Fan module

A fan module and fan technology, applied in cooling/ventilation/heating transformation, electrical equipment construction parts, electrical components, etc., can solve problems such as cumbersome process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

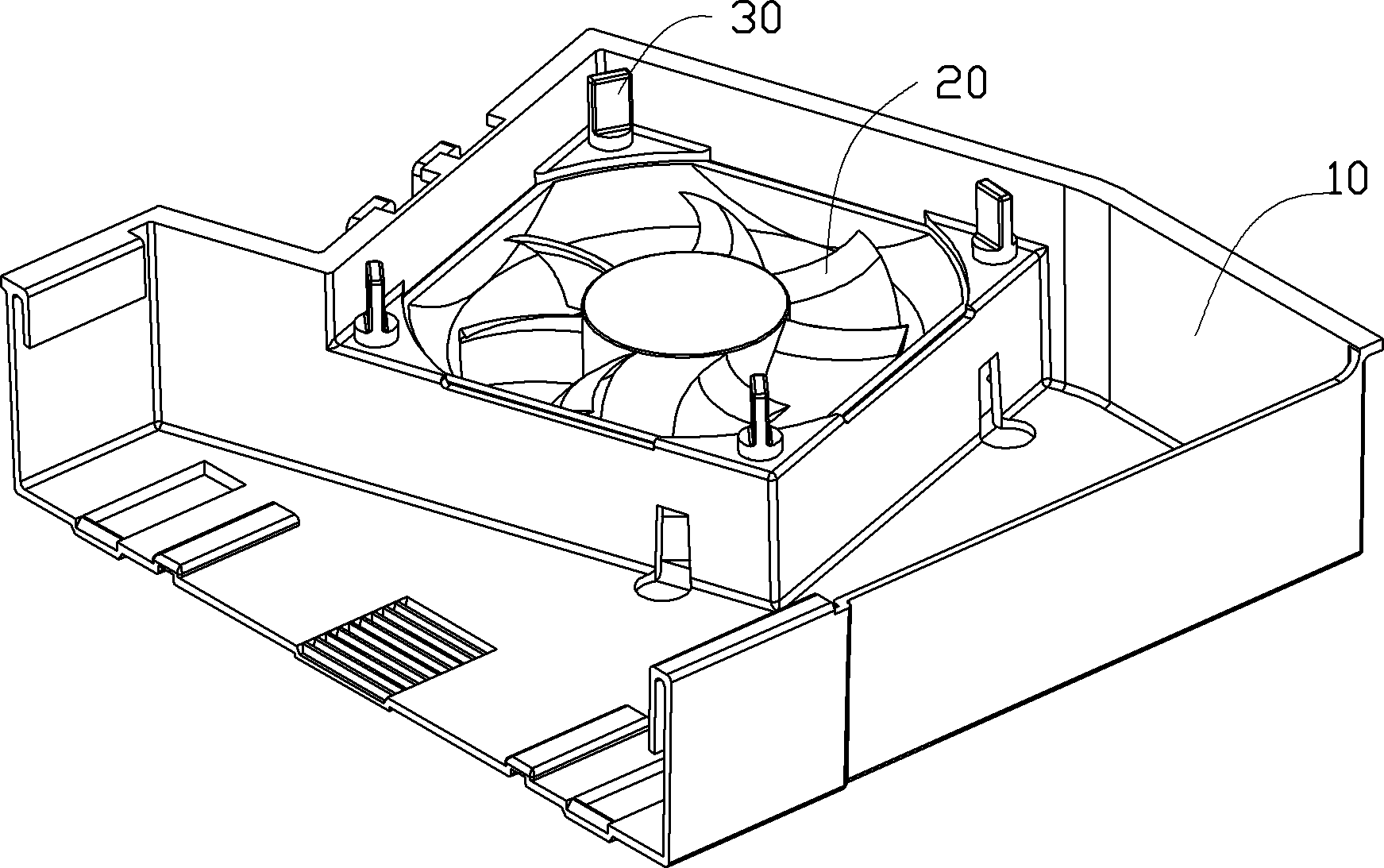

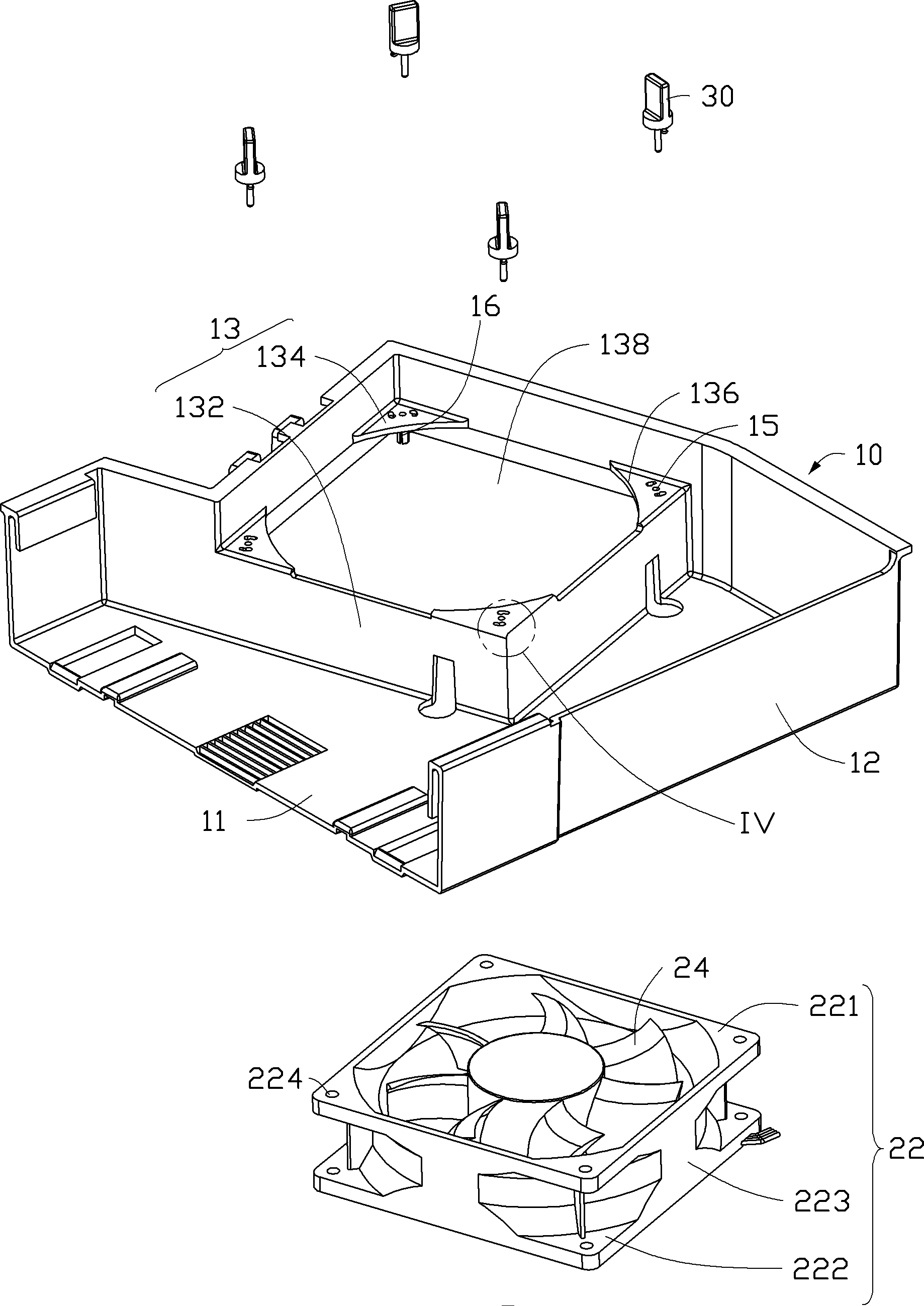

[0047] Such as figure 1 As shown, the fan module in the embodiment provided by the present invention includes a fixing frame 10 , a fan 20 and a fixing member 30 locking and fixing the fixing frame 10 and the fan 20 .

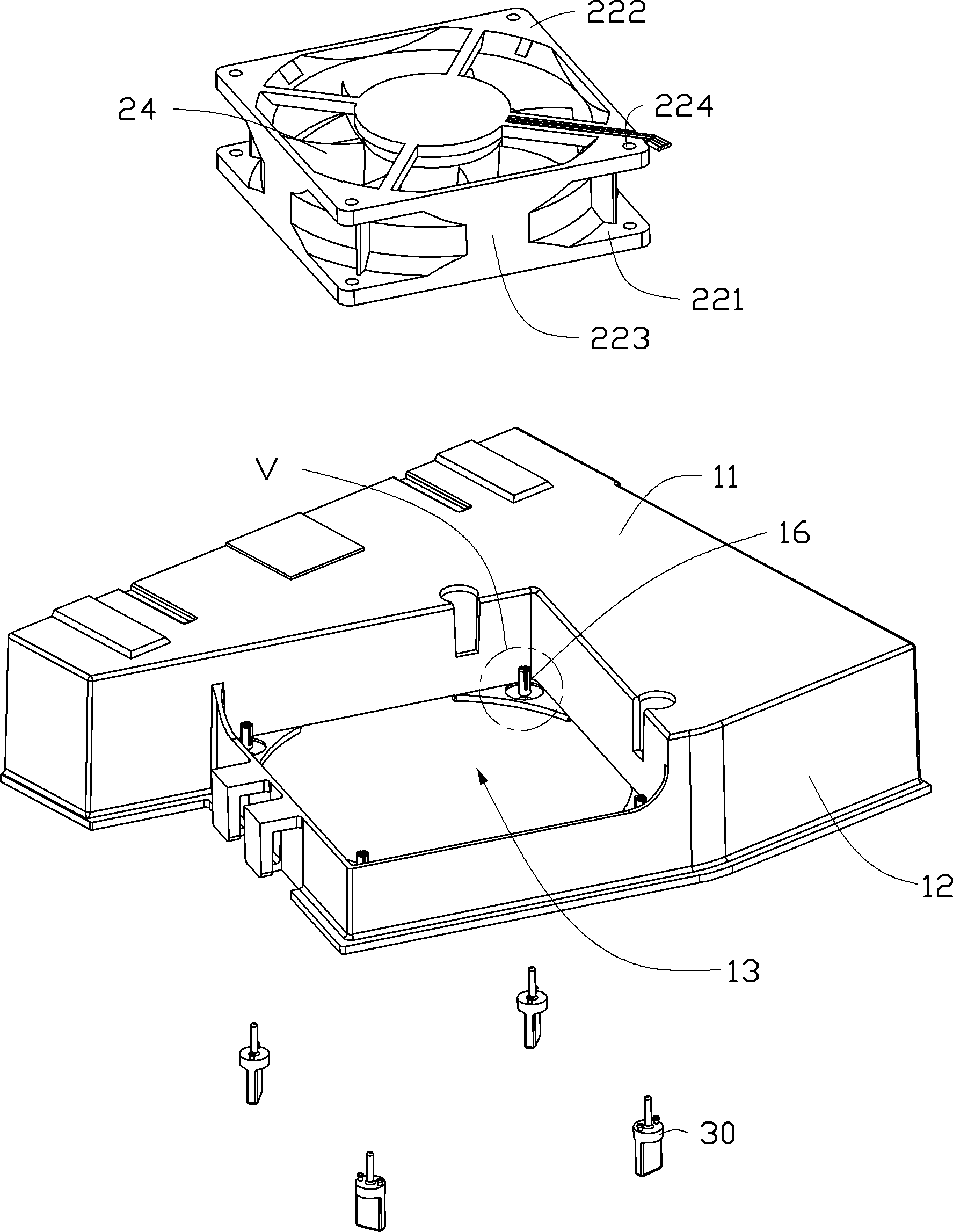

[0048] see figure 2 , the fan 20 includes a fan frame 22 and fan blades 24 accommodated in the fan frame 22 . The fan frame 22 is a hollow rectangle, which includes an upper end surface 221 , a lower end surface 222 and an annular side surface 223 connected between the upper end surface 221 and the lower end surface 222 . The outer contours of the upper end surface 221 and the lower end surface 222 are both square, and the four corners of the upper end surface 221 and the lower end surface 222 are respectively provided with connecting holes 224 . The fan 20 is an axial flow fan, and the centers of the upper end surface 221 and the lower end surface 222 respectively form an air inlet and an air outlet aligned in the axial direction.

[0049] Please also see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com