Locating pin

A technology of positioning pins and pins, applied in the direction of connecting components, bolts, mechanical equipment, etc., can solve problems affecting production efficiency, loose positioning pins, affecting continuity and stability of mechanical equipment, etc., to improve production efficiency and increase stability Effects of Sex and Continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

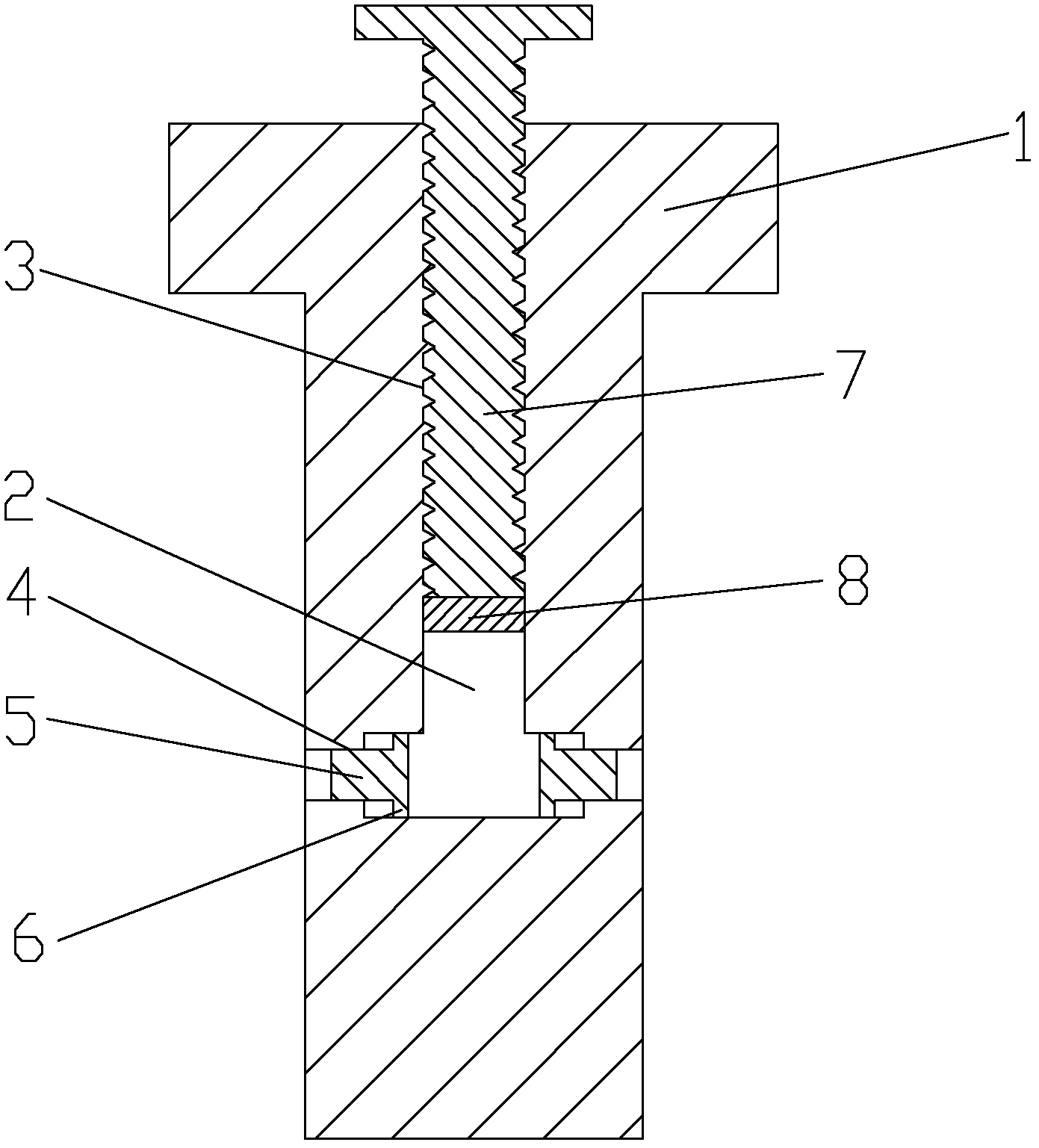

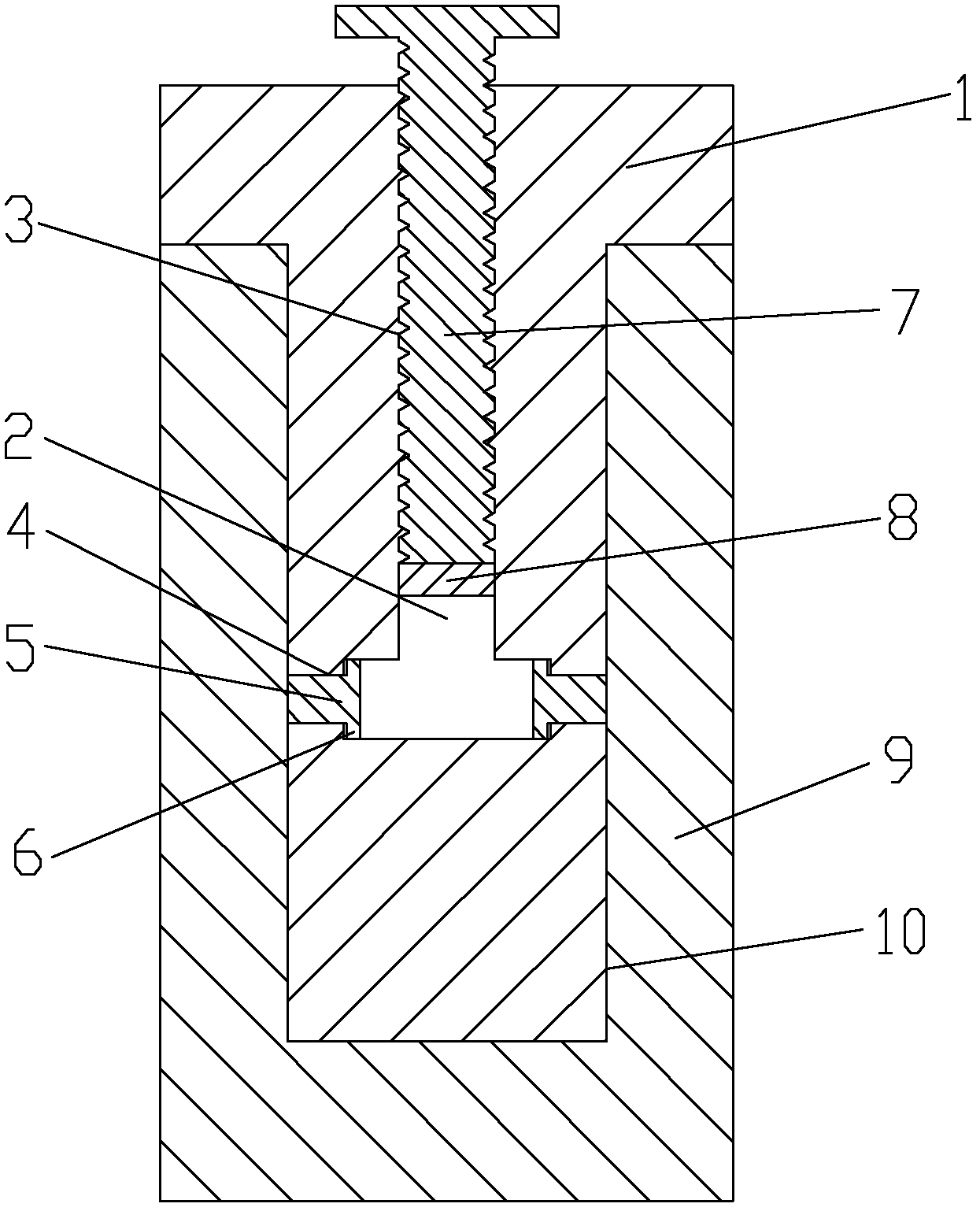

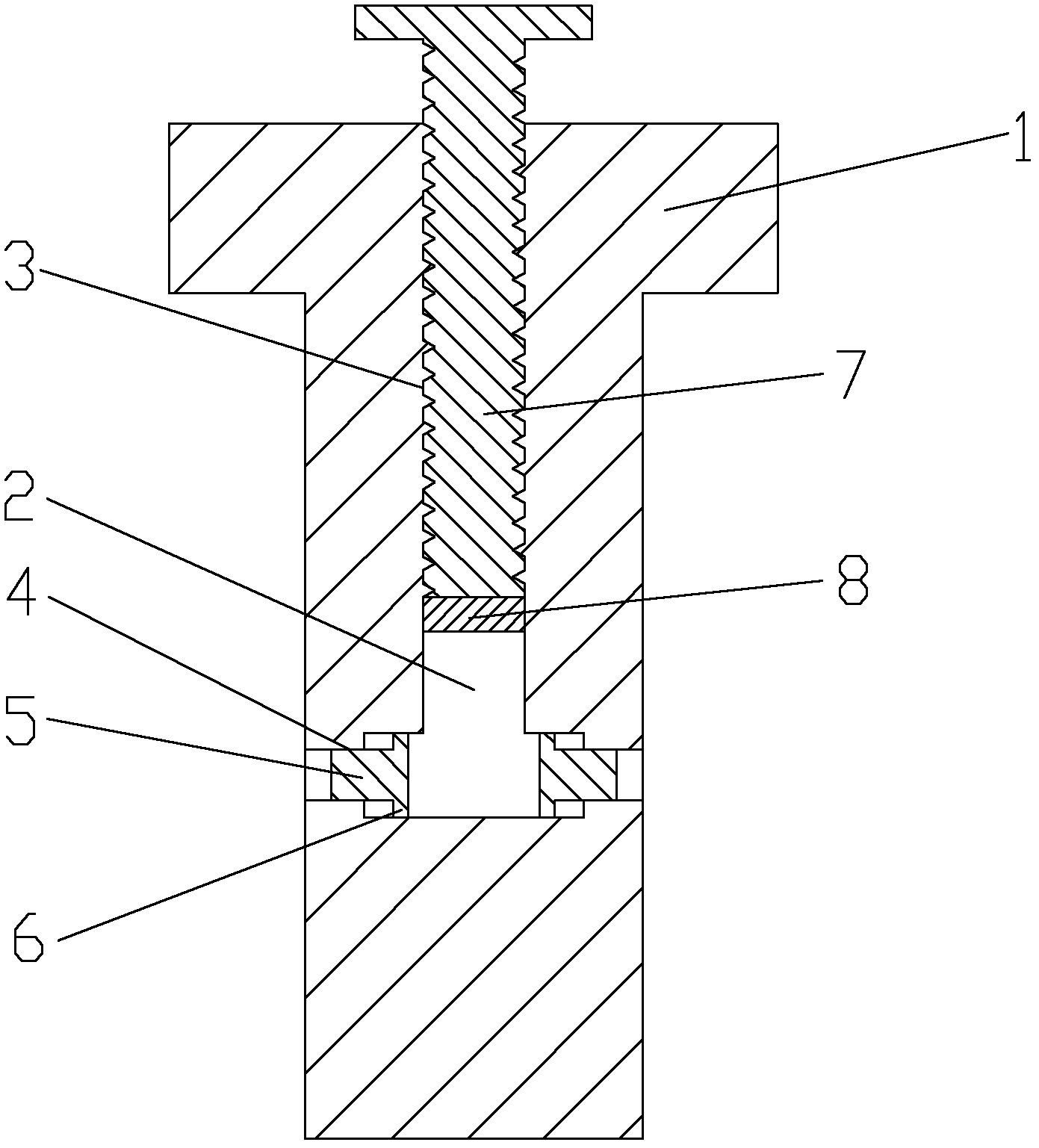

[0014] as attached figure 1 The shown positioning pin of the present invention includes a positioning pin body 1, and an inverted "T"-shaped slot 2 is opened in the positioning pin body 1; the "I" part of the inverted "T"-shaped slot 2 It is a threaded hole 3 communicating with the outside; the "-" part of the inverted "T"-shaped groove is symmetrically provided with a hole 4 communicating with the outside; the diameter of the hole 4 is smaller than the "-" of the inverted "T"-shaped groove 2 The diameter of the "part; the hole 3 is provided with a push block 5; the push block 5 is a rubber seal push block; the push block 5 is provided with a bump 6 to prevent the push block from coming out of the hole; the bump 6 The diameter is the same as that of the "-" part of the inverted "T" groove 3; a screw 7 is arranged in the threaded hole 3; a sealing member 8 is arranged under the screw 7....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com