Rapid tunable microfiber ring resonator

A ring resonant cavity and micro-fiber technology, applied in the field of micro-optical components, can solve the problems of slow response and large temperature device, and achieve the effect of good stability and fast adjustability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

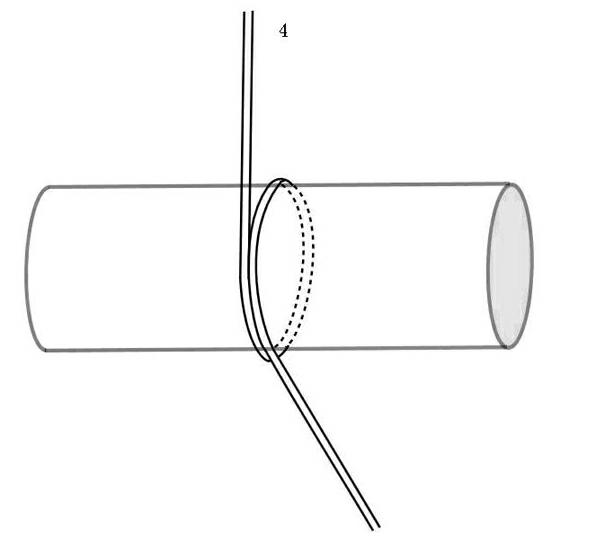

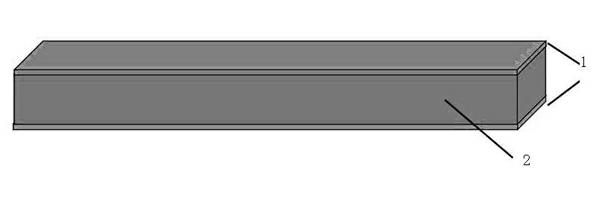

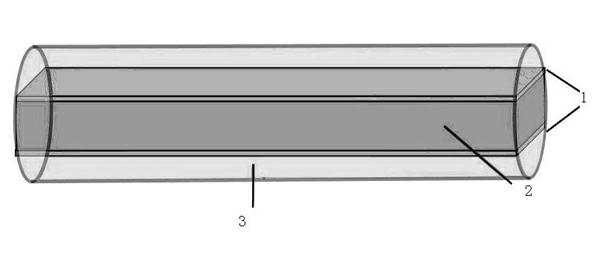

[0017] like figure 1 , shown in 2, an example of the present invention is to paste two metal electrodes 1 on the upper and lower sides of the piezoelectric ceramic (PZT) dielectric rod 2, and draw out a lead respectively, evenly smear Telfon3 on the piezoelectric ceramic dielectric rod to form Cylindrical medium rod. Then the micro-fiber 4 is wound on the dielectric rod to form a resonant cavity. Finally, use Telfon3 package and place in air to cure.

[0018] In this example, the diameter of the micro-optical fiber is 2um, and the length of the waist area (two turns of the winding area) is about 25mm. The size of the piezoelectric ceramic rod is 1 mm × 2 mm × 6 mm. The cylindrical dielectric rod has a diameter of about 2.5 mm, and the largest diameter of the dielectric rod is generally not more than 2 cm. The diameter of the ring resonant cavity is dete...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com