Z-axis lifting mechanism with stress state balancing function

A technology of stress state and lifting mechanism, which is applied in the direction of mechanical equipment, conveyor objects, belts/chains/gears, etc., can solve the problems of short service life of ball guide rails, large and micro deformation of ball guide rails, complex processing technology of columns, etc., to achieve Strong load capacity, correction of unstable center of gravity, stable center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

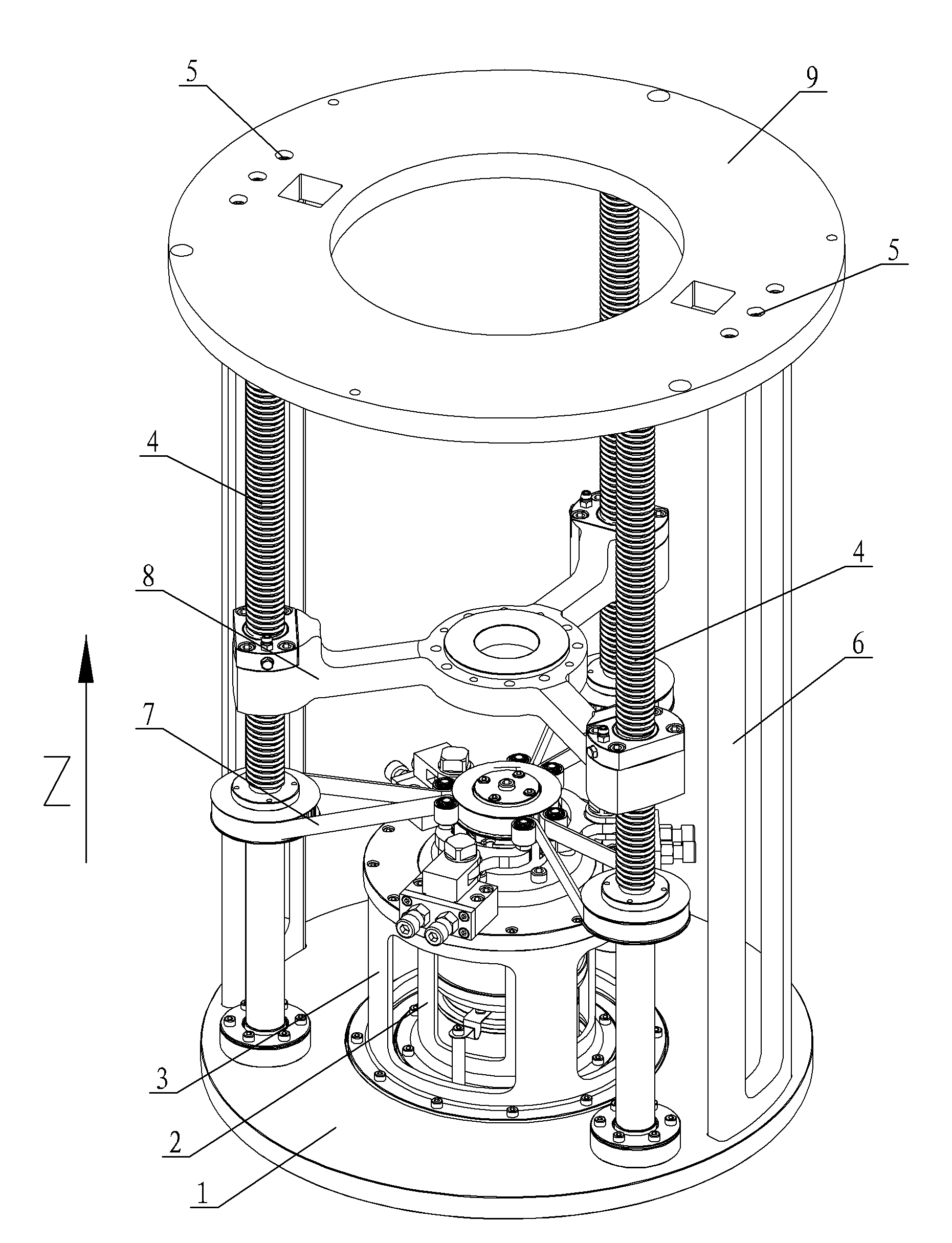

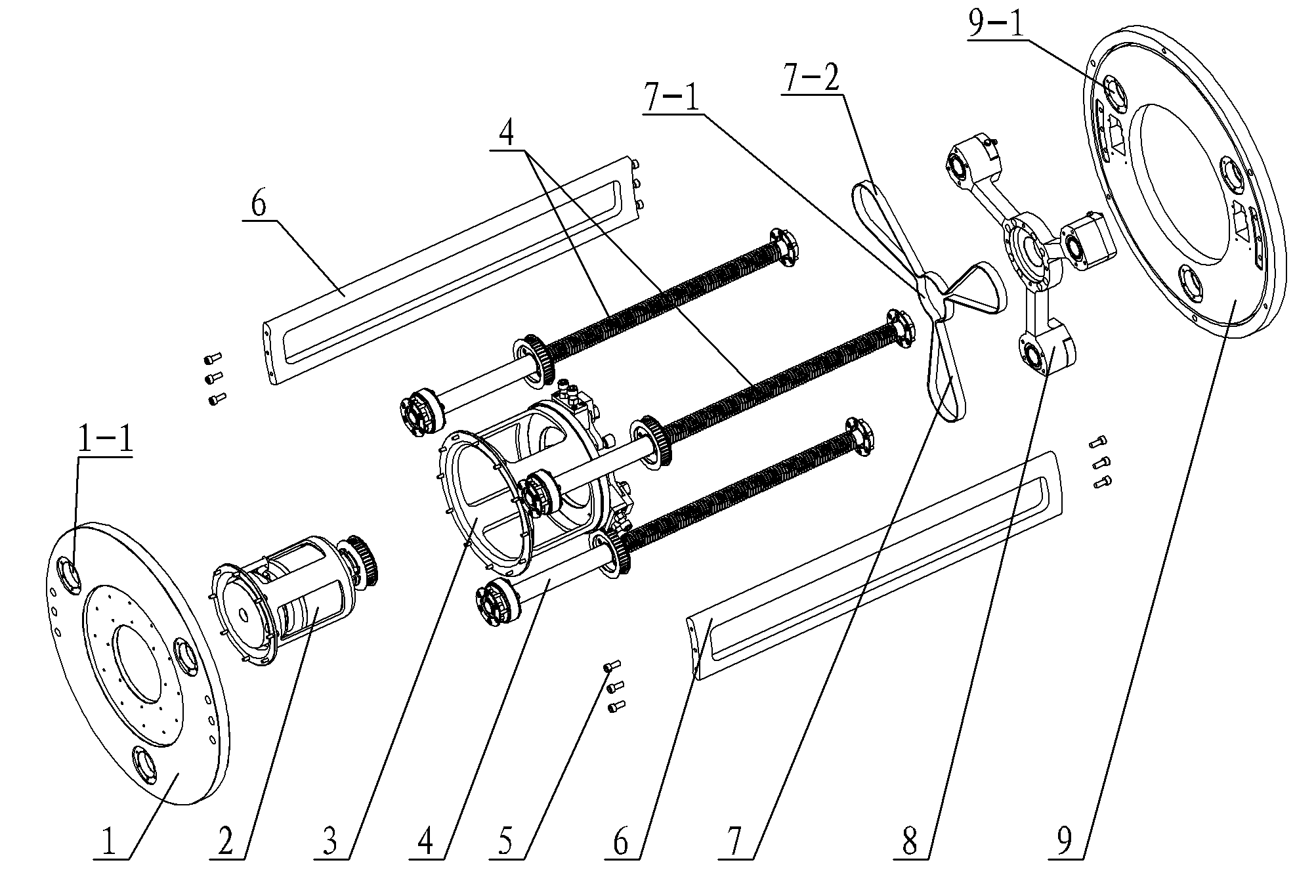

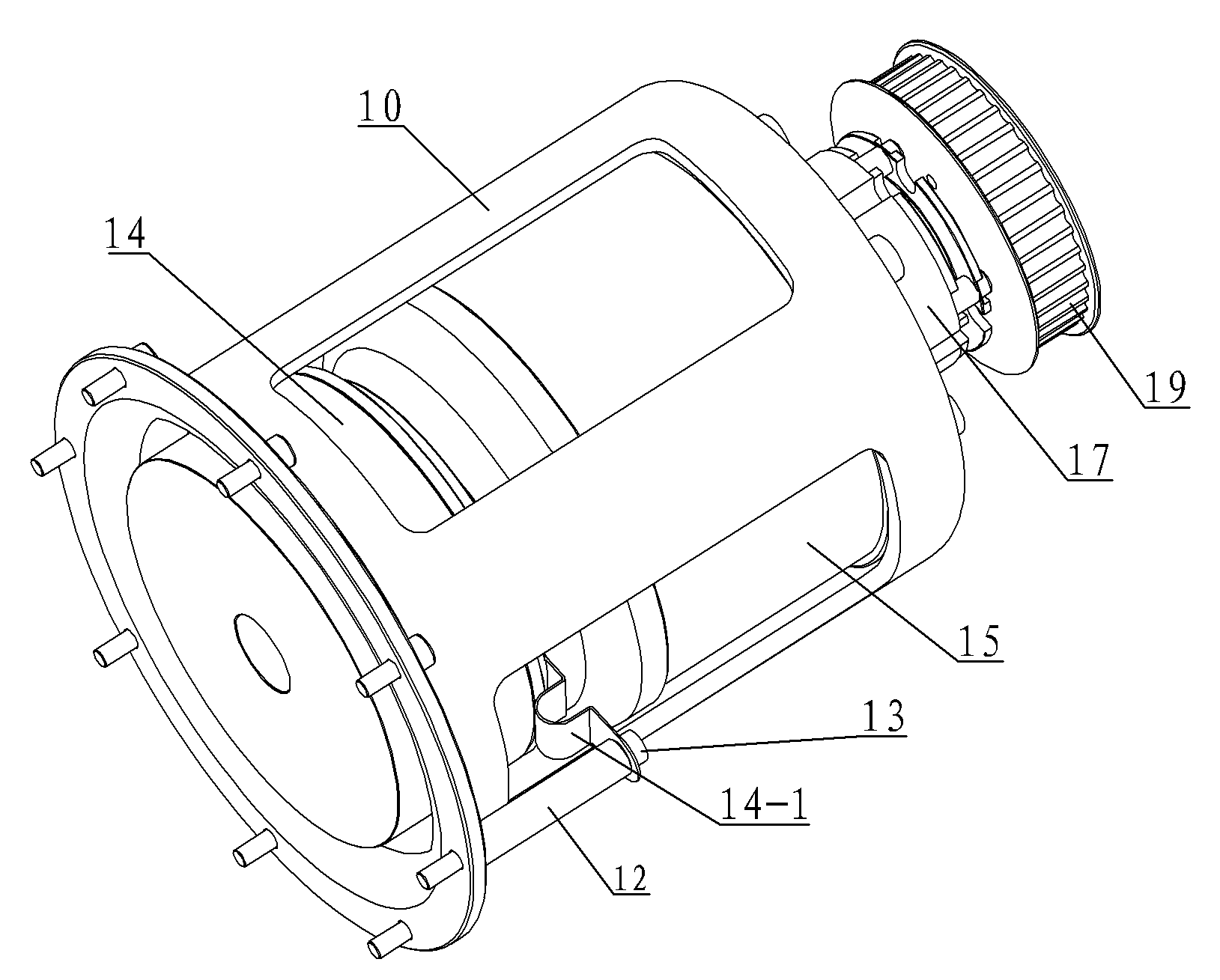

[0007] Specific implementation mode one: combine Figure 1 to Figure 8 Describe this embodiment, which includes a lower mounting base 1, a Z-axis drive assembly 2, a pretensioner support mechanism 3, a synchronous tooth transmission belt 7, a nut transmission mechanism 8, an upper mounting cover 9, two connecting plates 6 and Three screw drives 4, see image 3 with Figure 4 : Z-axis driving device assembly 2 includes Z-axis motor base 10, encoder positioning tube 12, encoder 14, Z-axis servo motor 15, friction brake 17, synchronous transmission driving gear 19 and connecting plate 20, the Z-axis servo The upper end of the motor 15 shaft is an output shaft 15-1, and the lower end is a motor shaft 15-2, and the Z-axis servo motor 15 is installed in the Z-axis motor seat 10 by a screw 16, and the output shaft 15-1 of the Z-axis servo motor 15- 1 is located outside the Z-axis motor base 10, and the upper end of the output shaft 15-1 is provided with a transmission external toot...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination Image 6 Describe this embodiment, each pretensioner mechanism 38 of this embodiment includes a pretensioner shaft 39, a pretensioner 41, a shaft circlip 42 and two pretensioner bearings 40, the pretensioner 41 A preload wheel bearing 40 is respectively installed at the upper and lower recesses of the inner cavity, the preload wheel 41 is installed on the preload wheel shaft 39, and the shaft circlip 42 is installed on the upper end of the preload wheel shaft 39 exposed on the preload wheel 41 upper end surface. In the groove, the circlip 42 for the shaft is used to fix the relative position of the pretensioner bearing 40 . Other components and connections are the same as those in the first embodiment.

[0009] The working principle of the present invention is: when the Z-axis servo motor 15 was running, the encoder 14 installed on the motor shaft 15-2 at the lower end of the Z-axis servo motor 15 started to work, and fed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com