Hydrostatic pressure testing device for underwater wellhead

A test device and technology of underwater wellhead, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems such as the hydrostatic pressure test device of the wellhead body that has not yet been seen, and achieves simple and reliable structure and reduces unit costs. To the total force area, the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

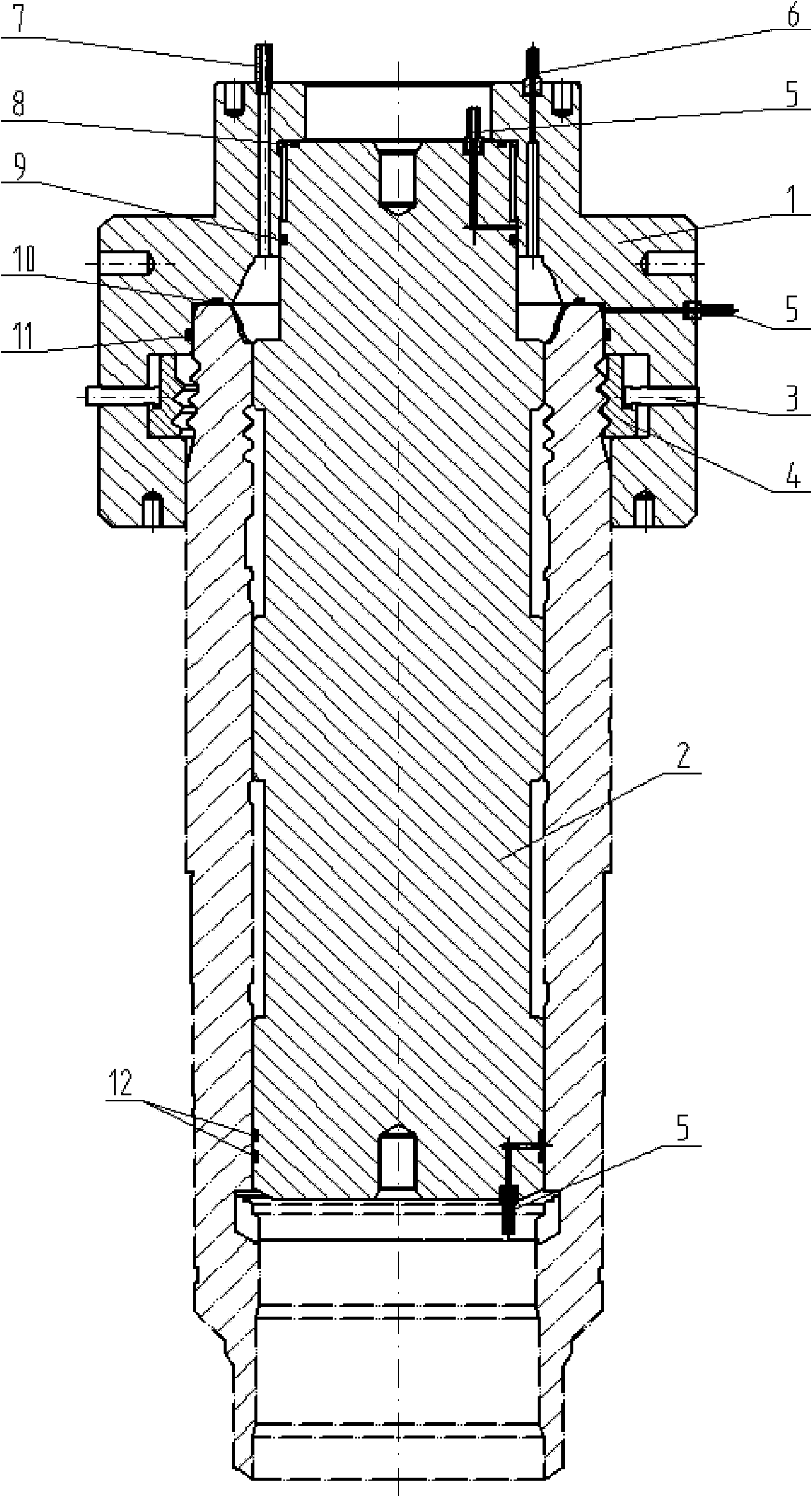

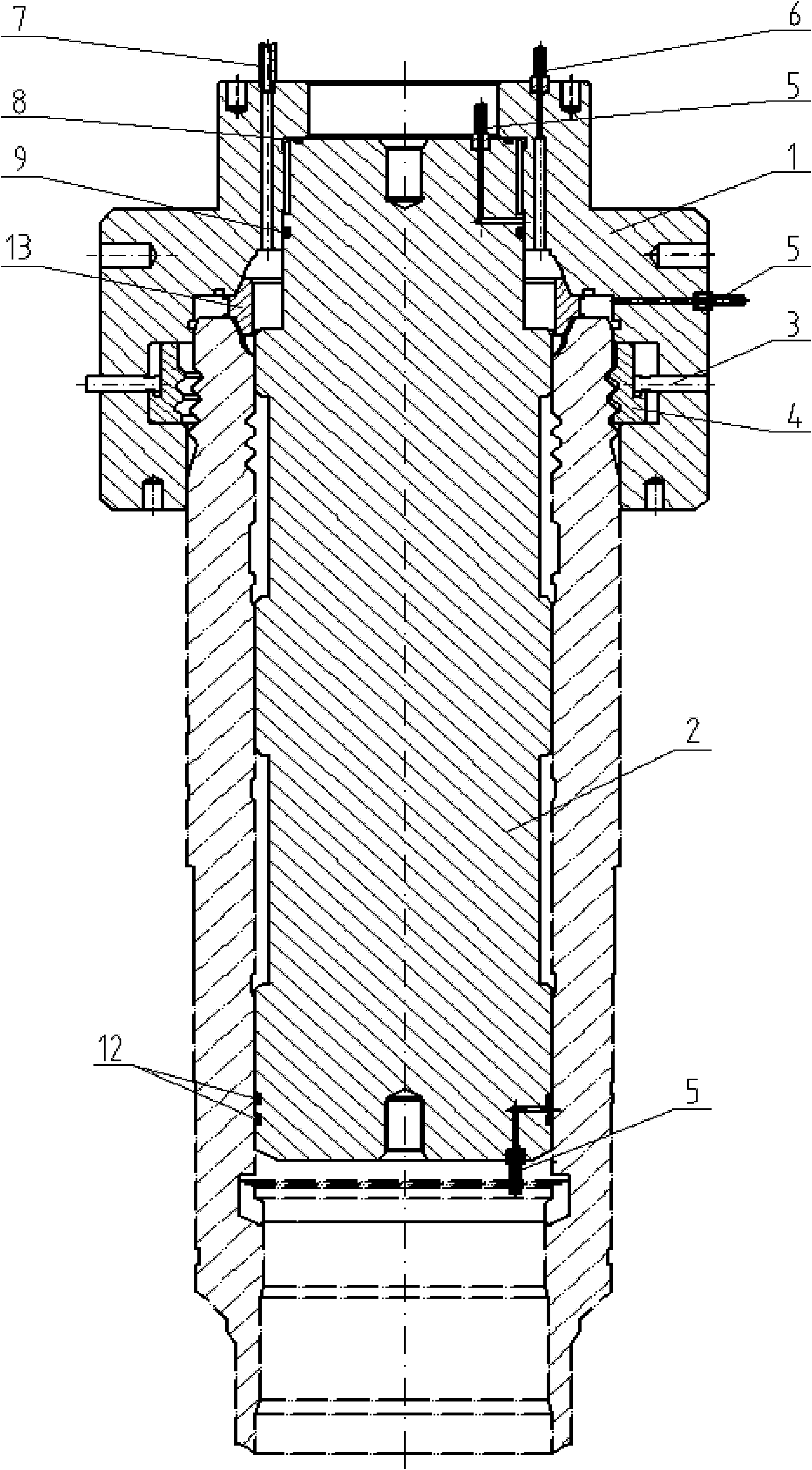

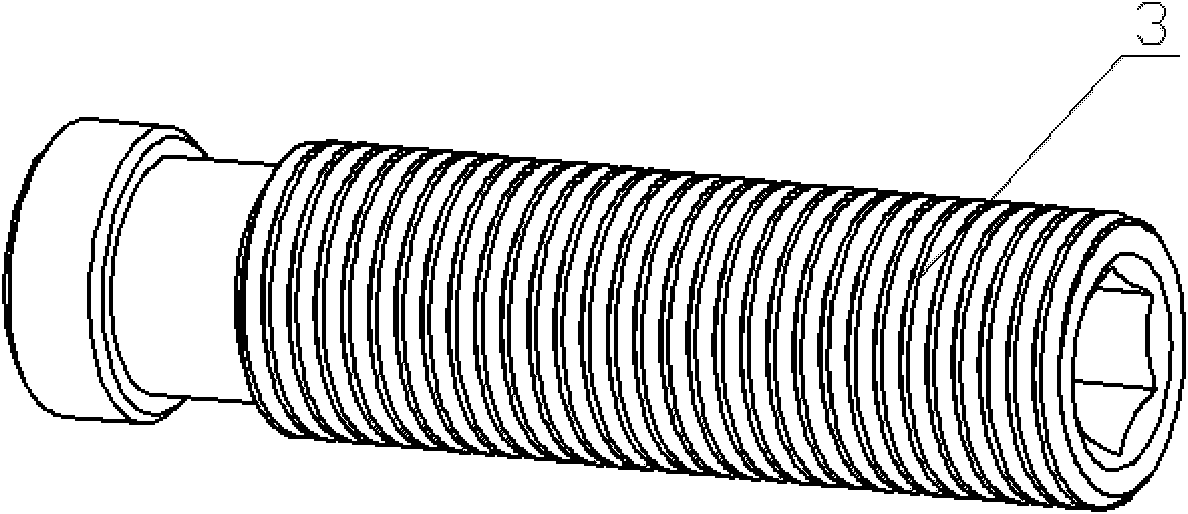

[0022] The first example is figure 1 , 3 , 4, including a sealing end cover 1 and a sealing mandrel 2, the sealing end cover is provided with a stepped through hole, the upper end of the stepped through hole is provided with a screw hole configured with the mandrel, and the upper end of the screw hole is provided with an upper hole shoulder Open a sealing groove on the upper end surface of the sealing mandrel to set the sealing ring 8 and the end face sealing configuration of the shoulder on the sealing end cover, open a sealing groove under the thread on the upper end of the sealing mandrel to install the sealing ring 9 and under the screw hole of the sealing end cover The sealing configuration of the sealing hole constitutes the upper sealing structure. The annular cavity between the above two sealing rings communicates with the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com