Container tipping device

A dumping device and container technology, which is applied in emptying containers, packaging, transportation and packaging, etc. It can solve the problems of time-consuming and labor-intensive work, high labor intensity of workers, and difficulty in accurately controlling the tilting angle of containers, so as to achieve the effect of convenient feeding and preventing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

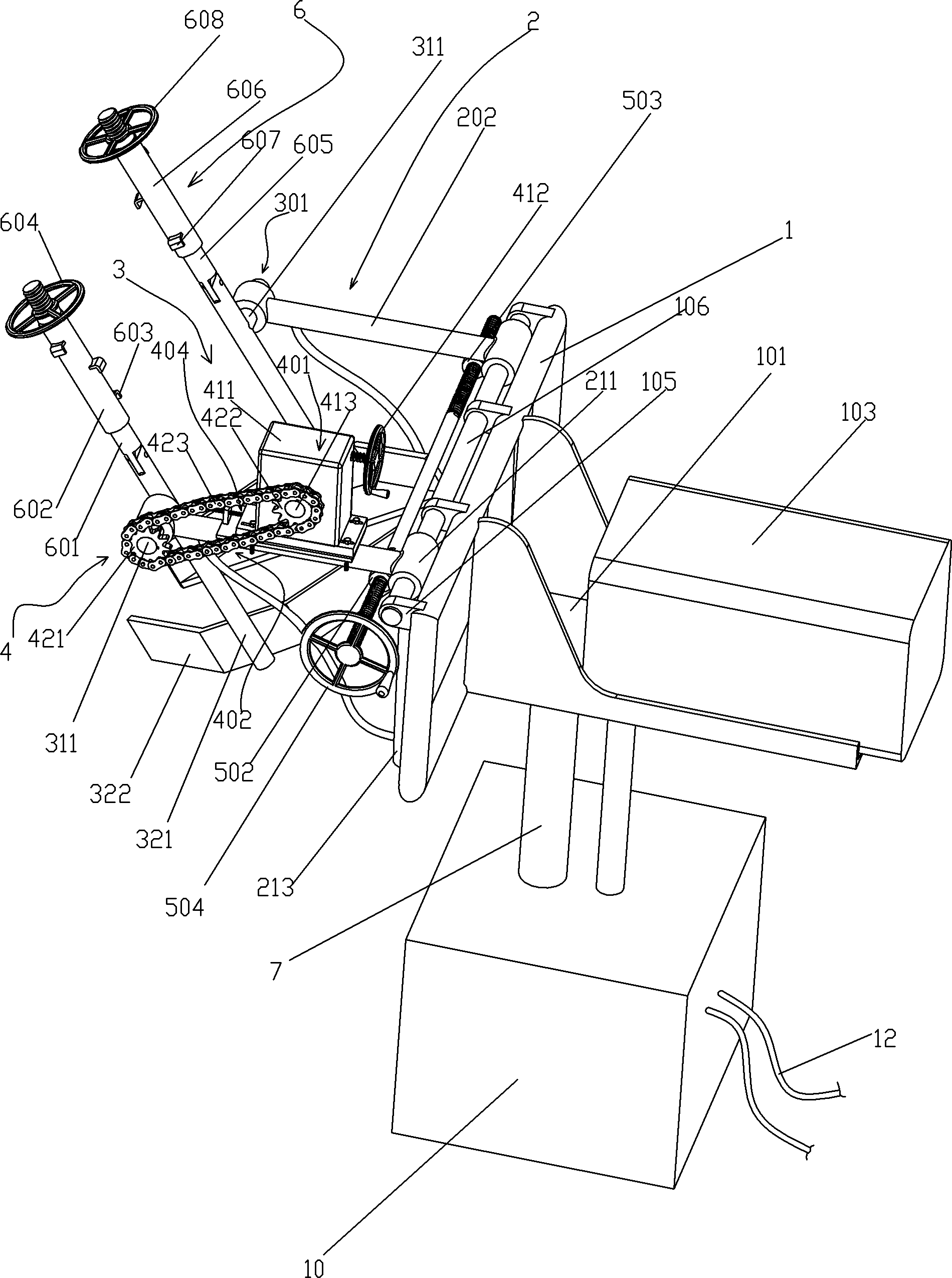

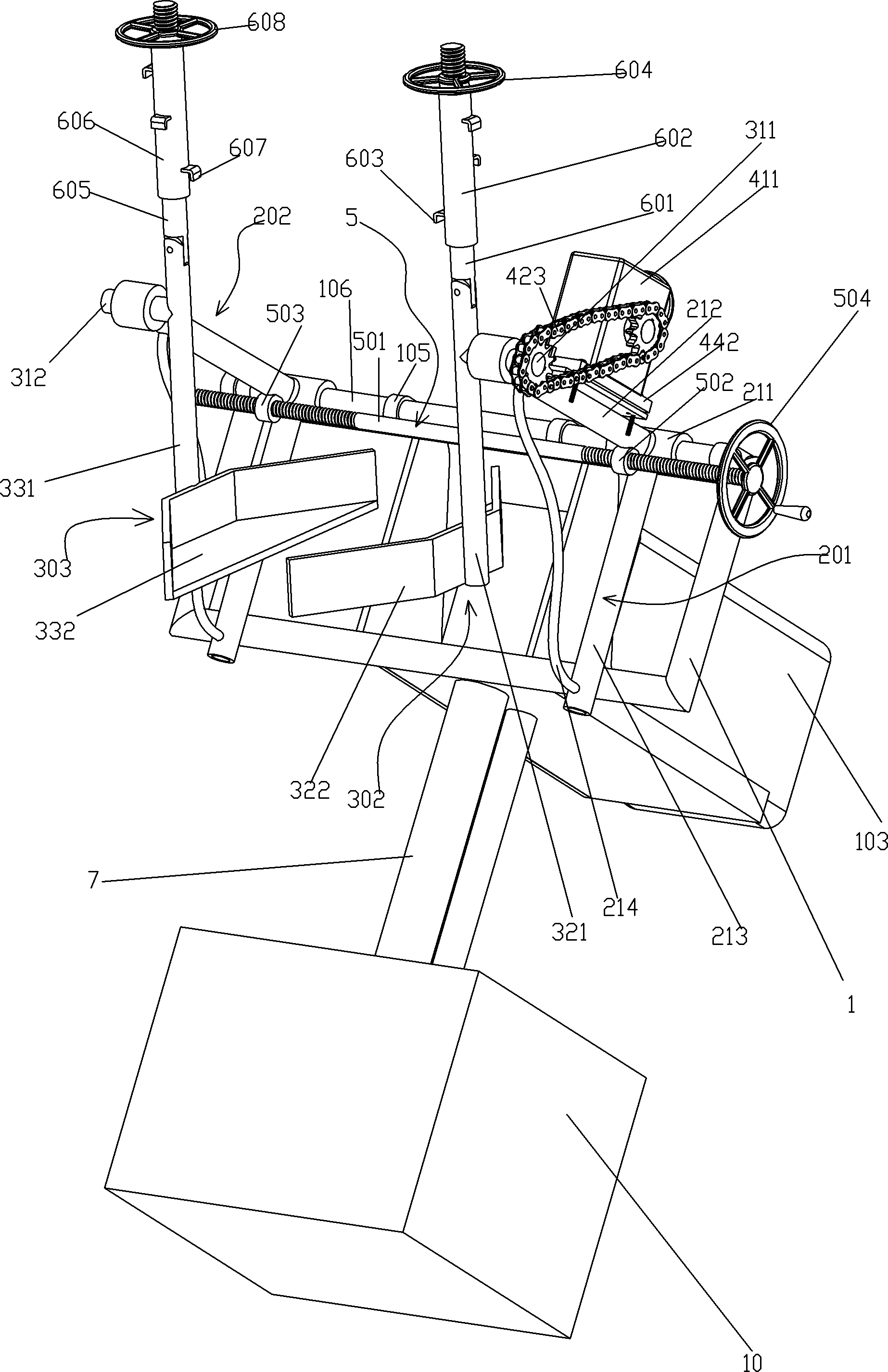

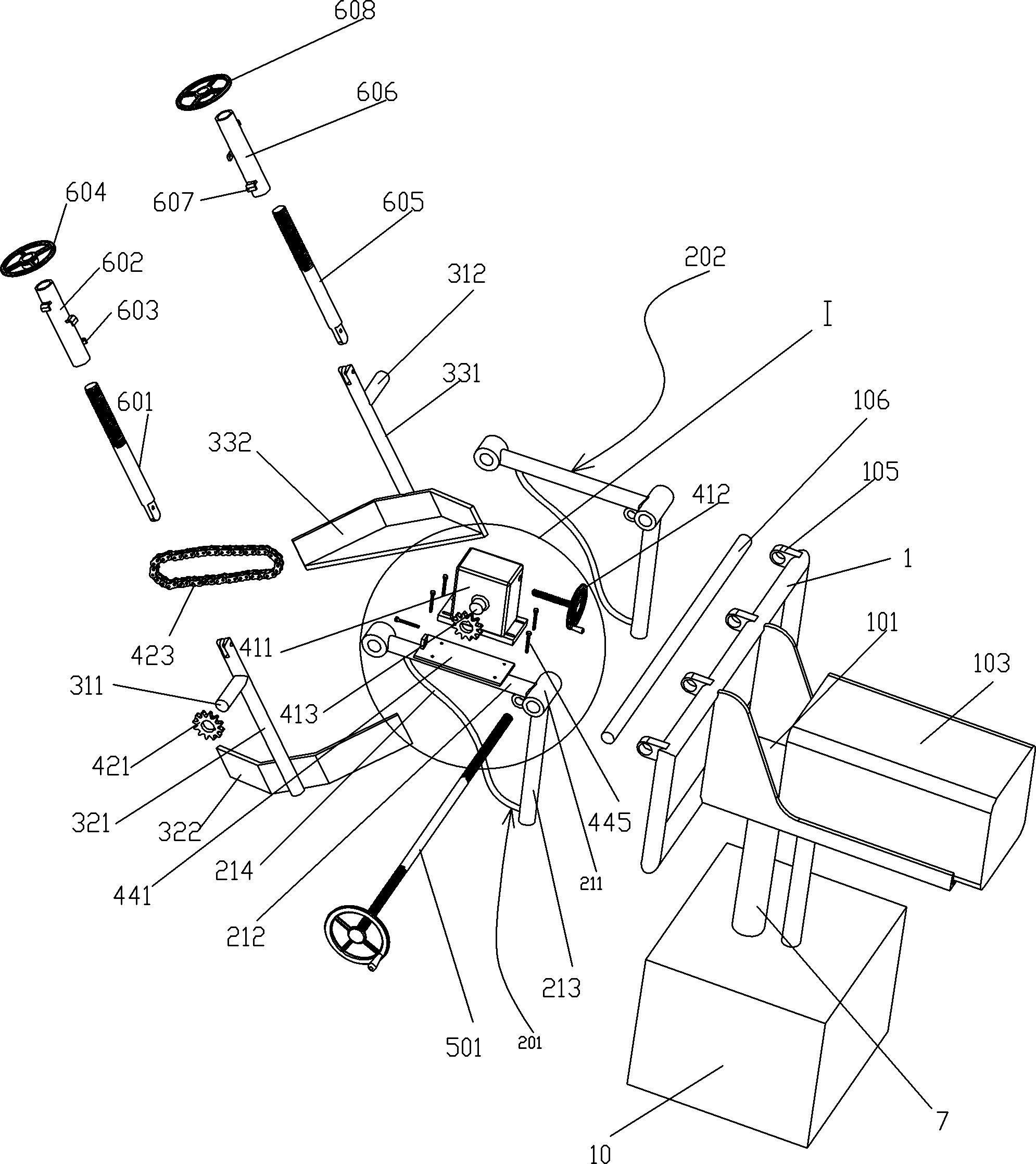

[0027] A container dumping device, comprising a base 10, the base 10 is supported and connected with a support 1 through the lifting device 7, the support 1 is provided with a plurality of hinge seats 105, and the hinge seats 105 are equipped with positioning Hinge shaft 106, the positioning hinge shaft 106 is hinged with a support 2 that can slide axially thereon, and the support 2 is hinged with a clamping support device 3 for clamping the material container. The clamping support device 3 is hinged on the support 2 through a hinge shaft 301, and the support 2 is provided with a dumping control device 4 for controlling the clamping support device 3 and the material container to fall to one side. The lifting device 7 can be an air cylinder, an oil cylinder, a screw or a worm gear and the like. The base 10 is connected with a hydraulic oil pipe or a high-pressure air pipe 12 .

[0028] The tipping control device 4 includes a driving device 401 arranged on the support 2, a tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com