Bobbin rolling device for the tobacco processing industry

A technology of processing industry and uncoiling device, which is applied in the fields of tobacco, mechanical processing/deformation, and cigarette manufacturing, etc. It can solve the problem that the paper web cannot be wound neatly or evenly, and achieves the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

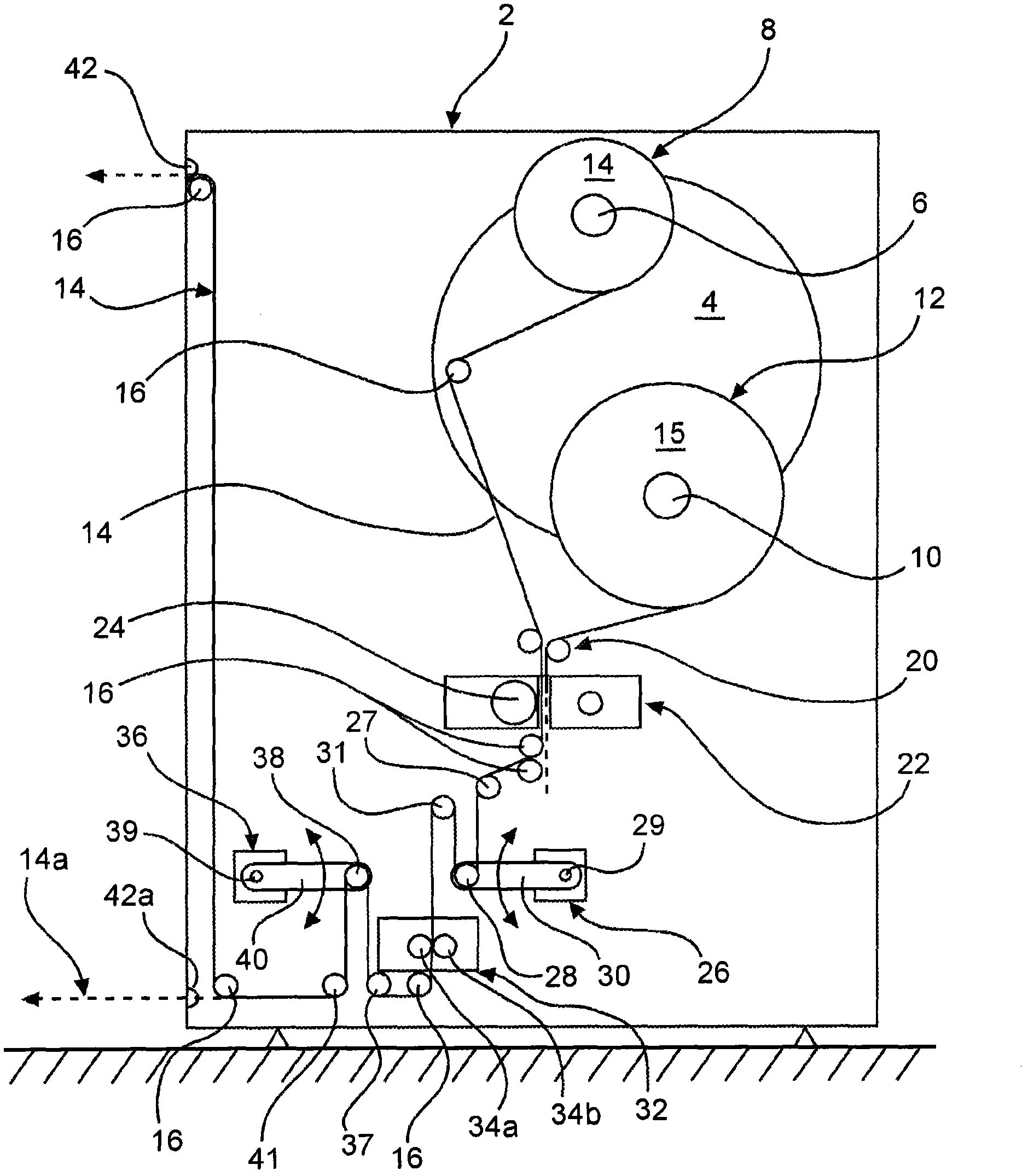

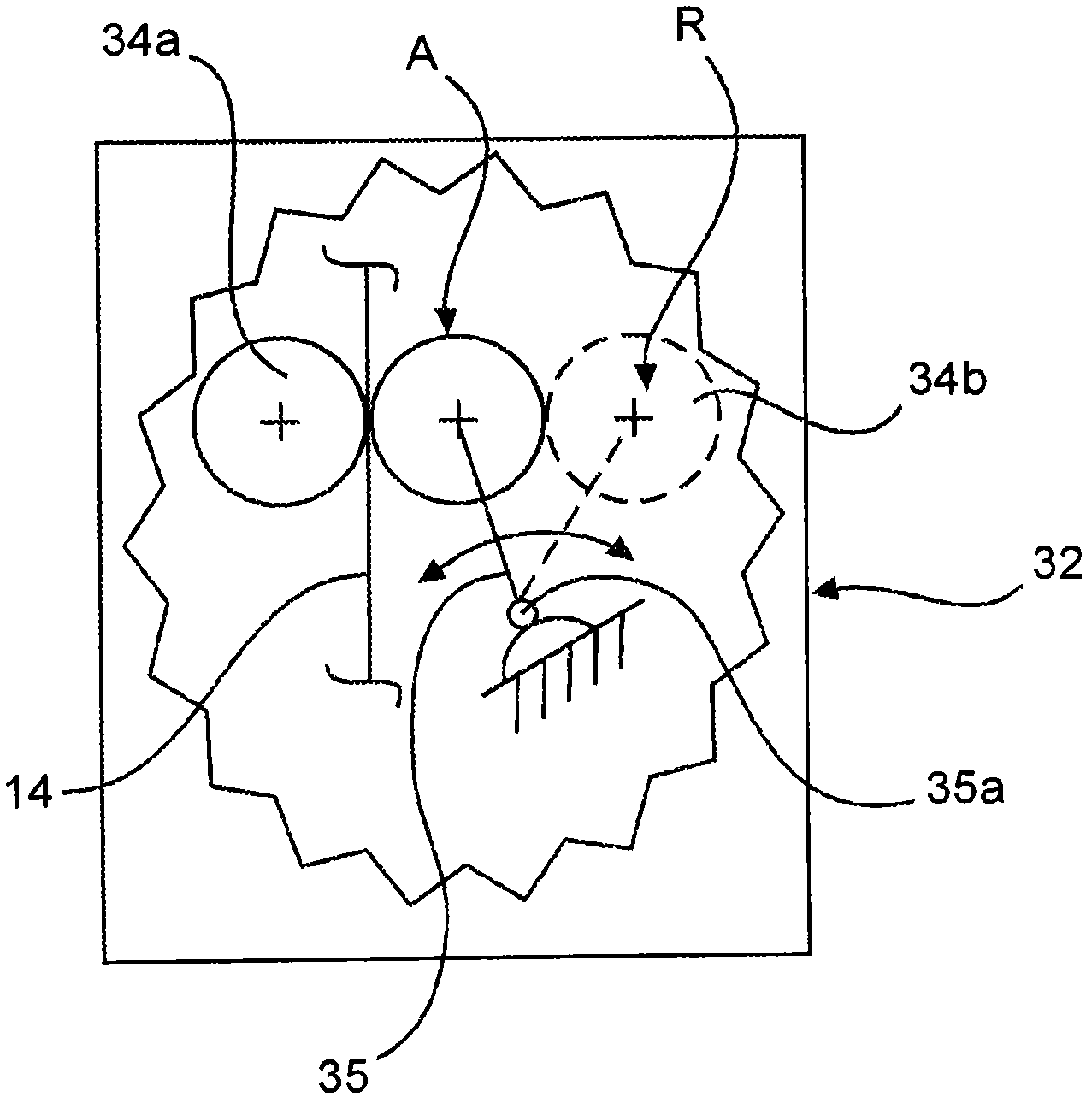

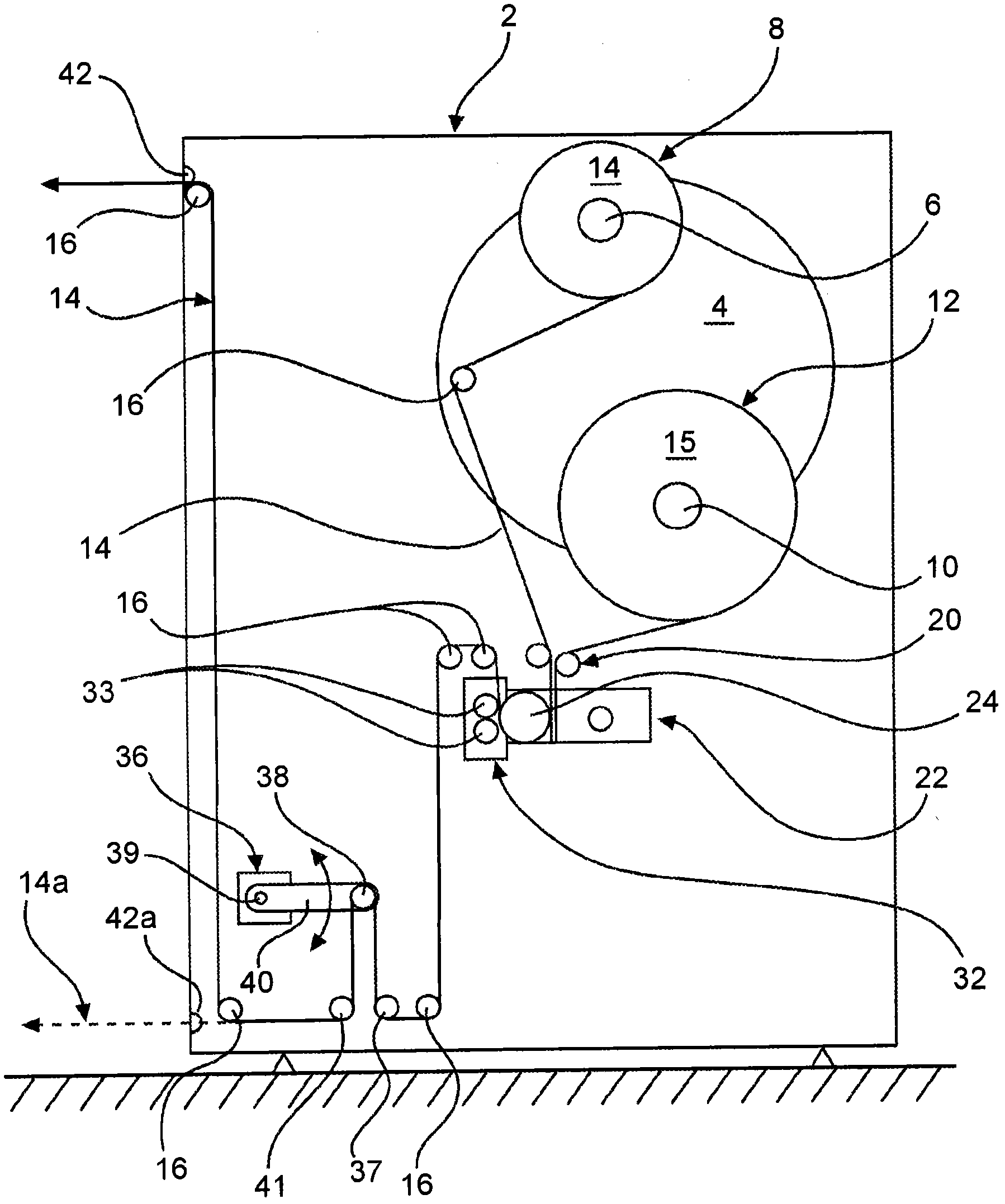

[0032] figure 1 A roll unwinding device 2 according to a first preferred embodiment is shown. The spool unwinding device 2 has a spool support 4 which, in the exemplary embodiment shown, is formed by a rotatably mounted disk and can be moved into different rotational positions and can be fixed in said rotational positions. In the exemplary embodiment shown, the roll holder 4 is associated with a first bearing neck 6 which is arranged perpendicularly to the disk-shaped roll holder 4 and which is provided for a rotatably mounted first roll 8 . . In a similar manner, in the exemplary embodiment shown, the second bearing neck 10 is arranged vertically or at right angles to the disk-shaped drum support 4 and serves for the rotatable mounting of the second drum 12 . Centers or axes of rotation (not shown) of the bearing necks 6 , 10 run parallel to one another and parallel to the axis of rotation (likewise not shown) of the drum holder 4 . A first paper web 14 is wound on the fir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap