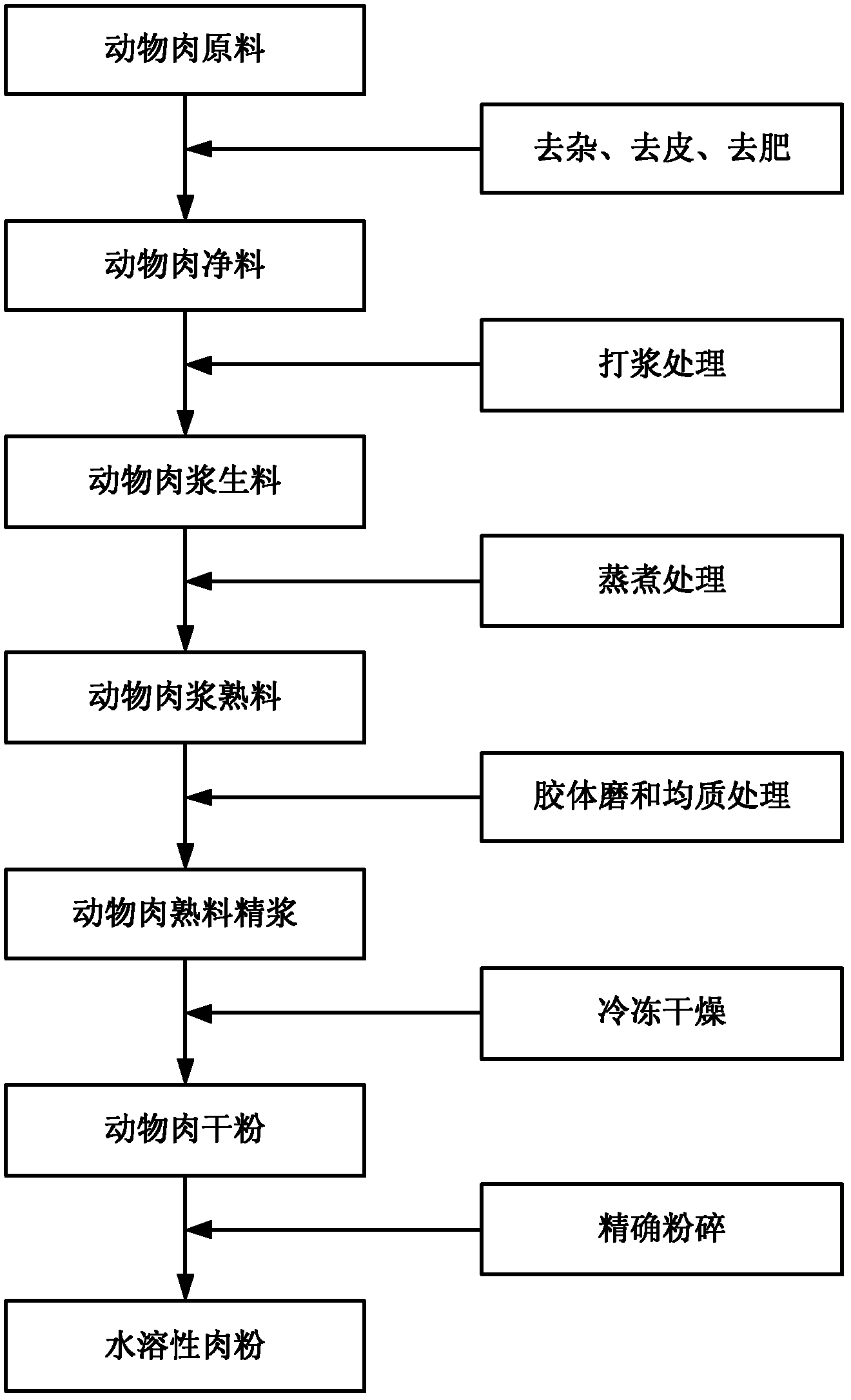

Process for preparing water-soluble meat powder

A water-soluble, meat meal technology, applied in food preparation, application, food science, etc., can solve the problems of portability and rapid absorption, insufficient time consumption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0006] (1) Select 1.0kg of boneless and skinless pork raw materials (fat content not exceeding 100g) that meet the relevant food hygiene standards;

[0007] (2) Add 1:1 potable water, and use a pulverizer to process the pork raw material into meat slurry;

[0008] (3) Use 80 mesh sieves to sieve the meat slurry, and discard the part remaining on the sieve;

[0009] (4) heating the sieved meat slurry, keeping it in a slightly boiling state for 10 minutes, and aging the pork;

[0010] (5) After the cured meat slurry is cooled, use a colloid mill to finely grind it so that the particle size of the raw material is not higher than 5.0 μm;

[0011] (6) Carry out high-pressure homogenization treatment (30MPa, 3 times) to the finely ground meat slurry;

[0012] (7) Use a freeze dryer to dehydrate the homogenized meat slurry. The parameters are cold trap temperature below -60°C, pressure below 5Pa, and freezing time for more than 72 hours.

[0013] (8) Precisely pulverize the dehydr...

Embodiment 2

[0016] (1) Select 1.0 kg of boneless and skinless cod block raw materials that meet relevant food hygiene standards;

[0017] (2) Add 1:0.8 potable water, and use a pulverizer to process the cod meat raw material into cod meat slurry;

[0018] (3) use 100 mesh sieves to sieve the cod pulp, and discard the part remaining on the sieve;

[0019] (4) Heating the sieved meat slurry to keep it in a slightly boiling state for 5 minutes, and ripening the cod meat;

[0020] (5) After the cooked cod meat slurry is cooled, use a colloid mill to finely grind it so that the particle size of the raw material is not higher than 5.0 μm;

[0021] (6) Carry out high-pressure homogenization treatment (40MPa, 3 times) to the cod meat slurry after fine grinding;

[0022] (7) Use a freeze dryer to dehydrate the homogenized meat slurry. The parameters are cold trap temperature below -60°C, pressure below 5Pa, and freezing time for more than 72 hours.

[0023] (8) Precisely pulverize the dehydrate...

Embodiment 3

[0026] (1) Select 1.0 kg of boneless and skinless chicken breast raw material that meets the relevant food hygiene standards;

[0027] (2) Add 1:1 potable water, and use a pulverizer to process the chicken raw material into a meat slurry;

[0028] (3) Use 80 mesh sieves to sieve the meat slurry, and discard the part remaining on the sieve;

[0029] (4) Heating the sieved meat slurry, keeping it in a slightly boiling state for 5 minutes, and aging the chicken;

[0030] (5) After the cured meat slurry is cooled, use a colloid mill to finely grind it so that the particle size of the raw material is not higher than 5.0 μm;

[0031] (6) Carry out high-pressure homogenization treatment (30MPa, 3 times) to the finely ground meat slurry;

[0032] (7) Use a freeze dryer to dehydrate the homogenized meat slurry. The parameters are cold trap temperature below -60°C, pressure below 5Pa, and freezing time for more than 72 hours.

[0033] (8) Precisely pulverize the dehydrated chicken po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap