Extrusion device

A tool, extrusion direction technology, used in packaging, devices for coating liquid on surfaces, distribution devices, etc., can solve the problems of ending the operation process, limiting the adjustment stroke, inaccuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

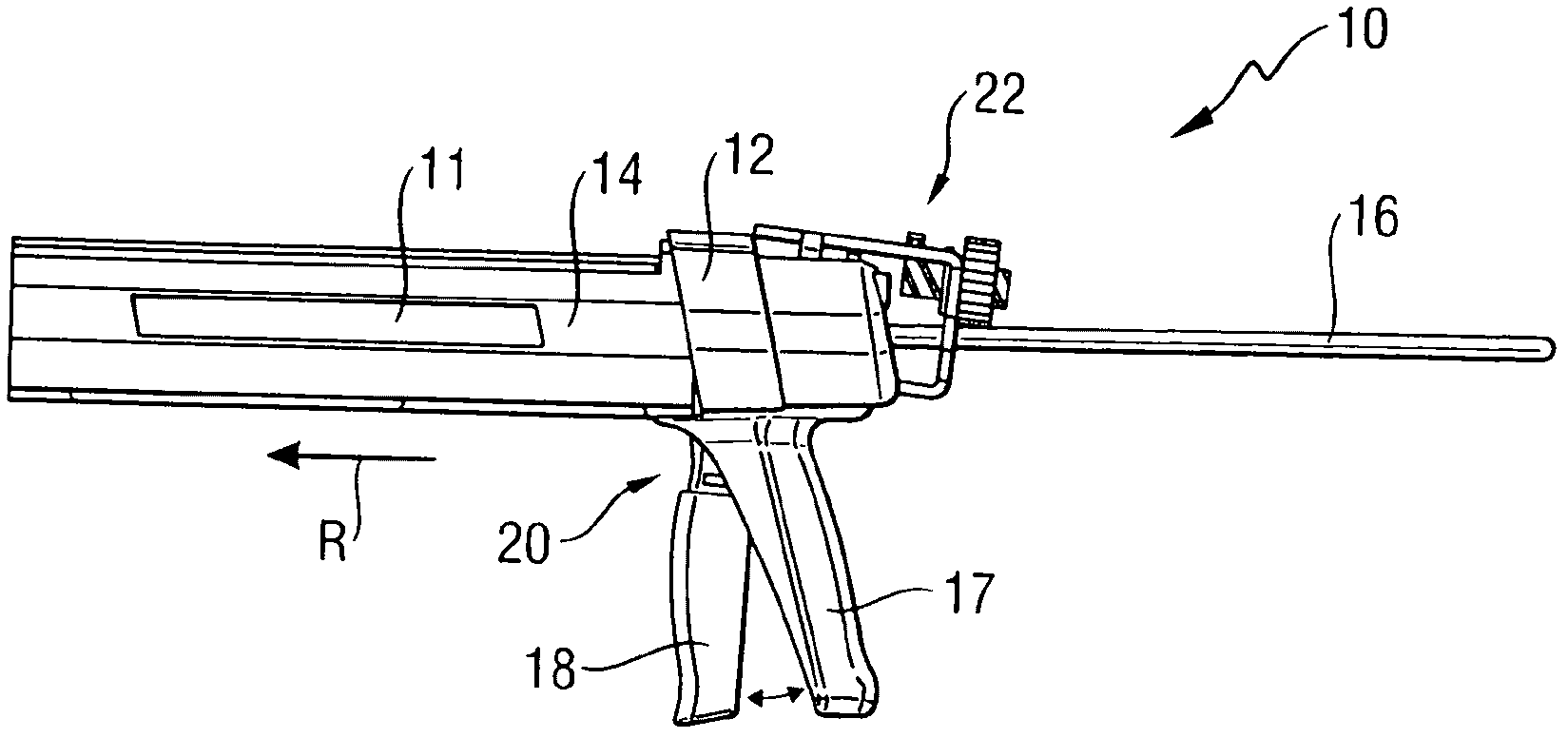

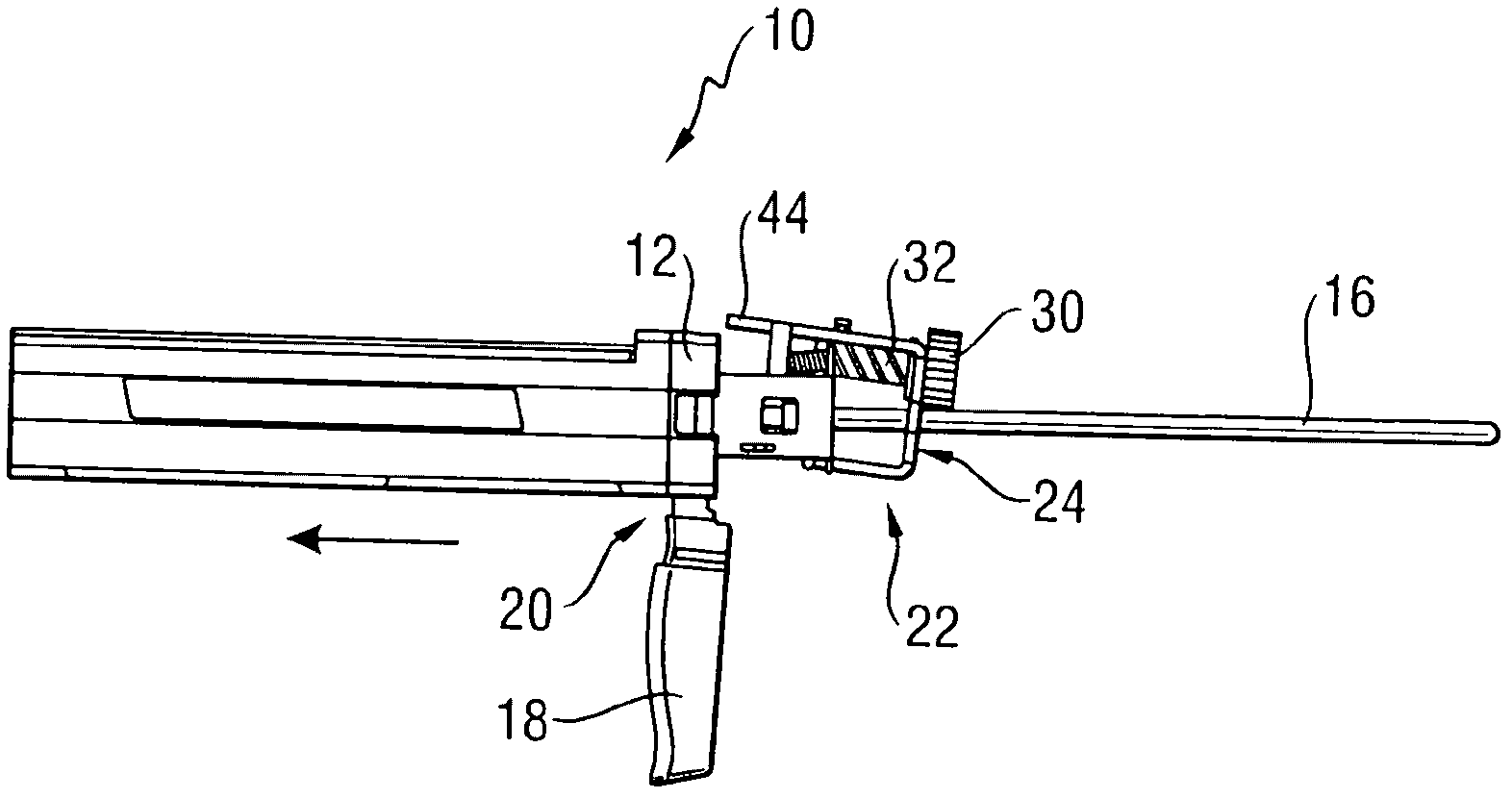

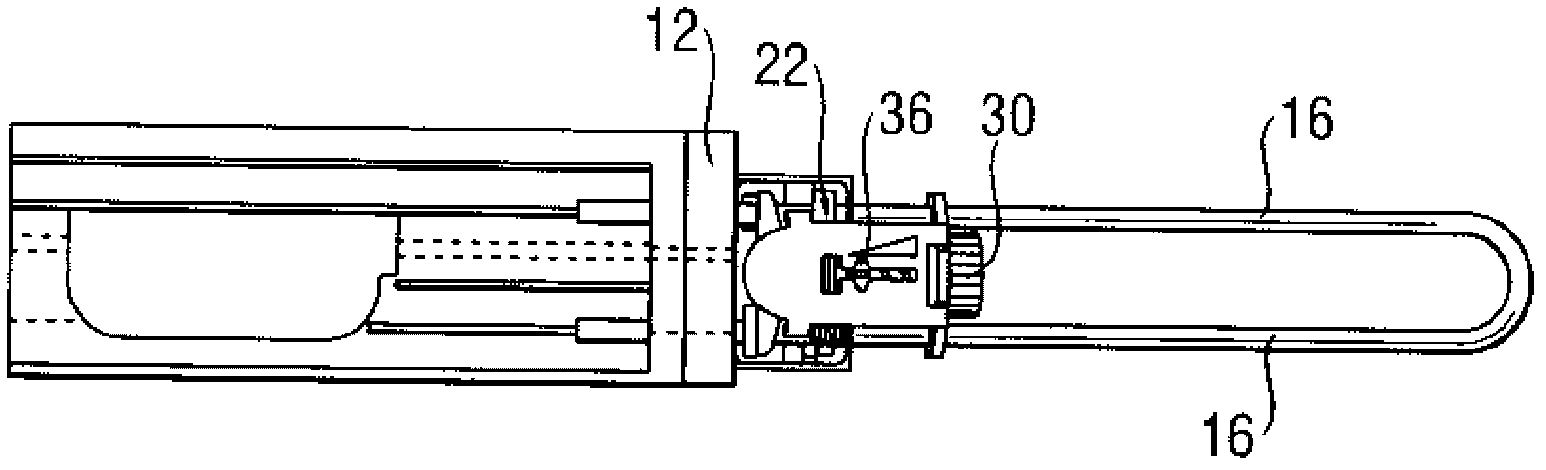

[0028] figure 1 An extrusion tool 10 for a cartridge 11 is shown. Such cartridges have a cylindrical base body filled with a flowable engineering material such as silicone. For very fluid engineering materials, this cartridge is also supported in an additional bag. on one end wall, here means figure 1 On the left end wall in the center, there is an output port for engineering materials. The opposite end wall is formed by a displaceable plunger which is mounted displaceably in the extrusion direction R in the direction of the first end wall in the cylindrical basic body. The volume of the base body is reduced by pushing the plunger in the feed direction R, so that the engineering material can be extruded from the outlet.

[0029] The extrusion tool 10 here has a housing 12 , a holding device 14 which can accommodate the cartridge 12 , and two parallel piston rods 16 , which are displaceably mounted in the housing 12 in the direction of advance R, And it can cooperate with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com