Method and device for braking revolution of upper car of rotary drilling rig

A technology of rotary drilling rig and rotary braking, which is applied to rotary drilling rigs, drilling equipment and methods, rotary drilling, etc. Swing braking capability, ease of use, reduced damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in combination with the accompanying drawings and specific embodiments.

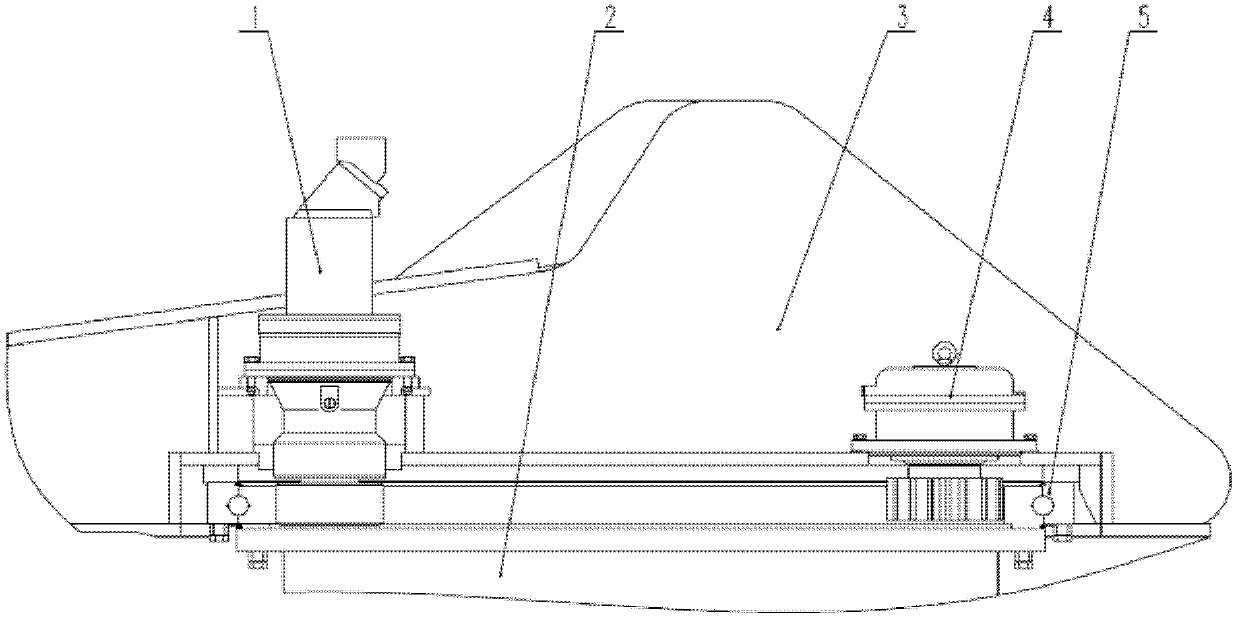

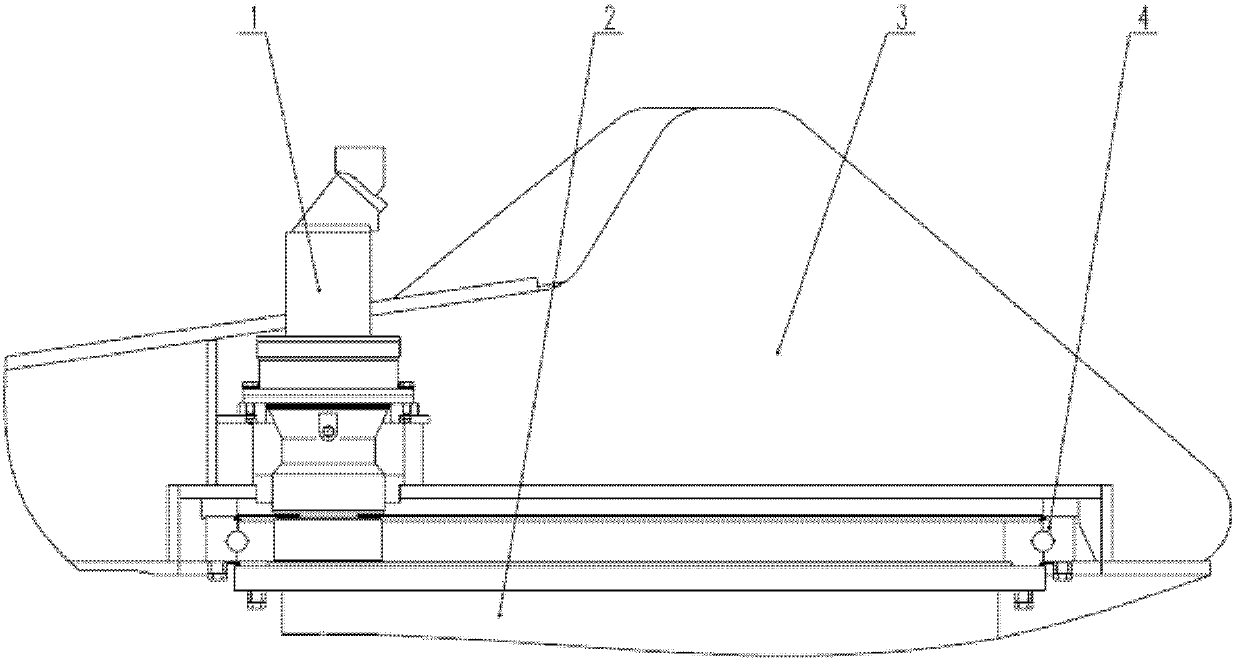

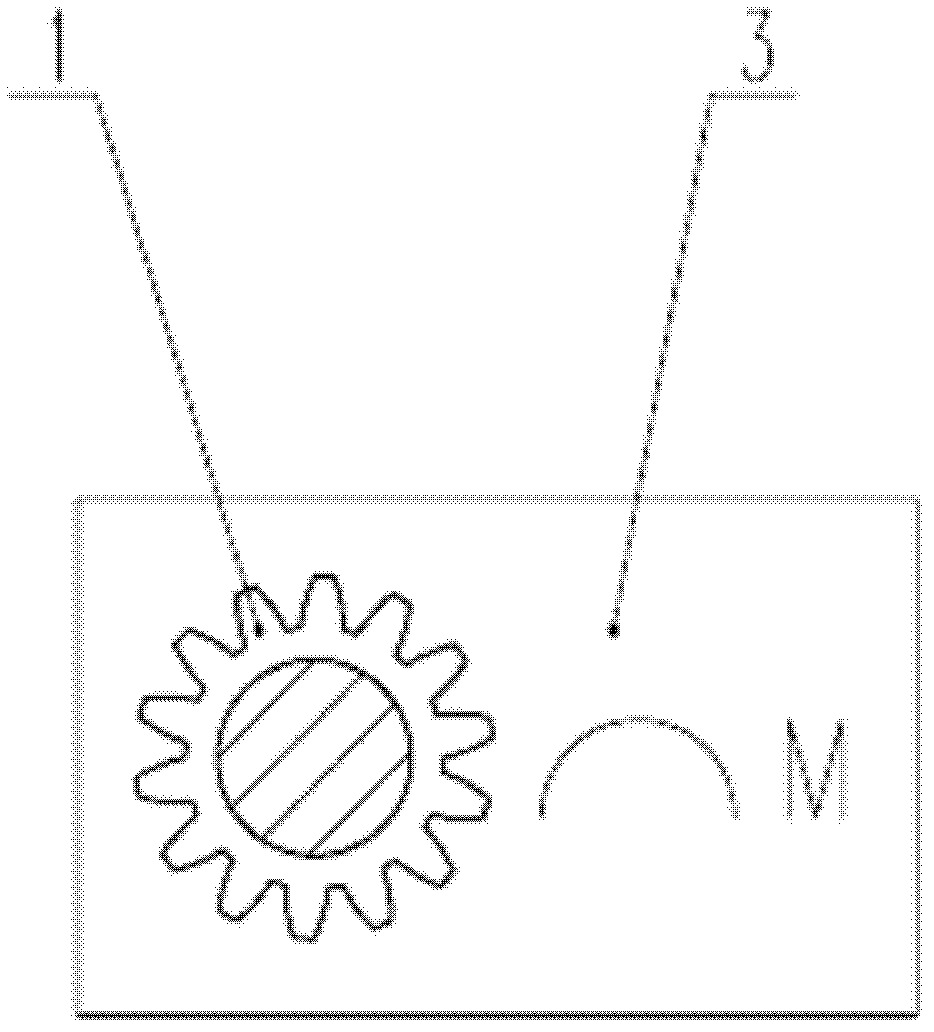

[0023] see figure 1 , the upper car 3 and the lower car 2 are connected through the slewing support 5 to ensure that the drilling machine can work at 360°. The slewing reducer 1 is installed on the upper car 3, and the output shaft of the slewing reducer 1 is engaged with the slewing support 5 for transmission. Normally closed hydraulic pressure The cylinder block of the brake 4 is installed on the upper car 3, the gear shaft of the normally closed hydraulic brake 4 is meshed with the slewing support 5 for transmission, and the slewing reducer 1 and the normally closed hydraulic brake 4 share a pilot oil circuit for oil supply through the drilling rig to ensure The reducer and the brake are turned on and off at the same time.

[0024] The normally closed hydraulic brake 4 is in a self-locking and opening state to meet the braking requirements of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com