Obtaining method of direct current magnetic biasing hysteresis loop of transformer core material

A technology of DC bias and hysteresis loop, applied in hysteresis curve measurement, magnetic performance measurement, etc., can solve problems such as inconsistency in series excitation methods, inability to separate AC magnetic flux and DC magnetic flux, and error in measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

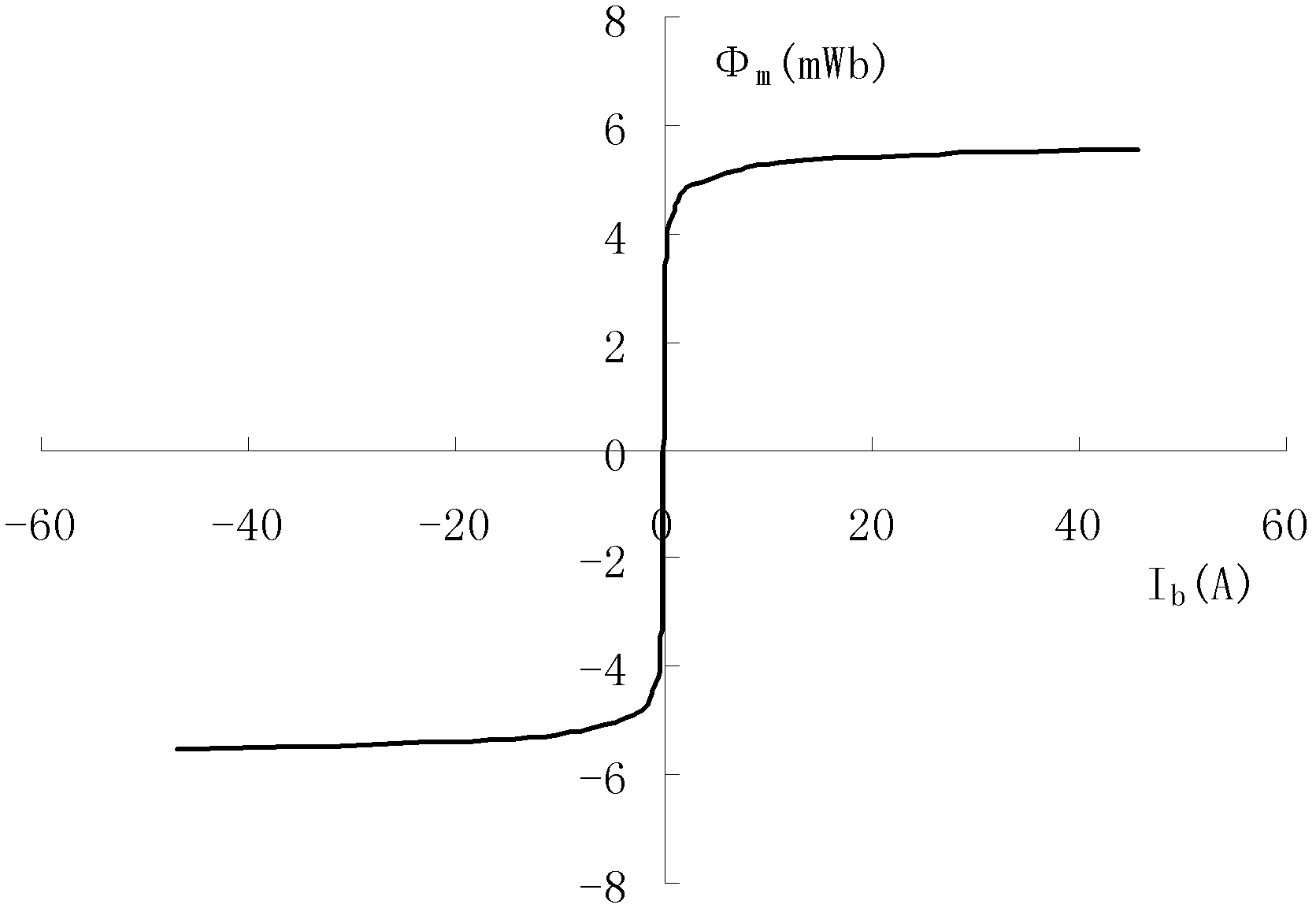

[0057]The method for obtaining the DC bias hysteresis loop of the transformer core material 30Q140 cold-rolled grain-oriented silicon steel sheet, the AC operating point of the given transformer core model is U g =459V is applied to the transformer core model at the same time with the given DC bias magnetic field strength as I dc = 0.1A.

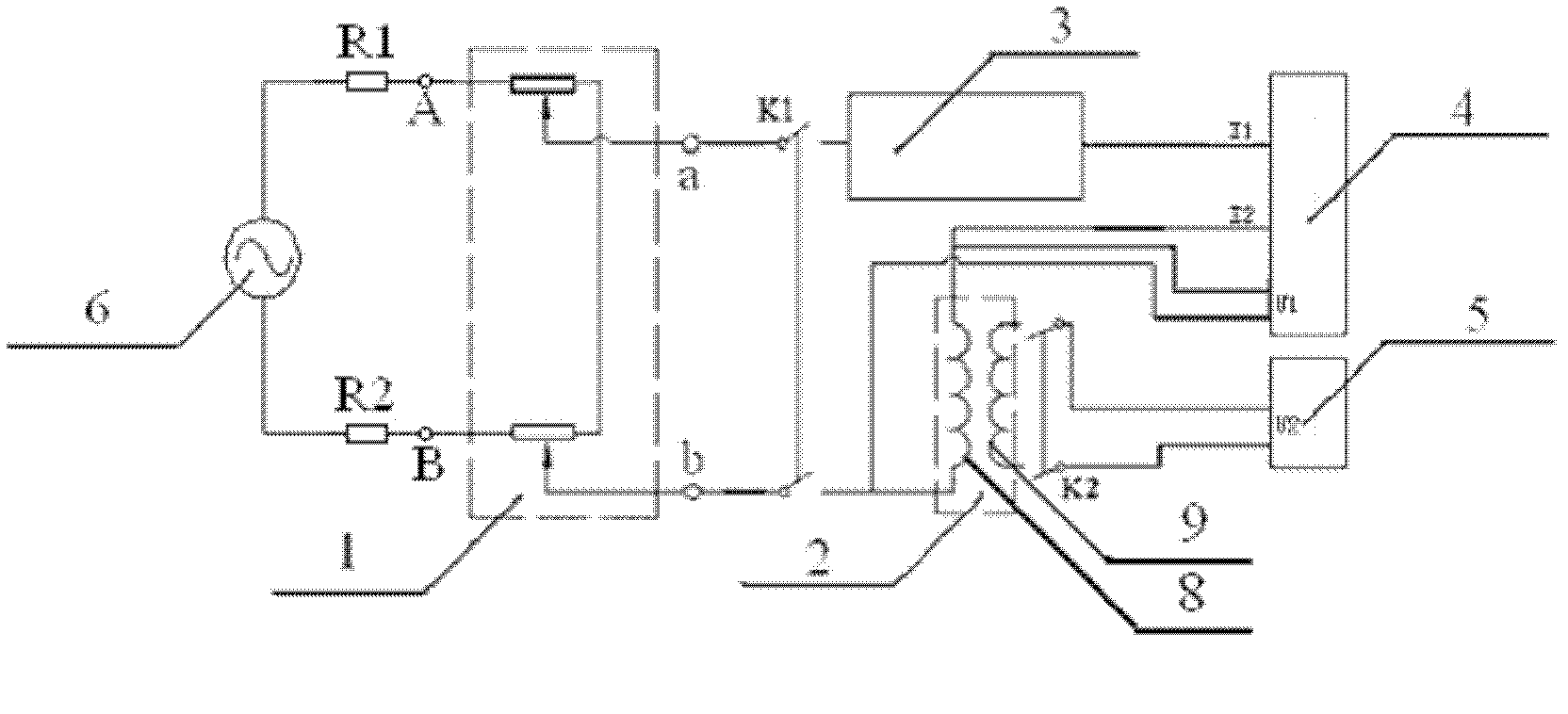

[0058] A. The device used to make the method of obtaining the DC bias hysteresis loop of the transformer core material

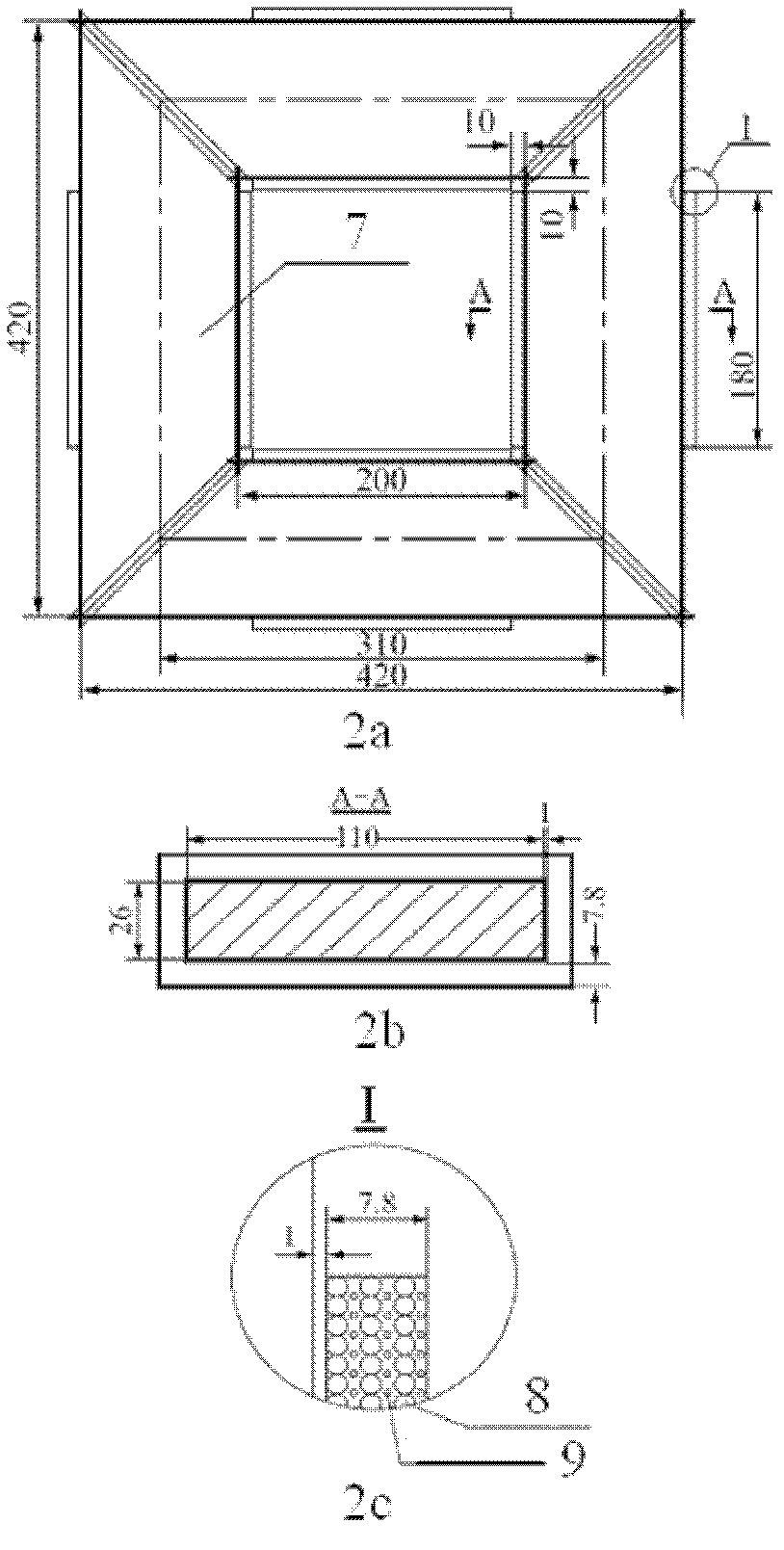

[0059] use figure 1 and figure 2 The embodiment shown constitutes the device used in the method for obtaining the DC bias hysteresis loop of the transformer core material in this embodiment, wherein the transformer core model 2 adopts 45° full oblique joints, two pieces per level and three steps 5mm overlapped stacking process, in order to ensure the accuracy of the experimental measurement results, the excitation coil 8 and the measurement coil 9 are wound close to the transformer laminated core 7 and clamped by insul...

Embodiment 2

[0083] The method for obtaining the DC bias hysteresis loop of the transformer core material 30Q140 cold-rolled grain-oriented silicon steel sheet, the AC operating point of the given transformer core model 2 is U g =27V is applied to the transformer core model 2 at the same time with the DC bias magnetic field strength as I dc = 1A.

[0084] A. The device used to make the method of obtaining the DC bias hysteresis loop of the transformer core material

[0085] With embodiment 1.

[0086] B. Using the device used in the method of obtaining the DC bias hysteresis loop of the transformer core material made by A, follow the steps below to obtain a given AC operating point U g =27V and a given DC bias magnetic field strength I dc = DC bias hysteresis loop of the tested transformer core material when 1A is applied.

[0087] The first step to the fourth step are carried out in full accordance with embodiment 1; in the fifth step to the thirteenth step, except that the given AC o...

Embodiment 3

[0089] The method for obtaining the DC bias hysteresis loop of the transformer core material 30Q140 cold-rolled grain-oriented silicon steel sheet, the AC operating point of the given transformer core model 2 is U g =486V is applied to the transformer core model 2 at the same time with the DC bias magnetic field intensity as I dc = 2A.

[0090] A. The device used to make the method of obtaining the DC bias hysteresis loop of the transformer core material

[0091] With embodiment 1.

[0092] B. Using the device used in the method of obtaining the DC bias hysteresis loop of the transformer core material made by A, follow the steps below to obtain a given AC operating point U g =486V and a given DC bias magnetic field strength I dc = DC bias hysteresis loop of the tested transformer core material when 2A is applied.

[0093] The first step to the fourth step are carried out in full accordance with embodiment 1, and in the fifth step to the thirteenth step, except that the giv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com