Mechanism for adjusting density and tightness of knitted coil

A technology of tightness and adjustment mechanism, applied in the directions of weft knitting, knitting, textiles and papermaking, etc., can solve the problems of uncontrollable fabrics, unable to realize precise coil adjustment, etc., achieve wide adjustment range, reduce breakage, and high knitting accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

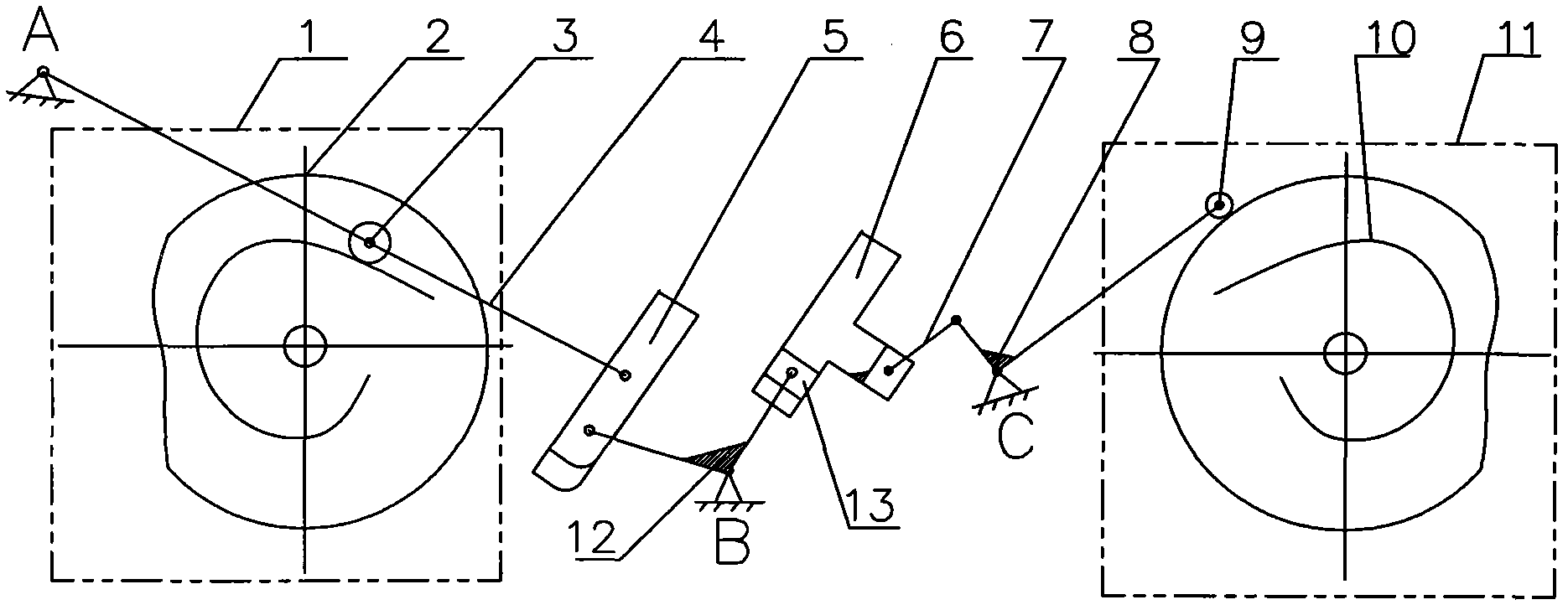

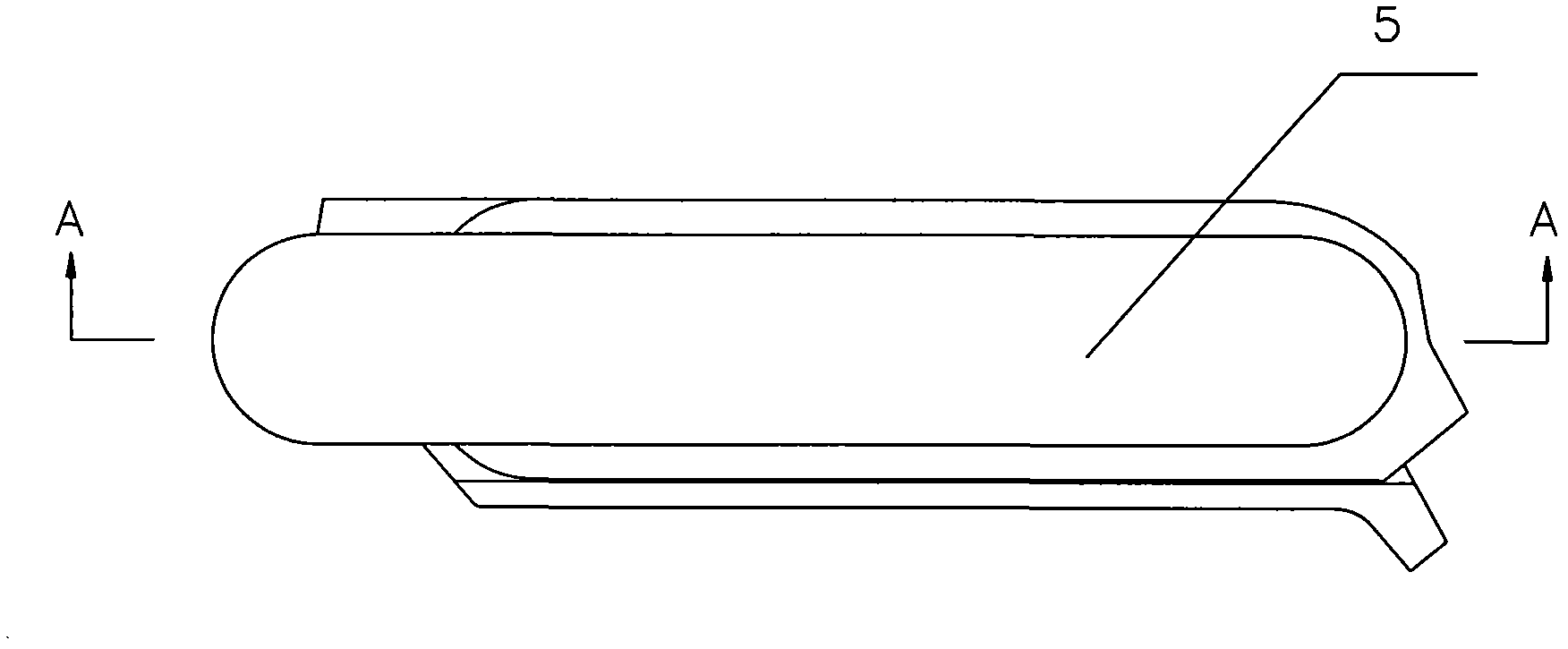

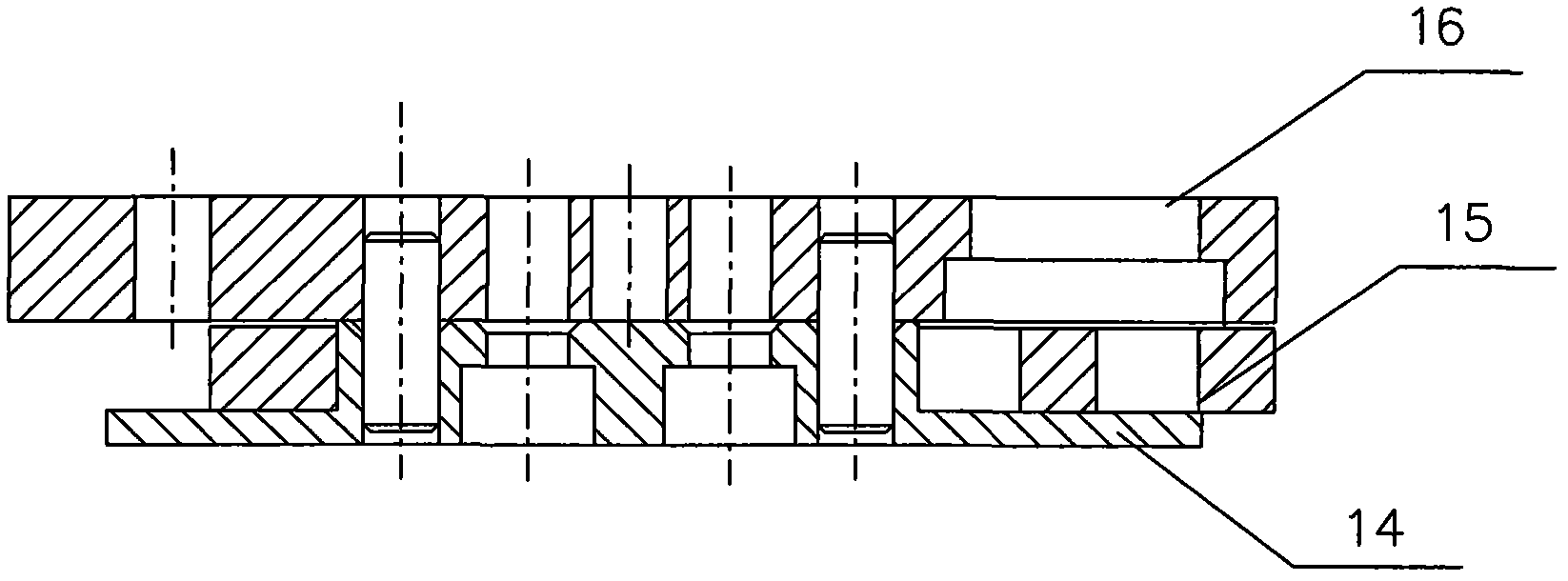

[0009] A mechanism for adjusting the tightness of the density of braided coils, which includes a first motor 1, a first end cam 2, a first bearing 3, a shift lever 4, a variable density triangle 5, a T-shaped slider 6, an eccentric connecting rod 7, a support The rod 8, the second bearing 9, the second end cam 10, the second motor 11, the V-shaped support rod 12 and the slider 13, the first end cam 2 is arranged on the output shaft of the first motor 1, and the first bearing 3 is arranged It is on the shift lever 4 and is in rolling connection with the first end surface cam 2. The connection point of the first bearing 3 and the first end surface cam 2 is located on the isometric curve of the end surface of the first end surface cam 2. One end of the shift lever 4 is connected to the fulcrum A Articulated, the other end is connected with the variable density triangle 5, the second end cam 10 is arranged on the output shaft of the second motor 11, the second bearing 9 is in rollin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com