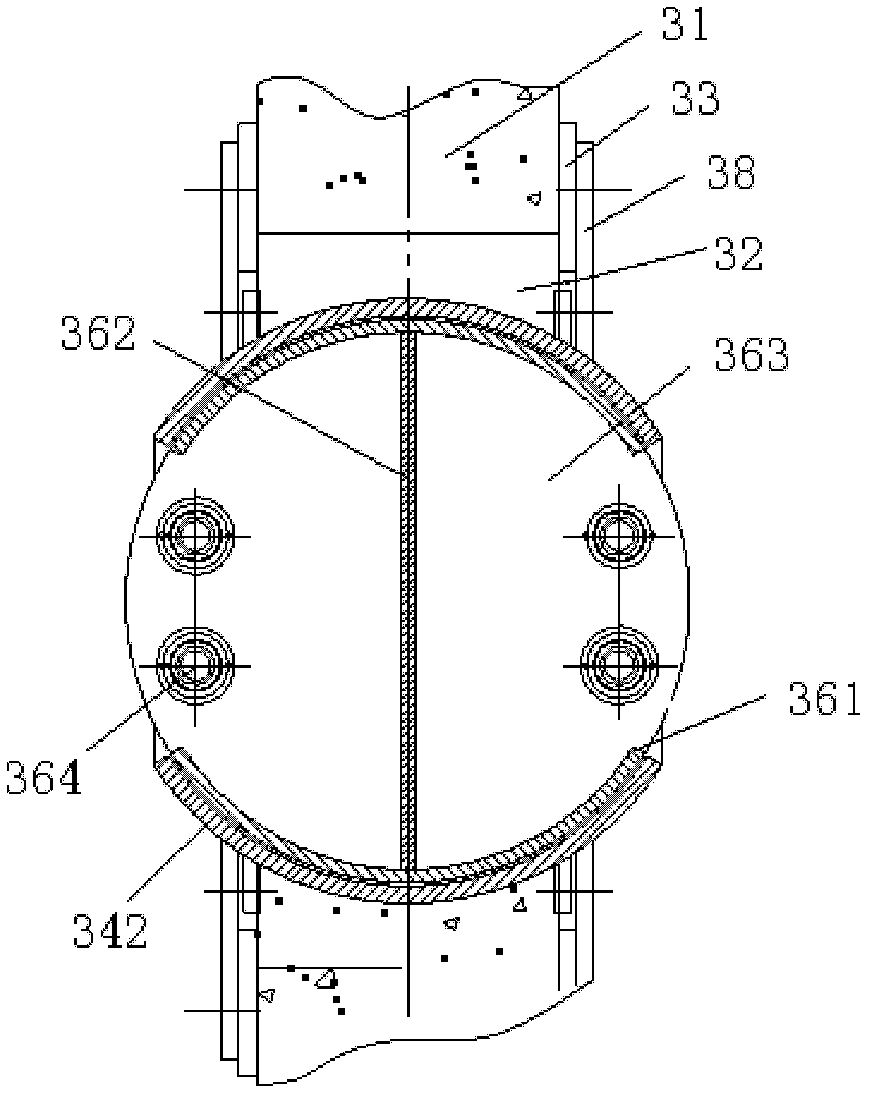

[0030]Each powder charging room 1 is provided with a powder weighing machine 8 respectively. On one side of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com