Electric tool

A technology for power tools and machine tools, applied in power tools, manufacturing tools, etc., can solve the problems of larger size of machine tools, rapid power consumption, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

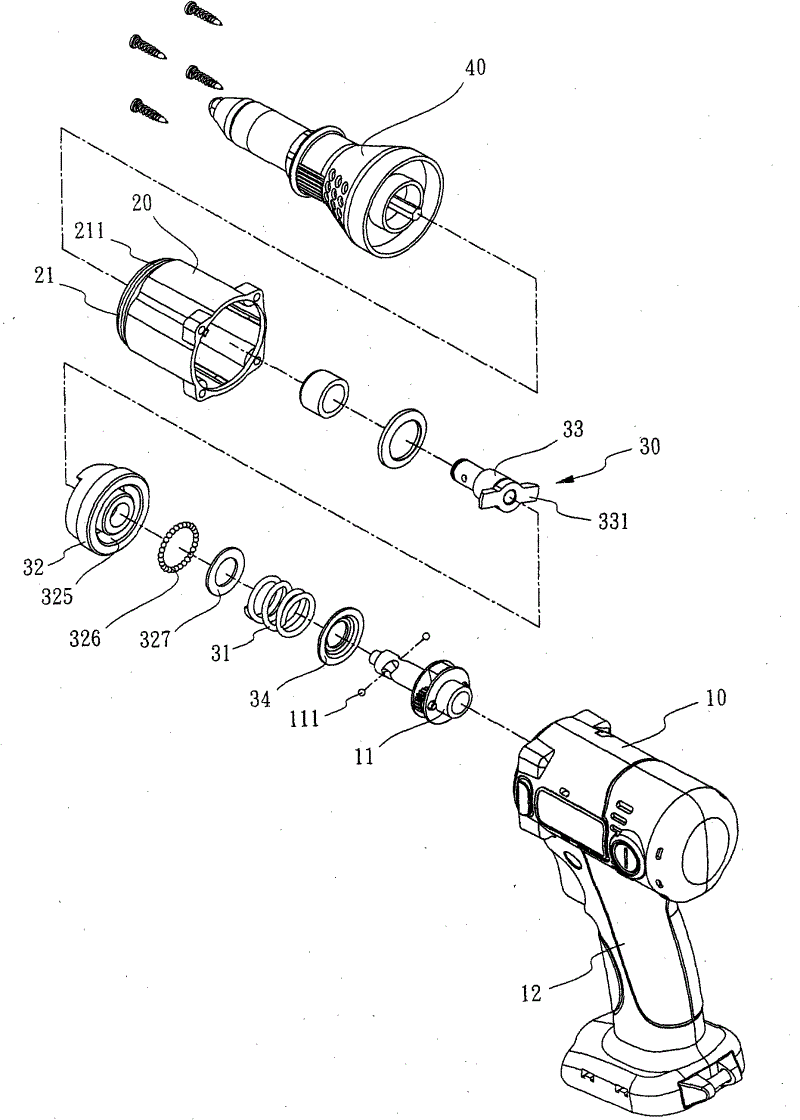

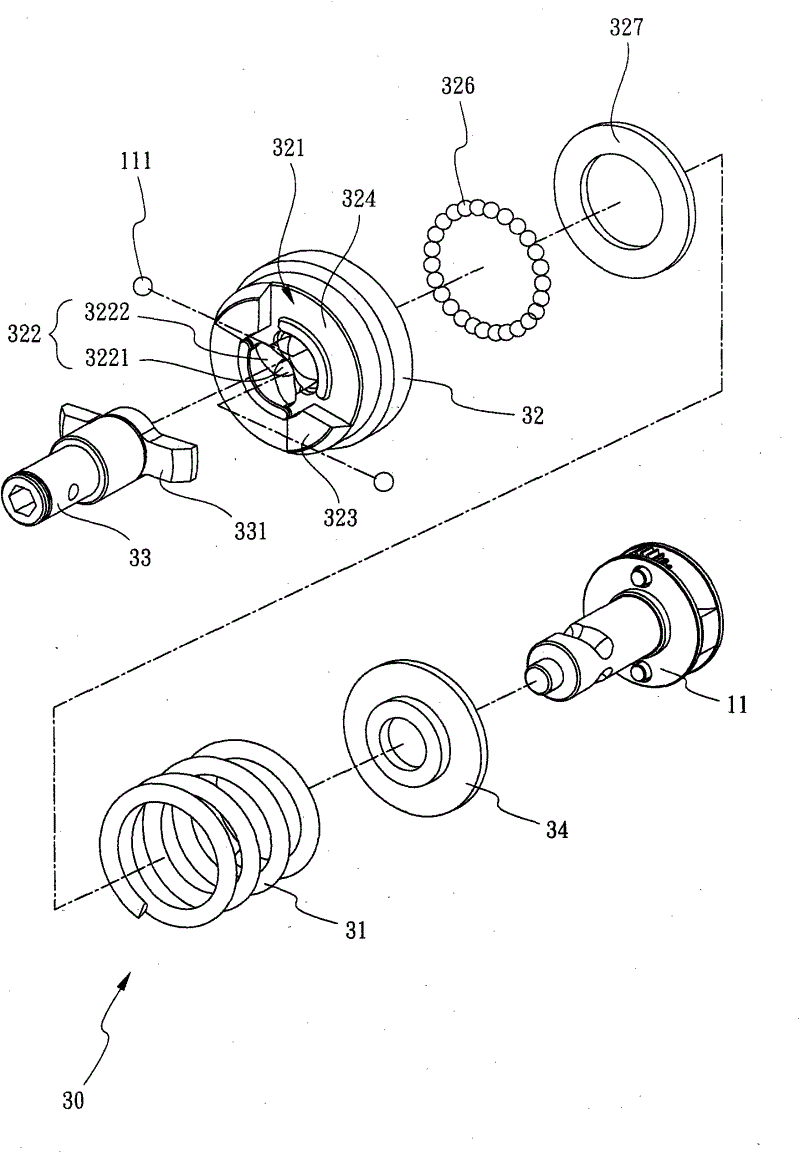

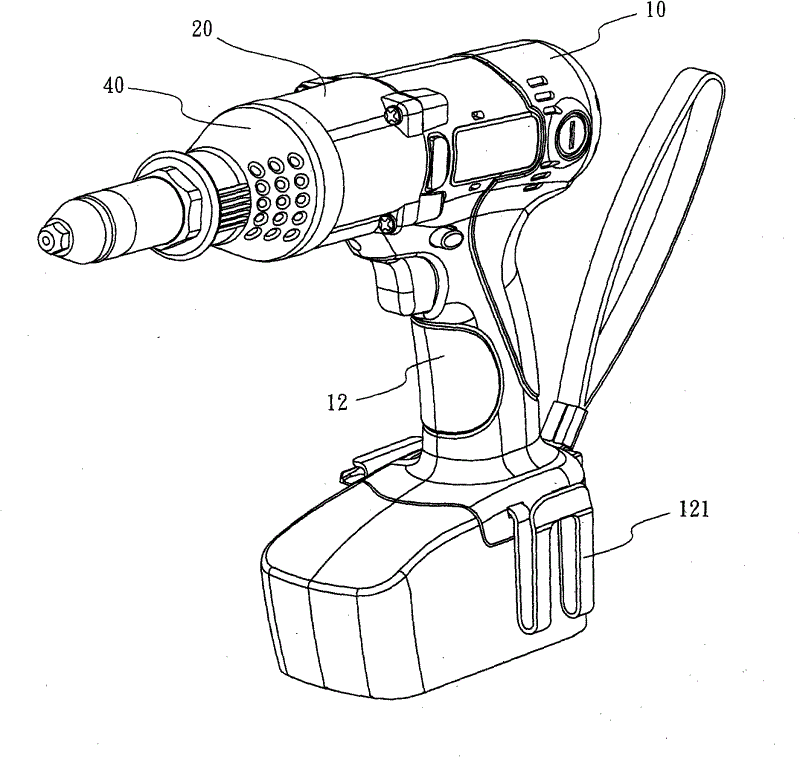

[0037] The invention relates to an electric tool, which is an electric tool that can be connected with a nail pulling mechanism or an impact driver head, and the electric tool has an impact structure at the end of the output shaft, so that the nail pulling mechanism can pass through the impact during the nail pulling operation. The action ends as a broken nail, see Figure 1 to Figure 4 As shown, the "electric tool" of the present invention includes a machine tool body 10, a front cover 20 locked at the output end of the machine tool body 10, and an impact unit 30 arranged inside the front cover 20 and connected to the machine tool body 10, A motor mechanism is built in the machine tool body 10, and the motor mechanism has a transmission shaft 11 that drives the impact unit 30 (the motor mechanism of the machine tool belongs to the prior art, and the accompanying drawing only shows the transmission shaft 11 of the motor mechanism):

[0038] The impact unit 30 includes a spring...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap