Master-slave control robot work platform for high-voltage live working

A working platform and high-voltage electrified technology, which is applied in the direction of program control manipulators, manipulators, manufacturing tools, etc., can solve personal casualty accidents, minor accidents, avoid touching wires or other live equipment, safety accidents and other problems during operation, and ensure the safety of man and machine , The effect of improving the safety of live operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment the novel of the present invention is further described.

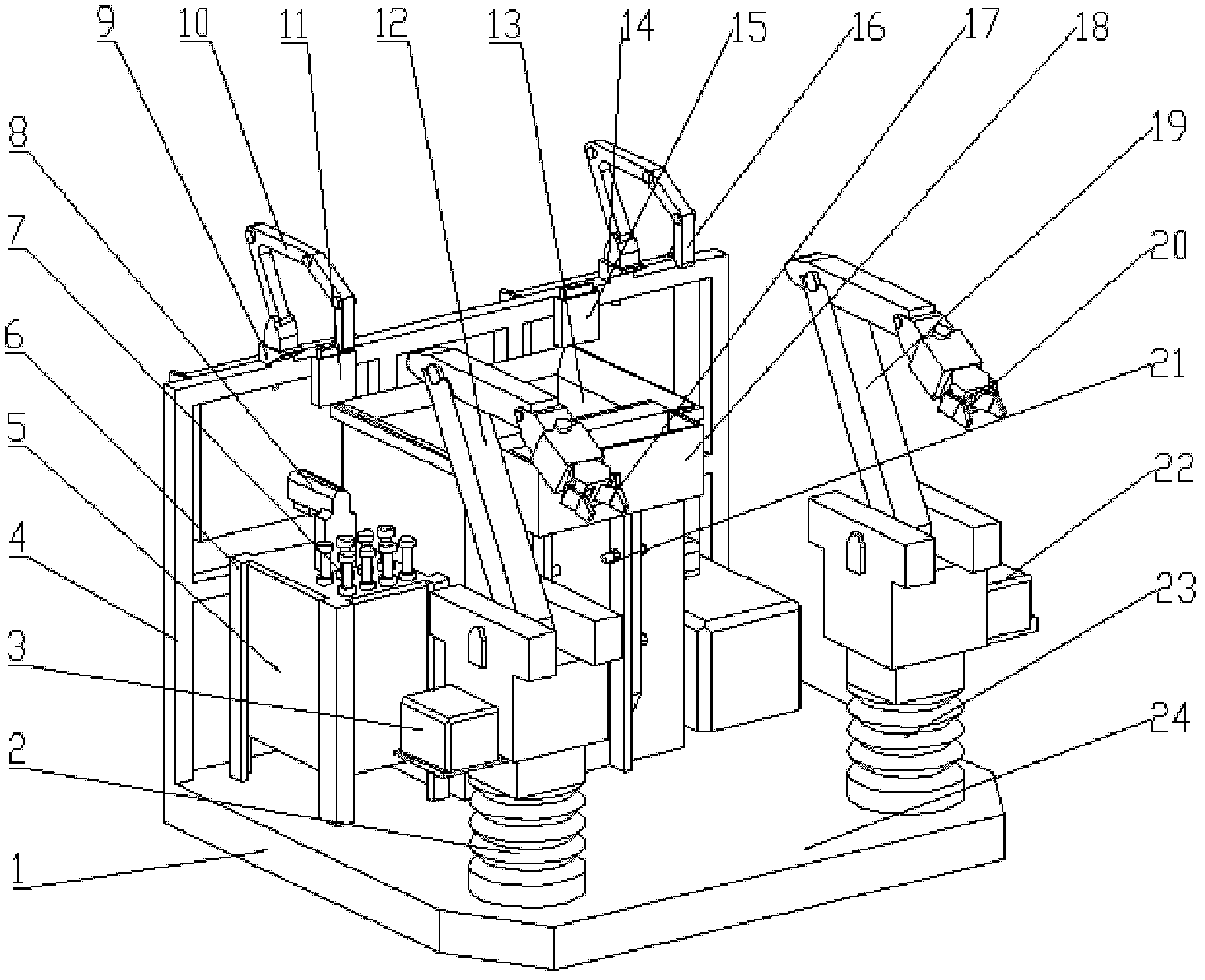

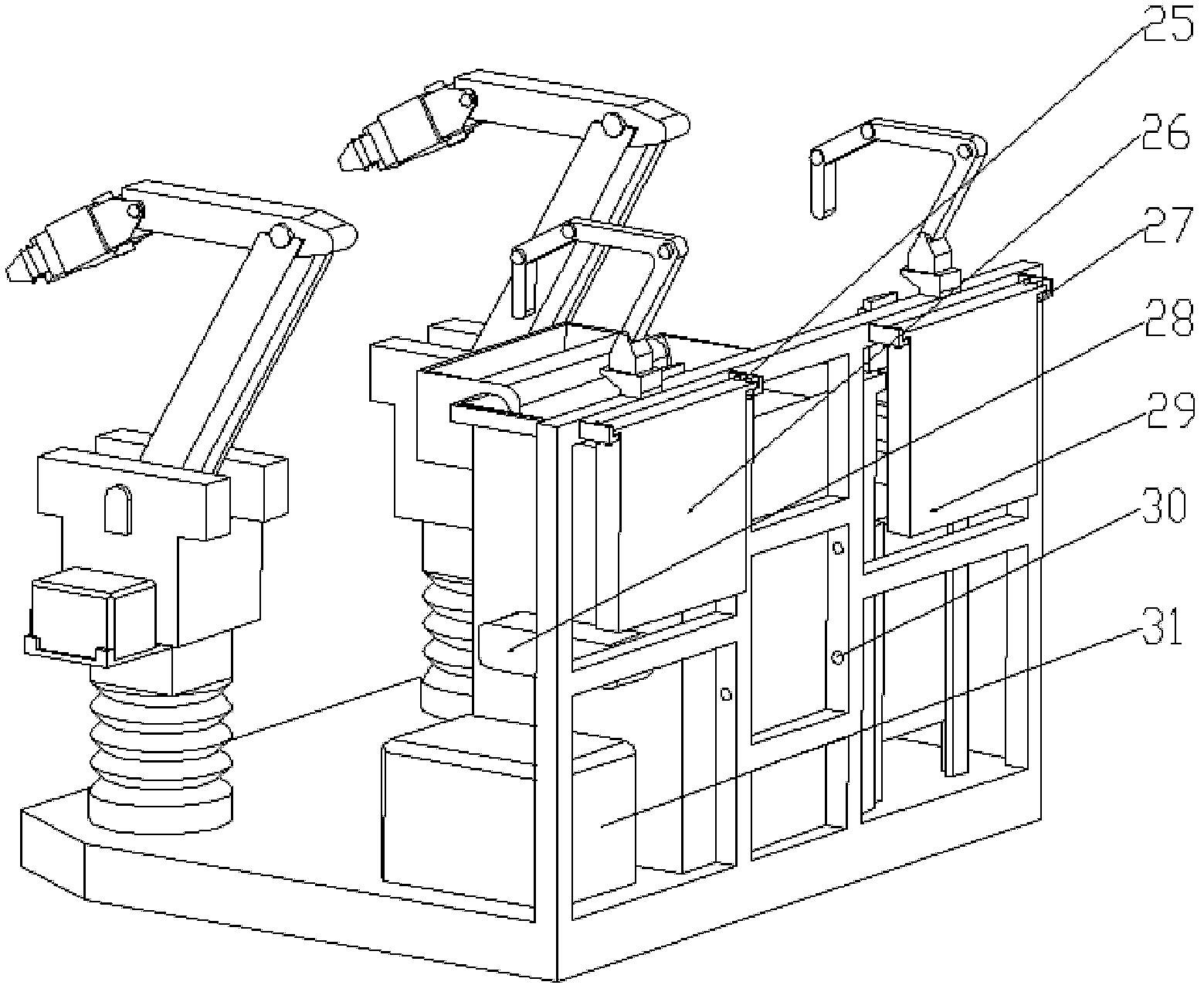

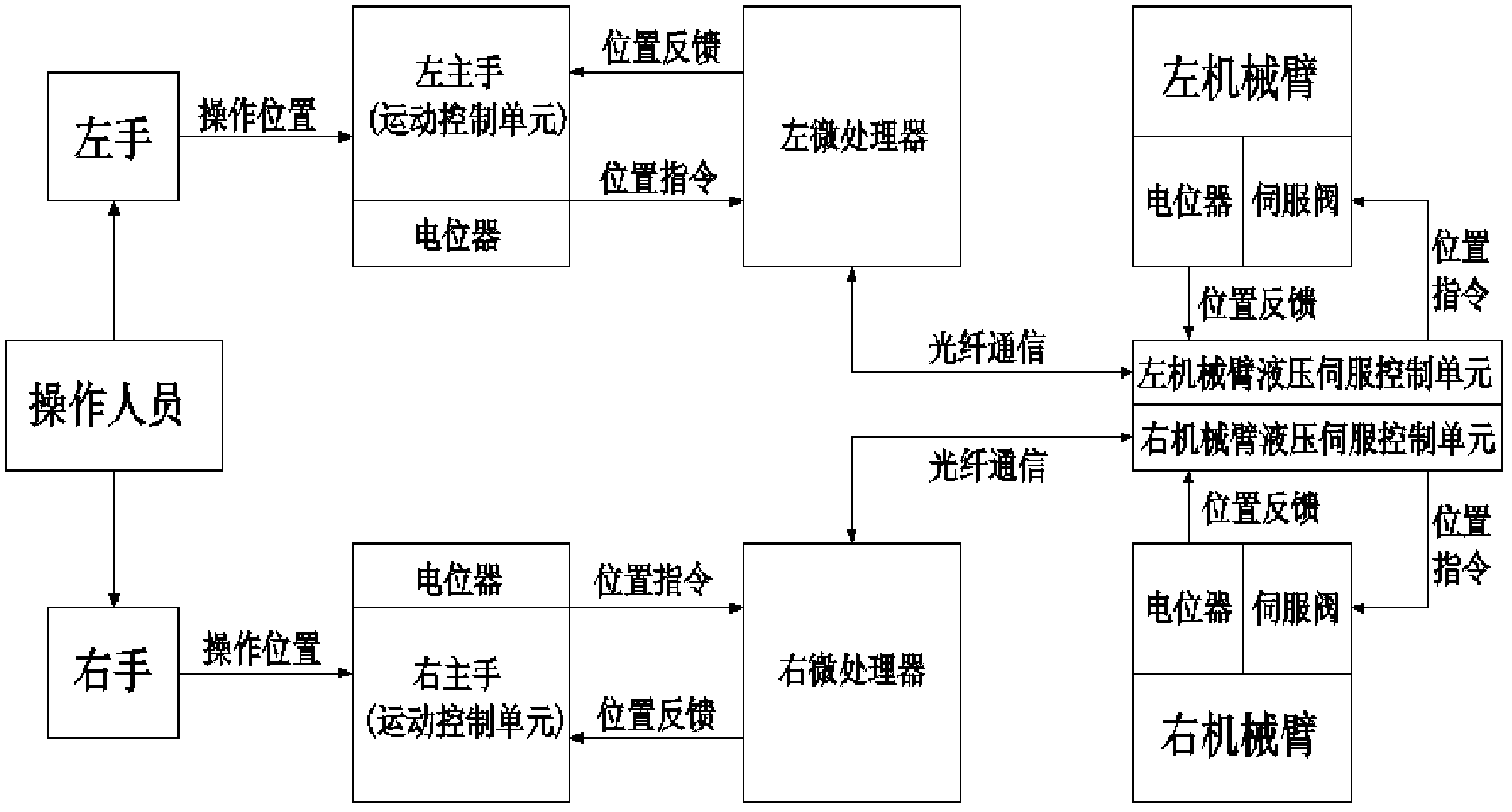

[0034] Such as Figure 1-Figure 3 As shown, the present invention is mainly composed of a robot operating platform support frame, a hydraulic lifting platform control integration 5, a robot operating system and an insulating bucket 13, and the robot operating platform support frame is respectively provided with a hydraulic lifting platform control integration 5, a robot operating system And the insulating bucket 13, the hydraulic lifting platform control integration 5 is connected with the robot operating system, and the hydraulic lifting platform control integration 5 and the robot operating system are all arranged outside the insulating bucket 13.

[0035] Among them, the support frame of the robot work platform is composed of the robot work platform chassis 1 and the robot work platform side connecting frame 4 to form an L-shaped structure. The rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com