Plug disc chain and chain wheel set matching structure in feeding system and winding method thereof

A feeding system and matching structure technology, applied in the field of breeding, can solve the problems of increasing the load and distortion of the piston chain and sprocket, and achieve the effect of avoiding distortion and reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

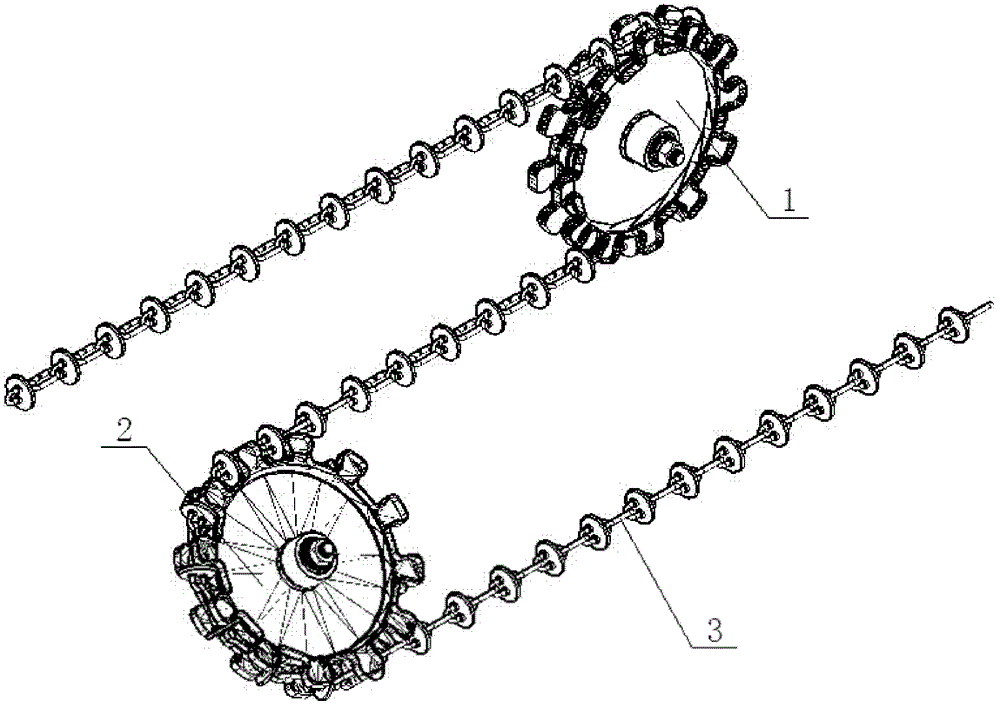

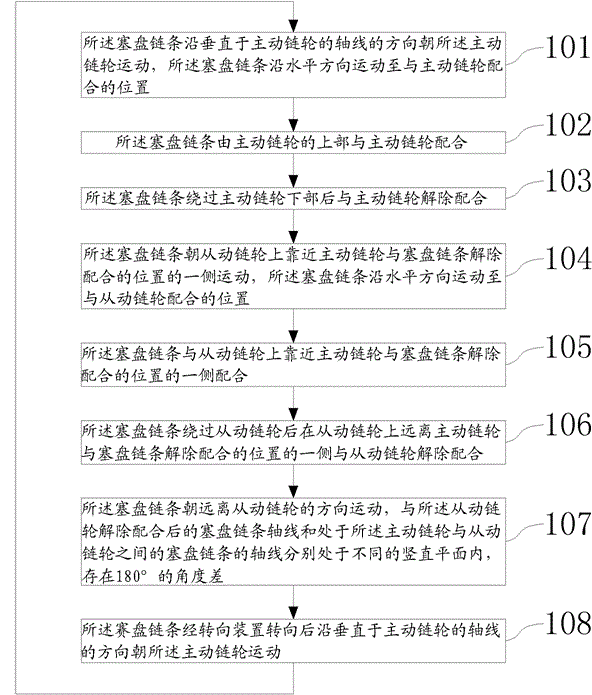

[0064] Such as figure 1 As shown, a cooperating structure between the plug chain 3 and the sprocket group in the feeding system, including the driving sprocket 1, the driven sprocket 2 and the plug chain 3;

[0065] The rotation axis direction of the driving sprocket 1 is perpendicular to the vertical direction; the driven sprocket 2 is positioned at one side of the driving sprocket 1; on the rotating shaft of the driving sprocket 1;

[0066] The plug disc chain 3 is matched with the driving sprocket 1 by the top of the driving sprocket 1, and is released from the driving sprocket 1 after bypassing the lower part of the driving sprocket 1;

[0067] After that, the stopper chain 3 is matched with the side of the driven sprocket 2 near the position where the driving sprocket 1 and the stopper chain 3 are disengaged, and the stopper chain between the driving sprocket 1 and the driven sprocket 2 The axis of 3 is in the same vertical plane as the axis of plug plate chain 3 before...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com