Flow battery test platform

A test platform and flow battery technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as the inability to test the relationship between vanadium battery stack structural parameters and vanadium battery performance, and achieve high speed, high precision, wide The effect of the working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

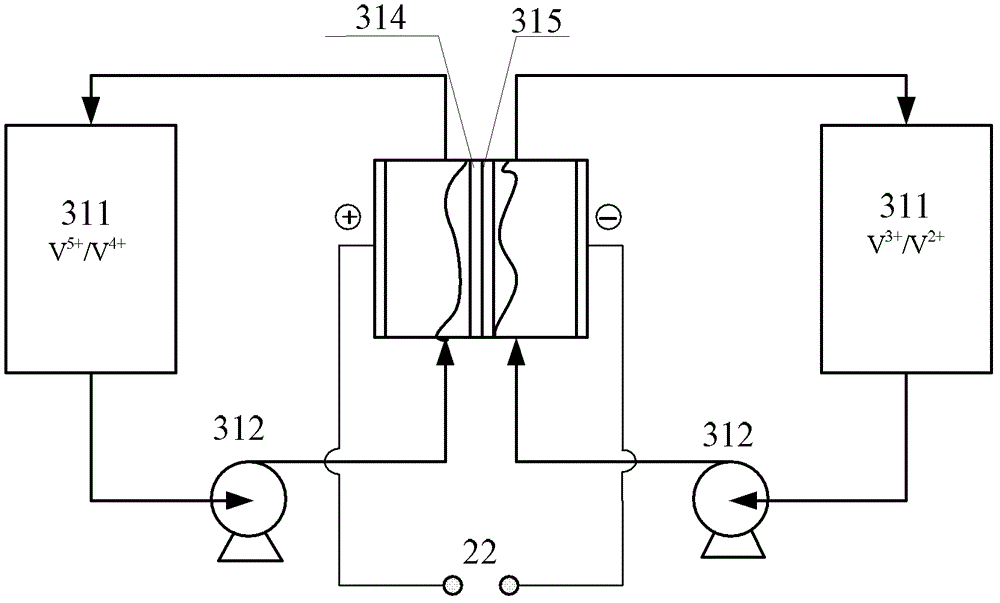

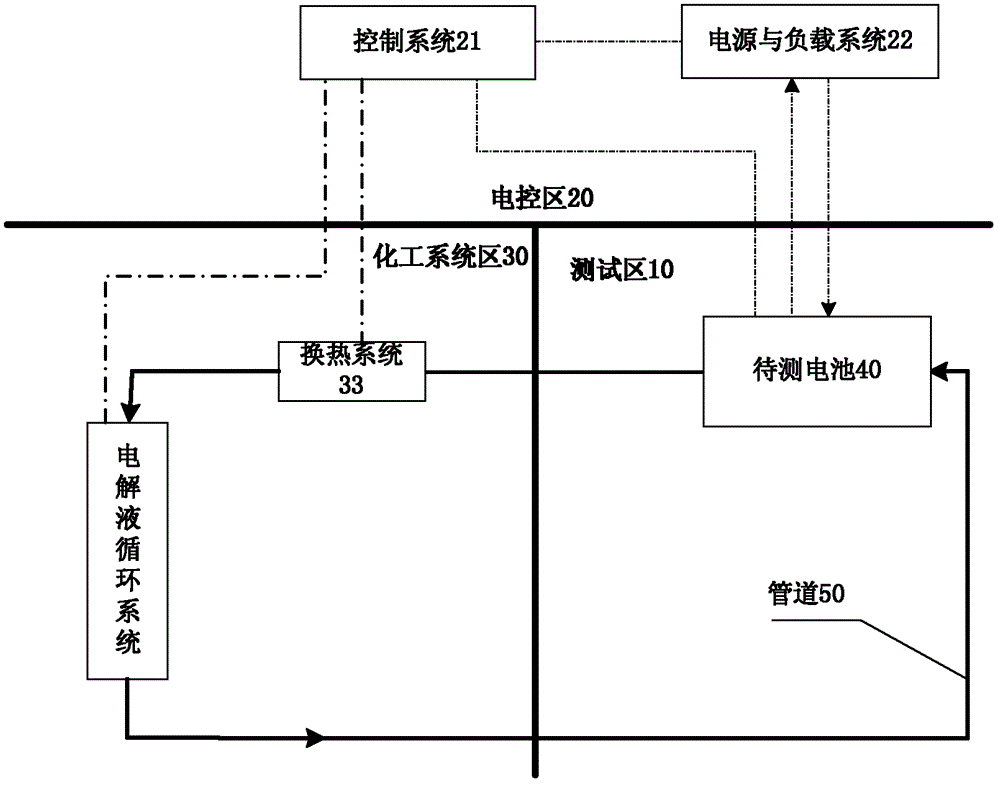

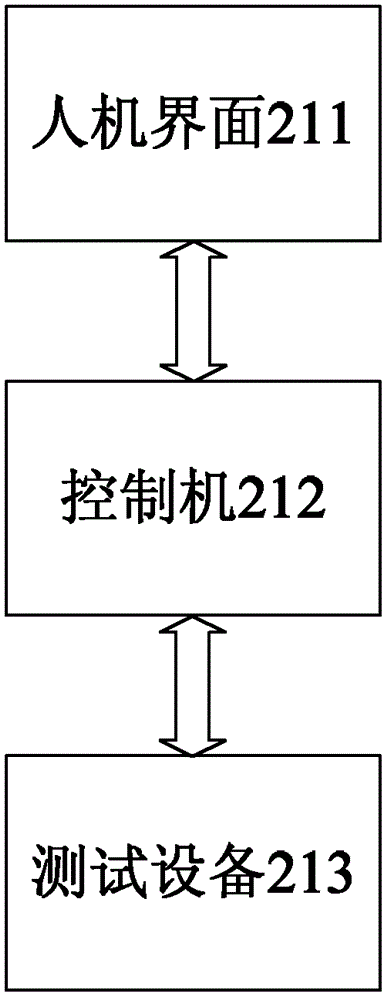

[0029] see Figure 2 to Figure 7 , according to the flow battery test platform of the present invention, comprising: a test area 10, the battery to be tested 40 is arranged in the test area 10; the electric control area 20, including a control system 21, a power supply and load system 22 and a manual debugging panel 23, and the control system 21 is electrically or wirelessly connected to the power supply and the load system 22, and the control system 21 is electrically or wirelessly connected to the manual debugging panel 23, and the power supply and the load system 22 are electrically or wirelessly connected to the test area 10; the chemical system area 30 includes the electrolyte circulation system , the chemical system area 30 is electrically or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com